engine Ram 2500 2020 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 2500, Model: Ram 2500 2020Pages: 553, PDF Size: 21.99 MB

Page 357 of 553

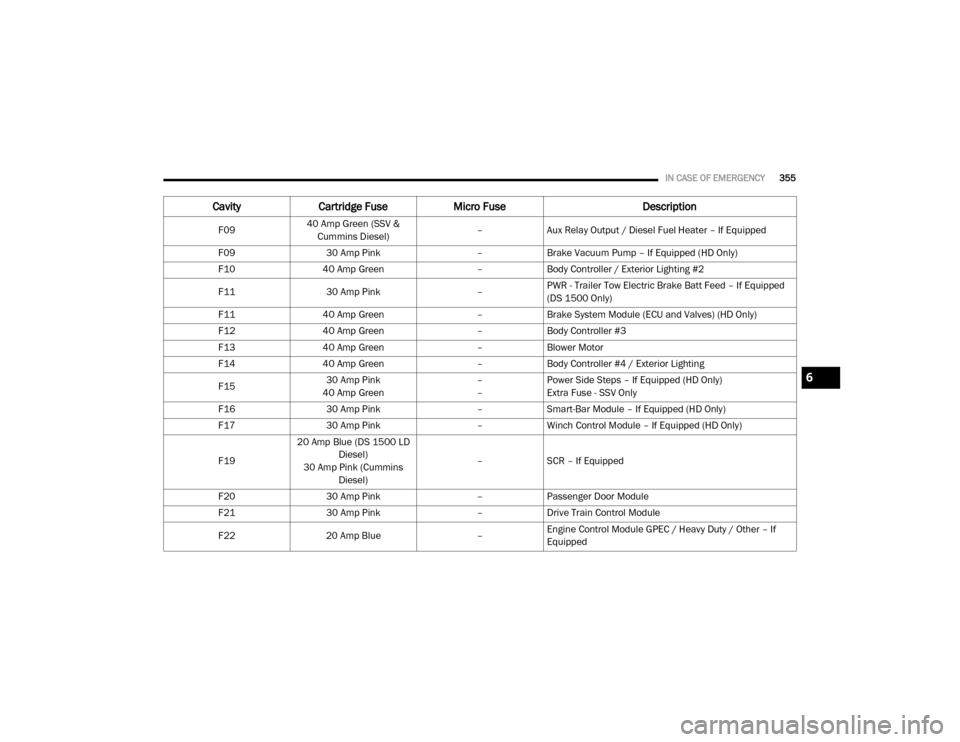

IN CASE OF EMERGENCY355

F0940 Amp Green (SSV &

Cummins Diesel) –

Aux Relay Output / Diesel Fuel Heater – If Equipped

F09 30 Amp Pink –Brake Vacuum Pump – If Equipped (HD Only)

F10 40 Amp Green –Body Controller / Exterior Lighting #2

F11 30 Amp Pink –PWR - Trailer Tow Electric Brake Batt Feed – If Equipped

(DS 1500 Only)

F11 40 Amp Green –Brake System Module (ECU and Valves) (HD Only)

F12 40 Amp Green –Body Controller #3

F13 40 Amp Green –Blower Motor

F14 40 Amp Green –Body Controller #4 / Exterior Lighting

F15 30 Amp Pink

40 Amp Green –

–Power Side Steps – If Equipped (HD Only)

Extra Fuse - SSV Only

F16 30 Amp Pink –Smart-Bar Module – If Equipped (HD Only)

F17 30 Amp Pink –Winch Control Module – If Equipped (HD Only)

F19 20 Amp Blue (DS 1500 LD

Diesel)

