technical specifications Ram 2500 2020 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 2500, Model: Ram 2500 2020Pages: 553, PDF Size: 21.99 MB

Page 3 of 553

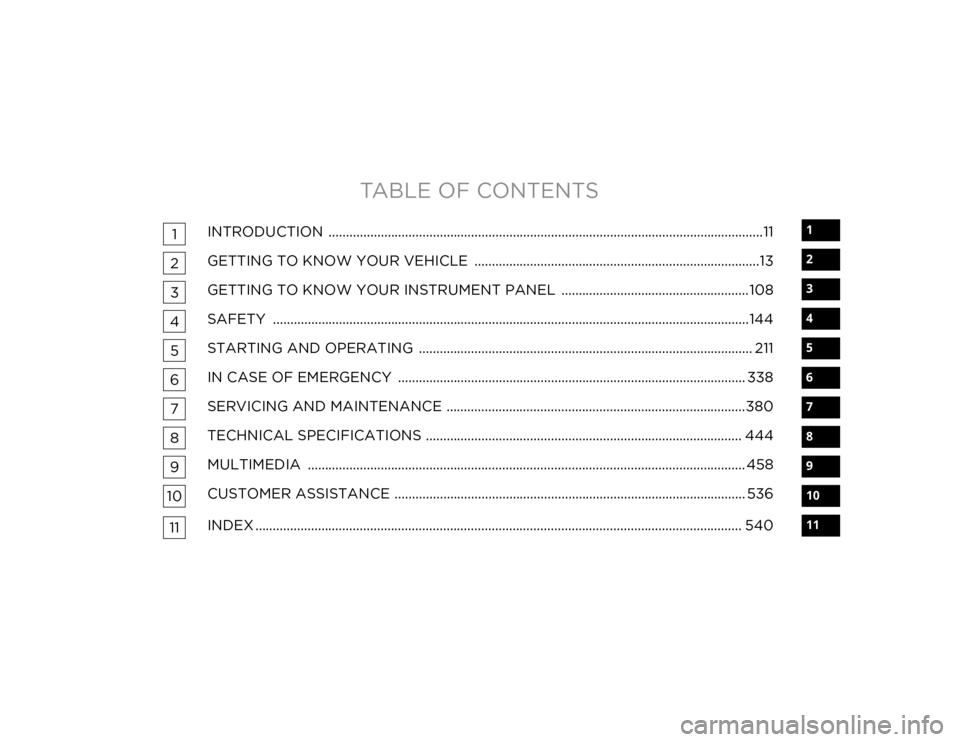

TABLE OF CONTENTS

1

2

3

4

5

6

7

8

9

10

11

1INTRODUCTION .............................................................................................................................11

2 G

E

TTING TO KNOW YOUR VEHICLE ..................................................................................13

3 GETTING TO KNOW YOUR INSTRUMENT PANEL ......................................................108

4 SAFETY .........................................................................................................................................144

5 STARTING AND OPERATING ................................................................................................ 211

6 IN CASE OF EMERGENCY .................................................................................................... 338

7 SERVICING AND MAINTENANCE ......................................................................................380

8 TECHNICAL SPECIFICATIONS ........................................................................................... 444

9 MULTIMEDIA .............................................................................................................................. 458

10 CUSTOMER ASSISTANCE ..................................................................................................... 536

11 INDEX ............................................................................................................................................ 540

