torque Ram 3500 Chassis Cab 2019 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2019, Model line: 3500 Chassis Cab, Model: Ram 3500 Chassis Cab 2019Pages: 607, PDF Size: 10.72 MB

Page 283 of 607

STARTING AND OPERATING 281

LIMITED-SLIP DIFFERENTIAL

The limited-slip differential provides additional traction on

snow, ice, mud, sand and gravel, particularly when there is

a difference between the traction characteristics of the

surface under the right and left rear wheels. During normal

driving and cornering, the limited-slip unit performs simi-

larly to a conventional differential. On slippery surfaces,

however, the differential delivers more of the driving effort

to the rear wheel having the better traction.

The limited-slip differential is especially helpful during slip -

pery driving conditions. With both rear wheels on a slippery

surface, a slight application of the accelerator will supply

maximum traction. When starting with only one rear wheel

on an excessively slippery surface, slight momentary appli -

cation of the parking brake may be necessary to gain

maximum traction. Care should be taken to avoid sudden accelerations when

both rear wheels are on a slippery surface. This could cause

both rear wheels to spin, and allow the vehicle to slide side

-

ways on the crowned surface of a road or in a turn.

POWER TAKE OFF OPERATION — IF EQUIPPED

(CHASSIS CAB ONLY)

This vehicle when equipped with PTO Prep and the AS66RC

automatic six-speed, will allow for an aftermarket upfit with

a transmission driven PTO (power take off). The customer

will have the ability to operate the PTO in either a

“stationary” or “mobile” mode. The vehicles will be factory

set to the “stationary” mode. To select “mobile” mode, you

will need to enter the commercial vehicle menu on the instru-

ment cluster screen and select mobile PTO mode. Details of

the PTO selection modes and further PTO information is

available at the Ram Truck Bodybuilders web site:

www.rambodybuilder.com .

AS66RC Six-Speed Automatic Transmission Only

The PTO drive gear (part of the AS66RC) operates at torque

converter turbine speed. The turbine speed will be less than

engine speed when the torque converter clutch is not

engaged and will be same as engine speed when the torque

converter clutch is engaged.

WARNING!

On vehicles equipped with a limited-slip differential

never run the engine with one rear wheel off the ground

since the vehicle may drive through the rear wheel

remaining on the ground. You could lose control of the

vehicle.

5

Page 284 of 607

282 STARTING AND OPERATING

Stationary Mode

To operate the PTO in this mode the vehicle must meet the

following conditions:

• Transmission in PARK position.

• PTO switch has been activated.

• Brake pedal must not be applied.

• Vehicle engine must be running.

• No vehicle, or brake faults present.

• PTO must be correctly installed using the vehicle providedcircuits.

The instrument cluster will display a "PTO On" message for

five seconds if the above conditions are met. Otherwise, the

instrument cluster will display a message "To Operate PTO

Shift To Park" indicating what operator action should be

taken to engage the PTO mode.

The customer has the choice to operate the PTO by utilizing

the cruise control switches or by utilizing a remote control

(provided by the PTO supplier). To operate the feature using

the cruise control switches, the customer must first activate

the PTO switch which will turn on the PTO. In order to

increase or decrease the engine idle speed, to optimize the

PTO function, the “RESUME/ACCEL” and “DECEL” cruise switches can be used respectively. To disengage PTO opera

-

tion and return to “standard vehicle operation” simply

toggle the PTO switch to the OFF position.

The torque converter clutch (TCC) will automatically engage

at engine speeds above 1,200 RPM (engine speed) in PTO

stationary mode. Once engaged, the TCC will remain

applied and will not disengage until the engine speed falls

below 1,000 RPM. TCC engagement is desirable for certain

types of PTO applications (Automatic Transmission Only).

To operate the PTO via a remote switch, the customer must

make sure the above conditions are met. It is vital for proper

operation that the PTO and remote have been installed

correctly, paying special attention to ensure the vehicle

provided wiring has been connected properly. This is the

responsibility of the installer of the PTO and switches/

remote system. It is the responsibility of the PTO manufac -

turer to ensure that their electrical (switches and remote)

system is compatible with the vehicle’s electrical architecture

and software functionality.