30 Amp Pink (Cummins Diesel) –

SCR – If Equipped

F20 30 Amp Pink –Passenger Door Module

F21 30 Amp Pink –Drive Train Control Module

F22 20 Amp Blue –Engine Control Module GPEC / Heavy Duty / Other – If

Equipped

Cavity

Cartridge Fuse Micro Fuse Description

6

20_DJD2_OM_EN_USC_t.book Page 355

Page 362 of 553

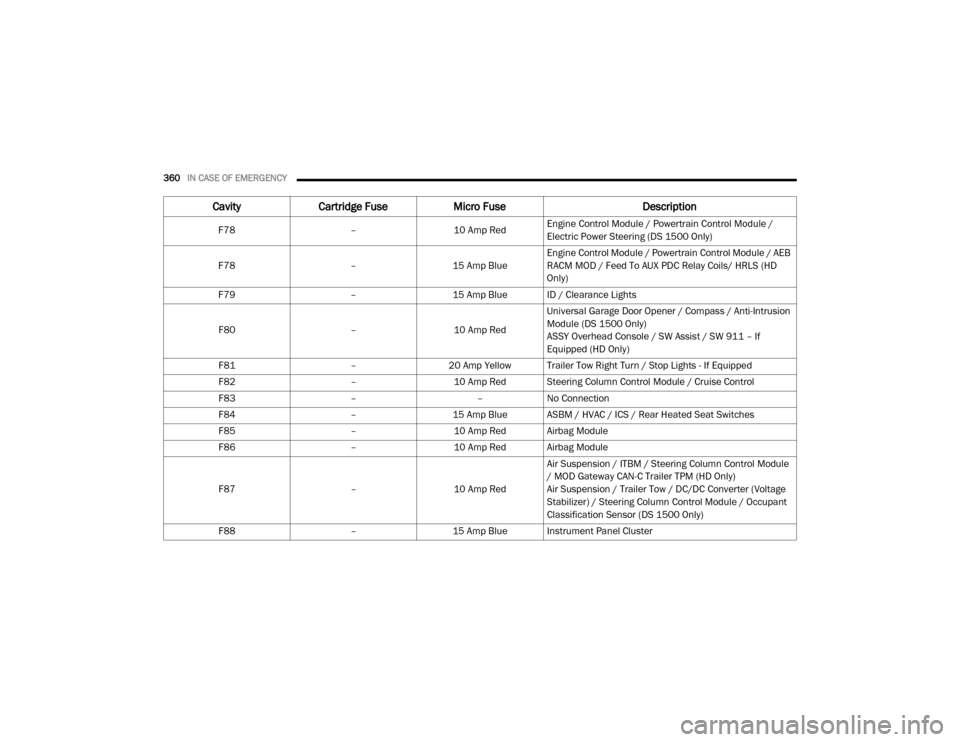

360IN CASE OF EMERGENCY

F78 –10 Amp RedEngine Control Module / Powertrain Control Module /

Electric Power Steering (DS 1500 Only)

F78 –15 Amp BlueEngine Control Module / Powertrain Control Module / AEB

RACM MOD / Feed To AUX PDC Relay Coils/ HRLS (HD

Only)

F79 –15 Amp Blue ID / Clearance Lights

F80 –10 Amp RedUniversal Garage Door Opener / Compass / Anti-Intrusion

Module (DS 1500 Only)

ASSY Overhead Console / SW Assist / SW 911 – If

Equipped (HD Only)

F81 –20 Amp Yellow Trailer Tow Right Turn / Stop Lights - If Equipped

F82 –10 Amp Red Steering Column Control Module / Cruise Control

F83 ––No Connection

F84 –15 Amp Blue ASBM / HVAC / ICS / Rear Heated Seat Switches

F85 –10 Amp Red Airbag Module

F86 –10 Amp Red Airbag Module

F87 –10 Amp RedAir Suspension / ITBM / Steering Column Control Module

/ MOD Gateway CAN-C Trailer TPM (HD Only)

Air Suspension / Trailer Tow / DC/DC Converter (Voltage

Stabilizer) / Steering Column Control Module / Occupant

Classification Sensor (DS 1500 Only)

