JACK Ram 2500 2017 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2017, Model line: 2500, Model: Ram 2500 2017Pages: 734, PDF Size: 7.3 MB

Page 585 of 734

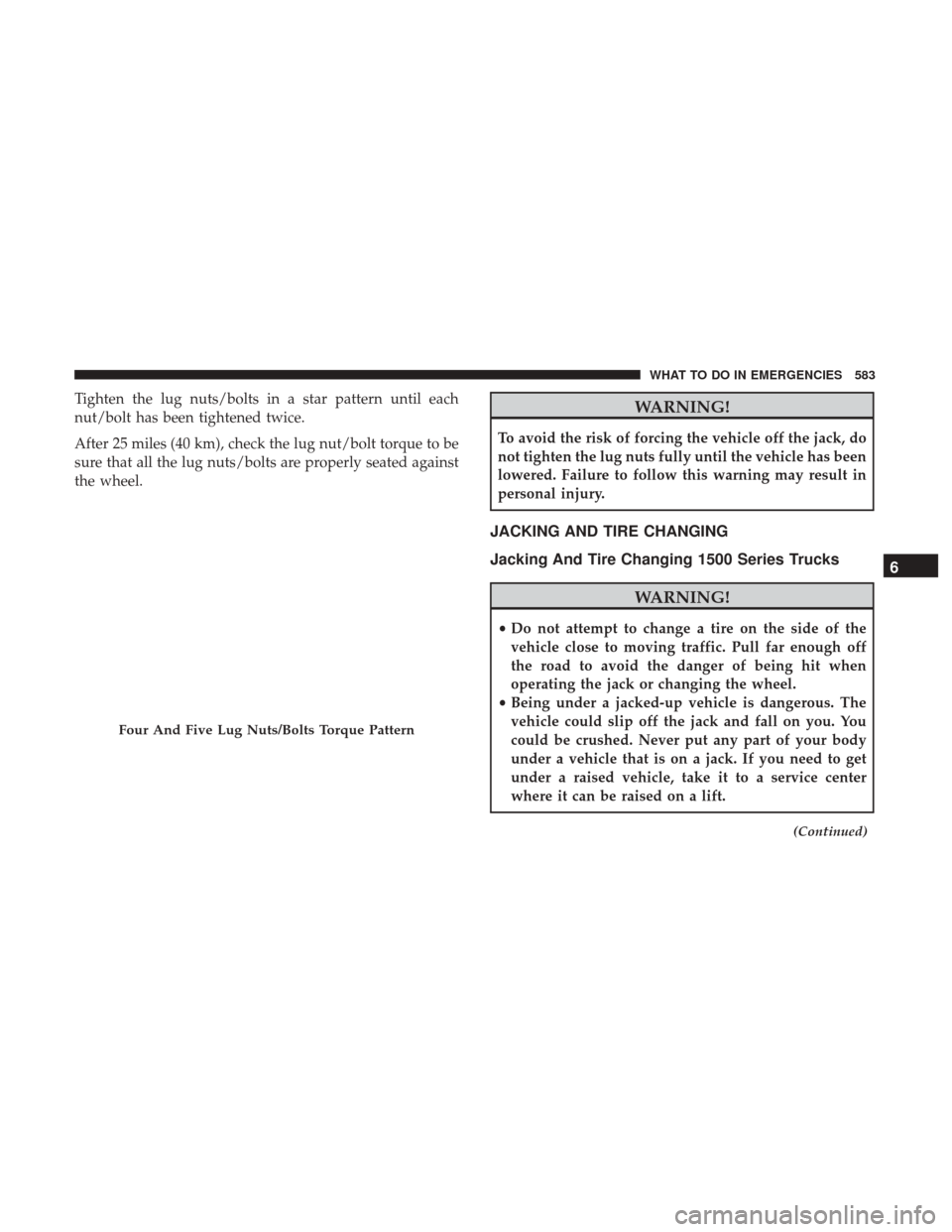

Tighten the lug nuts/bolts in a star pattern until each

nut/bolt has been tightened twice.

After 25 miles (40 km), check the lug nut/bolt torque to be

sure that all the lug nuts/bolts are properly seated against

the wheel.WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the lug nuts fully until the vehicle has been

lowered. Failure to follow this warning may result in

personal injury.

JACKING AND TIRE CHANGING

Jacking And Tire Changing 1500 Series Trucks

WARNING!

•Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

• Being under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never put any part of your body

under a vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service center

where it can be raised on a lift.

(Continued)

Four And Five Lug Nuts/Bolts Torque Pattern

6

WHAT TO DO IN EMERGENCIES 583

Page 586 of 734

WARNING!(Continued)

•Never start or run the engine while the vehicle is on

a jack.

• The jack is designed to be used as a tool for changing

tires only. The jack should not be used to lift the

vehicle for service purposes. The vehicle should be

jacked on a firm level surface only. Avoid ice or

slippery areas.

NOTE: If your vehicle is equipped with an air suspension

system, there is a feature which allows the automatic

leveling to be disabled to assist with changing a tire.

If your vehicle is equipped with a touchscreen, this feature

can be activated through the Uconnect system. Refer to

“Uconnect Settings” in “Understanding Your Instrument

Panel” for further information.

