run flat Ram 2500 2019 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2019, Model line: 2500, Model: Ram 2500 2019Pages: 696, PDF Size: 13.89 MB

Page 121 of 696

GETTING TO KNOW YOUR VEHICLE 119

Storage Bin (Regular Cab)

The storage bin is located behind the front seats and runs the

length of the cab.Storage Bin Fold Flat Load Floor — If Equipped

Crew Cab models with a 60/40 rear seat may be equipped

with a folding load floor.

WARNING!

Do not operate the vehicle with loose items stored on the

load floor. While driving or in an accident you may

experience abrupt stopping, rapid acceleration, or sharp

turns. Loose objects stored on the load floor may move

around with force and strike occupants, resulting in

serious or fatal injury. 2

Page 189 of 696

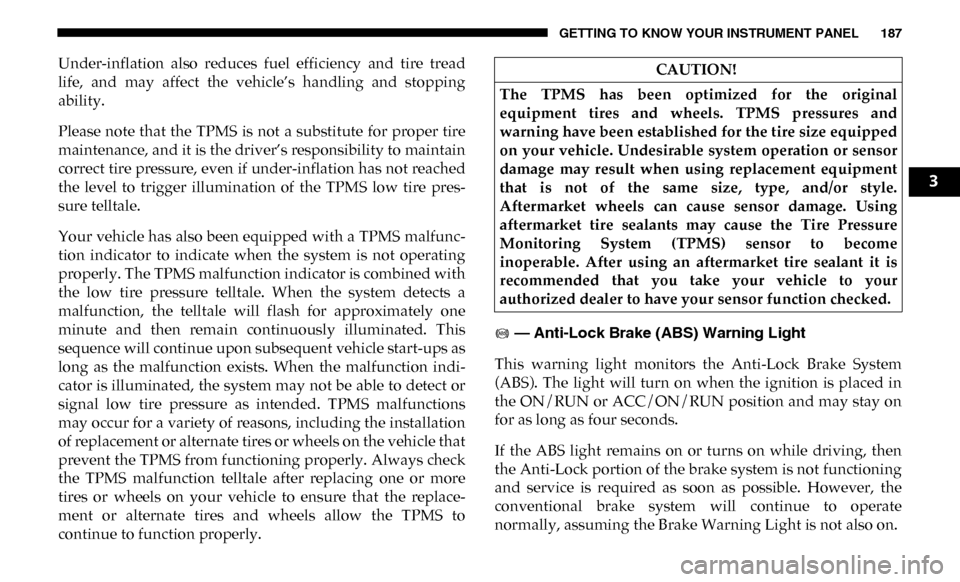

GETTING TO KNOW YOUR INSTRUMENT PANEL 187

Under-inflation also reduces fuel efficiency and tire tread

life, and may affect the vehicle’s handling and stopping

ability.

Please note that the TPMS is not a substitute for proper tire

maintenance, and it is the driver’s responsibility to maintain

correct tire pressure, even if under-inflation has not reached

the level to trigger illumination of the TPMS low tire pres-

sure telltale.

Your vehicle has also been equipped with a TPMS malfunc -

tion indicator to indicate when the system is not operating

properly. The TPMS malfunction indicator is combined with

the low tire pressure telltale. When the system detects a

malfunction, the telltale will flash for approximately one

minute and then remain continuously illuminated. This

sequence will continue upon subsequent vehicle start-ups as

long as the malfunction exists. When the malfunction indi -

cator is illuminated, the system may not be able to detect or

signal low tire pressure as intended. TPMS malfunctions

may occur for a variety of reasons, including the installation

of replacement or alternate tires or wheels on the vehicle that

prevent the TPMS from functioning properly. Always check

the TPMS malfunction telltale after replacing one or more

tires or wheels on your vehicle to ensure that the replace -

ment or alternate tires and wheels allow the TPMS to

continue to function properly. — Anti-Lock Brake (ABS) Warning Light

This warning light monitors the Anti-Lock Brake System

(ABS). The light will turn on when the ignition is placed in

the ON/RUN or ACC/ON/RUN position and may stay on

for as long as four seconds.

