wheel size Ram 3500 2020 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 3500, Model: Ram 3500 2020Pages: 568

Page 254 of 568

252STARTING AND OPERATING

Proper operation of four-wheel drive vehicles

depends on tires of equal size, type and

circumference on each wheel. Any difference in

tire size can cause damage to the drivetrain.

Because four-wheel drive provides improved

traction, there is a tendency to exceed safe

turning and stopping speeds. Do not go faster

than road conditions permit.

Shifting Procedure

NOTE:

If any of the requirements to select a new

transfer case position have not been met, the

transfer case will not shift. The position indi -

cator light for the previous position will

remain ON and the newly selected position

indicator light will continue to flash until all

the requirements for the selected position

have been met. To retry a shift: return the

control switch back to the original position,

make certain all shift requirements have

been met, wait five seconds and try the shift

again.

If all the requirements to select a new

transfer case position have been met, the

current position indicator light will turn OFF,

the selected position indicator light will flash until the transfer case completes the shift.

When the shift is complete, the position indi

-

cator light for the selected position will stop

flashing and remain ON.

2WD To 4WD HIGH

Push the desired position on the 4WD control

switch to shift the transfer case. Shifts between

2WD and 4WD HIGH can be done with the

vehicle stopped or in motion. With the vehicle in

motion, the transfer case will engage/

disengage faster if you momentarily release the

accelerator pedal after turning the control

switch. If the vehicle is stopped, the ignition

switch must be in the ON position with the

engine either running or off. This shift cannot be

completed if the ignition switch is in the ACC

position.

NOTE:

The four-wheel drive system will not allow shifts

between 2WD/4WD HIGH if the front and/or

rear wheels are spinning (no traction). In this

situation, the selected position indicator light

will flash and the original position indicator light

will remain on. At this time, reduce speed and

stop spinning the wheels to complete the shift. 2WD Or 4WD HIGH To 4WD LOW

NOTE:

When shifting into or out of 4WD LOW some

gear noise may be heard. This noise is normal

and is not detrimental to the vehicle or occu

-

pants.

Shifting can be performed with the vehicle

rolling 2 to 3 mph (3 to 5 km/h) or completely

stopped. You can use either of the following

procedures:

Preferred Procedure

1. With the engine running, slow the vehicle to 2 to 3 mph (3 to 5 km/h).

2. Shift the transmission into NEUTRAL.

3. While still rolling, push the desired position on the transfer case control switch.

4. After the desired position indicator light is on (not flashing), shift the transmission

back into gear.

20_DJD2_OM_EN_USC_t.book Page 252

Page 256 of 568

254STARTING AND OPERATING

met. Refer to “Shifting Procedure – Manually

Shifted Transfer Case” in this section for further

information.

The 4H and 4L positions are intended for loose,

slippery road surfaces only. Driving in the 4H

and 4L positions on dry, hard surfaced roads

may cause increased tire wear and damage to

the driveline components.

The “Transfer Case Position Indicator Light” in

the instrument cluster will alert the driver that

the vehicle is in four-wheel drive and that the

front and rear driveshafts are locked together.

This light will illuminate when the transfer case

is shifted into either the 4H or 4L position. There

is no light for the 2H or NEUTRAL positions on

some models.

When operating your vehicle in 4L, the engine

speed is approximately three times that of the

2H or 4H positions at a given road speed. Take

care not to overspeed the engine and do not

exceed 25 mph (40 km/h).

Proper operation of four-wheel drive vehicles

depends on tires of equal size, type and

circumference on each wheel. Any difference

will adversely affect shifting and can cause

damage to the drivetrain. NOTE:

Do not attempt to make a shift while only the

front or rear wheels are spinning, as this can

cause damage to driveline components.

Because four-wheel drive provides improved

traction, there is a tendency to exceed safe

turning and stopping speeds. Do not go faster

than road conditions permit.

NOTE:

Delayed shifts out of four-wheel drive may be

experienced due to uneven tire wear, low or

uneven tire pressures, excessive vehicle

loading, or cold temperatures.Two-Wheel Drive High Range (2H)

Two-Wheel Drive High Range — This range is for

normal street and highway driving on dry hard

surfaced roads.

