ignition Ram 2500 2018 Workshop Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 2500, Model: Ram 2500 2018Pages: 372, PDF Size: 7.1 MB

Page 183 of 372

REFUELING THE VEHICLE — GAS

ENGINE

The fuel filler cap (gas cap) is located behind

the fuel filler door, on the left side of the

vehicle. Open the fuel door and remove the

fuel cap by turning it counter-clockwise.

NOTE:

When removing the fuel filler cap, lay the cap

tether in the hook, located on the fuel filler

door.

WARNING!

• Never have any smoking materials lit inor near the vehicle when the gas cap is

removed or the tank is being filled.

• Never add fuel to the vehicle when the

engine is running.

• A fire may result if gasoline is pumped

into a portable container that is inside of

a vehicle. You could be burned. Always

place gas containers on the ground while

filling.

CAUTION!

• Damage to the fuel system or emissionscontrol system could result from using

an improper fuel tank filler tube cap.

• A poorly fitting fuel filler cap could let

impurities into the fuel system.

• A poorly fitting fuel filler cap may cause

the “Malfunction Indicator Light (MIL)”

to turn on.

• To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.

When the fuel nozzle “clicks” or shuts

off, the fuel tank is full.

NOTE:

• When the fuel nozzle “clicks” or shuts off, the fuel tank is full.

• Tighten the gas cap until you hear a “click- ing” sound. This is an indication that the

gas cap is tightened properly. The MIL in

the instrument cluster may turn on if the

gas cap is not secured properly. Make sure

that the gas cap is tightened each time the

vehicle is refueled.

WARNING!

Static electricity can cause an ignition of

flammable liquid, vapor or gas in any ve-

hicle or trailer. To reduce risk of serious

injury or death when filling containers:

• Always place container on the ground before filling.

• Keep the pump nozzle in contact with

the container when you are filling it.

• Use only approved containers for flam-

mable liquid.

• Do not leave container unattended while

filling.

• A static electric charge could cause a

spark and fire hazard.