If the ABS light remains on or turns on while driving, then

the Anti-Lock portion of the brake system is not functioning

and service is required as soon as possible. However, the

conventional brake system will continue to operate

normally, assuming the Brake Warning Light is not also on. CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures and

warning have been established for the tire size equipped

on your vehicle. Undesirable system operation or sensor

damage may result when using replacement equipment

that is not of the same size, type, and/or style.

Aftermarket wheels can cause sensor damage. Using

aftermarket tire sealants may cause the Tire Pressure

Monitoring System (TPMS) sensor to become

inoperable. After using an aftermarket tire sealant it is

recommended that you take your vehicle to your

authorized dealer to have your sensor function checked.

3

Page 229 of 696

SAFETY 227

Trailer Sensors Detected Do Not Match Active Trailer

The “Trailer Sensors Detected Do Not Match Active Trailer”

message will be displayed in the Instrument Cluster when

the trailer sensors being received by the TTPM module do

match the trailer sensors paired to the current trailer number

selected. This message will be displayed when the sensors

being received completely match the sensors paired to

another trailer number configured in the TTPM module.

To correct this condition, the correct trailer number must be

selected in the radio. Refer to the “Uconnect Settings” in

“Multimedia” for further information.

Tire Fill Alert

This feature notifies the user when the placard tire pressure

is attained while inflating or deflating the tire.

The customer may choose to disable or enable the Tire Fill

Alert feature through use of the customer settings in the

radio.

NOTE:

• Only one tire can be filled at a time when using the Tire FillAlert system. • The Tire Fill Alert feature cannot be entered if an existing

TPM system fault is set to “active” or if the system is in

deactivation mode (if equipped).

The system will be activated when the TPM receiver module

detects a change in tire pressure. The ignition must be in the

RUN mode, with the transmission in PARK (P).

NOTE:

It is not required to have the engine running to enter Tire Fill

Alert mode.

The hazard lamps will come on to confirm the vehicle is in

Tire Fill Alert mode.

When Tire Fill Alert Mode is entered, the tire pressure

display screen will be displayed in the instrument cluster.

Operation:

• The horn will chirp to let the user know when to stop filling the tire, when it reaches recommended pressure.

• The horn will chirp three times if the tire is over filled and will continue to chirp every five seconds if the user

continues to inflate the tire.

4

Page 230 of 696

228 SAFETY

• The horn will chirp once again when enough air is let outto reach proper inflation level.

• The horn will also chirp three times if the tire is then under-inflated and will continue to chirp every five

seconds if the user continues to deflate the tire.

Selectable Tire Fill Alert (STFA)

The Selectable Tire Fill Alert (STFA) system is an optional

feature that is included as part of the normal Tire Fill Alert

system. The system is designed to allow the customer to

select a pressure to inflate or deflate the vehicle's front and

rear axle tires to and to provide feedback to the customer

while inflating or deflating the vehicle's tires.

In the Selectable Tire Fill Alert customer settings menu in the

radio, the customer will be able to select a pressure setting

for both the front and rear axle tire pressures by scrolling

through a pressure range from XX to 15 psi in 1 psi incre -

ments for each axle setting. XX = the vehicle’s cold placard

pressure values for the front and rear axles as shown on the

vehicle placard pressure label.

The customer may also store the pressure values chosen for

each axle in the radio as a preset pressure. The customer will

be allowed to store up to two sets of preset values in the radio

for the front and rear axle pressure values. Once the customer selects the tire pressures for the front and

rear axles that they want to inflate or deflate to, they can

begin inflating or deflating one tire at a time.

NOTE:

The STFA system will only support inflating or deflating one

tire at a time.

The system will be activated when the TPM receiver module

detects a change in tire pressure. The ignition must be in the

RUN mode, with the transmission in PARK (P).

The hazard lamps will come on to confirm the vehicle is in

Tire Fill Alert mode.

