Page 90 Ram 2500 2020 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 2500, Model: Ram 2500 2020Pages: 553, PDF Size: 21.99 MB

Page 373 of 553

IN CASE OF EMERGENCY371

Emergency Tow Hooks — If Equipped

Your vehicle may be equipped with emergency

tow hooks.

NOTE:

For off-road recovery, it is recommended to use

both of the front tow hooks to minimize the risk

of damage to the vehicle.

Front Tow Hooks

ENHANCED ACCIDENT RESPONSE SYSTEM

(EARS)

This vehicle is equipped with an Enhanced Acci

-

dent Response System.

Please refer to “Occupant Restraint Systems” in

“Safety” for further information on the

Enhanced Accident Response System (EARS)

function.

EVENT DATA RECORDER (EDR)

This vehicle is equipped with an Event Data

Recorder (EDR). The main purpose of an EDR is

to record data that will assist in understanding

how a vehicle’s systems performed under

certain crash or near crash-like situations, such

as an air bag deployment or hitting a road

obstacle.

Please refer to “Occupant Restraint Systems” in

“Safety” for further information on the Event

Data Recorder (EDR).

CAUTION!

Front or rear wheel lifts must not be used (if

the remaining wheels are on the ground).

Internal damage to the transmission or

transfer case will occur if a front or rear

wheel lift is used when towing.

Towing this vehicle in violation of the above

requirements can cause severe transmis -

sion and/or transfer case damage.

Damage from improper towing is not

covered under the New Vehicle Limited

Warranty.

WARNING!

Do not use a chain for freeing a stuck

vehicle. Chains may break, causing serious

injury or death.

Stand clear of vehicles when pulling with

tow hooks. Tow straps may become disen -

gaged, causing serious injury.

CAUTION!

Tow hooks are for emergency use only, to

rescue a vehicle stranded off road. Do not

use tow hooks for tow truck hookup or

highway towing. You could damage your

vehicle.

6

20_DJD2_OM_EN_USC_t.book Page 371

Page 374 of 553

372IN CASE OF EMERGENCY

BULB REPLACEMENT

Replacement Bulbs

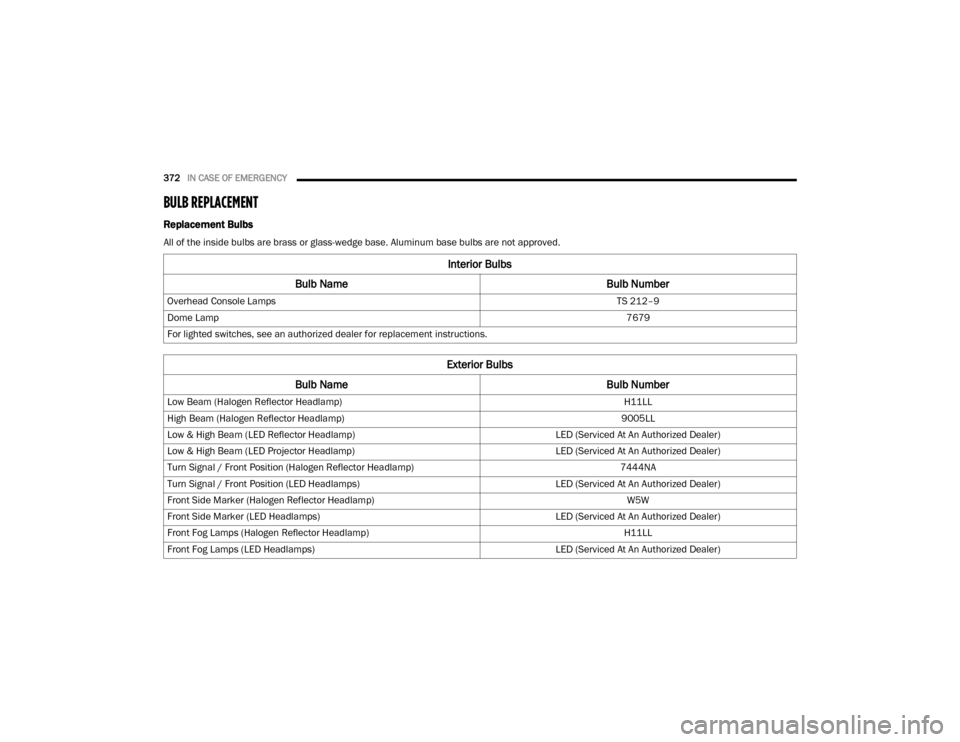

All of the inside bulbs are brass or glass-wedge base. Aluminum base bulbs are not approved.