F88 –15 Amp Blue Instrument Panel Cluster

CavityCartridge Fuse Micro Fuse Description

20_DJD2_OM_EN_USC_t.book Page 360

Page 365 of 553

IN CASE OF EMERGENCY363

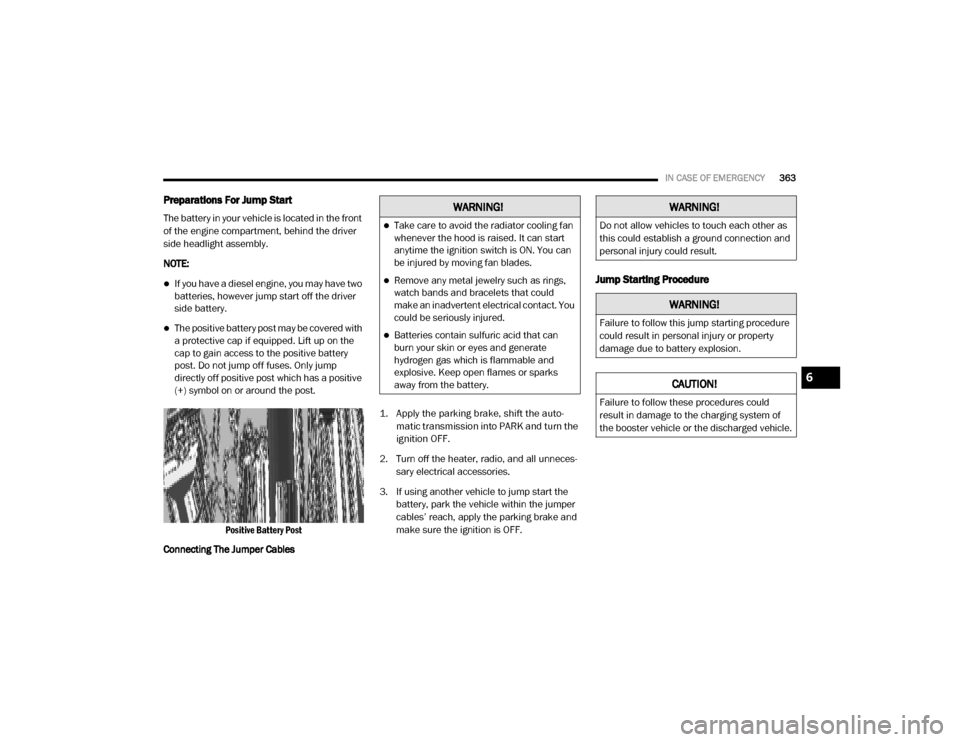

Preparations For Jump Start

The battery in your vehicle is located in the front

of the engine compartment, behind the driver

side headlight assembly.

NOTE:

If you have a diesel engine, you may have two

batteries, however jump start off the driver

side battery.

The positive battery post may be covered with

a protective cap if equipped. Lift up on the

cap to gain access to the positive battery

post. Do not jump off fuses. Only jump

directly off positive post which has a positive

(+) symbol on or around the post.

Positive Battery Post

1. Apply the parking brake, shift the auto

-

matic transmission into PARK and turn the

ignition OFF.

2. Turn off the heater, radio, and all unneces -

sary electrical accessories.

3. If using another vehicle to jump start the battery, park the vehicle within the jumper

cables’ reach, apply the parking brake and

make sure the ignition is OFF.

Jump Starting Procedure

Connecting The Jumper Cables

WARNING!

Take care to avoid the radiator cooling fan

whenever the hood is raised. It can start

anytime the ignition switch is ON. You can

be injured by moving fan blades.

Remove any metal jewelry such as rings,

watch bands and bracelets that could

make an inadvertent electrical contact. You

could be seriously injured.

Batteries contain sulfuric acid that can

burn your skin or eyes and generate

hydrogen gas which is flammable and

explosive. Keep open flames or sparks

away from the battery.

WARNING!

Do not allow vehicles to touch each other as

this could establish a ground connection and

personal injury could result.