20_DJD2_OM_EN_USC_t.book Page 1

Page 11 of 553

9

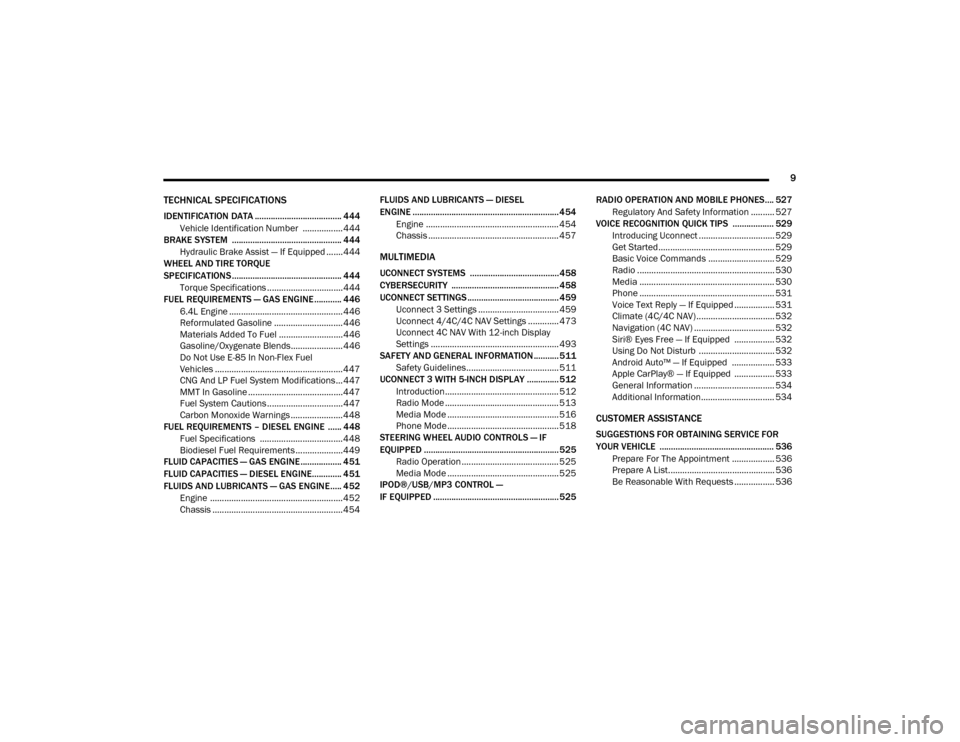

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA ...................................... 444Vehicle Identification Number ................. 444

BRAKE SYSTEM ................................................ 444

Hydraulic Brake Assist — If Equipped .......444

WHEEL AND TIRE TORQUE

SPECIFICATIONS ................................................ 444

Torque Specifications ................................444

FUEL REQUIREMENTS — GAS ENGINE ............ 446

6.4L Engine ................................................446

Reformulated Gasoline .............................446

Materials Added To Fuel ...........................446

Gasoline/Oxygenate Blends......................446

Do Not Use E-85 In Non-Flex Fuel

Vehicles ......................................................447 CNG And LP Fuel System Modifications ...447