Interior Bulbs

Bulb Name Bulb Number

Overhead Console Lamps TS 212–9

Dome Lamp 7679

For lighted switches, see an authorized dealer for replacement instructions.

Exterior Bulbs

Bulb Name Bulb Number

Low Beam (Halogen Reflector Headlamp) H11LL

High Beam (Halogen Reflector Headlamp) 9005LL

Low & High Beam (LED Reflector Headlamp) LED (Serviced At An Authorized Dealer)

Low & High Beam (LED Projector Headlamp) LED (Serviced At An Authorized Dealer)

Turn Signal / Front Position (Halogen Reflector Headlamp) 7444NA

Turn Signal / Front Position (LED Headlamps) LED (Serviced At An Authorized Dealer)

Front Side Marker (Halogen Reflector Headlamp) W5W

Front Side Marker (LED Headlamps) LED (Serviced At An Authorized Dealer)

Front Fog Lamps (Halogen Reflector Headlamp) H11LL

Front Fog Lamps (LED Headlamps) LED (Serviced At An Authorized Dealer)

20_DJD2_OM_EN_USC_t.book Page 372

Page 375 of 553

IN CASE OF EMERGENCY373

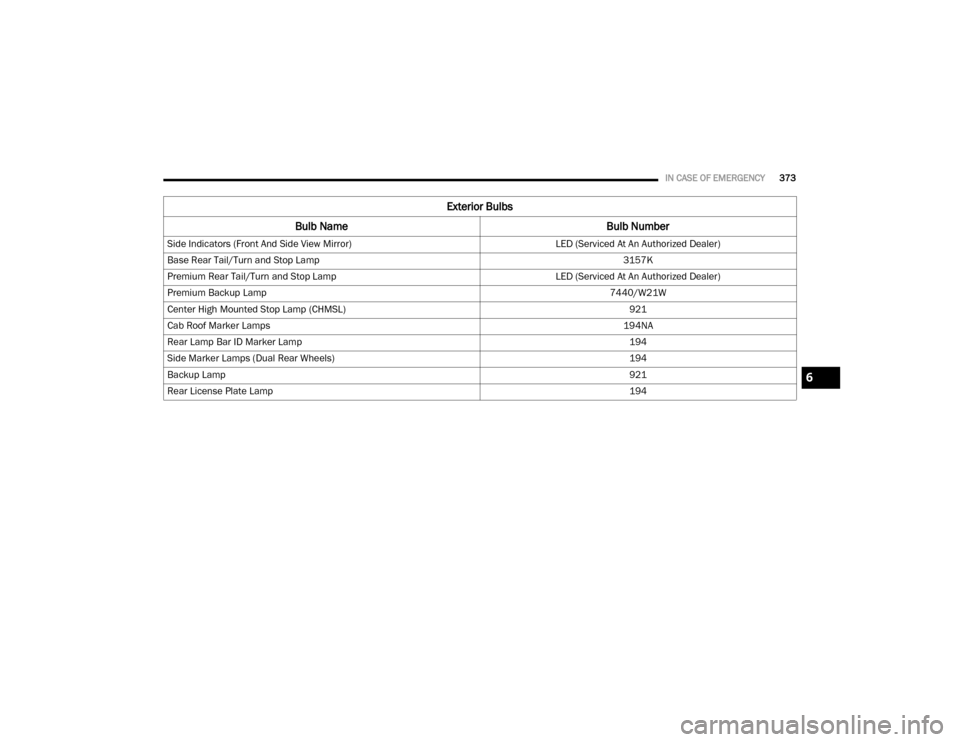

Side Indicators (Front And Side View Mirror) LED (Serviced At An Authorized Dealer)

Base Rear Tail/Turn and Stop Lamp 3157K

Premium Rear Tail/Turn and Stop Lamp LED (Serviced At An Authorized Dealer)

