lock Ram 3500 2011 Diesel Supplement

[x] Cancel search | Manufacturer: RAM, Model Year: 2011, Model line: 3500, Model: Ram 3500 2011Pages: 170, PDF Size: 0.66 MB

Page 71 of 170

PARK

This range supplements the parking brake by locking the

transmission. The engine can be started in this range.

Never use PARK while the vehicle is in motion. Apply

the parking brake when leaving the vehicle in this range.

Always apply parking brake first, then place the shift

lever in PARK position. On four-wheel drive vehicles be

sure that the transfer case is in a drive position.

WARNING!

•Never use the PARK position as a substitute for

the parking brake. Always apply the parking

brake fully when parked to guard against vehicle

movement and possible injury or damage.(Continued)

WARNING! (Continued)

•Your vehicle could move and injure you and others

if it is not completely in PARK. Check by trying to

move the shift lever back and forth without first

pulling it toward you after you have set it in

PARK. Make sure it is in PARK before leaving the

vehicle.

•It is dangerous to move the shift lever out of PARK

or NEUTRAL if the engine speed is higher than

idle speed. If your foot is not firmly on the brake

pedal, the vehicle could accelerate quickly forward

or in reverse. You could lose control of the vehicle

and hit someone or something. Only shift into

gear when the engine is idling normally and when

your right foot is firmly on the brake pedal.