MMT In Gasoline ........................................447

Fuel System Cautions ................................447

Carbon Monoxide Warnings ......................448

FUEL REQUIREMENTS – DIESEL ENGINE ...... 448

Fuel Specifications ...................................448

Biodiesel Fuel Requirements ....................449

FLUID CAPACITIES — GAS ENGINE .................. 451

FLUID CAPACITIES — DIESEL ENGINE............. 451

FLUIDS AND LUBRICANTS — GAS ENGINE ..... 452

Engine ........................................................ 452

Chassis .......................................................454 FLUIDS AND LUBRICANTS — DIESEL

ENGINE ................................................................ 454

Engine ........................................................ 454

Chassis ....................................................... 457

MULTIMEDIA

UCONNECT SYSTEMS .......................................458

CYBERSECURITY ............................................... 458

UCONNECT SETTINGS ........................................ 459

Uconnect 3 Settings .................................. 459

Uconnect 4/4C/4C NAV Settings ............. 473

Uconnect 4C NAV With 12-inch Display

Settings ...................................................... 493

SAFETY AND GENERAL INFORMATION ........... 511

Safety Guidelines....................................... 511

UCONNECT 3 WITH 5-INCH DISPLAY ..............512

Introduction................................................ 512

Radio Mode ................................................ 513

Media Mode ............................................... 516

Phone Mode ............................................... 518

STEERING WHEEL AUDIO CONTROLS — IF

EQUIPPED ...........................................................525

Radio Operation ......................................... 525

Media Mode ............................................... 525

IPOD®/USB/MP3 CONTROL —

IF EQUIPPED ....................................................... 525 RADIO OPERATION AND MOBILE PHONES.... 527

Regulatory And Safety Information .......... 527

VOICE RECOGNITION QUICK TIPS .................. 529

Introducing Uconnect ................................ 529

Get Started................................................. 529

Basic Voice Commands ............................ 529

Radio .......................................................... 530

Media ......................................................... 530

Phone ......................................................... 531

Voice Text Reply — If Equipped ................. 531

Climate (4C/4C NAV)................................. 532

Navigation (4C NAV) .................................. 532

Siri® Eyes Free — If Equipped ................. 532

Using Do Not Disturb ................................ 532

Android Auto™ — If Equipped .................. 533

Apple CarPlay® — If Equipped ................. 533

General Information .................................. 534

Additional Information............................... 534

CUSTOMER ASSISTANCE

SUGGESTIONS FOR OBTAINING SERVICE FOR

YOUR VEHICLE .................................................. 536

Prepare For The Appointment .................. 536

Prepare A List............................................. 536

Be Reasonable With Requests ................. 536

20_DJD2_OM_EN_USC_t.book Page 9

Page 137 of 553

GETTING TO KNOW YOUR INSTRUMENT PANEL135

Service LaneSense Warning Light — If

Equipped

This warning light will illuminate when

the LaneSense system is not oper-

ating and requires service. Please see

an authorized dealer.

Low Washer Fluid Warning Light

This warning light will illuminate when

the windshield washer fluid is low.

Refer to “Engine Compartment” in

“Servicing And Maintenance” for

further information.

Low Fuel Warning Light

When the fuel level reaches approxi -

mately 3.2 gal (12 L) this light will turn

on, and remain on until fuel is added.

A single warning chime will sound with

Low Fuel Warning.

Low Coolant Level Warning Light

This telltale will turn on to indicate the

vehicle coolant level is low.

Refer to “Fluids And Lubricants” in

“Technical Specifications” for further

information.

Loose Fuel Filler Cap Warning Light — If

Equipped

This warning light will illuminate when

the fuel filler cap is loose. Properly

close the filler cap to disengage the

light. If the light does not turn off,

please see an authorized dealer.

Trailer Merge Assist Indicator Light — If

Equipped

This indicator light will illuminate to

indicate when Trailer Merge Assist

has been activated.

Refer to “Blind Spot Monitoring (BSM)” in

“Safety” for further information.

Tire Pressure Monitoring System (TPMS)

Warning Light

The warning light switches on and a

message is displayed to indicate that

the tire pressure is lower than the

recommended value and/or that slow

pressure loss is occurring. In these cases,

optimal tire duration and fuel consumption may

not be guaranteed.

Should one or more tires be in the condition

mentioned above, the display will show the indi -

cations corresponding to each tire. Each tire, including the spare (if provided),

should be checked monthly when cold and

inflated to the inflation pressure recommended

by the vehicle manufacturer on the vehicle

placard or tire inflation pressure label. If your

vehicle has tires of a different size than the size

indicated on the vehicle placard or tire inflation

pressure label, you should determine the

proper tire inflation pressure for those tires.

As an added safety feature, your vehicle has

been equipped with a Tire Pressure Monitoring

System (TPMS) that illuminates a low tire pres

-

sure telltale when one or more of your tires is

significantly under-inflated. Accordingly, when

the low tire pressure telltale illuminates, you

should stop and check your tires as soon as

possible, and inflate them to the proper pres -

sure. Driving on a significantly under-inflated

CAUTION!

Do not continue driving with one or more flat

tires as handling may be compromised. Stop

the vehicle, avoiding sharp braking and

steering. If a tire puncture occurs, repair

immediately using the dedicated tire repair

kit and contact an authorized dealer as soon

as possible.