When Tire Fill Alert Mode is entered, the tire pressure

display screen will be displayed in the instrument cluster.

Operation:

• The horn will chirp once when the selected pressure is

reached to let the user know when to stop inflating or

deflating the tire.

• The horn will chirp three times if the tire is over inflated or over deflated and will continue to chirp every five seconds

if the user continues to inflate or deflate the tire.

• The horn will chirp once again when enough air is added or removed to reach proper selected pressure level.

Page 247 of 696

SAFETY 245

Supplemental Restraint Systems (SRS)

Some of the safety features described in this section may be

standard equipment on some models, or may be optional

equipment on others. If you are not sure, ask an authorized

dealer.

The air bag system must be ready to protect you in a colli-

sion. The Occupant Restraint Controller (ORC) monitors the

internal circuits and interconnecting wiring associated with

the electrical Air Bag System Components. Your vehicle may

be equipped with the following Air Bag System Compo -

nents:

Air Bag System Components

• Occupant Restraint Controller (ORC)

• Air Bag Warning Light

• Steering Wheel and Column

• Instrument Panel

• Knee Impact Bolsters

• Driver and Front Passenger Air Bags

• Seat Belt Buckle Switch

• Supplemental Side Air Bags • Front and Side Impact Sensors — If Equipped

• Seat Belt Pretensioners

• Seat Track Position Sensors

Air Bag Warning Light

The ORC monitors the readiness of the elec -

tronic parts of the air bag system whenever

the ignition switch is in the START or ON/

RUN position. If the ignition switch is in the

OFF position or in the ACC position, the air

bag system is not on and the air bags will not

inflate.

The ORC contains a backup power supply system that may

deploy the air bag system even if the battery loses power or

it becomes disconnected prior to deployment.

The ORC turns on the Air Bag Warning Light in the instru-

ment panel for approximately four to eight seconds for a

self-check when the ignition switch is first in the ON/RUN

position. After the self-check, the Air Bag Warning Light will

turn off. If the ORC detects a malfunction in any part of the

system, it turns on the Air Bag Warning Light, either

momentarily or continuously. A single chime will sound to

alert you if the light comes on again after initial startup.

4

Page 248 of 696

246 SAFETY

The ORC also includes diagnostics that will illuminate the

instrument panel Air Bag Warning Light if a malfunction is

detected that could affect the air bag system. The diagnostics

also record the nature of the malfunction. While the air bag

system is designed to be maintenance free, if any of the

following occurs, have an authorized dealer service the air

bag system immediately.

• The Air Bag Warning Light does not come on during thefour to eight seconds when the ignition switch is first in the

ON/RUN position.

• The Air Bag Warning Light remains on after the four to eight-second interval.

• The Air Bag Warning Light comes on intermittently or remains on while driving. NOTE:

If the speedometer, tachometer, or any engine related gauges

are not working, the Occupant Restraint Controller (ORC)

may also be disabled. In this condition the air bags may not

be ready to inflate for your protection. Have an authorized

dealer service the air bag system immediately.

WARNING!

Ignoring the Air Bag Warning Light in your instrument

panel could mean you won’t have the air bag system to

protect you in a collision. If the light does not come on as

a bulb check when the ignition is first turned on, stays

on after you start the vehicle, or if it comes on as you

drive, have an authorized dealer service the air bag

system immediately.