Four-Wheel Drive High Range (4H)

Four-Wheel Drive High Range — This range locks

the front and rear driveshafts together forcing

the front and rear wheels to rotate at the same

speed. Additional traction for loose, slippery

road surfaces only.

N (Neutral)

N (Neutral) — This range disengages the front

and rear driveshafts from the powertrain. To be

used for flat towing behind another vehicle.

Refer to “Recreational Towing” in “Starting And

Operating” for further information.

Four-Wheel Drive Low Range (4L)

Four-Wheel Drive Low Range — This range locks

the front and rear driveshafts together forcing

the front and rear wheels to rotate at the same

speed. Additional traction and maximum pulling

power for loose, slippery road surfaces only. Do

not exceed 25 mph (40 km/h).

WARNING!

You or others could be injured or killed if you

leave the vehicle unattended with the transfer

case in the NEUTRAL position without first

fully engaging the parking brake. The transfer

case NEUTRAL position disengages both the

front and rear drive shafts from the

powertrain and will allow the vehicle to roll,

even if the transmission is in PARK. The

parking brake should always be applied when

the driver is not in the vehicle.

20_DJD2_OM_EN_USC_t.book Page 254

Page 286 of 568

284STARTING AND OPERATING

NOTE:

Any chassis/suspension or tire size modifica -

tions to the vehicle will affect the performance

of the Adaptive Cruise Control and Forward

Collision Warning System.

ACTIVATING ADAPTIVE CRUISE CONTROL

(ACC)

You can only engage ACC if the vehicle speed is

above 0 mph (0 km/h).

The minimum set speed for the ACC system is

20 mph (32 km/h).

When the system is turned on and in the ready

state, the instrument cluster display will read

“ACC Ready.”

When the system is off, the instrument cluster

display will read “Adaptive Cruise Control (ACC)

Off.”

NOTE:

You cannot engage ACC under the following

conditions:

When in Four-Wheel Drive Low.

When you apply the brakes.

When the parking brake is applied.

When the automatic transmission is in PARK,

REVERSE or NEUTRAL.

When the vehicle speed is outside of the

speed range.

When the brakes are overheated.

When the driver door is open at low speed.

When the driver seat belt is unbuckled at low

speed.

Electronic Stability Control (ESC) Full Off

mode is active.

TO ACTIVATE/DEACTIVATE

Push and release the Adaptive Cruise Control

(ACC) on/off button. The ACC menu in the

instrument cluster displays “ACC Ready.”

Adaptive Cruise Control Ready

To turn the system off, push and release the

Adaptive Cruise Control (ACC) on/off button

again. At this time, the system will turn off and

the instrument cluster display will show

“Adaptive Cruise Control (ACC) Off.”

Adaptive Cruise Control Off

WARNING!

Leaving the Adaptive Cruise Control (ACC)

system on when not in use is dangerous. You

could accidentally set the system or cause it

to go faster than you want. You could lose

control and have a collision. Always leave the

system off when you are not using it.

20_DJD2_OM_EN_USC_t.book Page 284

Page 326 of 568

324STARTING AND OPERATING

system to operate properly at temperatures

below 12°F (-11°C). If your vehicle is not in

operation for an extended period of time with

temperatures below 12°F (-11°C), the DEF in

the tank may freeze. If the tank is overfilled and

freezes, it could be damaged. Therefore, do not

overfill the DEF tank.

Extra care should be taken when filling with

portable containers to avoid overfilling. Note the

level of the DEF gauge in your instrument

cluster. You may safely add a maximum of

2 Gallons (7.5 Liters) of DEF from portable

containers when your DEF gauge is reading

½ full.

VEHICLE LOADING

GROSS VEHICLE WEIGHT RATING

(GVWR)

The GVWR is the total permissible weight of your

vehicle including driver, passengers, vehicle,

options and cargo. The label also specifies

maximum capacities of front and rear axle

systems (GAWR). Total load must be limited so

GVWR and front and rear GAWR are not

exceeded.