181

Page 195 of 372

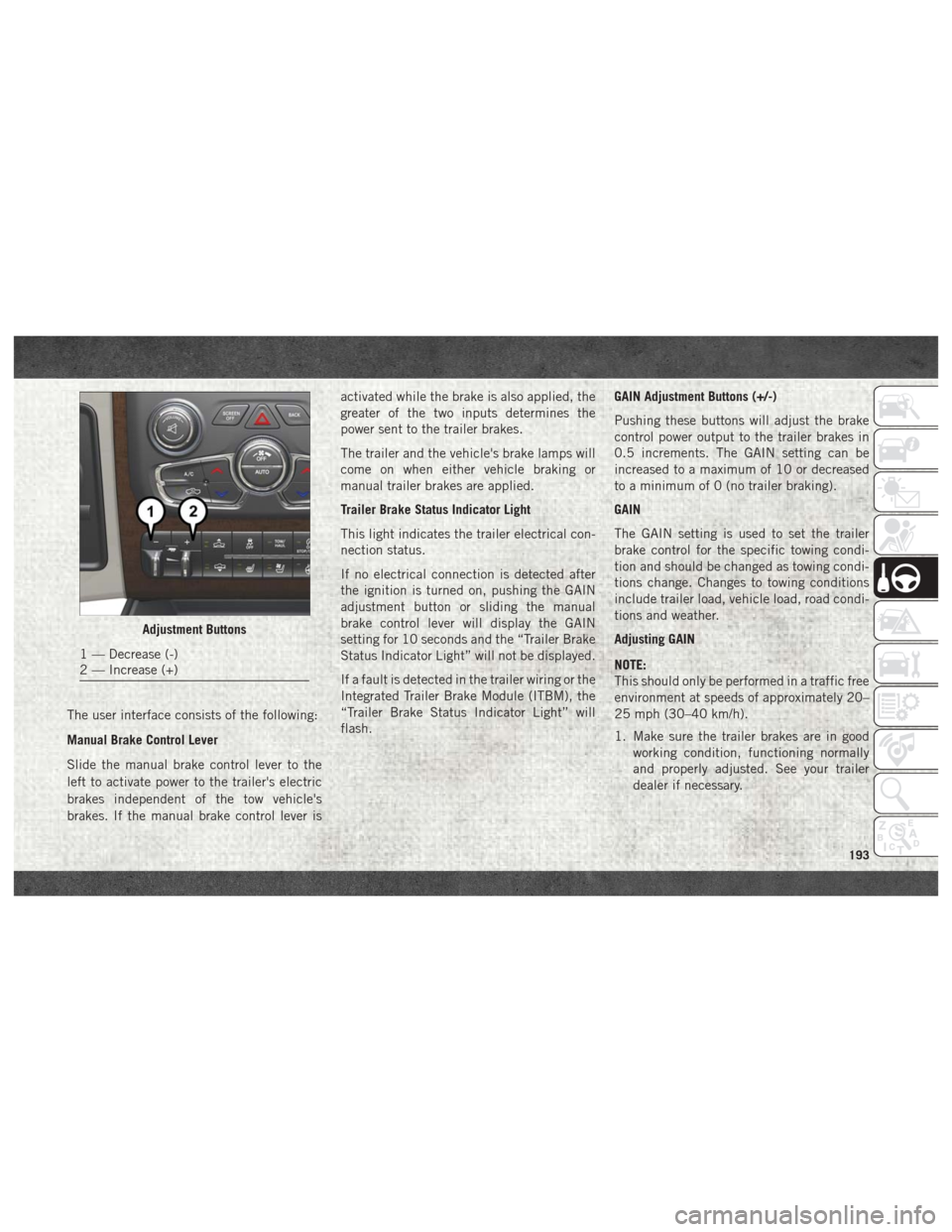

The user interface consists of the following:

Manual Brake Control Lever

Slide the manual brake control lever to the

left to activate power to the trailer's electric

brakes independent of the tow vehicle's

brakes. If the manual brake control lever isactivated while the brake is also applied, the

greater of the two inputs determines the

power sent to the trailer brakes.

The trailer and the vehicle's brake lamps will

come on when either vehicle braking or

manual trailer brakes are applied.

Trailer Brake Status Indicator Light

This light indicates the trailer electrical con-

nection status.

If no electrical connection is detected after

the ignition is turned on, pushing the GAIN

adjustment button or sliding the manual

brake control lever will display the GAIN

setting for 10 seconds and the “Trailer Brake

Status Indicator Light” will not be displayed.

If a fault is detected in the trailer wiring or the

Integrated Trailer Brake Module (ITBM), the

“Trailer Brake Status Indicator Light” will

flash.

GAIN Adjustment Buttons (+/-)

Pushing these buttons will adjust the brake

control power output to the trailer brakes in

0.5 increments. The GAIN setting can be

increased to a maximum of 10 or decreased

to a minimum of 0 (no trailer braking).

GAIN

The GAIN setting is used to set the trailer

brake control for the specific towing condi-

tion and should be changed as towing condi-

tions change. Changes to towing conditions

include trailer load, vehicle load, road condi-

tions and weather.

Adjusting GAIN

NOTE:

This should only be performed in a traffic free

environment at speeds of approximately 20–

25 mph (30–40 km/h).

1. Make sure the trailer brakes are in good

working condition, functioning normally

and properly adjusted. See your trailer

dealer if necessary.

Adjustment Buttons

1 — Decrease (-)

2 — Increase (+)

193

Page 199 of 372

Recreational Towing —

Two-Wheel Drive Models

DO NOT flat tow this vehicle. Damage to the

drivetrain will result.

Recreational towing (for two-wheel drive

models) is allowedONLYif the rear wheels are

OFF the ground. This may be accomplished

using a tow dolly or vehicle trailer. If using a

tow dolly, follow this procedure:

NOTE:

If vehicle is equipped with air suspension,

ensure the vehicle is set to Normal Ride

Height.

1. Properly secure the dolly to the tow ve- hicle, following the dolly manufacturer's

instructions.

2. Drive the rear wheels onto the tow dolly. 3. Firmly apply the parking brake. Place au-

tomatic transmission in PARK, manual

transmission in gear (not in NEUTRAL).

4. Properly secure the rear wheels to the dolly, following the dolly manufacturer's

instructions.

5. Turn the ignition OFF and remove the key fob.

6. Install a suitable clamping device, de- signed for towing, to secure the front

wheels in the straight position.

CAUTION!

• Towing with the rear wheels on theground will cause severe transmission

damage. Damage from improper towing

is not covered under the New Vehicle

Limited Warranty.

• Do not disconnect the driveshaft be-

cause fluid may leak from the transmis-

sion, causing damage to internal parts.

Recreational Towing —

Four-Wheel Drive Models

NOTE:

Both the manual shift and electronic shift

transfer cases must be shifted into NEUTRAL

(N) for recreational towing. Automatic trans-

missions must be shifted into PARK for rec-

reational towing. Manual transmissions must

be placed in gear (NOT in NEUTRAL) for

recreational towing. Refer to the following for

the proper transfer case NEUTRAL (N) shift-

ing procedure for your vehicle.

