instrument panel Ram 2500 2018 Workshop Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 2500, Model: Ram 2500 2018Pages: 372, PDF Size: 7.1 MB

Page 178 of 372

Transport Mode

To assist with flat bed towing, the air suspen-

sion system has a feature which will put the

vehicle below Normal Ride Height (NRH) and

disable the automatic load leveling system.

This mode is intended to be enabled with

engine running. Refer to “Instrument Cluster

Display” in “Getting To Know Your Instru-

ment Panel” or “Uconnect Settings” in “Mul-

timedia” if equipped with a touch screen

radio, in your Owner’s Manual for further

information.

NOTE:

This mode is intended to be enabled with

engine running.

Wheel Alignment Mode

Before performing a wheel alignment this

mode must be enabled. Refer to “Instrument

Cluster Display” in “Getting To Know Your

Instrument Panel” or “Uconnect Settings” in

“Multimedia” if equipped with a touch

screen radio, in your Owner’s Manual for

further information.NOTE:

This mode is intended to be enabled with

engine running.

Protection Strategy

In order to “protect” the air suspension sys-

tem, the vehicle will disable load leveling as

required (suspension overloaded, battery

charge low, etc.). Load leveling will automati-

cally resume as soon as system operation

requirements are met. See your authorized

dealer if system does not resume.

