tire type Ram 3500 Chassis Cab 2019 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2019, Model line: 3500 Chassis Cab, Model: Ram 3500 Chassis Cab 2019Pages: 607, PDF Size: 10.72 MB

Page 352 of 607

350 STARTING AND OPERATING

GAIN Adjustment Buttons (+/-)

Pushing these buttons will adjust the brake control power

output to the trailer brakes in 0.5 increments. The GAIN

setting can be increased to a maximum of 10 or decreased to

a minimum of 0 (no trailer braking).

GAIN

The GAIN setting is used to set the trailer brake control for

the specific towing condition and should be changed as

towing conditions change. Changes to towing conditions

include trailer load, vehicle load, road conditions and

weather.

Adjusting GAIN

NOTE:

This should only be performed in a traffic free environment

at speeds of approximately 20–25 mph (30–40 km/h).

1. Make sure the trailer brakes are in good working condi-

tion, functioning normally and properly adjusted. See

your trailer dealer if necessary.

2. Hook up the trailer and make the electrical connections according to the trailer manufacturer's instructions. 3. When a trailer with electric/EOH brakes is plugged in,

the trailer connected message should appear in the

instrument cluster display (if the connection is not recog -

nized by the ITBM, braking functions will not be avail -

able), the GAIN setting will illuminate and the correct

type of trailer must be selected from the instrument

cluster display options.

4. Push the UP or DOWN button on the steering wheel until “TRAILER TOW” appears on the screen.

5. Push the RIGHT arrow on the steering wheel to enter “TRAILER TOW”.

6. Push the UP or DOWN buttons until the Trailer Brake Type appears on the screen.

7. Push the RIGHT arrow and then push the UP or DOWN buttons until the proper Trailer Brake Type appears on

the screen.

8. In a traffic-free environment, tow the trailer on a dry, level surface at a speed of 20–25 mph (30–40 km/h) and

squeeze the manual brake control lever completely.

9. If the trailer wheels lockup (indicated by squealing tires), reduce the GAIN setting; if the trailer wheels turn freely,

increase the GAIN setting.

Page 457 of 607

SERVICING AND MAINTENANCE 455

Fuel Economy

Underinflated tires will increase tire rolling resistance

resulting in higher fuel consumption.

Tread Wear

Improper cold tire inflation pressures can cause abnormal

wear patterns and reduced tread life, resulting in the need

for earlier tire replacement.

Ride Comfort And Vehicle Stability

Proper tire inflation contributes to a comfortable ride.

Over-inflation produces a jarring and uncomfortable ride.

Tire Inflation Pressures

The proper cold tire inflation pressure is listed on the driver's

side B-Pillar or rear edge of the driver's side door.

At least once a month:

• Check and adjust tire pressure with a good qualitypocket-type pressure gauge. Do not make a visual judge -

ment when determining proper inflation. Tires may look

properly inflated even when they are under-inflated.

• Inspect tires for signs of tire wear or visible damage. Inflation pressures specified on the placard are always “cold

tire inflation pressure”. Cold tire inflation pressure is

defined as the tire pressure after the vehicle has not been

driven for at least three hours, or driven less than 1 mile

(1.6 km) after sitting for a minimum of three hours. The cold

tire inflation pressure must not exceed the maximum infla

-

tion pressure molded into the tire sidewall.

Check tire pressures more often if subject to a wide range of

outdoor temperatures, as tire pressures vary with tempera -

ture changes.

Tire pressures change by approximately 1 psi (7 kPa) per 12°F

(7°C) of air temperature change. Keep this in mind when

checking tire pressure inside a garage, especially in the Winter.

Example: If garage temperature = 68°F (20°C) and the

outside temperature = 32°F (0°C) then the cold tire inflation

pressure should be increased by 3 psi (21 kPa), which equals

1 psi (7 kPa) for every 12°F (7°C) for this outside temperature

condition. CAUTION!

After inspecting or adjusting the tire pressure, always

reinstall the valve stem cap. This will prevent moisture

and dirt from entering the valve stem, which could

damage the valve stem.

7

Page 458 of 607

456 SERVICING AND MAINTENANCE

Tire pressure may increase from 2 to 6 psi (13 to 40 kPa)

during operation. DO NOT reduce this normal pressure

build up or your tire pressure will be too low.

Tire Pressures For High Speed Operation

The manufacturer advocates driving at safe speeds and

within posted speed limits. Where speed limits or conditions

are such that the vehicle can be driven at high speeds, main-

taining correct tire inflation pressure is very important.