3

20_DJD2_OM_EN_USC_t.book Page 135

Page 225 of 553

STARTING AND OPERATING223

NOTE:

Use of Climatized Ultra Low Sulfur Diesel Fuel

or Number 1 Ultra Low Sulfur Diesel Fuel

results in a noticeable decrease in fuel

economy.

Climatized Ultra Low Sulfur Diesel Fuel is a

blend of Number 2 Ultra Low Sulfur and

Number 1 Ultra Low Sulfur Diesel Fuels

which reduces the temperature at which wax

crystals form in fuel.

The fuel grade should be clearly marked on

the pump at the fuel station.

The engine requires the use of “Ultra Low

Sulfur Diesel Fuel”. Use of incorrect fuel

could result in engine and exhaust system

damage. Refer to “Fuel Requirements” in

“Technical Specifications” for further infor -

mation.

If climatized or diesel Number 1 ULSD fuel is

not available, and you are operating below

(20°F/-6°C), in sustained arctic conditions,

Mopar Premium Diesel Fuel Treatment (or

equivalent) is recommended to avoid gelling

(see Fuel Operating Range Chart).

Under some circumstances increased

engine noise may be audible in the seconds

following a cold start. This is most likely to

occur when using fuel that isn't blended for

the ambient temperature present. This may

occur on an unseasonably cold day or when

a truck is fueled in a warmer climate and

driven to a colder climate. The noise can

typically be prevented by using Mopar

Premium Diesel Fuel Treatment as recom-

mended (see Fuel Operating Range Chart).

Engine Oil Usage

Refer to “Dealer Service” in “Servicing And

Maintenance” for the correct engine oil

viscosity.

Winter Front Cover Usage

A Winter front or cold weather cover is to be

used in ambient temperatures below 32°F

(0°C), especially during extended idle condi -

tions. This cover is equipped with four flaps for

managing total grille opening in varying ambient

temperatures. If a Winter front or cold weather

cover is to be used the flaps should be left in the

full open position to allow air flow to the charge

air cooler and automatic transmission oil

cooler. When ambient temperatures drop below

0°F (-17°C) the four flaps need to be closed. A suitable cold weather cover is available from

your Mopar dealer.

Battery Blanket Usage

A battery loses 60% of its cranking power as the

battery temperature decreases to 0°F (-18°C).

For the same decrease in temperature, the

engine requires twice as much power to crank

at the same RPM. The use of 120 VAC powered

battery blankets will greatly increase starting

capability at low temperatures. Suitable battery

blankets are available from your authorized

Mopar dealer.

Engine Warm-Up

Avoid full throttle operation when the engine is

cold. When starting a cold engine, bring the

engine up to operating speed slowly to allow the

oil pressure to stabilize as the engine warms up.

NOTE:

High-speed, no-load running of a cold engine

can result in excessive white smoke and poor

engine performance. No-load engine speeds

should be kept under 1,000 RPM during the

warm-up period, especially in cold ambient

temperature conditions.

5

20_DJD2_OM_EN_USC_t.book Page 223

Page 318 of 553

316STARTING AND OPERATING

(Continued)

gauge needle can stay on a fixed position and

may not move for extended periods of time.

This is a normal function of the system.

There is an electric heater inside the DEF

tank that automatically works when neces-

sary. And if the DEF supply does freeze, the

truck will operate normally until it thaws.

DEF Fill Procedure

NOTE:

Refer to “Fluids And Lubricants” in “Technical

Specifications” for the correct fluid type.

1. Remove cap from DEF tank (located on drivers side of the vehicle or in fuel door).

Fill Locations

2. Insert DEF fill adapter/nozzle into DEF tank

filler neck.

NOTE:The DEF gauge may take up to five seconds

to update after adding a gallon or more of

Diesel Exhaust Fluid (DEF) to the DEF tank. If

you have a fault related to the DEF system,

the gauge may not update to the new level.

See your authorized dealer for service.