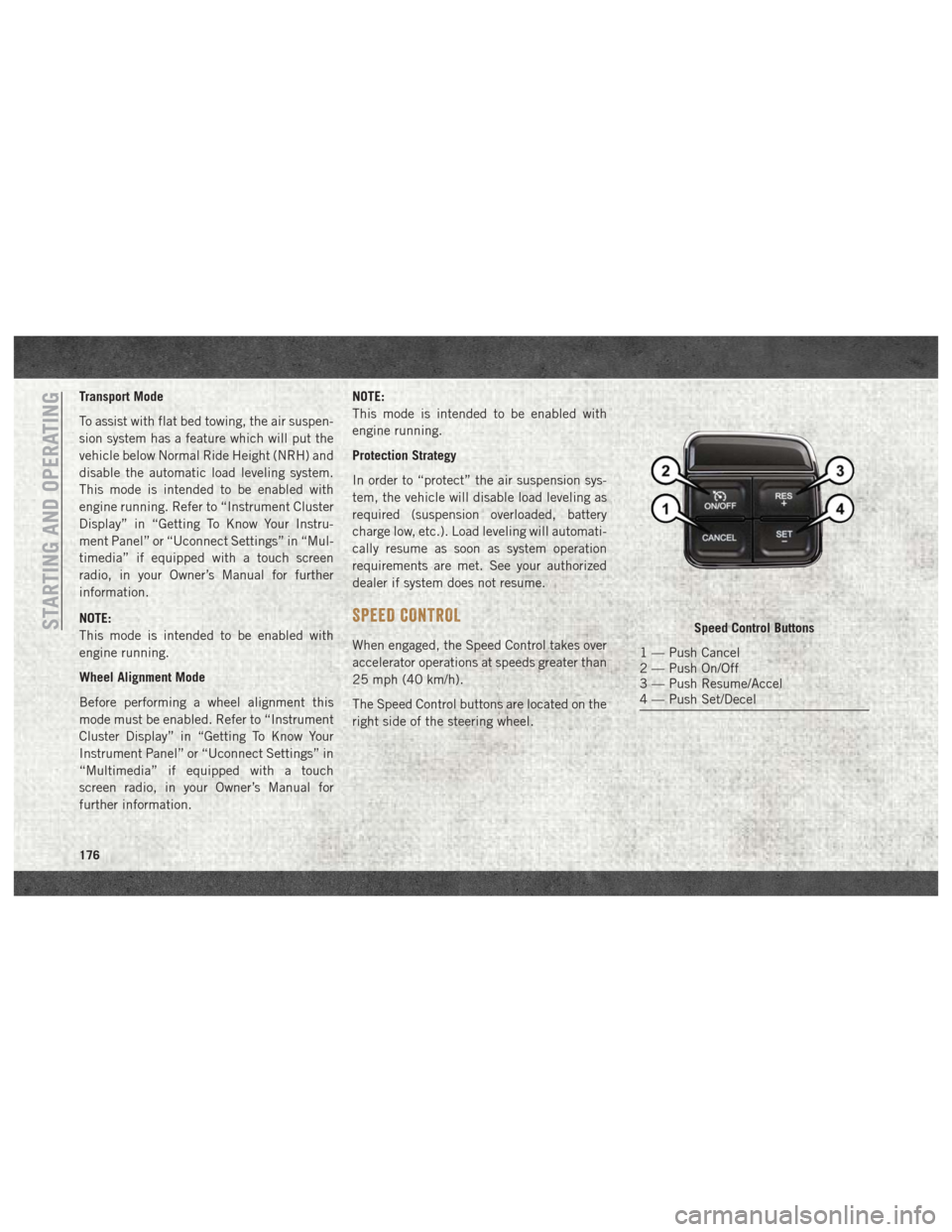

SPEED CONTROL

When engaged, the Speed Control takes over

accelerator operations at speeds greater than

25 mph (40 km/h).

The Speed Control buttons are located on the

right side of the steering wheel.

Speed Control Buttons

1 — Push Cancel

2 — Push On/Off

3 — Push Resume/Accel

4 — Push Set/Decel

STARTING AND OPERATING

176

Page 179 of 372

NOTE:

In order to ensure proper operation, the

Speed Control System has been designed to

shut down if multiple speed control functions

are operated at the same time. If this occurs,

the Speed Control System can be reactivated

by pushing the Speed Control ON/OFF button

and resetting the desired vehicle set speed.

To Activate

Push the ON/OFF button. The Cruise Indica-

tor Light in the instrument cluster display will

illuminate. To turn the system off, push the

ON/OFF button a second time. The Cruise

Indicator Light will turn off. The system

should be turned off when not in use.

WARNING!

Leaving the Speed Control system on when

not in use is dangerous. You could acci-

dentally set the system or cause it to go

faster than you want. You could lose con-

trol and have an accident. Always leave the

system off when you are not using it.

To Set A Desired Speed

Turn the Speed Control on. When the vehicle

has reached the desired speed, push the SET

(-) button and release. Release the accelera-

tor and the vehicle will operate at the se-

lected speed.

NOTE:

The vehicle should be traveling at a steady

speed and on level ground before pushing the

SET (-) button.

To Vary The Speed Setting

To Increase Speed

When the Speed Control is set, you can in-

crease speed by pushing the RES (+) button.

The driver’s preferred units can be selected

through the instrument panel settings if

equipped. Refer to “Getting To Know Your

Instrument Panel” in the Owner’s Manual formore information. The speed decrement

shown is dependant on the chosen speed unit

of U.S. (mph) or Metric (km/h):

U.S. Speed (mph)

• Pushing the RES (+) button once will result

in a 1 mph increase in set speed. Each

subsequent tap of the button results in an

increase of 1 mph.

• If the button is continually pushed, the set speed will continue to increase until the

button is released, then the new set speed

will be established.

Metric Speed (km/h)

• Pushing the RES (+) button once will result in a 1 km/h increase in set speed. Each

subsequent tap of the button results in an

increase of 1 km/h.

• If the button is continually pushed, the set speed will continue to increase until the

button is released, then the new set speed

will be established.

177

Page 180 of 372

To Decrease Speed

When the Speed Control is set, you can de-

crease speed by pushing the SET (-) button.

The driver’s preferred units can be selected

through the instrument panel settings if

equipped. Refer to “Getting To Know Your

Instrument Panel” in the Owner’s Manual for

more information. The speed increment

shown is dependent on the selected speed

unit of U.S. (mph) or Metric (km/h):

U.S. Speed (mph)

• Pushing the SET (-) button once will resultin a 1 mph decrease in set speed. Each

subsequent tap of the button results in a

decrease of 1 mph.

• If the button is continually pushed, the set speed will continue to decrease until the

button is released, then the new set speed

will be established.

Metric Speed (km/h)

• Pushing the SET (-) button once will result in a 1 km/h decrease in set speed. Each

subsequent tap of the button results in a

decrease of 1 km/h. • If the button is continually pushed, the set

speed will continue to decrease until the

button is released, then the new set speed

will be established.

To Accelerate For Passing

Press the accelerator as you would normally.

When the pedal is released, the vehicle will

return to the set speed.

Using Speed Control On Hills

The transmission may downshift on hills to

maintain the vehicle set speed.

NOTE:

The Speed Control system maintains speed

up and down hills. A slight speed change on

moderate hills is normal.