Increased tire pressure and reduced vehicle loading may be

required for high-speed vehicle operation. Refer to an autho -

rized tire dealer or original equipment vehicle dealer for

recommended safe operating speeds, loading and cold tire

inflation pressures. Radial Ply Tires

Tire Repair

If your tire becomes damaged, it may be repaired if it meets

the following criteria:

• The tire has not been driven on when flat.

• The damage is only on the tread section of your tire (side

-

wall damage is not repairable).

• The puncture is no greater than a ¼ of an inch (6 mm).

Consult an authorized tire dealer for tire repairs and addi -

tional information.

Damaged Run Flat tires, or Run Flat tires that have experi -

enced a loss of pressure should be replaced immediately

with another Run Flat tire of identical size and service

description (Load Index and Speed Symbol). Replace the tire

pressure sensor as well as it is not designed to be reused.

WARNING!

High speed driving with your vehicle under maximum

load is dangerous. The added strain on your tires could

cause them to fail. You could have a serious collision. Do

not drive a vehicle loaded to the maximum capacity at

continuous speeds above 75 mph (120 km/h).

WARNING!

Combining radial ply tires with other types of tires on

your vehicle will cause your vehicle to handle poorly.

The instability could cause a collision. Always use radial

ply tires in sets of four. Never combine them with other

types of tires.

Page 462 of 607

460 SERVICING AND MAINTENANCE

Tire Types

All Season Tires — If Equipped

All Season tires provide traction for all seasons (Spring,

Summer, Fall, and Winter). Traction levels may vary

between different all season tires. All season tires can be

identified by the M+S, M&S, M/S or MS designation on the

tire sidewall. Use all season tires only in sets of four; failure

to do so may adversely affect the safety and handling of your

vehicle.Summer Or Three Season Tires — If Equipped

Summer tires provide traction in both wet and dry condi

-

tions, and are not intended to be driven in snow or on ice. If

your vehicle is equipped with Summer tires, be aware these

tires are not designed for Winter or cold driving conditions.

Install Winter tires on your vehicle when ambient tempera -

tures are less than 40°F (5°C) or if roads are covered with ice

or snow. For more information, contact an authorized dealer.

Summer tires do not contain the all season designation or

mountain/snowflake symbol on the tire sidewall. Use

Summer tires only in sets of four; failure to do so may

adversely affect the safety and handling of your vehicle.

• Never use a tire with a smaller load index or capacity,

other than what was originally equipped on your

vehicle. Using a tire with a smaller load index could

result in tire overloading and failure. You could lose

control and have a collision.

• Failure to equip your vehicle with tires having adequate speed capability can result in sudden tire

failure and loss of vehicle control.

CAUTION!

Replacing original tires with tires of a different size may

result in false speedometer and odometer readings.

WARNING! (Continued)

WARNING!

Do not use Summer tires in snow/ice conditions. You

could lose vehicle control, resulting in severe injury or

death. Driving too fast for conditions also creates the

possibility of loss of vehicle control.

Page 463 of 607

SERVICING AND MAINTENANCE 461

Snow Tires

Some areas of the country require the use of snow tires

during the Winter. Snow tires can be identified by a “moun-

tain/snowflake” symbol on the tire sidewall.

If you need snow tires, select tires equivalent in size

and type to the original equipment tires. Use snow

tires only in sets of four; failure to do so may

adversely affect the safety and handling of your vehicle.

Snow tires generally have lower speed ratings than what was

originally equipped with your vehicle and should not be

operated at sustained speeds over 75 mph (120 km/h). For speeds above 75 mph (120 km/h) refer to original equipment

or an authorized tire dealer for recommended safe operating

speeds, loading and cold tire inflation pressures.

While studded tires improve performance on ice, skid and

traction capability on wet or dry surfaces may be poorer than

that of non-studded tires. Some states prohibit studded tires;

therefore, local laws should be checked before using these

tire types.Spare Tires — If Equipped

NOTE:

For vehicles equipped with Tire Service Kit instead of a spare

tire, please refer to “Tire Service Kit” in “In Case Of Emer -

gency” for further information.

Refer to the “Towing Requirements - Tires” in “Starting And

Operating” for restrictions when towing with a spare tire

designated for temporary emergency use.

Spare Tire Matching Original Equipped Tire And Wheel

— If Equipped

Your vehicle may be equipped with a spare tire and wheel

equivalent in look and function to the original equipment

tire and wheel found on the front or rear axle of your vehicle.

This spare tire may be used in the tire rotation for your

vehicle. If your vehicle has this option, refer to an authorized

tire dealer for the recommended tire rotation pattern.