PAYLOAD

The payload of a vehicle is defined as the

allowable load weight a truck can carry,

including the weight of the driver, all

passengers, options and cargo.

GROSS AXLE WEIGHT RATING (GAWR)

The GAWR is the maximum permissible load on

the front and rear axles. The load must be

distributed in the cargo area so that the GAWR

of each axle is not exceeded.

Each axle GAWR is determined by the

components in the system with the lowest load

carrying capacity (axle, springs, tires or wheels).

Heavier axles or suspension components

sometimes specified by purchasers for

increased durability does not necessarily

increase the vehicle's GVWR.

TIRE SIZE

The tire size on the Vehicle Certification Label

represents the actual tire size on your vehicle.

Replacement tires must be equal to the load

capacity of this tire size.

RIM SIZE

This is the rim size that is appropriate for the tire

size listed.

INFLATION PRESSURE

This is the cold tire inflation pressure for your

vehicle for all loading conditions up to full

GAWR.

CURB WEIGHT

The curb weight of a vehicle is defined as the

total weight of the vehicle with all fluids,

including vehicle fuel, at full capacity

conditions, and with no occupants or cargo

loaded into the vehicle. The front and rear curb

weight values are determined by weighing your

vehicle on a commercial scale before any

occupants or cargo are added.

LOADING

The actual total weight and the weight of the

front and rear of your vehicle at the ground can

best be determined by weighing it when it is

loaded and ready for operation.

20_DJD2_OM_EN_USC_t.book Page 324

Page 328 of 568

326STARTING AND OPERATING

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front

and rear axles. Distribute the load over the front

and rear axles evenly. Make sure that you do

not exceed either front or rear GAWR. Refer to

“Vehicle Loading/Vehicle Certification Label” in

“Starting And Operating” for further

information.

Tongue Weight (TW)

The tongue weight is the downward force

exerted on the hitch ball by the trailer. You must

consider this as part of the load on your vehicle.

Trailer Frontal Area

The frontal area is the maximum height

multiplied by the maximum width of the front of

a trailer.

Trailer Sway Control

The trailer sway control can be a mechanical

telescoping link that can be installed between

the hitch receiver and the trailer tongue that

typically provides adjustable friction associated

with the telescoping motion to dampen any

unwanted trailer swaying motions while

traveling.

If equipped, the electronic Trailer Sway Control

(TSC) recognizes a swaying trailer and

automatically applies individual wheel brakes

and/or reduces engine power to attempt to

eliminate the trailer sway.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer

tongue weight, just as if it were luggage located

at a hitch ball or some other connecting point of

the vehicle. These kinds of hitches are the most

popular on the market today and they are

commonly used to tow small and medium sized

trailers.

Weight-Distributing Hitch

A weight-distributing system works by applying

leverage through spring (load) bars. They are

typically used for heavier loads to distribute

trailer tongue weight to the tow vehicle's front

axle and the trailer axle(s). When used in

accordance with the manufacturer's directions,

it provides for a more level ride, offering more

consistent steering and brake control, thereby

enhancing towing safety. The addition of a

friction/hydraulic sway control also dampens

sway caused by traffic and crosswinds and

contributes positively to tow vehicle and trailer

stability. Trailer Sway Control (TSC) and a weight

distributing (load equalizing) hitch are

recommended for heavier Tongue Weights (TW)

and may be required depending on vehicle and

trailer configuration/loading to comply with

GAWR requirements.

WARNING!

It is important that you do not exceed the

maximum front or rear GAWR. A dangerous

driving condition can result if either rating is

exceeded. You could lose control of the

vehicle and have a collision.

20_DJD2_OM_EN_USC_t.book Page 326

Page 333 of 568

STARTING AND OPERATING331

(Continued)

Towing Requirements — Tires

Do not attempt to tow a trailer while using a

compact spare tire.

Do not drive more than 50 mph (80 km/h) when towing while using a full size spare tire.

Proper tire inflation pressures are essential

to the safe and satisfactory operation of your

vehicle. Refer to “Tires” in “Servicing And

Maintenance” for proper tire inflation proce -

dures.

Check the trailer tires for proper tire inflation

pressures before trailer usage.