On steep hills, a greater speed loss or gain

may occur so it may be preferable to drive

without Speed Control.

WARNING!

Speed Control can be dangerous where the

system cannot maintain a constant speed.

Your vehicle could go too fast for the con-

WARNING!

ditions, and you could lose control and

have an accident. Do not use Speed Con-

trol in heavy traffic or on roads that are

winding, icy, snow-covered or slippery.

To Resume Speed

To resume a previously set speed, push the

RES (+) button and release. Resume can be

used at any speed above 20 mph (32 km/h).

To Deactivate

A soft tap on the brake pedal, pushing the

CANCEL button, or normal brake pressure

while slowing the vehicle will deactivate the

Speed Control without erasing the set speed

from memory.

Pushing the ON/OFF button or turning the

ignition switch OFF erases the set speed from

memory.STARTING AND OPERATING

178

Page 186 of 372

The DEF injection system consists of the

following components:

• DEF tank

• DEF pump

• DEF injector

• Electronically-heated DEF lines

• NOx sensors

• Temperature sensors

• SCR catalyst

The DEF injection system and SCR catalyst

enable the achievement of diesel emissions

requirements; while maintaining outstanding

fuel economy, drivability, torque and power

ratings.

Refer to “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel” for

system messages and warnings.

NOTE:

• Your vehicle is equipped with a DEF injec-tion system. You may occasionally hear an

audible clicking noise from under the ve-

hicle at a stop. This is normal operation. • The DEF pump will run for a period of time

after engine shutdown to purge the DEF

system. This is normal operation and may

be audible from the rear of the vehicle.

Adding Diesel Exhaust Fluid

The DEF gauge (located on the instrument

cluster) will display the level of DEF remain-

ing in the tank. Refer to “Instrument Cluster”

and “Instrument Cluster Descriptions” in

“Getting To Know Your Instrument Panel” for

further information.

NOTE:

• Driving conditions (altitude, vehicle speed,load, etc.) will effect the amount of DEF

that is used in your vehicle.

• Another factor is that outside temperature can affect DEF consumption. In cold con-

ditions, 12° F (-11° C) and below, the DEF

gauge needle can stay on a fixed position

and may not move for extended periods of

time. This is a normal function of the sys-

tem. • There is an electric heater inside the DEF

tank that automatically works when neces-

sary. And if the DEF supply does freeze, the

truck will operate normally until it thaws.

DEF Fill Procedure

NOTE:

Refer to “Fluids And Lubricants” in “Techni-

cal Specifications” for the correct fluid type.

1. Remove cap from DEF tank (located on

drivers side of the vehicle or in fuel door).

STARTING AND OPERATING

184

Page 190 of 372

Diesel Exhaust Fluid

Your vehicle is equipped with a Selective

Catalytic Reduction system to meet the very

stringent diesel emissions standards re-

quired by the Environmental Protection

Agency.

The purpose of the SCR system is to reduce

levels of NOx (oxides of nitrogen emitted from

engines) that are harmful to our health and

the environment to a near-zero level. Small

quantities of Diesel Exhaust Fluid (DEF) is

injected into the exhaust upstream of a cata-

lyst where, when vaporized, it converts smog-

forming nitrogen oxides (NOx) into harmless

nitrogen (N2) and water vapor (H2O), two

natural components of the air we breathe.

You can operate with the comfort that your

vehicle is contributing to a cleaner, healthier

world environment for this and generations to

come.

System Overview

This vehicle is equipped with a Diesel Ex-

haust Fluid (DEF) injection system and a

Selective Catalytic Reduction (SCR) catalyst

to meet the emission requirements.The DEF injection system consists of the

following components:

• DEF tank

• DEF pump

• DEF injector

• Electronically-heated DEF lines

• DEF control module

• NOx sensors

• Temperature sensors

• SCR catalyst

• UQS Sensor

Refer to “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel” for

system messages and warnings.

NOTE:

• Your vehicle is equipped with a DEF injec-

tion system. You may occasionally hear an

audible clicking noise. This is normal op-

eration.

• The DEF pump will run for a period of time after engine shutdown to purge the DEF

system. This is normal operation.

Diesel Exhaust Fluid Storage

Diesel Exhaust Fluid (DEF) is considered a

very stable product with a long shelf life. If

DEF is kept in temperatures between 10° and

90°F (-12° and 32°C), it will last a minimum

of one year.