WARNING!

Failure to follow this jump starting procedure

could result in personal injury or property

damage due to battery explosion.

CAUTION!

Failure to follow these procedures could

result in damage to the charging system of

the booster vehicle or the discharged vehicle.

6

20_DJD2_OM_EN_USC_t.book Page 363

Page 366 of 553

364IN CASE OF EMERGENCY

1. Connect the positive

(+) end of the jumper

cable to the positive (+)

post of the

discharged vehicle.

NOTE:

Do not jump off fuses. Only jump directly off

positive post.

2. Connect the opposite end of the positive (+)

jumper cable to the positive (+) post of the

booster battery.

3. Connect the negative (-) end of the jumper

cable to the negative (-) post of the booster

battery.

4. Connect the opposite end of the negative (-)

jumper cable to a good engine ground

(exposed metal part of the discharged vehicle’s engine) away from the battery and

the fuel injection system.

5. Start the engine in the vehicle that has the booster battery, let the engine idle a few

minutes, and then start the engine in the

vehicle with the discharged battery.

6. Once the engine is started, remove the jumper cables in the reverse sequence. Disconnecting The Jumper Cables

1. Disconnect the negative

(-)

end of the

jumper cable from the engine ground of

the vehicle with the discharged battery.

2. Disconnect the opposite end of the negative (-) jumper cable from the negative (-) post of

the booster battery.

3. Disconnect the positive (+) end of the

jumper cable from the positive (+) post of

the booster battery.

4. Disconnect the opposite end of the positive (+) jumper cable from the positive (+) post

of the vehicle with the discharged battery.

If frequent jump starting is required to start your

vehicle you should have the battery and

charging system inspected at an authorized

dealer.

WARNING!

Do not connect the jumper cable to the

negative (-) post of the discharged battery.

The resulting electrical spark could cause the

battery to explode and could result in

personal injury. Only use the specific ground

point, do not use any other exposed metal

parts.

CAUTION!

Do not connect jumper cable to any of the

fuses on the positive battery terminal. The

resulting electrical current will blow the fuse.

20_DJD2_OM_EN_USC_t.book Page 364

Page 367 of 553

IN CASE OF EMERGENCY365

GEAR SELECTOR OVERRIDE — 6–SPEED

TRANSMISSION

If a malfunction occurs and the gear selector

cannot be moved out of the PARK position, you

can use the following procedure to temporarily

move the gear selector:

1. Turn the engine OFF.

2. Firmly apply the parking brake.

3. Tilt the steering wheel to the full up position.

4. Press and maintain firm pressure on the

brake pedal. 5. Insert a screwdriver or similar tool into the

access port (ringed circle) on the bottom of

the steering column, and push and hold the

override release lever up.

Gear Selector Override Access Port Location Gear Selector Override Access Port Engaging The Access Port

6. Move the gear selector to the NEUTRAL position.

7. The vehicle may then be started in NEUTRAL.

CAUTION!

Accessories plugged into the vehicle power

outlets draw power from the vehicle’s battery,

even when not in use (i.e., cellular devices,

etc.). Eventually, if plugged in long enough

without engine operation, the vehicle’s

battery will discharge sufficiently to degrade

battery life and/or prevent the engine from

starting.

6

20_DJD2_OM_EN_USC_t.book Page 365

Page 369 of 553

IN CASE OF EMERGENCY367

To Reset The Manual Park Release:

1. Push the locking tab to the right, to unlock

the lever.

2. Rotate the Manual Park Release lever forward to its original position, until the

locking tab snaps into place to secure the

lever.

3. Pull gently on the tether strap to confirm that the lever is locked in its stowed posi-

tion.

4. Re-install the access cover.

IF YOUR ENGINE OVERHEATS

In any of the following situations, you can

reduce the potential for overheating by taking

the appropriate action.

On the highways — slow down.