Premium Backup Lamp 7440/W21W

Center High Mounted Stop Lamp (CHMSL) 921

Cab Roof Marker Lamps 194NA

Rear Lamp Bar ID Marker Lamp 194

Side Marker Lamps (Dual Rear Wheels) 194

Backup Lamp 921

Rear License Plate Lamp 194

Exterior Bulbs

Bulb Name Bulb Number

6

20_DJD2_OM_EN_USC_t.book Page 373

Page 376 of 553

374IN CASE OF EMERGENCY

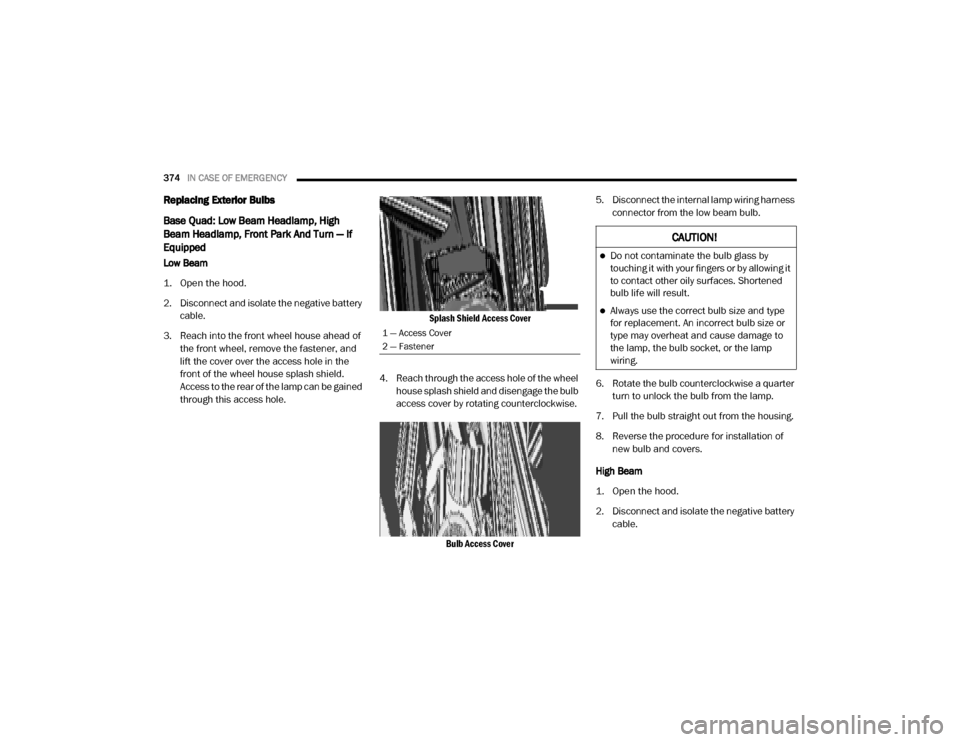

Replacing Exterior Bulbs

Base Quad: Low Beam Headlamp, High

Beam Headlamp, Front Park And Turn — If

Equipped

Low Beam

1. Open the hood.

2. Disconnect and isolate the negative battery

cable.

3. Reach into the front wheel house ahead of the front wheel, remove the fastener, and

lift the cover over the access hole in the

front of the wheel house splash shield.

Access to the rear of the lamp can be gained

through this access hole.

Splash Shield Access Cover

4. Reach through the access hole of the wheel house splash shield and disengage the bulb

access cover by rotating counterclockwise.

Bulb Access Cover

5. Disconnect the internal lamp wiring harness

connector from the low beam bulb.

6. Rotate the bulb counterclockwise a quarter turn to unlock the bulb from the lamp.

7. Pull the bulb straight out from the housing.

8. Reverse the procedure for installation of new bulb and covers.

High Beam

1. Open the hood.

2. Disconnect and isolate the negative battery cable.

1 — Access Cover

2 — Fastener

CAUTION!

Do not contaminate the bulb glass by

touching it with your fingers or by allowing it

to contact other oily surfaces. Shortened

bulb life will result.

Always use the correct bulb size and type

for replacement. An incorrect bulb size or

type may overheat and cause damage to

the lamp, the bulb socket, or the lamp

wiring.