NOTE:

Single set speed can be programmed via the PTO menu on

the instrument cluster display. Further details are available

at the Ram Truck Bodybuilders web site located at rambody-

builder.com

Page 397 of 607

IN CASE OF EMERGENCY 395

5. Remove the lug nuts and pull the wheel off. Install thespare wheel and lug nuts with the cone shaped end of the

nuts toward the wheel on single rear wheel (SRW)

models. On dual rear wheel models (DRW) the lug nuts

are a two-piece assembly with a flat face. Lightly tighten

the nuts. To avoid risk of forcing the vehicle off the jack,

do not fully tighten the nuts until the vehicle has been

lowered.

6. Using the lug wrench, finish tightening the nuts using a crisscross pattern. For the proper lug nut torque specifica -

tions refer to “Wheel And Tire Torque Specifications” in

“Technical Specifications.” If in doubt about the correct

tightness, have them checked with a torque wrench by an

authorized dealer or at a service station. 7. Install wheel center cap (if equipped) and remove wheel

blocks. Do not install chrome or aluminum wheel center

caps on the spare wheel. This may result in cap damage.

8. Lower the jack to its fully closed position. If the jack will not lower by turning the dial (thumbwheel) by hand, it

may be necessary to use the jack driver in order to lower

the jack. Stow the replaced tire, jack, and tools as previ -

ously described.

9. Adjust the tire pressure when possible.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.WARNING!

A loose tire or jack thrown forward in a collision or hard

stop, could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided.

6

Page 398 of 607

396 IN CASE OF EMERGENCY

Dual Rear Wheels

Slots in the wheels will assist in properly orienting the inner

and outer wheels. Align these slots when assembling the

wheels for best access to the tire valve on the inner wheel.

The tires of both dual wheels must be completely off the

ground when tightening to insure wheel centering and

maximum wheel clamping.

Dual wheel models require a special heavy-duty lug nut

tightening adapter (included with the vehicle) to correctly

tighten the lug nuts. Also, when it is necessary to remove and

install dual rear wheels, use a proper vehicle lifting device.

NOTE:

When installing a spare tire (if equipped) as part of a dual

rear wheel end combination, the tire diameter of the two

individual tires must be compared. If there is a significant

difference, the larger tire should be installed in a front loca-

tion. The correct direction of rotation for dual tire installa -

tions must also be observed

It is recommended that wheel stud nuts be kept torqued to

specifications at all times. Torque wheel stud nuts to specifi -

cations at each lubrication interval.

Refer to “Wheel And Tire Torque Specifications” in “Tech -

nical Specifications” for further information. Wheel Nuts

All wheel nuts should be tightened occasionally to eliminate

the possibility of wheel studs being sheared or the bolt holes

in the wheels becoming elongated. This is especially

important during the first few hundred miles/kilometers of

operation to allow the wheel nuts to become properly set. All

wheel nuts should first be firmly seated against the wheel.

The wheel nuts should then be tightened to recommended

torque. Tighten the wheel nuts to final torque in increments.

Progress around the bolt circle, tightening the wheel nut

opposite to the wheel nut just previously tightened until

final torque is achieved.

Refer to “Wheel And Tire Torque Specifications” in “Tech

-

nical Specifications” for further information.

To Stow The Flat Or Spare — If Equipped

Refer to Upfitters Body Builder’s Guide for information on

stowing your spare tire (if equipped).

Page 441 of 607

SERVICING AND MAINTENANCE 439

Automatic Transmission

Selection Of Lubricant

It is important to use the proper transmission fluid to ensure

optimum transmission performance and life. Use only the

manufacturer’s specified transmission fluid. Refer to “Fluids

And Lubricants” in “Technical Specifications”. It is

important to maintain the transmission fluid at the correct

level using the recommended fluid. No chemical flushes

should be used in any transmission; only the approved lubri-

cant should be used. Special Additives

The manufacturer strongly recommends against using any

special additives in the transmission. Automatic Transmis

-

sion Fluid (ATF) is an engineered product and its perfor -

mance may be impaired by supplemental additives.

Therefore, do not add any fluid additives to the transmis -

sion. The only exception to this policy is the use of special

dyes for diagnosing fluid leaks in six-speed transmissions.