70 STARTING AND OPERATING

Page 76 of 170

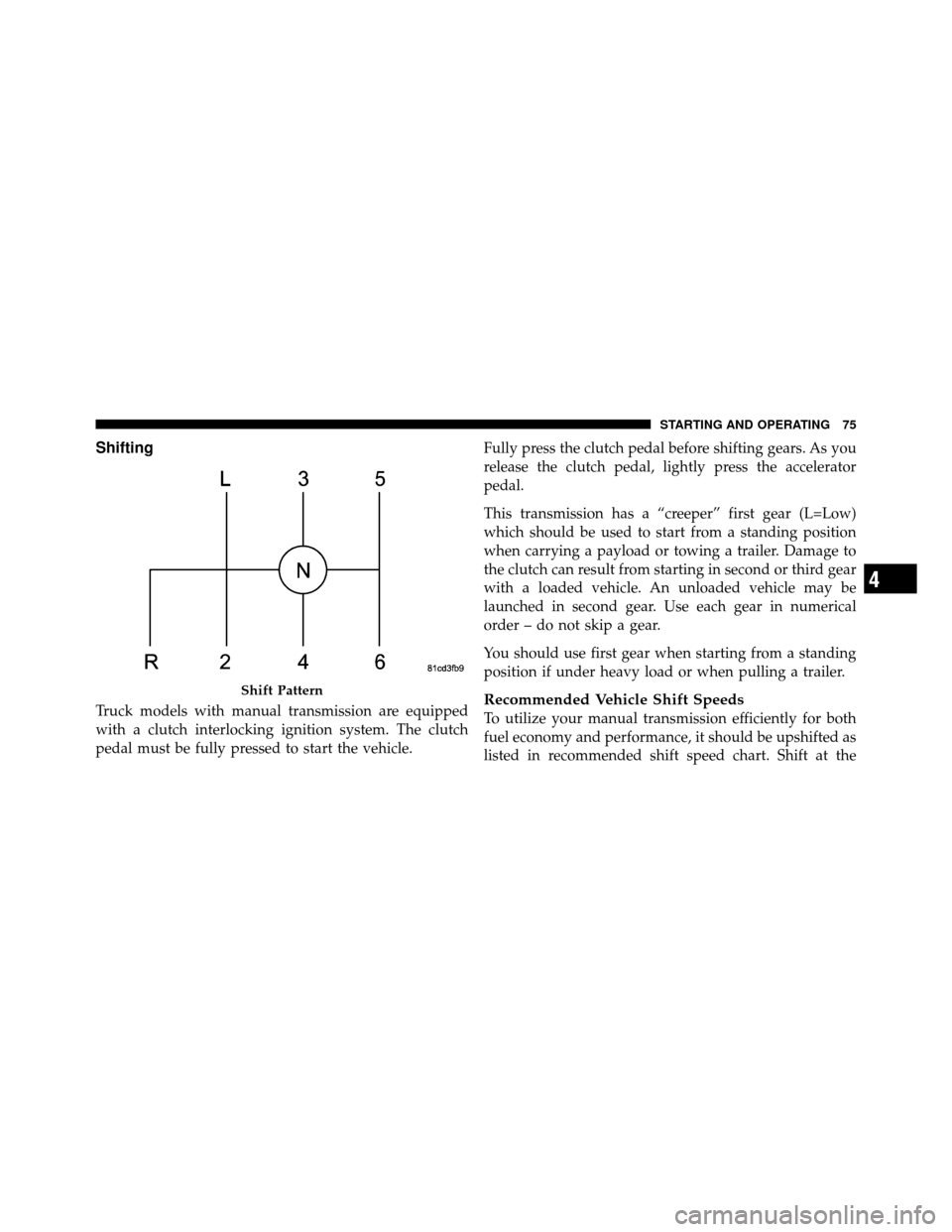

Shifting

Truck models with manual transmission are equipped

with a clutch interlocking ignition system. The clutch

pedal must be fully pressed to start the vehicle.Fully press the clutch pedal before shifting gears. As you

release the clutch pedal, lightly press the accelerator

pedal.

This transmission has a “creeper” first gear (L=Low)

which should be used to start from a standing position

when carrying a payload or towing a trailer. Damage to

the clutch can result from starting in second or third gear

with a loaded vehicle. An unloaded vehicle may be

launched in second gear. Use each gear in numerical

order – do not skip a gear.

You should use first gear when starting from a standing

position if under heavy load or when pulling a trailer.Recommended Vehicle Shift Speeds

To utilize your manual transmission efficiently for both

fuel economy and performance, it should be upshifted as

listed in recommended shift speed chart. Shift at the

Shift Pattern

4

STARTING AND OPERATING 75

Page 80 of 170

The customer has the choice to operate the PTO by

utilizing the cruise control switches or by utilizing a

remote control (provided by the PTO supplier). To oper-

ate the feature using the cruise control switches, the

customer must first activate the upfitter-provided on/off

switch which will turn on the PTO. In order to increase or

decrease the engine idle speed, to optimize the PTO

function, the “RESUME/ACCEL” and “DECEL” cruise

switches can be used respectively. To disengage PTO

operation and return to “standard vehicle operation”

simply turn the upfitter-provided on/off switch to the

OFF position.

The torque converter lockup clutch will automatically

engage at engine speeds above 1,200 RPM (engine speed)

in PTO stationary mode. Once engaged, the lockup clutch

will remain on and not disengage until the engine speed

is below 1,000 RPM. Lockup clutch engagement is desir-

able for certain types of PTO applications (AS68RC

Six-Speed Automatic Transmission Only).To operate the PTO via a remote switch, the customer

must make sure the above conditions are met. It is vital

for proper operation that the PTO and remote have been

installed correctly, paying special attention to ensure the

vehicle provided wiring has been connected properly.

This is the responsibility of the installer of the PTO and

switches/remote system. It is the responsibility of the

PTO manufacturer to ensure that their electrical (switches

and remote) system is compatible with the vehicle’s

electrical architecture and software functionality.

Mobile Mode

To operate the PTO in this mode the vehicle must meet

the following conditions:

•Authorized dealer-selected “mobile” mode activated

via authorized dealer proprietary service tool

•Upfitter-provided (on/off) switch has been activated

4

STARTING AND OPERATING 79

Page 93 of 170

2. Connect one end of the other jumper cable to negative

(-) post of booster battery. Connect the other end of the

jumper cable to a good ground on the engine block of the

vehicle with the discharged battery. Make sure a good

connection is made, free of dirt and grease.

WARNING!

•Do not connect the cable to the negative post of the

discharge battery. The resulting electrical spark

could cause the battery to explode.

•During cold weather when temperatures are be-

low freezing point, electrolyte in a discharged

battery may freeze. Do not attempt jump starting

because the battery could rupture or explode. The

battery temperature must be brought up above

freezing point before attempting to jump start.3. Take care that the clamps from one cable do not

inadvertently touch clamps from the other cable. Do not

lean over the battery when making connection. The

negative connection must provide good electrical con-

ductivity and current carrying capacity.