CAUTION!

• DO NOT dolly tow any 4WD vehicle.Towing with only one set of wheels on the

ground (front or rear) will cause severe

transmission and/or transfer case dam-

age. Tow with all four wheels either ON

the ground, or OFF the ground (using a

vehicle trailer).

• Tow only in the forward direction. Towing

this vehicle backwards can cause severe

damage to the transfer case.

197

Page 201 of 372

The NEUTRAL (N) indicator light will

blink while the shift is in progress. The

light will stop blinking (stay on solid)

when the shift to NEUTRAL (N) is com-

plete. After the shift is completed and

the NEUTRAL (N) light stays on, re-

lease the NEUTRAL (N) button.

6. Release the parking brake.

7. Shift the transmission into REVERSE.

8. Release the brake pedal (and clutch pedal on manual transmissions) for five seconds

and ensure that there is no vehicle

movement.

9. Repeat steps 7 and 8 with automatic transmission in DRIVE or manual trans-

mission in first gear.

10. Shift the transmission to NEUTRAL. Firmly apply the parking brake. Turn OFF

the engine. For vehicles with Keyless

Enter-N-Go, push and hold the ENGINE

START/STOP button until the engine

shuts off.

11. Shift the transmission into PARK or place manual transmission in gear (NOT in Neutral). On 8-speed transmissions

the shifter will automatically select

PARK when the engine is turned off.

12. Turn the ignition to the OFF mode, then cycle the ignition to the RUN mode and

back to the OFF mode. Remove the key

fob from the ignition.

13. Attach the vehicle to the tow vehicle using a suitable tow bar.

14. Release the parking brake.

NOTE:

With electronic shift transfer case:

• Steps 2 through 4 are requirements that must be met before pushing the NEUTRAL

(N) button, and must continue to be met

until the shift has been completed. If any of

these requirements are not met before

pushing the NEUTRAL (N) button or are no

longer met during the shift, the NEUTRAL

(N) indicator light will flash continuously

until all requirements are met or until the

NEUTRAL (N) button is released. • The ignition must be in the ON/RUN mode

for a shift to take place and for the position

indicator lights to be operable. If the igni-

tion is not in the ON/RUN mode, the shift

will not take place and no position indicator

lights will be on or flashing.

• A flashing NEUTRAL (N) position indicator light indicates that shift requirements have

not been met.

• If the vehicle is equipped with air suspen- sion, the engine should be started and left

running for a minimum of 60 seconds (with

all the doors closed) at least once every

24 hours. This process allows the air sus-

pension to adjust the vehicle’s ride height

to compensate for temperature effects.

Shifting Out Of NEUTRAL (N)

Use the following procedure to prepare your

vehicle for normal usage:

1. Bring the vehicle to a complete stop, leav-

ing it connected to the tow vehicle.

2. Firmly apply the parking brake.

3. Press and hold the brake pedal.

199

Page 202 of 372

4. Start the engine. Shift the transmissioninto NEUTRAL. Depress the clutch pedal

on a manual transmission.

• With manual shift transfer case, shift the transfer case lever to the desired

position.

• With electronic shift transfer case with rotary selector switch, push and hold

the transfer case NEUTRAL (N) button

until the NEUTRAL (N) indicator light

turns off. After the NEUTRAL (N) indi-

cator light turns off, release the NEU-

TRAL (N) button. After the NEUTRAL

(N) button has been released, the

transfer case will shift to the position

indicated by the selector switch.

• With electronic shift transfer case with push-button selector switch, push and

hold the switch for the desired transfer

case position, until the NEUTRAL (N)

indicator light turns off and the desired

position indicator light turns on. NOTE:

When shifting out of transfer case NEUTRAL

(N), turning the engine OFF is not required,

but may be helpful to avoid gear clash. With

the 8-speed automatic transmission, the en-

gine must remain running, since turning the

engine OFF will shift the transmission to

PARK (and the transmission must be in NEU-

TRAL for the transfer case to shift out of

NEUTRAL).

5. Turn the engine OFF. Shift automatic

transmission into PARK. On 8-speed

transmissions the shifter will automati-

cally select PARK when the engine is

turned off.