The DEF gauge may also not immediately

update after a refill if the temperature of the

DEF fluid is below 12°F (-11°C). The DEF line

heater will possibly warm up the DEF fluid

and allow the gauge to update after a period

of run time. Under very cold conditions, it is

possible that the gauge may not reflect the

new fill level for several drives.

Excessive overfilling of the DEF tank can

result in a MIL lamp/fault code and inaccu -

rate level readings.

1 — Diesel Exhaust Fluid (DEF) Fill Location

2 — Diesel Fuel Fill Location

CAUTION!

To avoid DEF spillage, and possible

damage to the DEF tank from overfilling, do

not “top off” the DEF tank after filling.

DO NOT OVERFILL. DEF will freeze below

12ºF (-11ºC). The DEF system is designed

to work in temperatures below the DEF

freezing point, however, if the tank is over -

filled and freezes, the system could be

damaged.

When DEF is spilled, clean the area imme -

diately with water and use an absorbent

material to soak up the spills on the ground.

Do not attempt to start your engine if DEF is

accidentally added to the diesel fuel tank

as it can result in severe damage to your

engine, including but not limited to failure

of the fuel pump and injectors.

20_DJD2_OM_EN_USC_t.book Page 316

Page 352 of 553

350IN CASE OF EMERGENCY

Dual Rear Wheel Jack Placement

6. Finish tightening the lug nuts. Push down on the lug wrench while at the end of the handle

for increased leverage. Tighten the lug nuts in

a star pattern until each nut has been tight -

ened twice. For the correct lug nut torque refer

to “Wheel And Tire Torque Specifications” in

“Technical Specifications”. If in doubt about

the correct tightness, have them checked with

a torque wrench by an authorized dealer or

service station. 7. Install the wheel center cap and remove the

wheel blocks. Do not install chrome or

aluminum wheel center caps on the spare

wheel. This may result in cap damage.

8. Lower the jack to its fully closed position. Stow the replaced tire, jack, and tools as

previously described.

NOTE:

The bottle jack will not lower by turning the dial

(thumbwheel) by hand, it may be necessary to

use the jack driver in order to lower the jack.

9. Adjust the tire pressure when possible.

NOTE:

Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated lug nuts.

To Stow The Flat Or Spare

NOTE:

Have the flat tire repaired or replaced immedi -

ately.

1. Turn the wheel so that the valve stem is facing the ground and toward the rear of

the vehicle for convenience in checking the

spare tire inflation. Slide the wheel retainer

through the center of the wheel.

Reinstalling The Retainer

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired

or replaced immediately.

20_DJD2_OM_EN_USC_t.book Page 350

Page 414 of 553

412SERVICING AND MAINTENANCE

Engine Coolant Checks

Check the engine coolant (antifreeze) protec-

tion every 12 months (before the onset of

freezing weather, where applicable). If the

engine coolant (antifreeze) is dirty or rusty in

appearance, the system should be drained,

flushed and refilled with fresh coolant. Check

the front of the A/C condenser (if equipped) or

radiator for any accumulation of bugs, leaves,

etc. If dirty, clean by gently spraying water from

a garden hose vertically down the face of the

A/C condenser (if equipped) or the back of the

radiator core. Check the engine cooling system hoses for

brittle rubber, cracking, tears, cuts and tight

-

ness of the connection at the coolant recovery

bottle and radiator. Inspect the entire system

for leaks.

DO NOT REMOVE THE COOLANT PRESSURE CAP

WHEN THE COOLING SYSTEM IS HOT.

Cooling System — Drain, Flush And Refill

NOTE:

Some vehicles require special tools to add

coolant properly. Failure to fill these systems

properly could lead to severe internal engine

damage. If any coolant is needed to be added to

the system please contact an authorized

dealer.

If the engine coolant (antifreeze) is dirty or

contains visible sediment, have an authorized

dealer clean and flush with OAT coolant (anti -

freeze) (conforming to MS.90032).

Refer to the “Maintenance Plan” in this section

for the proper maintenance intervals.