CAUTION!

Because of the reduced ground clearance, do not take

your vehicle through an automatic car wash with a

compact or limited use temporary spare installed.

Damage to the vehicle may result.

7

Page 467 of 607

SERVICING AND MAINTENANCE 465

Dark Vapor Chrome, Black Satin Chrome, or Low Gloss

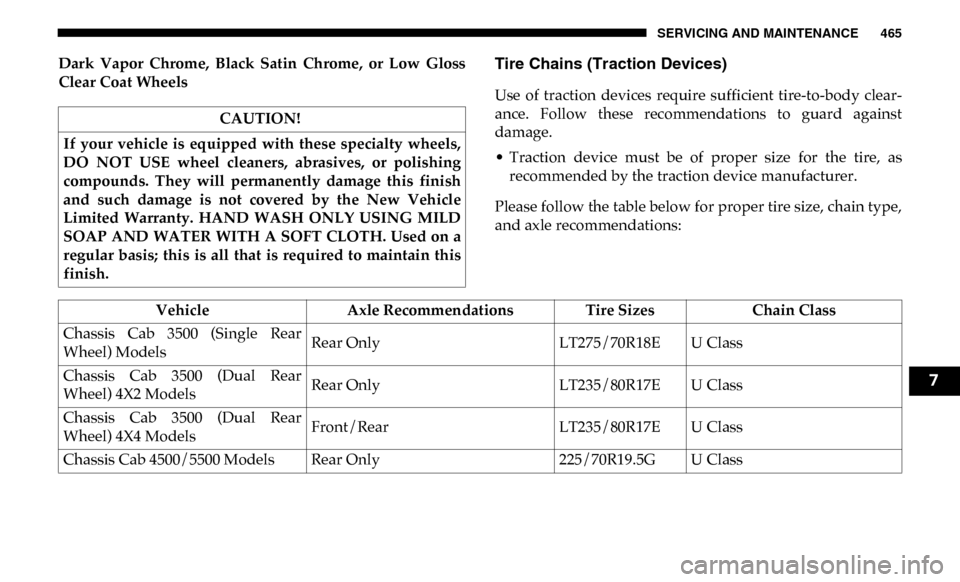

Clear Coat WheelsTire Chains (Traction Devices)

Use of traction devices require sufficient tire-to-body clear-

ance. Follow these recommendations to guard against

damage.

• Traction device must be of proper size for the tire, as recommended by the traction device manufacturer.

Please follow the table below for proper tire size, chain type,

and axle recommendations:

CAUTION!

If your vehicle is equipped with these specialty wheels,

DO NOT USE wheel cleaners, abrasives, or polishing

compounds. They will permanently damage this finish

and such damage is not covered by the New Vehicle

Limited Warranty. HAND WASH ONLY USING MILD

SOAP AND WATER WITH A SOFT CLOTH. Used on a

regular basis; this is all that is required to maintain this

finish.

Vehicle Axle Recommendations Tire Sizes Chain Class

Chassis Cab 3500 (Single Rear

Wheel) Models Rear Only

LT275/70R18E U Class

Chassis Cab 3500 (Dual Rear

Wheel) 4X2 Models Rear Only

LT235/80R17E U Class

Chassis Cab 3500 (Dual Rear

Wheel) 4X4 Models Front/Rear

LT235/80R17E U Class

Chassis Cab 4500/5500 Models Rear Only 225/70R19.5G U Class

7

Page 468 of 607

466 SERVICING AND MAINTENANCE

(Continued)

Tire Rotation Recommendations

Tires on the front and rear axles of vehicles operate at

different loads and perform different steering, driving, and

braking functions. For these reasons, they wear at unequal

rates.

These effects can be reduced by timely rotation of tires. The

benefits of rotation are especially worthwhile with aggres-

sive tread designs such as those on On/Off Road type tires.

Rotation will increase tread life, help to maintain mud, snow,

and wet traction levels, and contribute to a smooth, quiet

ride.

WARNING!

Using tires of different size and type (M+S, Snow)

between front and rear axles can cause unpredictable

handling. You could lose control and have a collision.

CAUTION!

To avoid damage to your vehicle or tires, observe the

following precautions:

• Because of restricted traction device clearance between tires and other suspension components, it is important

that only traction devices in good condition are used.

Broken devices can cause serious damage. Stop the

vehicle immediately if noise occurs that could indicate

device breakage. Remove the damaged parts of the

device before further use.

• Install device as tightly as possible and then retighten after driving about ½ mile (0.8 km).