6. Release the brake pedal (and clutch pedal on a manual transmission).

7. Disconnect vehicle from the tow vehicle.

8. Start the engine.

9. Press and hold the brake pedal.

10. Release the parking brake.

11. Shift the transmission into gear, release the brake pedal (and clutch pedal on

manual transmissions), and check that

the vehicle operates normally. NOTE:

With electronic shift transfer case:

• Steps 3 and 4 are requirements that must

be met before pushing the button to shift

out of NEUTRAL (N), and must continue to

be met until the shift has been completed.

If any of these requirements are not met

before pushing the button or are no longer

met during the shift, the NEUTRAL (N)

indicator light will flash continuously until

all requirements are met or until the button

is released.

• The ignition must be in the ON/RUN mode for a shift to take place and for the position

indicator lights to be operable. If the igni-

tion is not in the ON/RUN mode, the shift

will not take place and no position indicator

lights will be on or flashing.

• A flashing NEUTRAL (N) position indicator light indicates that shift requirements have

not been met.

STARTING AND OPERATING

200

Page 204 of 372

HAZARD WARNING FLASHERS

The Hazard Warning flasher switch is located

on the upper switch bank just below the

radio.

Push the switch to turn on the Hazard Warn-

ing flasher. When the switch is activated, all

directional turn signals will flash on and off to

warn oncoming traffic of an emergency. Push

the switch a second time to turn off the

Hazard Warning flashers.

This is an emergency warning system and it

should not be used when the vehicle is in

motion. Use it when your vehicle is disabled

and it is creating a safety hazard for other

motorists.

When you must leave the vehicle to seek

assistance, the Hazard Warning flashers will

continue to operate even though the ignition

is placed in the OFF position.

NOTE:

With extended use the Hazard Warning flash-

ers may wear down your battery.

BULB REPLACEMENT

Replacement Bulbs

All of the inside bulbs are brass or glass-

wedge base. Aluminum base bulbs are not

approved.

Interior Bulbs

Bulb Number

Overhead Console

Lamps TS 212–9

Dome Lamp 7679

For lighted switches, see your authorized

dealer for replacement instructions.

Exterior Bulbs

Bulb Number

Base Quad Head-

lamp – Low Beam H11LL

Base Quad Head-

lamp – High Beam 9005LL

Front Turn Signal

Lamp (Base Quad

Headlamp) 3157NA

Bulb Number

Premium Bi Halogen

Projector Headlamp -

Low Beam 9005Sl+

Premium Bi Halogen

Projector Headlamp -

High Beam 9005LL

Front Turn Signal

Lamp (Premium

Headlamp) LED (Serviced at au-

thorized dealer)

Fog Lamp (Horizontal

shape) 9145

Fog Lamp (Vertical

shape) 9006

Center High Mounted

Stop Lamp (CHMSL) 921K

Rear Cargo Lamp 921

LED Center High

Mounted Stop Lamp

(CHMSL)/Cargo

Lamp LED (Serviced at au-

thorized dealer)

Cab Roof Marker

Lamps 194NA

Base Rear Tail/Turn

and Stop Lamp 3157K

Premium Rear Tail/

Turn and Stop Lamp LED (Serviced at au-

thorized dealer)

IN CASE OF EMERGENCY

202

Page 205 of 372

Bulb Number

Premium Backup

Lamp 7440/W21W

Rear Lamp Bar ID

Marker Lamp 194

Side Marker Lamps

(Dual Rear Wheels) 194

Backup Lamp 921

Rear License Plate

Lamp 194

FUSES

WARNING!

• When replacing a blown fuse, always use

an appropriate replacement fuse with

the same amp rating as the original fuse.

Never replace a fuse with another fuse of

WARNING!

higher amp rating. Never replace a

blown fuse with metal wires or any other

material. Do not place a fuse inside a

circuit breaker cavity or vice versa. Fail-

ure to use proper fuses may result in

serious personal injury, fire and/or prop-

erty damage.

• Before replacing a fuse, make sure that

the ignition is off and that all the other

services are switched off and/or disen-

gaged.

• If the replaced fuse blows again, contact

an authorized dealer.

• If a general protection fuse for safety

systems (air bag system, braking sys-

tem), power unit systems (engine sys-

tem, transmission system) or steering

WARNING!

system blows, contact an authorized

dealer.

Power Distribution Center

The Power Distribution Center is located in

the engine compartment near the battery.

This center contains cartridge fuses, micro

fuses, relays, and circuit breakers. A descrip-

tion of each fuse and component may be

stamped on the inside cover, otherwise the

cavity number of each fuse is stamped on the

inside cover that corresponds to the following

chart.