In city traffic — while stopped, place the trans -

mission in NEUTRAL, but do not increase the

engine idle speed while preventing vehicle

motion with the brakes. NOTE:

There are steps that you can take to slow down

an impending overheat condition:

If your Air Conditioner (A/C) is on, turn it off.

The A/C system adds heat to the engine

cooling system and turning the A/C off can

help remove this heat.

You can also turn the temperature control to

maximum heat, the mode control to floor and

the blower control to high. This allows the

heater core to act as a supplement to the

radiator and aids in removing heat from the

engine cooling system.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or

snow, it can often be moved using a rocking

motion. Turn the steering wheel right and left to

clear the area around the front wheels. Then

shift back and forth between DRIVE (D) and

REVERSE (R), while gently pressing the acceler

-

ator. Use the least amount of accelerator pedal

pressure that will maintain the rocking motion,

without spinning the wheels or racing the

engine.

WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from

your radiator. If you see or hear steam coming

from under the hood, do not open the hood

until the radiator has had time to cool. Never

try to open a cooling system pressure cap

when the radiator or coolant bottle is hot.

CAUTION!

Driving with a hot cooling system could

damage your vehicle. If the temperature

gauge reads HOT (H), pull over and stop the

vehicle. Idle the vehicle with the air

conditioner turned off until the pointer drops

back into the normal range. If the pointer

remains on HOT (H), and you hear continuous

chimes, turn the engine off immediately and

call for service.

6

20_DJD2_OM_EN_USC_t.book Page 367

Page 370 of 553

368IN CASE OF EMERGENCY

(Continued)

NOTE:

For trucks equipped with an 8–speed trans-

mission, shifts between DRIVE and REVERSE

can only be achieved at wheel speeds of

5 mph (8 km/h) or less. Whenever the trans -

mission remains in NEUTRAL (N) for more

than two seconds, you must press the brake

pedal to engage DRIVE or REVERSE.

Push the “ESC OFF” switch, to place the Elec -

tronic Stability Control (ESC) system in

“Partial Off” mode, before rocking the

vehicle. Refer to “Electronic Brake Control

System” in “Safety” for further information.

Once the vehicle has been freed, push the

“ESC OFF” switch again to restore “ESC On”

mode.

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may

cause damage, or even failure, of the axle

and tires. A tire could explode and injure

someone. Do not spin your vehicle's wheels

faster than 30 mph (48 km/h) or for longer

than 30 seconds continuously without

stopping when you are stuck and do not let

anyone near a spinning wheel, no matter

what the speed.

CAUTION!

Racing the engine or spinning the wheels

may lead to transmission overheating and

failure. Allow the engine to idle with the

transmission in NEUTRAL for at least one

minute after every five rocking-motion

cycles. This will minimize overheating and

reduce the risk of transmission failure

during prolonged efforts to free a stuck

vehicle.

When “rocking” a stuck vehicle by shifting

between DRIVE and REVERSE, do not spin

the wheels faster than 15 mph (24 km/h),

or drivetrain damage may result.

Revving the engine or spinning the wheels

too fast may lead to transmission over -

heating and failure. It can also damage the

tires. Do not spin the wheels above 30 mph

(48 km/h) while in gear (no transmission

shifting occurring).

CAUTION! (Continued)