• Do not exceed 30 mph (48 km/h).

• Drive cautiously and avoid severe turns and large bumps, especially with a loaded vehicle.

• Do not drive for a prolonged period on dry pavement.

• Observe the traction device manufacturer’s instruc -

tions on the method of installation, operating speed,

and conditions for use. Always use the suggested oper -

ating speed of the device manufacturer’s if it is less

than 30 mph (48 km/h).

• Do not use traction devices on a compact spare tire. CAUTION!

(Continued)

Page 469 of 607

SERVICING AND MAINTENANCE 467

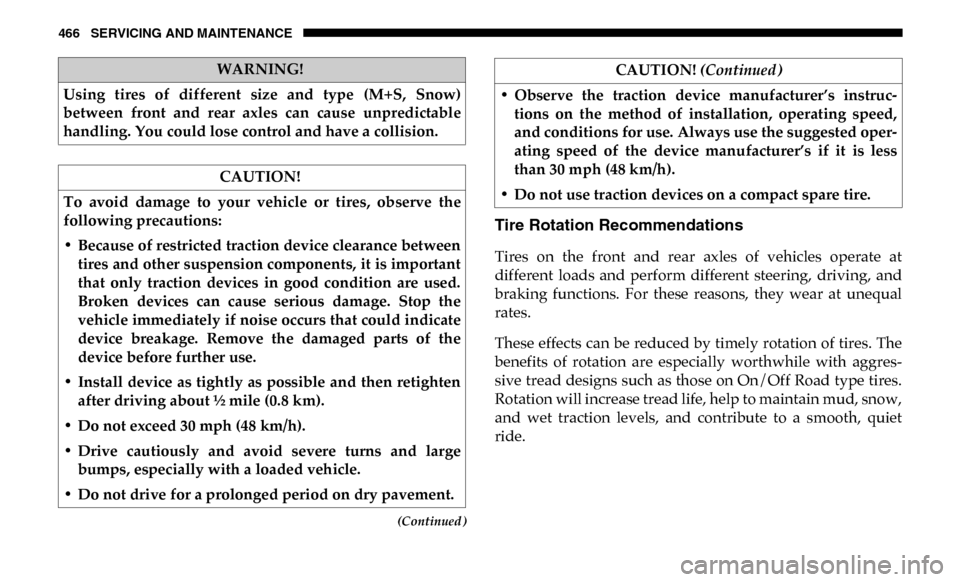

Refer to the “Maintenance Plan” for the proper maintenance

intervals. More frequent rotation is permissible if desired.

The reasons for any rapid or unusual wear should be

corrected prior to rotation being performed.Tire Rotation

NOTE:

On Canadian vehicles only, if your vehicle is equipped with

All-Season type tires on the front and On/Off Road type tires

mounted on the rear, do not use a front to back rotation

pattern. Instead, rotate your tires side to side at the recom -

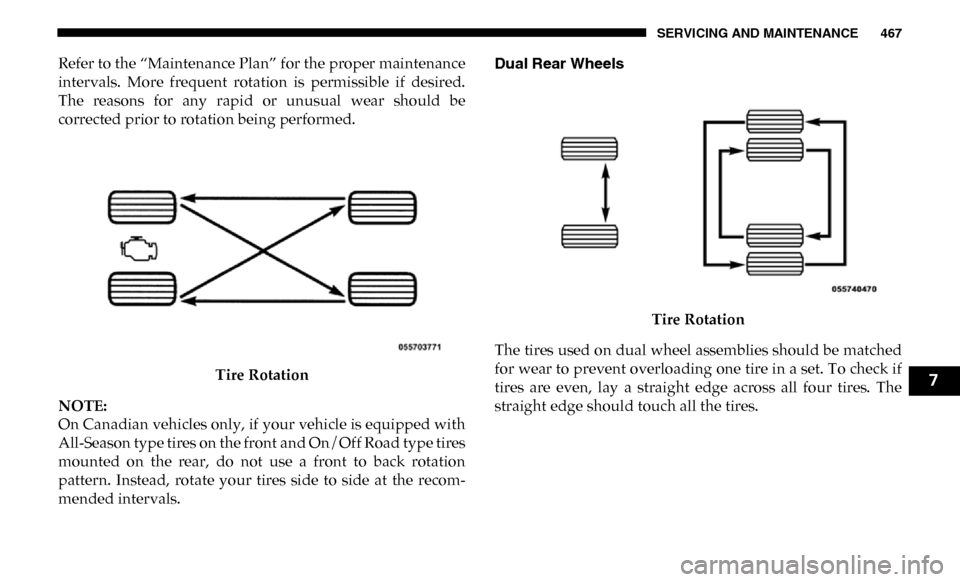

mended intervals. Dual Rear Wheels

Tire Rotation

The tires used on dual wheel assemblies should be matched

for wear to prevent overloading one tire in a set. To check if

tires are even, lay a straight edge across all four tires. The

straight edge should touch all the tires.