Check for signs of tire wear or visible tire

damage before towing a trailer. Refer to

“Tires” in “Servicing And Maintenance” for

the proper inspection procedure.

When replacing tires, refer to “Tires” in

“Servicing And Maintenance” for the proper

tire replacement procedures. Replacing tires

with a higher load carrying capacity will not

increase the vehicle's GVWR and GAWR

limits.

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake

system or vacuum system of your vehicle

with that of the trailer. This could cause inad -

equate braking and possible personal injury.

An electronically actuated trailer brake

controller is required when towing a trailer

with electronically actuated brakes. When

towing a trailer equipped with a hydraulic

surge actuated brake system, an electronic

brake controller is not required.

Trailer brakes are recommended for trailers

over 1,000 lbs (453 kg) and required for

trailers in excess of 2,000 lbs (907 kg).

When hauling cargo or towing a trailer, do

not overload your vehicle or trailer. Over -

loading can cause a loss of control, poor

performance or damage to brakes, axle,

engine, transmission, steering, suspension,

chassis structure or tires.

Safety chains must always be used

between your vehicle and trailer. Always

connect the chains to the hook retainers of

the vehicle hitch. Cross the chains under

the trailer tongue and allow enough slack

for turning corners.

Vehicles with trailers should not be parked

on a grade. When parking, apply the

parking brake on the tow vehicle. Put the

tow vehicle transmission in PARK. For

four-wheel drive vehicles, make sure the

transfer case is not in NEUTRAL. Always,

block or "chock" the trailer wheels.

GCWR must not be exceeded.

WARNING! (Continued)

Total weight must be distributed between

the tow vehicle and the trailer such that the

following four ratings are not exceeded :

GVWR

GTW

GAWR

Tongue weight rating for the trailer

hitch utilized.

WARNING! (Continued)

5

20_DJD2_OM_EN_USC_t.book Page 331

Page 355 of 568

IN CASE OF EMERGENCY353

REPLACING EXTERIOR BULBS

Base Quad: Low Beam Headlamp, High

Beam Headlamp, Front Park And Turn — If

Equipped

Low Beam

1. Open the hood.

2. Disconnect and isolate the negative battery

cable.

3. Reach into the front wheel house ahead of the front wheel, remove the fastener, and

lift the cover over the access hole in the

front of the wheel house splash shield.

Access to the rear of the lamp can be gained

through this access hole.

Splash Shield Access Cover

4. Reach through the access hole of the wheel

house splash shield and disengage the bulb

access cover by rotating counterclockwise.

Bulb Access Cover

5. Disconnect the internal lamp wiring harness connector from the low beam bulb. 6. Rotate the bulb counterclockwise a quarter

turn to unlock the bulb from the lamp.

7. Pull the bulb straight out from the housing.

8. Reverse the procedure for installation of new bulb and covers.

High Beam

1. Open the hood.

2. Disconnect and isolate the negative battery cable.

Bulb Access Cover

3. Look under the hood and behind the headlamp to find the high beam bulb

access cover.

CAUTION!

Do not contaminate the bulb glass by

touching it with your fingers or by allowing it

to contact other oily surfaces. Shortened

bulb life will result.

Always use the correct bulb size and type

for replacement. An incorrect bulb size or

type may overheat and cause damage to

the lamp, the bulb socket, or the lamp

wiring.

6

20_DJD2_OM_EN_USC_t.book Page 353

Page 356 of 568

354IN CASE OF EMERGENCY

4. Reach behind the headlamp and disengage

the access cover by rotating counter -

clockwise.

5. Disconnect the internal lamp wiring harness connector from the high beam bulb.

6. Rotate the bulb counterclockwise a quarter turn to unlock the bulb from the lamp.

7. Pull the bulb straight out from the housing.

8. Reverse the procedure for installation of new bulb and covers. Front Park And Turn

1. Open the hood.

2. Disconnect and isolate the negative battery

cable.