4. After the engine is started or if the engine fails to start,

cables must be disconnected in the following order:

a. Disconnect the negative cable at the engine ground.

b. Disconnect the negative cable at the negative post

on booster battery.

c. Disconnect the cable from the positive post of both

batteries.

92 WHAT TO DO IN EMERGENCIES

Page 106 of 170

CAUTION!

If the “Water In Fuel Indicator Light” remains on, DO

NOT START the engine before you drain water from

the fuel filter to avoid engine damage.

If the “Water In Fuel Indicator Light” comes on and a

single chime is heard while you are driving, or with the

ignition switch in the ON position, there may be a

problem with your water separator wiring or sensor. See

your authorized dealer for service.

Upon proper draining of the water from the fuel filter, the

“Water In Fuel Indicator Light” will remain illuminated

for approximately 10 seconds. If the water was drained

while the engine was running, the “Water In Fuel Indi-

cator Light” may remain on for approximately three

minutes. NOTE:

Care should be taken in disposing of used fluids

from your vehicle. Used fluids, indiscriminately dis-

carded, can present a problem to the environment. Con-

tact an authorized dealer, service station, or government

agency for advice on recycling programs and for where

used fluids and filters can be properly disposed of in

your area.

Drain the fuel/water separator filter when the “Water In

Fuel Indicator Light” is ON. Within 10 minutes of vehicle

shutdown, turn the drain valve (located on the side of the

filter) counterclockwise 1/4 turn, turn the ignition switch

to the ON position, and allow any accumulated water to

drain. Leave the drain valve open until all water and

contaminants have been removed. When clean fuel is

visible, close the drain valve by turning it clockwise, and

turn the ignition switch to OFF.

6

MAINTAINING YOUR VEHICLE 105

Page 108 of 170

CAUTION! (Continued)

•Do not prefill the fuel filter when installing a new

fuel filter. There is a possibility debris could be

introduced into the fuel filter during this action. It

is best to install the filter dry and allow the in-tank

lift pump to prime the fuel system.

1. Ensure engine is turned off.

2. Place drain pan under the fuel filter drain hose.

3. Open the water drain valve 1/4 turn counterclockwise

and completely drain fuel and water into the approved

container.

4. Close the water drain valve.

5. Remove lid using a socket or strap wrench. Rotate

counterclockwise for removal. Remove used o-ring and

discard it. 6. Remove the used filter cartridge from the housing and

dispose of according to your local regulations.

7. Wipe clean the sealing surfaces of the lid and housing.

8. Install new o-ring back into ring groove on the filter

housing and lubricate with clean engine oil.

9. Remove new filter cartridge from plastic bag and

install into housing.

NOTE:

Do not remove cartridge from bag until you

reach this step in order to keep cartridge clean.

10. Push down on the cartridge to ensure it is properly

seated. Do not pre-fill the filter housing with fuel.

11. Install lid onto housing and tighten to 22.5 ft lbs

(30.5 N.m). Do not overtighten the lid.

12. Prime the engine using the procedure in “Priming If

The Engine Has Run Out Of Fuel.” Then start the engine

and confirm there are no leaks.