If your vehicle is not equipped with a touchscreen, this

feature can be activated through the instrument cluster

display. Refer to “Instrument Cluster Display” in “Under-

standing Your Instrument Panel” for further information.

Jack Location

The jack and jack tools are stored under the front passenger

seat.

Removal Of Jack And Tools (1500 Series)

To access the jack and jack tools, you must remove the

plastic access cover located on the side of the front passen-

ger ’s seat. To remove the cover, pull the front part of the

cover (closest to the front of the seat) toward you to release

a locking tab. Once the front of the cover is loose, slide the

cover toward the front of the seat until it is free from the

seat frame.

Jack Access Cover

584 WHAT TO DO IN EMERGENCIES

Page 587 of 734

Remove the jack and tools by turning the wing bolt

counterclockwise, remove the wing bolt and then slide the

assembly out from under the seat.Release the tool bag straps from the jack and remove tools

from bag.

Jack And Tools (1500 Series)

Jack And Tool Bag

6

WHAT TO DO IN EMERGENCIES 585

Page 589 of 734

Assembled For Jack OperationWARNING!

After using the jack and tools, always reinstall them in

the original carrier and location. While driving you

may experience abrupt stopping, rapid acceleration or

sharp turns. A loose jack, tools, bracket or other objects

in the vehicle may move around with force, resulting

in serious injury.

Assembled For Jack Operation

1 — Extension With Jack Hook 4 — Extension 4

2 — Extension 2 5 — Wheel Wrench

3 — Extension 3

6

WHAT TO DO IN EMERGENCIES 587

Page 590 of 734

Removing The Spare Tire

1. Remove the spare tire before attempting to jack up thetruck. Attach the wheel wrench to the jack extension

tube with the curved angle facing away from the

vehicle. Insert the tube through the access hole between

the lower tailgate and the top of the bumper and into the

winch mechanism tube. 2. Rotate the wheel wrench handle counterclockwise until

the spare tire is on the ground with enough cable slack

to allow you to pull it out from under the vehicle.

Inserting The Jack Extension Tube Into The Access Hole

Rotating The Wheel Wrench Handle

588 WHAT TO DO IN EMERGENCIES

Page 592 of 734

5. Pull the retainer through the center of the wheel.

NOTE:The winch mechanism is designed for use with the

jack extension tube only. Use of an air wrench or other

power tools is not recommended and can damage the

winch.Preparations

1. Park the vehicle on a firm, level surface. Avoid ice or slippery areas.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic, pull far enough off the

road to avoid the danger of being hit when operating

the jack or changing the wheel.

2. Turn on the Hazard Warning flasher.

3. Apply the parking brake.

4. Place the gear selector into PARK. On four-wheel drive vehicles, shift the transfer case to the 4L position.

5. Turn the ignition OFF.

Block both the front and rear of the wheel diagonally

opposite the jacking position. For example, if the right front

wheel is being changed, block the left rear wheel. NOTE:Passengers should not remain in the

vehicle when the vehicle is being jacked.

Pulling The Retainer Through The Center Of The Wheel

590 WHAT TO DO IN EMERGENCIES

Page 593 of 734

Jack Instructions (1500 Series)

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

•Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the wheel to be

raised.

• Set the parking brake firmly and set an automatic

transmission in PARK; a manual transmission in

REVERSE.

• Never start or run the engine with the vehicle on a

jack.

• Do not let anyone sit in the vehicle when it is on a

jack.

• Do not get under the vehicle when it is on a jack. If

you need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

• Only use the jack in the positions indicated and for

lifting this vehicle during a tire change.

(Continued)

WARNING! (Continued)

•If working on or near a roadway, be extremely

careful of motor traffic.

• To assure that spare tires, flat or inflated, are securely

stowed, spares must be stowed with the valve stem

facing the ground.

Jack Warning Label

6

WHAT TO DO IN EMERGENCIES 591

Page 594 of 734

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the Jacking

Instructions for this vehicle.

1. Remove the spare wheel, jack, and tools from storage.

2. Using the wheel wrench, loosen, but do not remove, the wheel nuts by turning them counterclockwise one turn

while the wheel is still on the ground.

3. Placement of the jack: 4x2 Series Trucks Front Jacking Location

There is a jack location indicator on the rear portion of the

lower control arm.

4X2 Front Jacking Location Indicator

592 WHAT TO DO IN EMERGENCIES

Page 595 of 734

When changing a front wheel, place the scissor jack under

the rear portion of the lower control arm as shown below.4x4 Series Trucks Front Jacking Location

There is a jack location indicator on the rear portion of the

lower control arm.

4X2 Front Jacking Location

4X4 Front Jacking Location Indicator

6

WHAT TO DO IN EMERGENCIES 593

Page 596 of 734

When changing a front wheel, place the scissor jack under

the rear portion of the lower control arm as shown below.4x2 and 4x4 Rear Jacking Location

Operate the jack using the jack drive tube and the wheel

wrench. The tube extension may be used but is not

required.

For 4x2 and 4x4 trucks, when changing a rear wheel,

assemble the jack drive tube to the jack and connect the

drive tube to the extension tube. Place the jack under the

axle between the wheel and the shock bracket with the

drive tubes extending to the rear.

4X4 Front Jacking Location

Rear Jacking Location

594 WHAT TO DO IN EMERGENCIES