20_DJD2_OM_EN_USC_t.book Page 368

Page 371 of 553

IN CASE OF EMERGENCY369

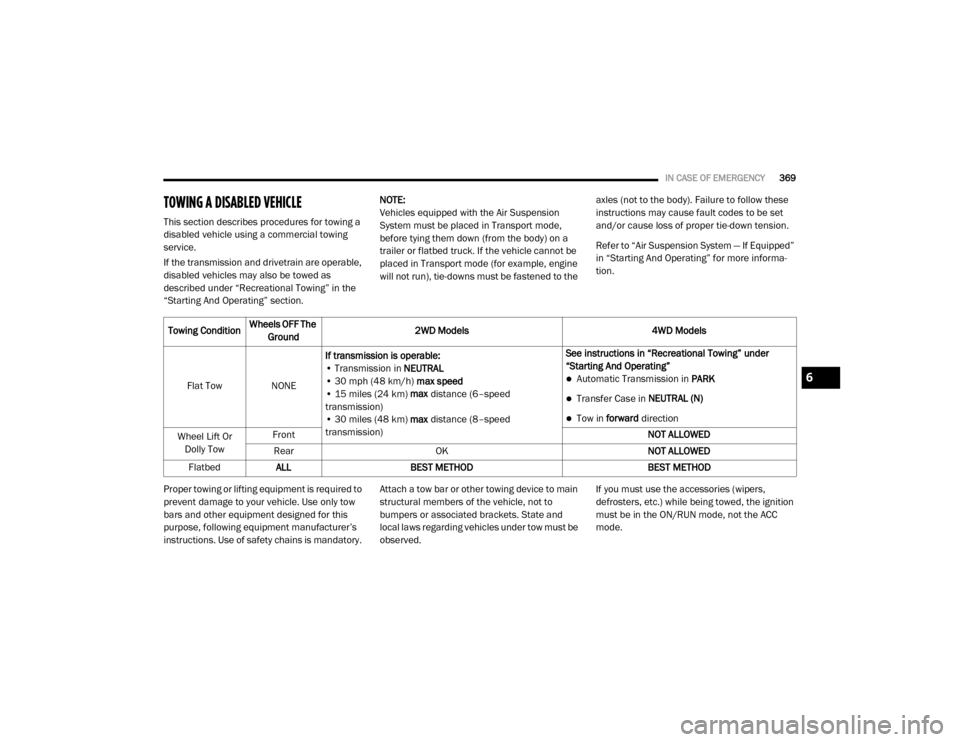

TOWING A DISABLED VEHICLE

This section describes procedures for towing a

disabled vehicle using a commercial towing

service.

If the transmission and drivetrain are operable,

disabled vehicles may also be towed as

described under “Recreational Towing” in the

“Starting And Operating” section. NOTE:

Vehicles equipped with the Air Suspension

System must be placed in Transport mode,

before tying them down (from the body) on a

trailer or flatbed truck. If the vehicle cannot be

placed in Transport mode (for example, engine

will not run), tie-downs must be fastened to the

axles (not to the body). Failure to follow these

instructions may cause fault codes to be set

and/or cause loss of proper tie-down tension.

Refer to “Air Suspension System — If Equipped”

in “Starting And Operating” for more informa

-

tion.

Proper towing or lifting equipment is required to

prevent damage to your vehicle. Use only tow

bars and other equipment designed for this

purpose, following equipment manufacturer’s

instructions. Use of safety chains is mandatory. Attach a tow bar or other towing device to main

structural members of the vehicle, not to

bumpers or associated brackets. State and

local laws regarding vehicles under tow must be

observed.If you must use the accessories (wipers,

defrosters, etc.) while being towed, the ignition

must be in the ON/RUN mode, not the ACC

mode.

Towing Condition

Wheels OFF The

Ground 2WD Models

4WD Models

Flat Tow NONE If transmission is operable:

• Transmission in NEUTRAL

• 30 mph (48 km/h) max speed

• 15 miles (24 km) max distance (6–speed

transmission)

• 30 miles (48 km) max distance (8–speed

transmission) See instructions in “Recreational Towing” under

“Starting And Operating”

Automatic Transmission in

PARK

Transfer Case in NEUTRAL (N)

Tow in forward direction

Wheel Lift Or Dolly Tow Front

NOT ALLOWED

Rear OK NOT ALLOWED

Flatbed ALL BEST METHOD BEST METHOD

6

20_DJD2_OM_EN_USC_t.book Page 369

Page 372 of 553

370IN CASE OF EMERGENCY

If the key fob is unavailable or the vehicle's

battery is discharged, refer to ”Manual Park

Release” in this section for instructions on

shifting the transmission out of PARK for

towing.