Selection Of Coolant

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information. NOTE:

Mixing of engine coolant (antifreeze) other

than specified Organic Additive Technology

(OAT) engine coolant (antifreeze), may result

in engine damage and may decrease corro

-

sion protection. Organic Additive Technology

(OAT) engine coolant is different and should

not be mixed with Hybrid Organic Additive

Technology (HOAT) engine coolant (anti -

freeze) or any “globally compatible” coolant

(antifreeze). If a non-OAT engine coolant

(antifreeze) is introduced into the cooling

system in an emergency, the cooling system

will need to be drained, flushed, and refilled

with fresh OAT coolant (conforming to

MS.90032), by an authorized dealer as soon

as possible.

Do not use water alone or alcohol-based

engine coolant (antifreeze) products. Do not

use additional rust inhibitors or antirust prod -

ucts, as they may not be compatible with the

radiator engine coolant and may plug the

radiator.

Keep hands, tools, clothing, and jewelry

away from the radiator cooling fan when

the hood is raised. The fan starts automati -

cally and may start at any time, whether the

engine is running or not.

When working near the radiator cooling fan,

disconnect the fan motor lead or turn the

ignition to the OFF mode. The fan is

temperature controlled and can start at any

time the ignition is in the ON mode.

WARNING! (Continued)

20_DJD2_OM_EN_USC_t.book Page 412

Page 417 of 553

SERVICING AND MAINTENANCE415

(Continued)

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning,

keep the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever

necessary, install ONLY the correct type ther -

mostat. Other designs may result in unsatis -

factory engine coolant (antifreeze)

performance, poor gas mileage, and

increased emissions.

Charge Air Cooler — Inter-Cooler

The charge air cooler is positioned below the

radiator and the air conditioner condenser. Air

enters the engine through the air cleaner and

passes through the turbocharger, where it is

pressurized. This pressurized air rapidly

reaches high temperature. The air is then

directed through a hose to the charge air cooler

and through another hose to the intake mani -

fold of the engine. The air entering the engine

has been cooled by about 50° to 100°F (10° to

38°C). This cooling process enables more effi -

cient burning of fuel resulting in fewer emis -

sions.

To guarantee optimum performance of the

system, keep the surfaces of the charge air

cooler, condenser and radiator clean and free of debris. Periodically check the hoses leading

to and from the charge air cooler for cracks or

loose clamps resulting in loss of pressure and

reduced engine performance.

Brake System

In order to ensure brake system performance,

all brake system components should be

inspected periodically. Refer to the “Mainte

-

nance Plan” in this section for the proper main -

tenance intervals.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked when performing under the hood

service or immediately if the brake system

warning lamp indicates system failure. If necessary, add fluid to bring level within the

designated marks on the side of the reservoir of

the brake master cylinder. Be sure to clean the

top of the master cylinder area before removing

cap.

With disc brakes the fluid level can be expected

to fall as the brake linings wear. However, an

unexpected drop in fluid level may be caused by

a leak and a system check should be

conducted.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your foot

resting or riding on the brake pedal can result

in abnormally high brake temperatures,

excessive lining wear, and possible brake

damage. You would not have your full braking

capacity in an emergency.WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri

-

cants” in “Technical Specifications” for

further information. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory

installed hydraulic master cylinder reser -

voir.

7

20_DJD2_OM_EN_USC_t.book Page 415

Page 418 of 553

416SERVICING AND MAINTENANCE

Automatic Transmission

Selection Of Lubricant

It is important to use the proper transmission

fluid to ensure optimum transmission perfor-

mance and life. Use only the manufacturer’s

specified transmission fluid. Refer to “Fluids

And Lubricants” in “Technical Specifications”. It

is important to maintain the transmission fluid

at the correct level using the recommended

fluid. No chemical flushes should be used in any

transmission; only the approved lubricant

should be used.