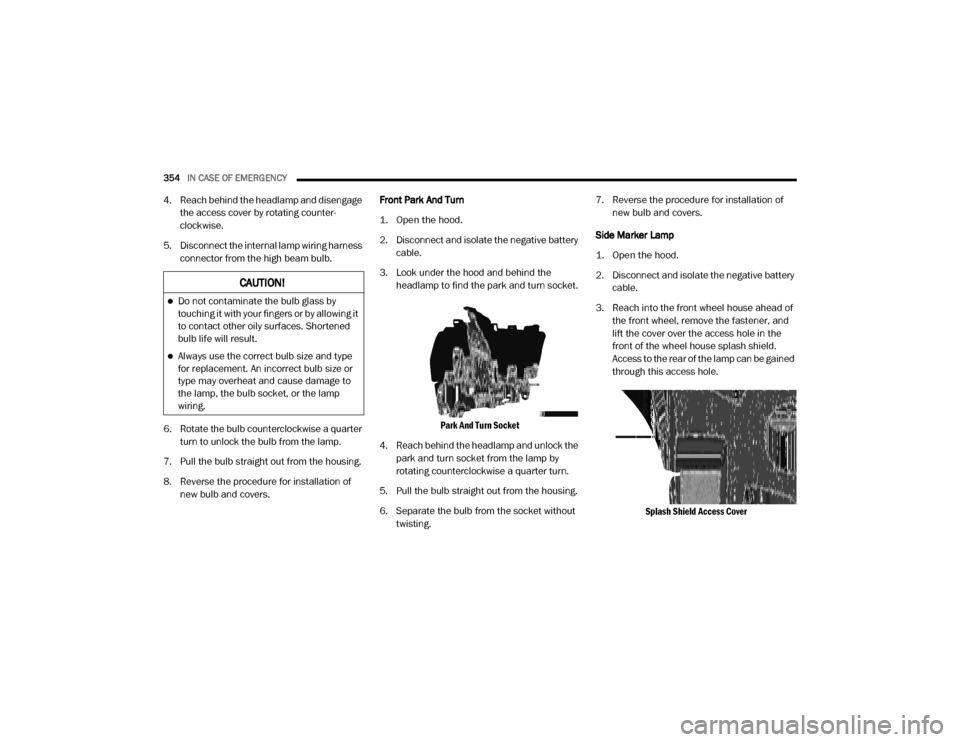

3. Look under the hood and behind the headlamp to find the park and turn socket.

Park And Turn Socket

4. Reach behind the headlamp and unlock the park and turn socket from the lamp by

rotating counterclockwise a quarter turn.

5. Pull the bulb straight out from the housing.

6. Separate the bulb from the socket without twisting. 7. Reverse the procedure for installation of

new bulb and covers.

Side Marker Lamp

1. Open the hood.

2. Disconnect and isolate the negative battery cable.

3. Reach into the front wheel house ahead of the front wheel, remove the fastener, and

lift the cover over the access hole in the

front of the wheel house splash shield.

Access to the rear of the lamp can be gained

through this access hole.

Splash Shield Access Cover

CAUTION!

Do not contaminate the bulb glass by

touching it with your fingers or by allowing it

to contact other oily surfaces. Shortened

bulb life will result.

Always use the correct bulb size and type

for replacement. An incorrect bulb size or

type may overheat and cause damage to

the lamp, the bulb socket, or the lamp

wiring.

20_DJD2_OM_EN_USC_t.book Page 354

Page 441 of 568

SERVICING AND MAINTENANCE439

(Continued)

Life Of Tire

The service life of a tire is dependent upon

varying factors including, but not limited to:

Driving style.

Tire pressure - Improper cold tire inflation

pressures can cause uneven wear patterns

to develop across the tire tread. These

abnormal wear patterns will reduce tread life,

resulting in the need for earlier tire replace -

ment.

Distance driven.

Performance tires, tires with a speed rating of

V or higher, and Summer tires typically have

a reduced tread life. Rotation of these tires

per the vehicle scheduled maintenance is

highly recommended. NOTE:

Wheel valve stem must be replaced as well

when installing new tires due to wear and tear

in existing tires.

Keep dismounted tires in a cool, dry place with

as little exposure to light as possible. Protect

tires from contact with oil, grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance

of many characteristics. They should be

inspected regularly for wear and correct cold

tire inflation pressures. The manufacturer

strongly recommends that you use tires

equivalent to the originals in size, quality and

performance when replacement is needed.