Two-Wheel Drive Models

The manufacturer recommends towing your

vehicle with all four wheels OFF the ground

using a flatbed.

If flatbed equipment is not available, and the

transmission is operable, the vehicle may be

towed (with rear wheels ON the ground) under

the following conditions:

The transmission must be in NEUTRAL. NOTE:

Refer to “Manual Park Release” in this section

for instructions on shifting the transmission to

NEUTRAL when the engine is OFF.

The towing speed must not exceed 30 mph

(48 km/h).

The towing distance must not exceed

30 miles (48 km) for 8–speed transmission.

The towing distance must not exceed

15 miles (24 km) for 6–speed transmission.

If the transmission is not operable, or the

vehicle must be towed faster than 30 mph

(48 km/h) or farther than 30 miles (48 km) for 8–speed transmission, tow with the rear wheels

OFF the ground. Acceptable methods are to tow

the vehicle on a flatbed, or with the front wheels

raised and the rear wheels on a towing dolly, or

(when using a suitable steering wheel stabilizer

to hold the front wheels in the straight position)

with the rear wheels raised and the front wheels

on the ground.

Four-Wheel Drive Models

The manufacturer recommends towing with all

wheels OFF the ground. Acceptable methods

are to tow the vehicle on a flatbed or with one

end of vehicle raised and the opposite end on a

towing dolly.

If flatbed equipment is not available, and the

transfer case is operable, the vehicle may be

towed (in the forward direction, with ALL wheels

on the ground), IF the transfer case is in

NEUTRAL (N) and the transmission is in PARK.

Refer to “Recreational Towing” in “Starting And

Operating” for further information and detailed

instructions.

CAUTION!

Do not use sling type equipment when

towing. Vehicle damage may occur.

When securing the vehicle to a flat bed

truck, do not attach to front or rear suspen -

sion components. Damage to your vehicle

may result from improper towing.

CAUTION!

Towing this vehicle in violation of the above

requirements can cause severe transmission

damage. Damage from improper towing is not

covered under the New Vehicle Limited

Warranty.

20_DJD2_OM_EN_USC_t.book Page 370

Page 382 of 553

380

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GAS ENGINE

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indi-

cator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent

short-trips, trailer tow, extremely hot or cold

ambient temperatures, and E85 fuel usage will

influence when the “Oil Change Required”

message is displayed. Severe Operating Condi-

tions can cause the change oil message to illu -

minate as early as 3,500 miles (5,600 km)

since last reset. Have your vehicle serviced as

soon as possible, within the next 500 miles

(805 km).

Your authorized dealer will reset the oil change

indicator message after completing the sched -

uled oil change.

If a scheduled oil change is performed by

someone other than your authorized dealer, the

message can be reset by referring to the steps described under “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel”.

NOTE:

Under no circumstances should oil change

intervals exceed 8,000 miles (13,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty All Models

NOTE:

Change Engine Oil at 4,000 miles (6,500 km) or

350 hours of engine run time if the vehicle is

operated in a dusty and off road environment or

is operated predominantly at idle, or only very

low engine RPM. This type of vehicle use is

considered Severe Duty.

Once A Month Or Before A Long Trip:

Check engine oil level

Check windshield washer fluid level

Check tire pressure and look for unusual

wear or damage. Rotate tires at the first sign

of irregular wear, even if it occurs before the

oil indicator system turns on.

Check the fluid levels of the coolant reservoir,

brake master cylinder, power steering and

automatic transmission (six-speed only) and

fill as needed

Check function of all interior and exterior

lights

Maintenance Plan — Gasoline Engine

Required Maintenance

Refer to the Maintenance Plan on the following

pages for required maintenance. More frequent

maintenance may be needed in severe condi

-

tions, such as dusty areas and very short trip

driving. In some extreme conditions, additional

maintenance not specified in the maintenance

schedule may be required.

20_DJD2_OM_EN_USC_t.book Page 380