Special Additives

The manufacturer strongly recommends

against using any special additives in the trans -

mission. Automatic Transmission Fluid (ATF) is an engineered product and its performance

may be impaired by supplemental additives.

Therefore, do not add any fluid additives to the

transmission. The only exception to this policy is

the use of special dyes for diagnosing fluid

leaks in six-speed transmissions. Avoid using

transmission sealers as they may adversely

affect seals.

Fluid Level Check — Eight-Speed

Transmission

The fluid level is preset at the factory and does

not require adjustment under normal operating

conditions. Routine fluid level checks are not

required, therefore the transmission has no

dipstick. An authorized dealer can check your

transmission fluid level using special service

tools.

If you notice fluid leakage or transmission

malfunction, visit an authorized dealer immedi

-

ately to have the transmission fluid level

To avoid contamination from foreign matter

or moisture, use only new brake fluid or

fluid that has been in a tightly closed

container. Keep the master cylinder reser -

voir cap secured at all times. Brake fluid in

a open container absorbs moisture from

the air resulting in a lower boiling point. This

may cause it to boil unexpectedly during

hard or prolonged braking, resulting in

sudden brake failure. This could result in a

collision.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

WARNING! (Continued)

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may

cause deterioration in transmission shift

quality and/or torque converter shudder, and

(for six-speed transmissions) will require

more frequent fluid and filter changes. Refer

to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications.

CAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage

your transmission components. Such damage

is not covered by the New Vehicle Limited

Warranty.

20_DJD2_OM_EN_USC_t.book Page 416

Page 420 of 553

418SERVICING AND MAINTENANCE

8. Reinsert the dipstick. Check for leaks.

Release the parking brake.

NOTE:

If it is necessary to check the transmission

below the operating temperature, the fluid level

should be between the two COLD (lower) holes

on the dipstick with the fluid at 68-86°F /

20-30°C. Only use the COLD region of the

dipstick as a rough reference when setting the

fluid level after a transmission service or fluid

change. Re-check the fluid level, and adjust as

required, once the transmission reaches

normal operating temperature.Fluid And Filter Changes — Eight-Speed

Transmission

Under normal operating conditions, the fluid

installed at the factory will provide satisfactory

lubrication for the life of the vehicle.

Routine fluid and filter changes are not

required. However, change the fluid and filter if

the fluid becomes contaminated (with water,

etc.), or if the transmission is disassembled for

any reason.

Fluid And Filter Changes — Six Speed

Transmission

Refer to the “Maintenance Plan” for the proper

maintenance intervals.

In addition, change the fluid and filters if the

fluid becomes contaminated (with water, etc.),

or if the transmission is disassembled for any

reason.

Rear Axle And 4x4 Front Driving Axle Fluid

Level

For normal service, periodic fluid level checks

are not required. When the vehicle is serviced

for other reasons the exterior surfaces of the

axle assembly should be inspected. If gear oil

leakage is suspected inspect the fluid level.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information. This

inspection should be made with the vehicle in a

level position.

For all 2500/3500 Model axles, the fluid level

should be 1/4 in ± 1/4 in (6.4 mm ± 6.4 mm)

below the fill hole on the 9.25 in front, 11.5 in

rear axle, and 12.0 in rear axle.

Drain And Refill

Refer to the “Maintenance Plan” for the proper

maintenance intervals.

Lubricant Selection

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

NOTE:

The presence of water in the gear lubricant will

result in corrosion and possible failure of differ -

ential components. Operation of the vehicle in

CAUTION!

If the fluid temperature is below 50°F (10°C)

it may not register on the dipstick. Do not add

fluid until the temperature is elevated enough

to produce an accurate reading. Run the

engine at idle, in PARK, to warm the fluid.

CAUTION!

If the fluid temperature is below 50°F (10°C)

it may not register on the dipstick. Do not add

fluid until the temperature is elevated enough

to produce an accurate reading. Run the

engine at idle, in PARK, to warm the fluid.

20_DJD2_OM_EN_USC_t.book Page 418