Avoid using transmission sealers as they may adversely

affect seals.

• Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts, causing the

brake fluid to catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

• Do not allow petroleum based fluid to contaminate the brake fluid. Brake seal components could be damaged,

causing partial or complete brake failure. This could

result in a collision.

WARNING! (Continued)CAUTION!

Using a transmission fluid other than the manufacturer’s

recommended fluid may cause deterioration in

transmission shift quality and/or torque converter

shudder, and (for six-speed transmissions) will require

more frequent fluid and filter changes. Refer to “Fluids

And Lubricants” in “Technical Specifications” for fluid

specifications.

7

Page 478 of 607

476 TECHNICAL SPECIFICATIONS

BRAKE SYSTEM

If power assist is lost for any reason (for example, repeated

brake applications with the engine off), the brakes will still

function. However, you will experience a substantial

increase in braking effort to stop the vehicle.

If either the front or rear hydraulic system loses normal

braking capability, the remaining system will still function

with some loss of overall braking effectiveness. This will be

evident by increased pedal travel during application, greater

pedal force required to slow or stop, and activation of the

“Brake Warning Light” and the “ABS Warning Light” (if

equipped) during brake use.

The brake system power assist is provided by a hydro-boost

unit which shares fluid with the power steering system. You

may experience some clicking or hissing noises from the

hydro-boost system during hard braking conditions.

NOTE:

Under cold temperatures, pedal effort will be higher than

normal until the power steering fluid reaches operating

temperature.

Hydraulic Brake Assist

The brake system power assist is provided by a hydro-boost

unit which shares fluid with the power steering system. You

may experience some clicking or hissing noises from the

hydro-boost system during hard braking conditions.

NOTE:

Under cold temperatures, pedal effort will be higher than

normal until the power steering fluid reaches operating

temperature.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure that

the wheel is properly mounted to the vehicle. Any time a

wheel has been removed and reinstalled on the vehicle, the

lug nuts/bolts should be torqued using a properly calibrated

torque wrench using a high quality six sided (hex) deep wall

socket.

Page 479 of 607

TECHNICAL SPECIFICATIONS 477

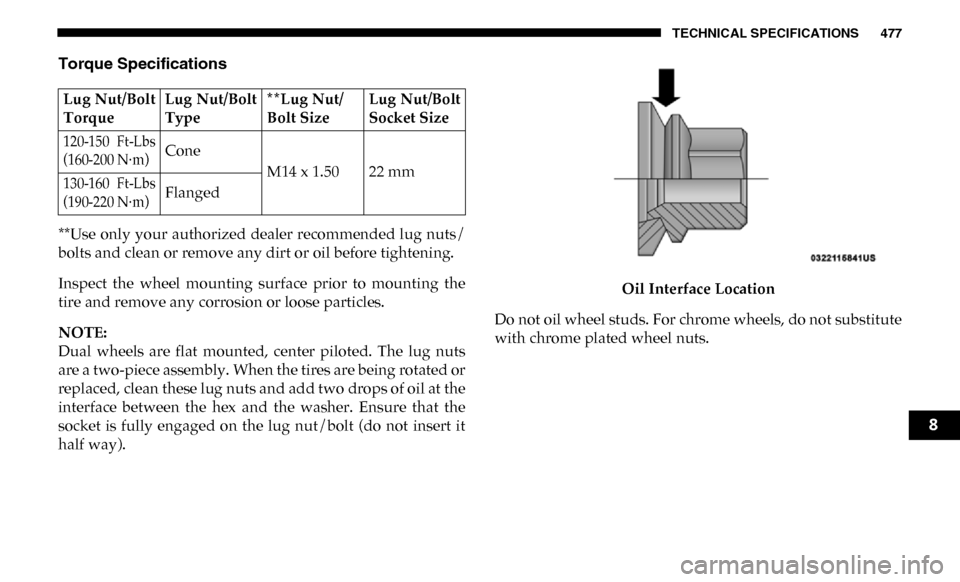

Torque Specifications

**Use only your authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.

Inspect the wheel mounting surface prior to mounting the

tire and remove any corrosion or loose particles.