Page 432 of 696

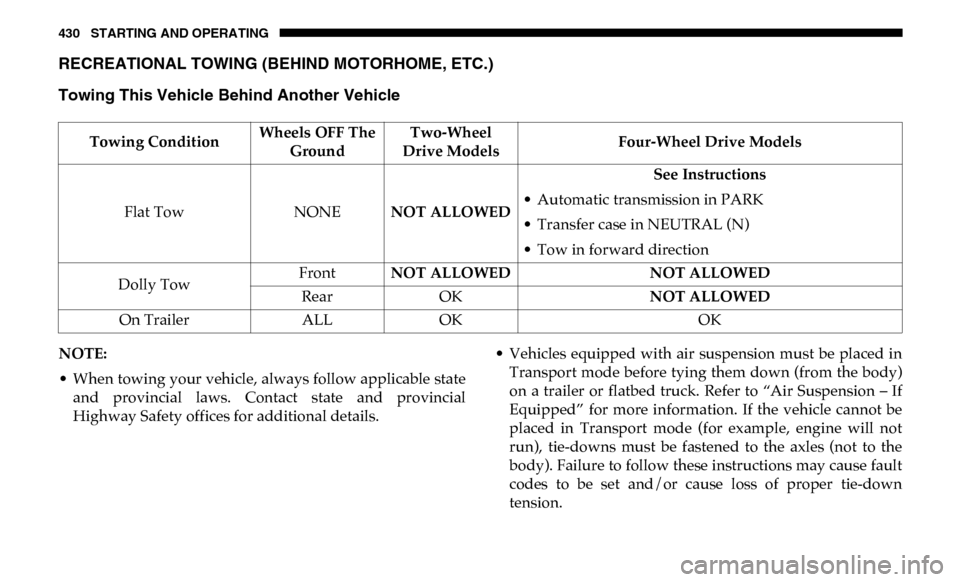

430 STARTING AND OPERATING

RECREATIONAL TOWING (BEHIND MOTORHOME, ETC.)

Towing This Vehicle Behind Another Vehicle

NOTE:

• When towing your vehicle, always follow applicable stateand provincial laws. Contact state and provincial

Highway Safety offices for additional details. • Vehicles equipped with air suspension must be placed in

Transport mode before tying them down (from the body)

on a trailer or flatbed truck. Refer to “Air Suspension – If

Equipped” for more information. If the vehicle cannot be

placed in Transport mode (for example, engine will not

run), tie-downs must be fastened to the axles (not to the

body). Failure to follow these instructions may cause fault

codes to be set and/or cause loss of proper tie-down

tension.

Towing Condition

Wheels OFF The

Ground Two-Wheel

Drive Models Four-Wheel Drive Models

Flat Tow NONENOT ALLOWED See Instructions

• Automatic transmission in PARK

• Transfer case in NEUTRAL (N)

• Tow in forward direction

Dolly Tow Front

NOT ALLOWED NOT ALLOWED

Rear OK NOT ALLOWED

On Trailer ALLOK OK

Page 479 of 696

IN CASE OF EMERGENCY 477

(Continued)

Jacking Instructions

Jack Warning Label

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

• Always park on a firm, level surface as far from the edge of the roadway as possible before raising the

vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the wheel to be raised.

• Apply the parking brake firmly and set the transmis -

sion in PARK.

• Never start or run the engine with the vehicle on a jack.

• Do not let anyone sit in the vehicle when it is on a jack.

• Do not get under the vehicle when it is on a jack. If you need to get under a raised vehicle, take it to a service

center where it can be raised on a lift.

• Only use the jack in the positions indicated and for lifting this vehicle during a tire change.

• If working on or near a roadway, be extremely careful of motor traffic.• To assure that spare tires, flat or inflated, are securelystowed, spares must be stowed with the valve stem

facing the ground.

WARNING! (Continued)

