ABS Ram 3500 2019 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2019, Model line: 3500, Model: Ram 3500 2019Pages: 696, PDF Size: 13.89 MB

Page 364 of 696

362 STARTING AND OPERATING

To Cancel

The following conditions cancel the system:

• The brake pedal is applied.

• The CANC (cancel) button is pushed.

• An Anti-Lock Brake System (ABS) event occurs.

• The gear selector is removed from the DRIVE position.

• The Electronic Stability Control/Traction Control System(ESC/TCS) activates.

• The vehicle parking brake is applied.

• Driver seatbelt is unbuckled at low speeds.

• Driver door is opened at low speeds.

• A Trailer Sway Control (TSC) event occurs.

• The driver switches ESC to full-off mode.

• The braking temperature exceeds normal range (overheated).

To Turn Off

The system will turn off and clear the set speed in memory if:

• The Adaptive Cruise Control (ACC) on/off button is pushed. • The Normal (Fixed Speed) Cruise Control on/off button is

pushed.

• The ignition is turned OFF.

• You switch to Four-Wheel Drive Low.

To Resume

If there is a set speed in memory push the RES (+) button and

then remove your foot from the accelerator pedal. The instru-

ment cluster display will display the last set speed.

NOTE:

• If your vehicle stays at standstill for longer than two seconds, the driver will have to push the RES (+) button to

reengage the ACC to the existing set speed.

• ACC cannot be resumed if there is a stationary vehicle in-front of your vehicle in close proximity.

WARNING!

The Resume function should only be used if traffic and road

conditions permit. Resuming a set speed that is too high or

too low for prevailing traffic and road conditions could

cause the vehicle to accelerate or decelerate too sharply for

safe operation. Failure to follow these warnings can result in

a collision and death or serious personal injury.

Page 460 of 696

458 IN CASE OF EMERGENCY

Power Distribution Center

The Power Distribution Center is located in the engine

compartment near the battery. This center contains cartridge

fuses, micro fuses, relays, and circuit breakers. A description

of each fuse and component may be stamped on the insidecover, otherwise the cavity number of each fuse is stamped

on the inside cover that corresponds to the following chart.

Power Distribution Center Location

Cavity Cartridge Fuse Micro Fuse Description

F01 80 Amp Black –Rad Fan Control Module – If Equipped (DS 1500

Only)

F02 60 Amp Yellow –ABS Pump Motor (HD Only)

F03 60 Amp Yellow –Rad Fan – If Equipped

F04 50 Amp Red 400W Inverter – If Equipped (HD Only)

F05 40 Amp Green

50 Amp Red (Special

Services Vehicle (SSV)) –

Compressor For Air Suspension – If Equipped

Page 461 of 696

IN CASE OF EMERGENCY 459

F0640 Amp Green –ABS Pump Motor (DS 1500 Only)

F07 40 Amp Green –Starter Solenoid

F08 20 Amp Blue (DS 1500

LD/Cummins Diesel) 40 Amp Green –

–

NOX Sensor – If Equipped

Aux Relay Output- SSV Only

F09 40 Amp Green (SSV &

Cummins Diesel) –Aux Relay Output / Diesel Fuel Heater – If

Equipped

F09 30 Amp Pink –Brake Vacuum Pump – If Equipped (HD Only)

F10 40 Amp Green –Body Controller / Exterior Lighting #2

F11 30 Amp Pink –PWR - Trailer Tow Electric Brake Batt Feed – If

Equipped (DS 1500 Only)

F11 40 Amp Green –Brake System Module (ECU and Valves) (HD

Only)

F12 40 Amp Green –Body Controller #3

F13 40 Amp Green –Blower Motor

F14 40 Amp Green –Body Controller #4 / Exterior Lighting

F15 30 Amp Pink

40 Amp Green –

–Power Side Steps – If Equipped (HD Only)

Extra Fuse - SSV Only

F16 30 Amp Pink –Smart-Bar Module – If Equipped (HD Only)

F17 30 Amp Pink –Winch Control Module – If Equipped (HD Only)

Cavity

Cartridge Fuse Micro Fuse Description

6

Page 516 of 696

514 SERVICING AND MAINTENANCE

4. Remove the filter cover by pushing in on the finger tabson each end of the filter cover.

Filter Cover Filter Cover Removal

1 — Finger Tabs

Page 529 of 696

SERVICING AND MAINTENANCE 527

(Continued)

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically. Refer

to the “Maintenance Plan” in this section for the proper

maintenance intervals.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be checked

when performing under the hood service or immediately if

the brake system warning lamp indicates system failure.

If necessary, add fluid to bring level within the designated

marks on the side of the reservoir of the brake master

cylinder. Be sure to clean the top of the master cylinder area

before removing cap.With disc brakes the fluid level can be expected to fall as the

brake linings wear. However, an unexpected drop in fluid

level may be caused by a leak and a system check should be

conducted.