NOTE:

Dual wheels are flat mounted, center piloted. The lug nuts

are a two-piece assembly. When the tires are being rotated or

replaced, clean these lug nuts and add two drops of oil at the

interface between the hex and the washer. Ensure that the

socket is fully engaged on the lug nut/bolt (do not insert it

half way). Oil Interface Location

Do not oil wheel studs. For chrome wheels, do not substitute

with chrome plated wheel nuts.

Lug Nut/Bolt

Torque

Lug Nut/Bolt

Type**Lug Nut/

Bolt SizeLug Nut/Bolt

Socket Size

120-150 Ft-Lbs

(160-200 N·m)

Cone

M14 x 1.50 22 mm

130-160 Ft-Lbs

(190-220 N·m)

Flanged

8

Page 480 of 607

478 TECHNICAL SPECIFICATIONS

Wheel Mounting Surface

Retighten the wheel nuts in the same sequence to the torques

listed in the table. Go through the sequence a second time to

verify that specific torque has been achieved. Retighten to

specifications after 25 miles (40 km) and check the lug nut/

bolt torque to be sure that all the lug nuts/bolts are properly

seated against the wheel. 8/10 Lug Nuts/Bolts Torque Patterns

It is recommended that wheel stud nuts be kept torqued to

specifications at all times. Torque wheel stud nuts to specifi -

cations at each lubrication interval.

All wheel nuts should be tightened occasionally to eliminate

the possibility of wheel studs being sheared or the bolt holes

in the wheels becoming elongated. This is especially

important during the first few hundred miles/kilometers of

operation to allow the wheel nuts to become properly set. All

wheel nuts should first be firmly seated against the wheel.

1 — 10 Bolt Pattern

2 — 8 Bolt Pattern

Page 481 of 607

TECHNICAL SPECIFICATIONS 479

The wheel nuts should then be tightened to recommended

torque. Tighten the wheel nuts to final torque in increments.

Progress around the bolt circle, tightening the wheel nut

opposite to the wheel nut just previously tightened until

final torque is achieved.

FUEL REQUIREMENTS

6.4L Engine

Do not use E-85 flex fuel or ethanol blends greater than 15%

in this engine.This engines is designed to meet all emissions regu -

lations and provide satisfactory fuel economy and

performance when using high quality unleaded

gasoline having a posted octane number range of 87 to 89 as

specified by the (R+M)/2 method. The use of 89 octane

“Plus” gasoline is recommended for optimum performance

and fuel economy. While operating on gasoline with an octane number of 87,

hearing a light knocking sound from the engine is not a cause

for concern. However, if the engine is heard making a heavy

knocking sound, see your dealer immediately. Use of gaso

-

line with an octane number lower than 87 can cause engine

failure and may void or not be covered by the New Vehicle

Limited Warranty.

Poor quality gasoline can cause problems such as hard

starting, stalling, and hesitations. If you experience these

symptoms, try another brand of gasoline before considering

service for the vehicle.

Reformulated Gasoline

Many areas of the country require the use of cleaner burning

gasoline referred to as “Reformulated Gasoline”. Reformu-

lated gasoline contains oxygenates and are specifically

blended to reduce vehicle emissions and improve air quality.

The use of reformulated gasoline is recommended. Properly

blended reformulated gasoline will provide improved

performance and durability of engine and fuel system

components.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the lug nuts/bolts fully until the vehicle has

been lowered. Failure to follow this warning may result

in personal injury.

8

Page 494 of 607

492 MULTIMEDIA

Voice

After pressing the “Voice” button on the touchscreen, the following settings will be available:

Clock

After pressing the “Clock” button on the touchscreen, the following settings will be available:Power — If Equipped

HP (US)HP (UK) Kw

Temperature °C °F

Torque — If Equipped lb-ft Nm

Setting Name

Selectable Options

Setting NameSelectable Options

Voice Response Length Brief Detailed

Show Command List AlwaysWith Help Never

Setting Name Selectable Options

Set Time 12 hour24 hour

NOTE:

Within the “Set Time” feature, press the corresponding arrow above and below the current time to adjust, then select “AM”

or “PM.”