Cavity Cartridge Fuse Micro Fuse Description

F01 80 Amp Black –Rad Fan Control Module – If Equipped

F03 60 Amp Yellow –Rad Fan – If Equipped

F05 40 Amp Green –Compressor for Air Suspension – If Equipped

F06 40 Amp Green –Antilock Brakes/Electronic Stability Control Pump

203

Page 207 of 372

CavityCartridge Fuse Micro Fuse Description

F25 30 Amp Pink – Front Wiper

F26 30 Amp Pink –Antilock Brakes / Stability Control Module / Valves

F28 20 Amp Blue –Trailer Tow Backup Lights – If Equipped

F29 20 Amp Blue –Trailer Tow Parking Lights – If Equipped

F30 30 Amp Pink –Trailer Tow Receptacle

F31 30 Amp Pink (1500 LD

Diesel) –

Urea Heater Control – If Equipped

F32 –– Spare Fuse

F33 20 Amp Blue –Special Services Vehicle Only

F34 30 Amp Pink –Vehicle System Interface Module #2 – If Equipped

F35 30 Amp Pink –Sunroof – If Equipped

F36 30 Amp Pink –Rear Defroster – If Equipped

F37 30 Amp Pink –Cummins Diesel Fuel Heater #2 – If Equipped

F38 30 Amp Pink –Power Inverter 115V AC – If Equipped

F39 20 Amp Blue –Power Outlet – Special Services Only

F41 –10 Amp Red Active Grill Shutter – If Equipped

F42 –20 Amp Yellow Horn

F44 –10 Amp Red Diagnostic Port

F46 –10 Amp Red Upfitter – If Equipped

F49 –10 Amp Red Instrument Panel Cluster (Except Fleet Vehicles)

F50 –20 Amp Yellow Air Suspension Control Module – If Equipped

F51 –10 Amp Red Ignition Node Module / Keyless Ignition (Instrument

Panel Cluster – Fleet Vehicles Only)

205

Page 208 of 372

CavityCartridge Fuse Micro Fuse Description

F52 –5 Amp Tan Battery Sensor

F53 –20 Amp Yellow Trailer Tow – Left Turn/Stop Lights

F54 –20 Amp Yellow Adjustable Pedals

F56 –15 Amp Blue Additional Diesel Content – If Equipped

F57 –20 Amp Yellow Transmission

F58 –20 Amp Yellow Spare Fuse

F59 –10 Amp Red SCR Relay – If Equipped

F60 –15 Amp Blue Underhood Lamp

F61 –10 Amp Red (1500 LD Die-

sel & Cummins Diesel) PM Sensor – If Equipped

F62 –10 Amp Red Air Conditioning Clutch

F63 –20 Amp Yellow Ignition Coils (Gas), Urea Heater (Cummins Diesel)

F64 –25 Amp Clear Fuel Injectors / Powertrain

F65 –– Spare Fuse

F66 –10 Amp Red Sunroof / Passenger Window Switches / Rain Sensor

F67 –10 Amp Red CD / DVD / Bluetooth Hands-free Module – If Equipped

F69 –15 Amp Blue Mod SCR 12V (Cummins Diesel) – If Equipped

F70 –30 Amp Green Fuel Pump Motor

F71 –25 Amp Clear Amplifier

F72 –10 Amp Red PCM – If Equipped

F73 –20 Amp Yellow Fuel Transfer Pump (HD Only) – If Equipped

F74 –20 Amp Yellow (Gas Engine

& 1500 LD Diesel) Brake Vacuum Pump Gas/Diesel – If Equipped

IN CASE OF EMERGENCY

206

Page 212 of 372

NOTE:

Always stow the spare tire with the valve stem

facing the ground. It is recommended that

you stow the flat or spare to avoid tangling the

loose cable.NOTE:

The winch mechanism is designed for use

with the extension tube only. Use of an air

wrench or other power tools is not recom-

mended and can damage the winch.

Preparations For Jacking

1. Park the vehicle on a firm, level surface.

Avoid ice or slippery areas.

WARNING!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic, pull

far enough off the road to avoid being hit

when operating the jack or changing the

wheel.

2. Place the gear selector into PARK. On four-wheel drive vehicles, shift the trans-

fer case to the 4L position.

3. Turn on the Hazard Warning flasher.

4. Apply the parking brake.

5. Turn the ignition OFF. 6. Block both the front and rear of the wheel

diagonally opposite the jacking position.

For example, if the right front wheel is

being changed, block the left rear wheel.

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being jacked.

Lug Wrench/Spare Tire

1 — Lug Wrench 2 — Spare Tire

Wheel Blocked

IN CASE OF EMERGENCY

210