DEF is subject to freezing at the lowest tem-

peratures. For example, DEF may freeze at

temperatures at or below 12° F (-11° C). The

system has been designed to operate in this

environment.

NOTE:

When working with DEF, it is important to

know that:

• Any containers or parts that come into con-tact with DEF must be DEF compatible

(plastic or stainless steel). Copper, brass,

aluminum, iron or non-stainless steel

should be avoided as they are subject to

corrosion by DEF.

• If DEF is spilled, it should be wiped up completely.

STARTING AND OPERATING

188

Page 191 of 372

Adding Diesel Exhaust Fluid

The DEF gauge (located on the instrument

cluster) will display the level of DEF remain-

ing in the tank. Refer to “Instrument Cluster”

and “Instrument Cluster Descriptions” in

“Getting To Know Your Instrument Panel” for

further information.

NOTE:

• Driving conditions (altitude, vehicle speed,load, etc.) will effect the amount of DEF

that is used in your vehicle.

• Another factor is that outside temperature can affect DEF consumption. In cold con-

ditions, 12° F (-11° C) and below, the DEF

gauge needle can stay on a fixed position

and may not move for extended periods of

time. This is a normal function of the sys-

tem.

• There is an electric heater inside the DEF tank that automatically works when neces-

sary. And if the DEF supply does freeze, the

truck will operate normally until it thaws. DEF Fill Procedure

NOTE:

Refer to “Fluids And Lubricants” in “Techni-

cal Specifications” for the correct fluid type.

1. Remove cap from DEF tank (located on

drivers side of the vehicle or in fuel door). 2. Insert DEF fill adapter/nozzle into DEF

tank filler neck.

NOTE: • The DEF gauge may take up to five seconds to update after adding a gallon

or more of Diesel Exhaust Fluid (DEF)

to the DEF tank. If you have a fault

related to the DEF system, the gauge

may not update to the new level. See

your authorized dealer for service.

• The DEF gauge may also not immedi- ately update after a refill if the tempera-

ture of the DEF fluid is below 12F

(-11C). The DEF line heater will possi-

bly warm up the DEF fluid and allow the

gauge to update after a period of run

time. Under very cold conditions, it is

possible that the gauge may not reflect

the new fill level for several drives.

CAUTION!

•To avoid DEF spillage, and possible dam-

age to the DEF tank from overfilling, do

not “top off” the DEF tank after filling.