20_DJD2_OM_EN_USC_t.book Page 374

Page 377 of 553

IN CASE OF EMERGENCY375

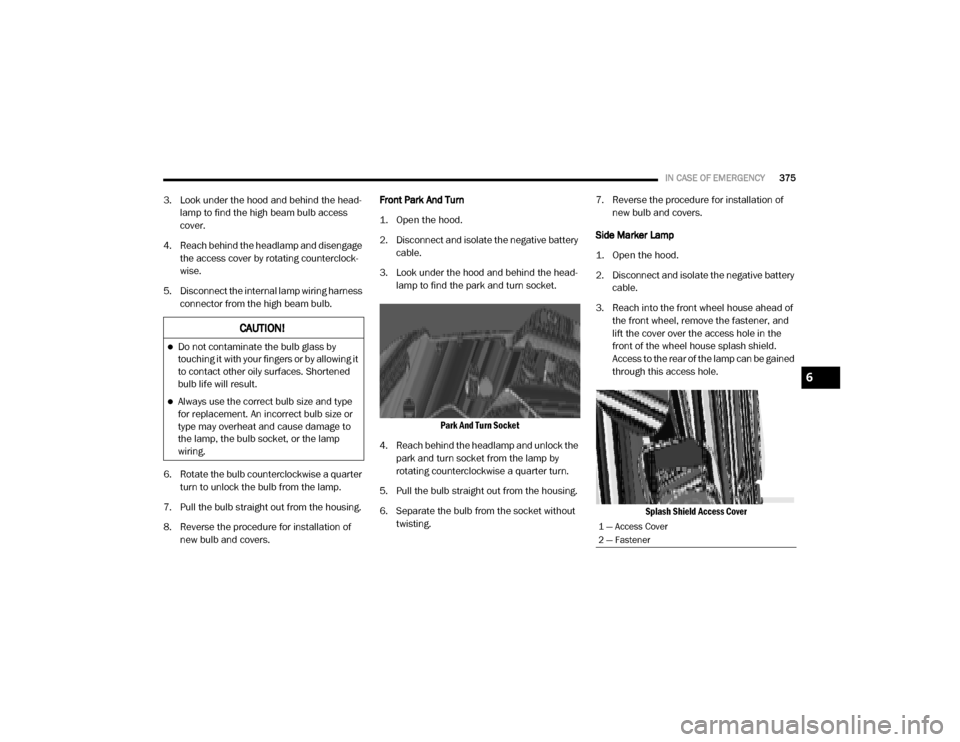

3. Look under the hood and behind the head -

lamp to find the high beam bulb access

cover.

4. Reach behind the headlamp and disengage the access cover by rotating counterclock -

wise.

5. Disconnect the internal lamp wiring harness connector from the high beam bulb.

6. Rotate the bulb counterclockwise a quarter turn to unlock the bulb from the lamp.

7. Pull the bulb straight out from the housing.

8. Reverse the procedure for installation of new bulb and covers. Front Park And Turn

1. Open the hood.

2. Disconnect and isolate the negative battery

cable.

3. Look under the hood and behind the head -

lamp to find the park and turn socket.

Park And Turn Socket

4. Reach behind the headlamp and unlock the park and turn socket from the lamp by

rotating counterclockwise a quarter turn.

5. Pull the bulb straight out from the housing.

6. Separate the bulb from the socket without twisting. 7. Reverse the procedure for installation of

new bulb and covers.

Side Marker Lamp

1. Open the hood.

2. Disconnect and isolate the negative battery cable.

3. Reach into the front wheel house ahead of the front wheel, remove the fastener, and

lift the cover over the access hole in the

front of the wheel house splash shield.

Access to the rear of the lamp can be gained

through this access hole.

Splash Shield Access Cover

CAUTION!

Do not contaminate the bulb glass by

touching it with your fingers or by allowing it

to contact other oily surfaces. Shortened

bulb life will result.

Always use the correct bulb size and type

for replacement. An incorrect bulb size or

type may overheat and cause damage to

the lamp, the bulb socket, or the lamp

wiring.

1 — Access Cover

2 — Fastener

6

20_DJD2_OM_EN_USC_t.book Page 375

Page 378 of 553

376IN CASE OF EMERGENCY

4. Reach through the access hole of the wheel

house splash shield and disengage the side

marker socket by rotating counterclockwise

a quarter turn.

Side Marker Socket

5. Pull the socket and bulb straight out from the housing.

6. Separate the bulb from the socket without twisting.

7. Reverse the procedure for installation of new bulb and covers.Fog Lamps — If Equipped

1. Reach under and behind the front bumper to access the back of the front fog lamp

housing.

2. Disconnect the fog lamp wiring harness connector from the fog lamp bulb.

3. Rotate the bulb counterclockwise a quarter turn to unlock the bulb from the housing.

4. Pull the bulb straight out from the housing.

Rear Tail/Stop, Turn Signal And Backup

Lamps

1. Remove the two screws and push pins that pass through the bed sheet metal.

Tail Lamp Locations

CAUTION!

Do not contaminate the bulb glass by

touching it with your fingers or by allowing it

to contact other oily surfaces. Shortened bulb

life will result.

1 — Tail Lamp

2 — Fasteners

20_DJD2_OM_EN_USC_t.book Page 376

Page 379 of 553

IN CASE OF EMERGENCY377

2. Pull the outboard side of the lamp rearward

far enough to unsnap the two receptacles

on the outboard side of the lamp housing

from the two plastic snap post retainers in

the outer box side panel.