Refer to “Fluids And Lubricants” in “Technical Specifica

-

tions” for further information.

WARNING!

Riding the brakes can lead to brake failure and possibly

a collision. Driving with your foot resting or riding on

the brake pedal can result in abnormally high brake

temperatures, excessive lining wear, and possible brake

damage. You would not have your full braking capacity

in an emergency.

WARNING!

• Use only manufacturer's recommended brake fluid. Refer to “Fluids And Lubricants” in “Technical Speci -

fications” for further information. Using the wrong

type of brake fluid can severely damage your brake

system and/or impair its performance. The proper type

of brake fluid for your vehicle is also identified on the

original factory installed hydraulic master cylinder

reservoir.

• To avoid contamination from foreign matter or mois -

ture, use only new brake fluid or fluid that has been in

a tightly closed container. Keep the master cylinder

reservoir cap secured at all times. Brake fluid in a open

container absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil unexpect -

edly during hard or prolonged braking, resulting in

sudden brake failure. This could result in a collision.

7

Page 534 of 696

532 SERVICING AND MAINTENANCE

NOTE:

• P (Passenger) — Metric tire sizing is based on U.S. designstandards. P-Metric tires have the letter “P” molded into

the sidewall preceding the size designation. Example:

P215/65R15 95H.

• European — Metric tire sizing is based on European design standards. Tires designed to this standard have the

tire size molded into the sidewall beginning with the

section width. The letter "P" is absent from this tire size

designation. Example: 215/65R15 96H. • LT (Light Truck) — Metric tire sizing is based on U.S.

design standards. The size designation for LT-Metric tires

is the same as for P-Metric tires except for the letters “LT”

that are molded into the sidewall preceding the size desig -

nation. Example: LT235/85R16.

• Temporary spare tires are designed for temporary emergency use only. Temporary high pressure compact spare tires have

the letter “T” or “S” molded into the sidewall preceding the

size designation. Example: T145/80D18 103M.

• High flotation tire sizing is based on U.S. design standards and it begins with the tire diameter molded into the side -

wall. Example: 31x10.5 R15 LT.

Page 536 of 696

534 SERVICING AND MAINTENANCE

H = Speed Symbol

• A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain oper -

ating conditions

• The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle loading, road conditions, and posted speed limits)

Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

• XL = Extra load (or reinforced) tire, or

• LL = Light load tire or

• C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire EXAMPLE:

Page 567 of 696

TECHNICAL SPECIFICATIONS 565

BRAKE SYSTEM

If power assist is lost for any reason (for example, repeated

brake applications with the engine off), the brakes will still

function. However, you will experience a substantial

increase in braking effort to stop the vehicle.

If either the front or rear hydraulic system loses normal

braking capability, the remaining system will still function

with some loss of overall braking effectiveness. This will be

evident by increased pedal travel during application, greater

pedal force required to slow or stop, and activation of the

“Brake Warning Light” and the “ABS Warning Light” (if

equipped) during brake use.

Hydraulic Brake Assist — 2500/3500 Models Only

(Except Power Wagon)

The brake system power assist is provided by a hydro-boost

unit which shares fluid with the power steering system. You

may experience some clicking or hissing noises from the

hydro-boost system during hard braking conditions.

NOTE:

Under cold temperatures, pedal effort will be higher than

normal until the power steering fluid reaches operating

temperature.

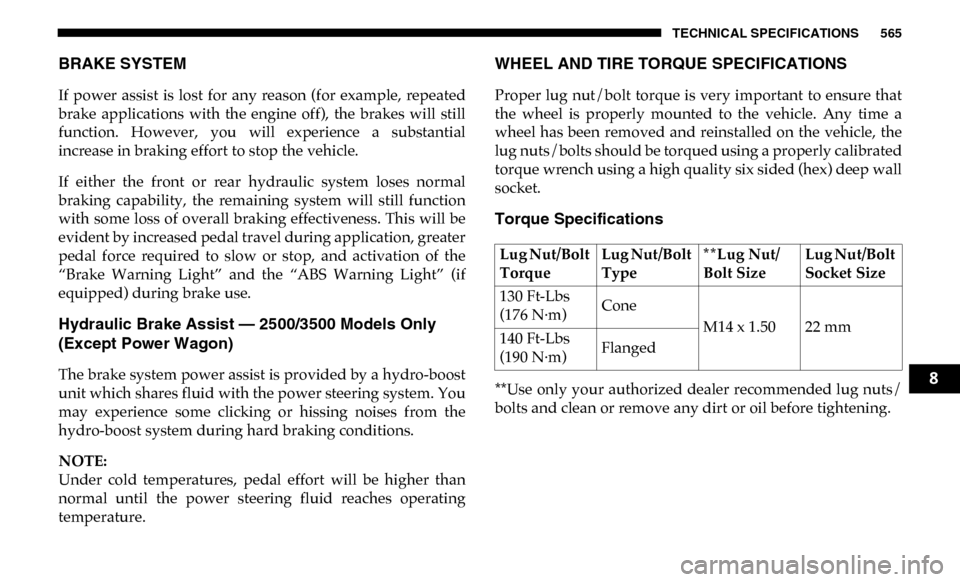

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure that

the wheel is properly mounted to the vehicle. Any time a

wheel has been removed and reinstalled on the vehicle, the

lug nuts/bolts should be torqued using a properly calibrated

torque wrench using a high quality six sided (hex) deep wall

socket.