Fill Locations

1 — Diesel Exhaust Fluid (DEF) Fill

Location

2 — Diesel Fuel Fill Location

189

Page 196 of 372

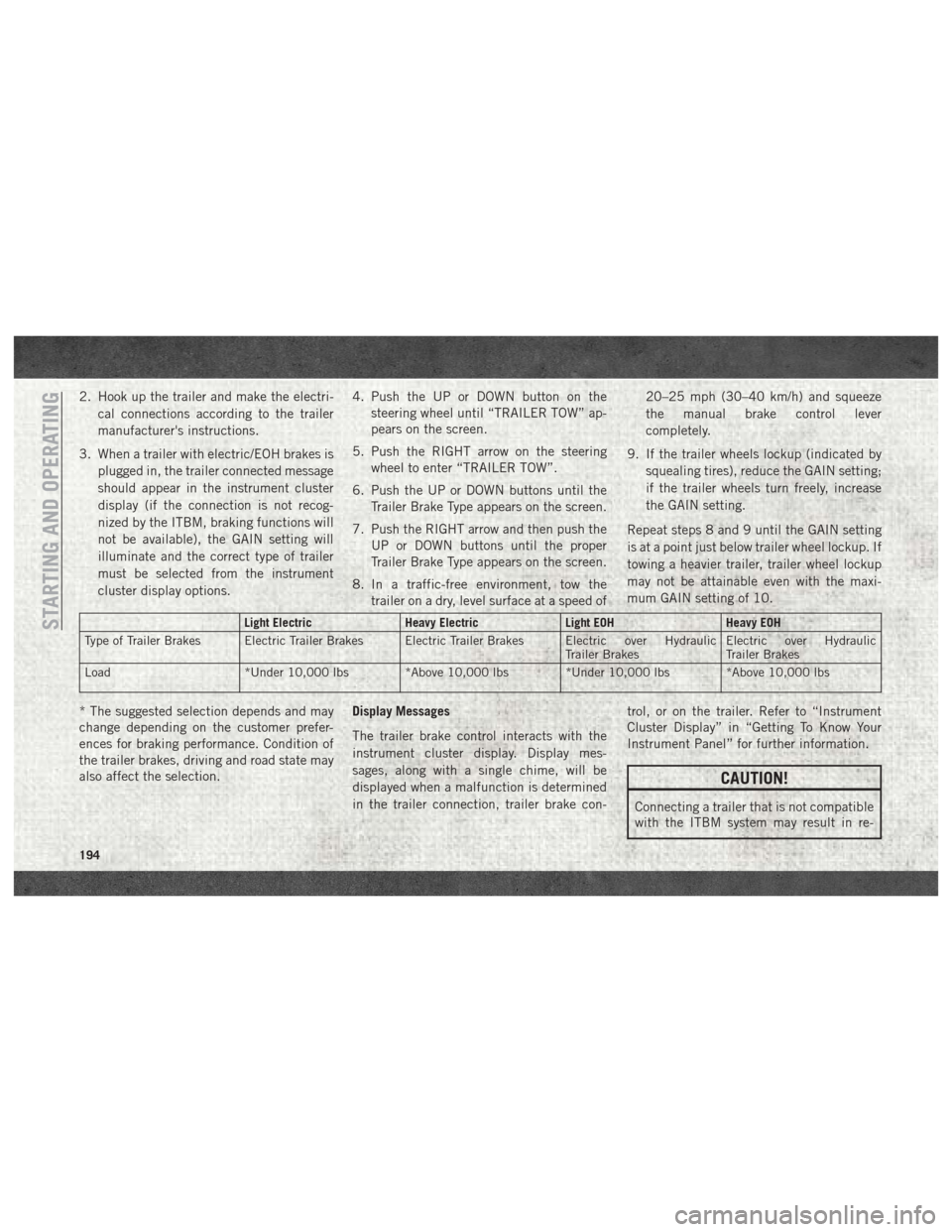

2. Hook up the trailer and make the electri-cal connections according to the trailer

manufacturer's instructions.

3. When a trailer with electric/EOH brakes is plugged in, the trailer connected message

should appear in the instrument cluster

display (if the connection is not recog-

nized by the ITBM, braking functions will

not be available), the GAIN setting will

illuminate and the correct type of trailer

must be selected from the instrument

cluster display options. 4. Push the UP or DOWN button on the

steering wheel until “TRAILER TOW” ap-

pears on the screen.

5. Push the RIGHT arrow on the steering wheel to enter “TRAILER TOW”.

6. Push the UP or DOWN buttons until the Trailer Brake Type appears on the screen.

7. Push the RIGHT arrow and then push the UP or DOWN buttons until the proper

Trailer Brake Type appears on the screen.

8. In a traffic-free environment, tow the trailer on a dry, level surface at a speed of 20–25 mph (30–40 km/h) and squeeze

the manual brake control lever

completely.

9. If the trailer wheels lockup (indicated by squealing tires), reduce the GAIN setting;

if the trailer wheels turn freely, increase

the GAIN setting.

Repeat steps 8 and 9 until the GAIN setting

is at a point just below trailer wheel lockup. If

towing a heavier trailer, trailer wheel lockup

may not be attainable even with the maxi-

mum GAIN setting of 10.

Light Electric Heavy ElectricLight EOHHeavy EOH

Type of Trailer Brakes Electric Trailer Brakes Electric Trailer Brakes Electric over Hydraulic Trailer BrakesElectric over Hydraulic

Trailer Brakes

Load *Under 10,000 lbs *Above 10,000 lbs *Under 10,000 lbs *Above 10,000 lbs

* The suggested selection depends and may

change depending on the customer prefer-

ences for braking performance. Condition of

the trailer brakes, driving and road state may

also affect the selection. Display Messages

The trailer brake control interacts with the

instrument cluster display. Display mes-

sages, along with a single chime, will be

displayed when a malfunction is determined

in the trailer connection, trailer brake con- trol, or on the trailer. Refer to “Instrument

Cluster Display” in “Getting To Know Your

Instrument Panel” for further information.

CAUTION!