6

Page 497 of 696

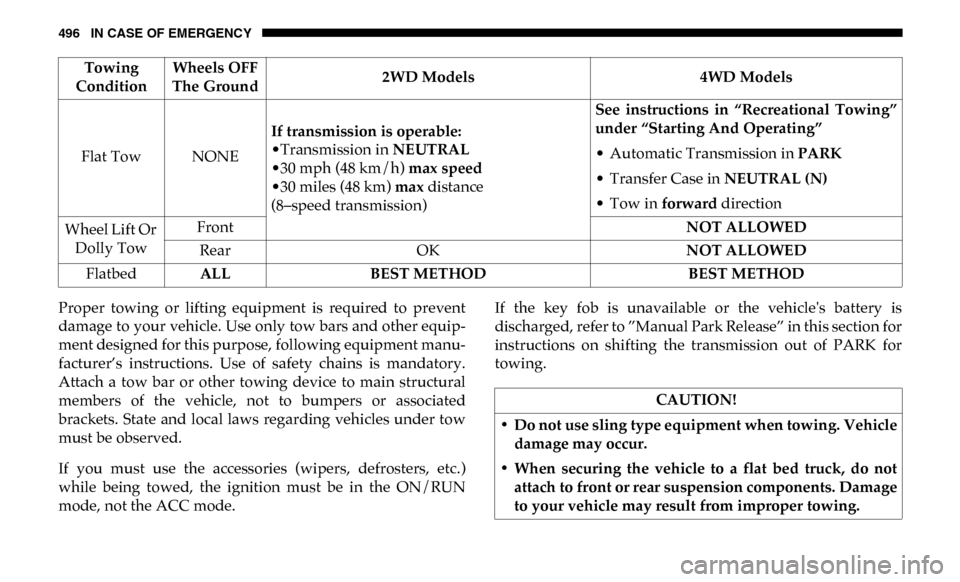

IN CASE OF EMERGENCY 495

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled

vehicle using a commercial towing service.

If the transmission and drivetrain are operable, disabled

vehicles may also be towed as described under “Recreational

Towing” in the “Starting And Operating” section.

NOTE:

Vehicles equipped with the Air Suspension System must be

placed in Transport mode, before tying them down (from the

body) on a trailer or flatbed truck. If the vehicle cannot be

placed in Transport mode (for example, engine will not run),

tie-downs must be fastened to the axles (not to the body).

Failure to follow these instructions may cause fault codes to

be set and/or cause loss of proper tie-down tension.

Refer to "Air Suspension System — If Equipped" in "Starting

And Operating" for more information.

CAUTION!

• Racing the engine or spinning the wheels may lead to transmission overheating and failure. Allow the engine

to idle with the transmission in NEUTRAL for at least

one minute after every five rocking-motion cycles. This

will minimize overheating and reduce the risk of trans -

mission failure during prolonged efforts to free a stuck

vehicle.

• When “rocking” a stuck vehicle by shifting between DRIVE and REVERSE, do not spin the wheels faster

than 15 mph (24 km/h), or drivetrain damage may

result.

• Revving the engine or spinning the wheels too fast may lead to transmission overheating and failure. It can also

damage the tires. Do not spin the wheels above 30 mph

(48 km/h) while in gear (no transmission shifting occur -

ring).

6

Page 498 of 696

496 IN CASE OF EMERGENCY

Proper towing or lifting equipment is required to prevent

damage to your vehicle. Use only tow bars and other equip-

ment designed for this purpose, following equipment manu-

facturer’s instructions. Use of safety chains is mandatory.

Attach a tow bar or other towing device to main structural

members of the vehicle, not to bumpers or associated

brackets. State and local laws regarding vehicles under tow

must be observed.

If you must use the accessories (wipers, defrosters, etc.)

while being towed, the ignition must be in the ON/RUN

mode, not the ACC mode. If the key fob is unavailable or the vehicle's battery is

discharged, refer to ”Manual Park Release” in this section for

instructions on shifting the transmission out of PARK for

towing.

Towing

Condition Wheels OFF

The Ground 2WD Models

4WD Models

Flat Tow NONE If transmission is operable:

•Transmission in

NEUTRAL

•30 mph (48 km/h) max speed

•30 miles (48 km) max distance

(8–speed transmission) See instructions in “Recreational Towing”

under “Starting And Operating”

• Automatic Transmission in

PARK

• Transfer Case in NEUTRAL (N)

• Tow in forward direction

Wheel Lift Or Dolly Tow Front

NOT ALLOWED

Rear OK NOT ALLOWED

Flatbed ALL BEST METHOD BEST METHOD

CAUTION!

• Do not use sling type equipment when towing. Vehicle damage may occur.

• When securing the vehicle to a flat bed truck, do not attach to front or rear suspension components. Damage

to your vehicle may result from improper towing.