Refer to the paragraph on “Tread Wear

Indicators” in this section. Refer to the Tire and

Loading Information placard or the Vehicle

Certification Label for the size designation of

your tire. The Load Index and Speed Symbol for

your tire will be found on the original equipment

tire sidewall.

See the Tire Sizing Chart example found in the

“Tire Safety Information” section of this manual

for more information relating to the Load Index

and Speed Symbol of a tire. It is recommended to replace the two front tires

or two rear tires as a pair. Replacing just one tire

can seriously affect your vehicle’s handling. If

you ever replace a wheel, make sure that the

wheel’s specifications match those of the

original wheels.

It is recommended you contact an authorized

tire dealer or original equipment dealer with any

questions you may have on tire specifications or

capability. Failure to use equivalent

replacement tires may adversely affect the

safety, handling, and ride of your vehicle.

WARNING!

Tires and the spare tire should be replaced

after six years, regardless of the remaining

tread. Failure to follow this warning can result

in sudden tire failure. You could lose control

and have a collision resulting in serious injury

or death.

WARNING!

Do not use a tire, wheel size, load rating, or

speed rating other than that specified for

your vehicle. Some combinations of unap

-

proved tires and wheels may change

suspension dimensions and performance

characteristics, resulting in changes to

steering, handling, and braking of your

vehicle. This can cause unpredictable

handling and stress to steering and

suspension components. You could lose

control and have a collision resulting in

serious injury or death. Use only the tire and

wheel sizes with load ratings approved for

your vehicle.

7

20_DJD2_OM_EN_USC_t.book Page 439

Page 443 of 568

SERVICING AND MAINTENANCE441

SPARE TIRES — IF EQUIPPED

Refer to the “Towing Requirements - Tires” in

“Starting And Operating” for restrictions when

towing with a spare tire designated for

temporary emergency use.

Spare Tire Matching Original Equipped Tire

And Wheel — If Equipped

Your vehicle may be equipped with a spare tire

and wheel equivalent in look and function to the

original equipment tire and wheel found on the

front or rear axle of your vehicle. This spare tire

may be used in the tire rotation for your vehicle.

If your vehicle has this option, refer to an

authorized tire dealer for the recommended tire

rotation pattern.

Compact Spare Tire — If Equipped

The compact spare is for temporary emergency

use only. You can identify if your vehicle is

equipped with a compact spare by looking at

the spare tire description on the Tire and

Loading Information Placard located on the

driver’s side door opening or on the sidewall of

the tire. Compact spare tire descriptions begin

with the letter “T” or “S” preceding the size

designation. Example: T145/80D18 103M.

T, S = Temporary Spare Tire

Since this tire has limited tread life, the original

equipment tire should be repaired (or replaced)

and reinstalled on your vehicle at the first

opportunity.

Do not install a wheel cover or attempt to mount

a conventional tire on the compact spare wheel,

since the wheel is designed specifically for the

compact spare tire. Do not install more than

one compact spare tire and wheel on the

vehicle at any given time.

Collapsible Spare Tire — If Equipped

The collapsible spare is for temporary

emergency use only. You can identify if your

vehicle is equipped with a collapsible spare by

looking at the spare tire description on the Tire

and Loading Information Placard located on the

driver’s side door opening or on the sidewall of

the tire.

Collapsible spare tire description example:

165/80-17 101P.

CAUTION!

Because of the reduced ground clearance, do

not take your vehicle through an automatic

car wash with a compact or limited use

temporary spare installed. Damage to the

vehicle may result.

WARNING!

Compact and collapsible spares are for

temporary emergency use only. With these

spares, do not drive more than 50 mph

(80 km/h). Temporary use spares have

limited tread life. When the tread is worn to

the tread wear indicators, the temporary use

spare tire needs to be replaced. Be sure to

follow the warnings, which apply to your

spare. Failure to do so could result in spare

tire failure and loss of vehicle control.

7

20_DJD2_OM_EN_USC_t.book Page 441