Connecting a trailer that is not compatible

with the ITBM system may result in re-

STARTING AND OPERATING

194

Page 207 of 372

CavityCartridge Fuse Micro Fuse Description

F25 30 Amp Pink – Front Wiper

F26 30 Amp Pink –Antilock Brakes / Stability Control Module / Valves

F28 20 Amp Blue –Trailer Tow Backup Lights – If Equipped

F29 20 Amp Blue –Trailer Tow Parking Lights – If Equipped

F30 30 Amp Pink –Trailer Tow Receptacle

F31 30 Amp Pink (1500 LD

Diesel) –

Urea Heater Control – If Equipped

F32 –– Spare Fuse

F33 20 Amp Blue –Special Services Vehicle Only

F34 30 Amp Pink –Vehicle System Interface Module #2 – If Equipped

F35 30 Amp Pink –Sunroof – If Equipped

F36 30 Amp Pink –Rear Defroster – If Equipped

F37 30 Amp Pink –Cummins Diesel Fuel Heater #2 – If Equipped

F38 30 Amp Pink –Power Inverter 115V AC – If Equipped

F39 20 Amp Blue –Power Outlet – Special Services Only

F41 –10 Amp Red Active Grill Shutter – If Equipped

F42 –20 Amp Yellow Horn

F44 –10 Amp Red Diagnostic Port

F46 –10 Amp Red Upfitter – If Equipped

F49 –10 Amp Red Instrument Panel Cluster (Except Fleet Vehicles)

F50 –20 Amp Yellow Air Suspension Control Module – If Equipped

F51 –10 Amp Red Ignition Node Module / Keyless Ignition (Instrument

Panel Cluster – Fleet Vehicles Only)

205

Page 209 of 372

CavityCartridge Fuse Micro Fuse Description

F75 –10 Amp Red Coolant Temperature Valve Actuator

F76 –10 Amp Red Antilock Brakes / Electronic Stability Control

F77 –10 Amp Red Drivetrain Control Module/Front Axle Disconnect Module

F78 –10 Amp Red Engine Control Module / Electric Power Steering

F79 –15 Amp Blue Clearance Lights

F80 –10 Amp Red Universal Garage Door Opener / Compass

F81 –20 Amp Yellow Trailer Tow Right Turn / Stop Lights

F82 –10 Amp Red Steering Column Control Module / Cruise Control

F84 –15 Amp Blue Switch Bank / Instrument Cluster

F85 –10 Amp Red Airbag Module

F86 –10 Amp Red Airbag Module

F87 –10 Amp Red Air Suspension – If Equipped / Trailer Tow / Steering Col-

umn Control Module

F88 –15 Amp Blue Instrument Panel Cluster

F90/F91 –20 Amp Yellow Power Outlet (Rear Seats) Customer Selectable

F93 –20 Amp Yellow Cigar Lighter

F94 –10 Amp Red Shifter / Transfer Case Module

F95 –10 Amp Red Rear Camera / Park Assist

F96 –10 Amp Red Rear Seat Heater Switch

F97 –25 Amp Clear Rear Heated Seats & Heated Steering Wheel – If

Equipped

F98 –25 Amp Clear Front Heated Seats – If Equipped

F99 –10 Amp Red Climate Control

207

Page 210 of 372

CavityCartridge Fuse Micro Fuse Description

F100 –10 Amp Red Upfitters – If Equipped

F101 –15 Amp Blue Electrochromatic Mirror / Smart High Beams – If

Equipped

F104 –20 Amp Yellow Power Outlets (Instrument Panel / Center Console)

CAUTION!

• When installing the power distribution

center cover, it is important to ensure

the cover is properly positioned and fully

latched. Failure to do so may allow water

to get into the power distribution center

and possibly result in an electrical sys-

tem failure.

• When replacing a blown fuse, it is impor-

tant to use only a fuse having the correct

amperage rating. The use of a fuse with

a rating other than indicated may result

in a dangerous electrical system over-

load. If a properly rated fuse continues

to blow, it indicates a problem in the

circuit that must be corrected.

JACKING AND TIRE CHANGING

Jack Location

The jack and jack tools are stored under the

front passenger seat.

Removal Of Jack And Tools

• To access the jack and jack tools you must

remove the plastic access cover, located on

the side of the seat. To remove the cover,

pull the front part of the cover (closest to

the front of the seat) toward you to release a

locking tab. Once the front of the cover is

loose, slide the cover toward the front of the

seat until it is free from the seat frame.

Jack And Tools Location

IN CASE OF EMERGENCY

208