7

Page 479 of 607

TECHNICAL SPECIFICATIONS 477

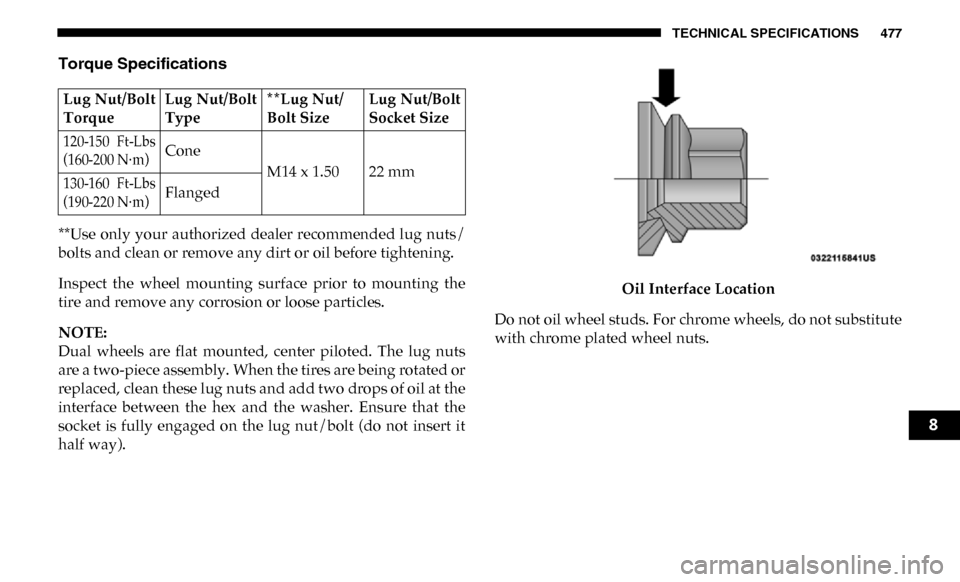

Torque Specifications

**Use only your authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.

Inspect the wheel mounting surface prior to mounting the

tire and remove any corrosion or loose particles.

NOTE:

Dual wheels are flat mounted, center piloted. The lug nuts

are a two-piece assembly. When the tires are being rotated or

replaced, clean these lug nuts and add two drops of oil at the

interface between the hex and the washer. Ensure that the

socket is fully engaged on the lug nut/bolt (do not insert it

half way). Oil Interface Location

Do not oil wheel studs. For chrome wheels, do not substitute

with chrome plated wheel nuts.

Lug Nut/Bolt

Torque

Lug Nut/Bolt

Type**Lug Nut/

Bolt SizeLug Nut/Bolt

Socket Size

120-150 Ft-Lbs

(160-200 N·m)

Cone

M14 x 1.50 22 mm

130-160 Ft-Lbs

(190-220 N·m)

Flanged

8

Page 497 of 607

MULTIMEDIA 495

NOTE:

When the vehicle is shifted out of REVERSE (with camera delay turned OFF), the rear camera mode is exited and the navi-

gation or audio screen appears again. When the vehicle is shifted out of REVERSE (with camera delay turned ON), the rear

view image with dynamic grid lines will be displayed for up to ten seconds after shifting out of REVERSE unless the forward

vehicle speed exceeds 8 mph (12 km/h), the transmission is shifted into PARK or the ignition is switched to the OFF position.

Forward Facing Camera

Guidelines — If Equipped On

Off

NOTE:

The “Forward Facing Camera Guidelines” feature is an off-road type of feature that shows the path of the tires based on the

steering wheel input.

CHMSL (Center High

Mounted Stop Lamp) Camera

Dynamic Centerline — If

Equipped

On

Off

NOTE:

When the “CHMSL Camera Dynamic Centerline” feature is selected, it will assist in backing up for trailer alignment and

hook up.

Rain Sensing Auto Wipers

— If Equipped On

Off

NOTE:

When the “Rain Sensing Auto Wipers” feature is selected, the system automatically activates the windshield wipers if it

senses moisture on the windshield. Setting Name

Selectable Options

9