6

MAINTAINING YOUR VEHICLE 107

Page 163 of 170

Adding Fuel............................ 83

Air Cleaner, Engine (Engine Air Cleaner

Filter) ............................. 102,126

Air Filter .............................. 102

Airbag Light ............................ 19

Antifreeze (Engine Coolant) .............. 114,115

Capacities ........................... 130

Disposal ............................ 117

Anti-Lock Warning Light ................... 19

Automatic Transmission .................... 68

Adding Fluid ......................... 122

Fluid Level Check ..................... 122

Fluid Type ........................ 122,133

Shifting .............................. 62

Axle Fluid ............................. 133

Battery ............................... 112

Blanket ........................... 51,113

Emergency Starting ..................... 90 Brake Fluid

............................ 133

Brake System ........................... 119

Fluid Check .......................... 119

Master Cylinder ....................... 119

Warning Light ......................... 14

Brake/Transmission Interlock ................ 61

Calibration, Compass ...................... 33

Capacities, Antifreeze (Engine Coolant) ........ 130

Capacities, Fluid ........................ 130

Caps, Filler Oil (Engine) .......................... 100

Radiator (Coolant Pressure) ............... 116

Charge Air Cooler ....................... 119

Check Engine Light (Malfunction Indicator

Light) ................................. 18

Compass .............................. 32

Compass Calibration ...................... 33

Compass Variance ........................ 33

162 INDEX

Page 164 of 170

Computer, Trip/Travel..................... 30

Conserving Fuel ......................... 30

Coolant Pressure Cap (Radiator Cap) .......... 116

Cooling System ......................... 113

Adding Coolant (Antifreeze) .............. 115

Coolant Capacity ...................... 130

Coolant Level ...................... 1 13,117

Disposal of Used Coolant ................ 117

Drain, Flush, and Refill .................. 114

Inspection ........................... 117

Points to Remember .................... 118

Pressure Cap ......................... 116

Radiator Cap ......................... 116

Selection of Coolant (Antifreeze) ......... 114,131

Diesel Exhaust Brake ...................... 58

Diesel Fuel ............................. 81

Diesel Fuel Requirements ................... 81

Bulk Storage of ........................ 84 Diesel Fuel System, Re-Priming

.............. 108

Dipsticks .............................. 98

Disposal .............................. 102

Antifreeze (Engine Coolant) ............... 117

Engine Oil ........................... 102

Draining Fuel/Water Separator Filter .......... 104

Electronic Range Select (ERS) ..............62,68

Electronic Vehicle Information Center (EVIC) ..... 21

Emergency, In Case of Jump Starting ......................... 90

Engine ................................ 97

Air Cleaner .......................... 102

Block Heater ........................ 44,57

Break-In Recommendations ................. 6

Compartment ......................... 97

Coolant (Antifreeze) .................... 131

Identification .......................... 97

Idling ............................... 52

8

INDEX 163

Page 166 of 170

Oil Pressure........................... 13

Speedometer .......................... 12

Tachometer ........................... 11

Voltmeter .......................... 14,49

Gear Ranges ........................ 64,69,75

Idle Up Feature .......................... 53

Information Center, Vehicle ................. 21

Instrument Cluster ...................... 10,11

Intervention Regeneration Strategy ........... 109

Jump Starting ........................... 90

Lights Airbag .............................. 19

Anti-Lock ............................ 19

Brake Warning ......................... 14

Check Engine (Malfunction Indicator) ........ 18

Electronic Stability Program (ESP) Indicator .... 20Fog ................................. 19

High Beam

........................... 14

High Beam Indicator .................... 14

Instrument Cluster ...................... 11

Seat Belt Reminder ...................... 20

Tire Pressure Monitoring (TPMS) ............ 16

Traction Control ........................ 20

Warning (Instrument Cluster Description) ...... 11

Locks Steering Wheel ......................... 6

Maintenance Procedures .................... 98

Maintenance Schedule .................... 136

Manual Transmission ...................... 74

Fluid Level Check ..................... 121

Lubricant Selection ..................... 133

Shift Speeds ........................... 75

Mini-Trip Computer ...................... 30

8

INDEX 165

Page 168 of 170

Resetting Oil Change Indicator............... 27

Resetting Perform Service Indicator ........... 138

Seat Belts Reminder ............................ 20

Selection of Coolant (Antifreeze) .......... 114,131

Settings, Personal ........................ 34

Shifting ............................... 60

Automatic Transmission .................. 62

Manual Transmission .................... 74

Signals, Turn ............................ 11

Speedometer ............................ 12

Starting ............................... 44

Automatic Transmission .................. 44

Engine Block Heater ................... 44,57

Manual Transmission .................... 44

Starting Procedures ....................... 44

Starting Procedures (Diesel Engines) ........... 44Steering

Wheel Lock ............................ 6

Synthetic Engine Oil ...................... 102

Tachometer ............................. 11

Temperature Gauge, Engine Coolant ........... 11

Tip Start ............................... 44

Ti re s Pressure Warning Light .................. 16

Torque Converter Clutch .................67,73

Tow/Haul ............................. 66

Traction Control ......................... 121

Traction Control Light ..................... 20

Transfer Case Fluid ............................... 133

Transmission Automatic .......................... 62,68

Fluid ............................... 133

Manual ............................ 44,74

8

INDEX 167