Tail Lamp Removed

3. Disconnect the wiring harness connectors from the bulb socket.

4. Rotate the bulb socket counterclockwise a quarter turn to unlock it from the housing.

5. Pull the bulb straight out of the socket. 6. Reverse the procedure to install the bulb

and housing.

Center High Mounted Stop Lamp (CHMSL)

With Cargo Lamp

1. Remove the two screws holding the housing/lens to the body as shown.

CHMSL Mounting Screw Locations

2. Separate the connector holding the housing and wiring harness to the body.

CHMSL Connector Location

3. Turn the desired bulb socket a quarter turn and remove the socket and bulb from

housing.

4. Pull the desired bulb straight from the socket.

CHMSL Bulb And Socket

1 — Tail Lamp Housing

2 — Bulb Socket Locations

CAUTION!

Do not contaminate the bulb glass by

touching it with your fingers or by allowing it

to contact other oily surfaces. Shortened bulb

life will result.

6

20_DJD2_OM_EN_USC_t.book Page 377

Page 380 of 553

378IN CASE OF EMERGENCY

Outside Bulbs: Cargo Lamps

Inside Bulb: Center High Mounted Stop

Lamp

5. Reverse the procedure for installation of bulbs and housing.

Cab Top Clearance Lamps — If Equipped

1. Remove the screws from the top of the lamp.

Removing Rear Screw From Clearance Lamp

2. Rotate the bulb socket a quarter turn and

pull it from the lamp assembly.

Removing Bulb Socket From Clearance Lamp

3. Pull the bulb straight from it's socket and replace.

Removing The Bulb From The Bulb Socket

Rear Lamp Bar ID Marker (Dual Rear Wheels)

— If Equipped

1. Loosen the two screws and the housing to gain access to the bulb sockets.

Screw Locations

2. Turn the socket a quarter turn counterclock -

wise to access the bulb.

3. Pull the bulb straight out from the socket.

4. Reverse the procedure for installation of the bulbs and housing.

CAUTION!

Do not contaminate the bulb glass by

touching it with your fingers or by allowing it

to contact other oily surfaces. Shortened bulb

life will result.

20_DJD2_OM_EN_USC_t.book Page 378

Page 381 of 553

IN CASE OF EMERGENCY379

Side Marker Lamps (Dual Rear Wheels) — If

Equipped

Side Marker Lamp Locations

1. Push rearward on the side marker lamp

assembly.

2. Pull the entire assembly from the fender.

3. Turn the socket a quarter turn counterclock -

wise and remove from assembly to access

the bulb. 4. Pull the bulb straight out from socket.

5. Reverse the procedure for installation of the

bulbs and housing.

6

20_DJD2_OM_EN_USC_t.book Page 379

Page 382 of 553

380

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GAS ENGINE

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indi-

cator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent

short-trips, trailer tow, extremely hot or cold

ambient temperatures, and E85 fuel usage will

influence when the “Oil Change Required”

message is displayed. Severe Operating Condi-

tions can cause the change oil message to illu -

minate as early as 3,500 miles (5,600 km)

since last reset. Have your vehicle serviced as

soon as possible, within the next 500 miles

(805 km).

Your authorized dealer will reset the oil change

indicator message after completing the sched -

uled oil change.

If a scheduled oil change is performed by

someone other than your authorized dealer, the

message can be reset by referring to the steps described under “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel”.

NOTE:

Under no circumstances should oil change

intervals exceed 8,000 miles (13,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty All Models

NOTE:

Change Engine Oil at 4,000 miles (6,500 km) or

350 hours of engine run time if the vehicle is

operated in a dusty and off road environment or

is operated predominantly at idle, or only very

low engine RPM. This type of vehicle use is

considered Severe Duty.

Once A Month Or Before A Long Trip:

Check engine oil level

Check windshield washer fluid level

Check tire pressure and look for unusual

wear or damage. Rotate tires at the first sign

of irregular wear, even if it occurs before the

oil indicator system turns on.

Check the fluid levels of the coolant reservoir,

brake master cylinder, power steering and

automatic transmission (six-speed only) and

fill as needed

Check function of all interior and exterior

lights

Maintenance Plan — Gasoline Engine

Required Maintenance

Refer to the Maintenance Plan on the following

pages for required maintenance. More frequent

maintenance may be needed in severe condi

-

tions, such as dusty areas and very short trip

driving. In some extreme conditions, additional

maintenance not specified in the maintenance

schedule may be required.

20_DJD2_OM_EN_USC_t.book Page 380