Torque Specifications

**Use only your authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.Lug Nut/Bolt

Torque

Lug Nut/Bolt

Type**Lug Nut/

Bolt SizeLug Nut/Bolt

Socket Size

130 Ft-Lbs

(176 N·m) Cone

M14 x 1.50 22 mm

140 Ft-Lbs

(190 N·m) Flanged8

Page 677 of 696

CUSTOMER ASSISTANCE 675

Customer Assistance For The Hearing Or Speech

Impaired (TDD/TTY)

To assist customers who have hearing difficulties, the manu-

facturer has installed special TDD (Telecommunication

Devices for the Deaf) equipment at its customer center. Any

hearing or speech impaired customer, who has access to a

TDD or a conventional teletypewriter (TTY) in the United

States, can communicate with the manufacturer by dialing

1-800-380-CHRY.

Canadian residents with hearing difficulties that require

assistance can use the special needs relay service offered by

Bell Canada. For TTY teletypewriter users, dial 711 and for

Voice callers, dial 1-800-855-0511 to connect with a Bell Relay

Service operator.

Service Contract

You may have purchased a service contract for a vehicle to

help protect you from the high cost of unexpected repairs

after the manufacturer's New Vehicle Limited Warranty

expires. The manufacturer stands behind only the manufac-

turer's service contracts. If you purchased a manufacturer's

service contract, you will receive Plan Provisions and an

Owner Identification Card in the mail within three weeks of the vehicle delivery date. If you have any questions about the

service contract, call the manufacturer's Service Contract

National Customer Hotline at 1-800-521-9922 (Canadian resi

-

dents, call (800) 465-2001 English / (800) 387-9983 French).

The manufacturer will not stand behind any service contract

that is not the manufacturer's service contract. It is not

responsible for any service contract other than the manufac -

turer's service contract. If you purchased a service contract

that is not a manufacturer's service contract, and you require

service after the manufacturer's New Vehicle Limited

Warranty expires, please refer to the contract documents,

and contact the person listed in those documents.

We appreciate that you have made a major investment when

you purchased the vehicle. An authorized dealer has also

made a major investment in facilities, tools, and training to

assure that you are absolutely delighted with the ownership

experience. You will be pleased with their sincere efforts to

resolve any warranty issues or related concerns.

10

Page 680 of 696

INDEX

A

Adaptive Cruise Control (ACC) (Cruise Control) ............. 357

Adding Engine Coolant (Antifreeze) ................................... 524

Adding Fuel ............................................................................. 408

Additives, Fuel ........................................................................ 568

Adjust Down....................................................................................... 44

Forward .................................................................................. 44

Rearward ................................................................................ 44

Up ............................................................................................ 44

Adjustable Pedals...................................................................... 56

Air Bag Air Bag Operation ............................................................... 249Air Bag Warning Light ....................................................... 245

Enhanced Accident Response ................................... 255, 498

Event Data Recorder (EDR) ............................................... 498

If Deployment Occurs ........................................................ 254

Knee Impact Bolsters .......................................................... 249Maintaining Your Air Bag System.................................... 256

Maintenance......................................................................... 256

Transporting Pets ................................................................ 286

Air Bag Light ........................................................... 180, 245, 287

Air Cleaner, Engine (Engine Air Cleaner Filter) ................ 509

Air Conditioner Maintenance ............................................... 511 Air Conditioner Refrigerant ..........................................511, 512

Air Conditioner System..........................................................511

Air Conditioning ................................................................. 79, 90

Air Conditioning Filter .....................................................93, 512

Air Conditioning System .........................................................91

Air Conditioning, Operating Tips ..........................................91

Air Filter ...................................................................................509

Air Pressure Tires .......................................................................................542

Alarm Panic ........................................................................................19

Security Alarm ...............................................................32, 181

Alterations/Modifications Vehicle.....................................................................................15

Android Auto ..........................................................................668

Antifreeze (Engine Coolant) ..........................................523, 571 Disposal ................................................................................525

Anti-Lock Brake System (ABS) .............................................195

Anti-Lock Warning Light.......................................................187

Apple CarPlay .........................................................................670

Assist, Hill Start .......................................................................198

Audio Systems (Radio)........................................................... 575

Auto Down Power Windows ..................................................95

Auto Unlock, Doors ................................................................306