lock Ram 3500 Chassis Cab 2020 Manual Online

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 3500 Chassis Cab, Model: Ram 3500 Chassis Cab 2020Pages: 516, PDF Size: 29.24 MB

Page 311 of 516

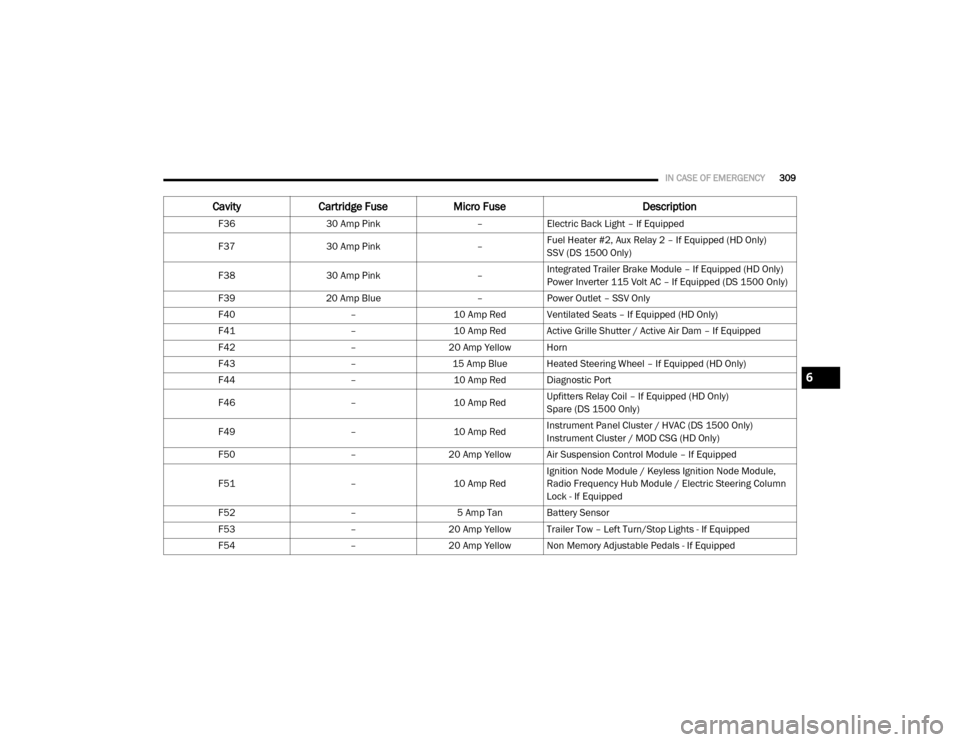

IN CASE OF EMERGENCY309

F3630 Amp Pink –Electric Back Light – If Equipped

F37 30 Amp Pink –Fuel Heater #2, Aux Relay 2 – If Equipped (HD Only)

SSV (DS 1500 Only)

F38 30 Amp Pink –Integrated Trailer Brake Module – If Equipped (HD Only)

Power Inverter 115 Volt AC – If Equipped (DS 1500 Only)

F39 20 Amp Blue –Power Outlet – SSV Only

F40 –10 Amp Red Ventilated Seats – If Equipped (HD Only)

F41 –10 Amp Red Active Grille Shutter / Active Air Dam – If Equipped

F42 –20 Amp Yellow Horn

F43 –15 Amp Blue Heated Steering Wheel – If Equipped (HD Only)

F44 –10 Amp Red Diagnostic Port

F46 –10 Amp RedUpfitters Relay Coil – If Equipped (HD Only)

Spare (DS 1500 Only)

F49 –10 Amp RedInstrument Panel Cluster / HVAC (DS 1500 Only)

Instrument Cluster / MOD CSG (HD Only)

F50 –20 Amp Yellow Air Suspension Control Module – If Equipped

F51 –10 Amp RedIgnition Node Module / Keyless Ignition Node Module,

Radio Frequency Hub Module / Electric Steering Column

Lock - If Equipped

F52 –5 Amp Tan Battery Sensor

F53 –20 Amp Yellow Trailer Tow – Left Turn/Stop Lights - If Equipped

F54 –20 Amp Yellow Non Memory Adjustable Pedals - If Equipped

CavityCartridge Fuse Micro Fuse Description

6

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 309

Page 312 of 516

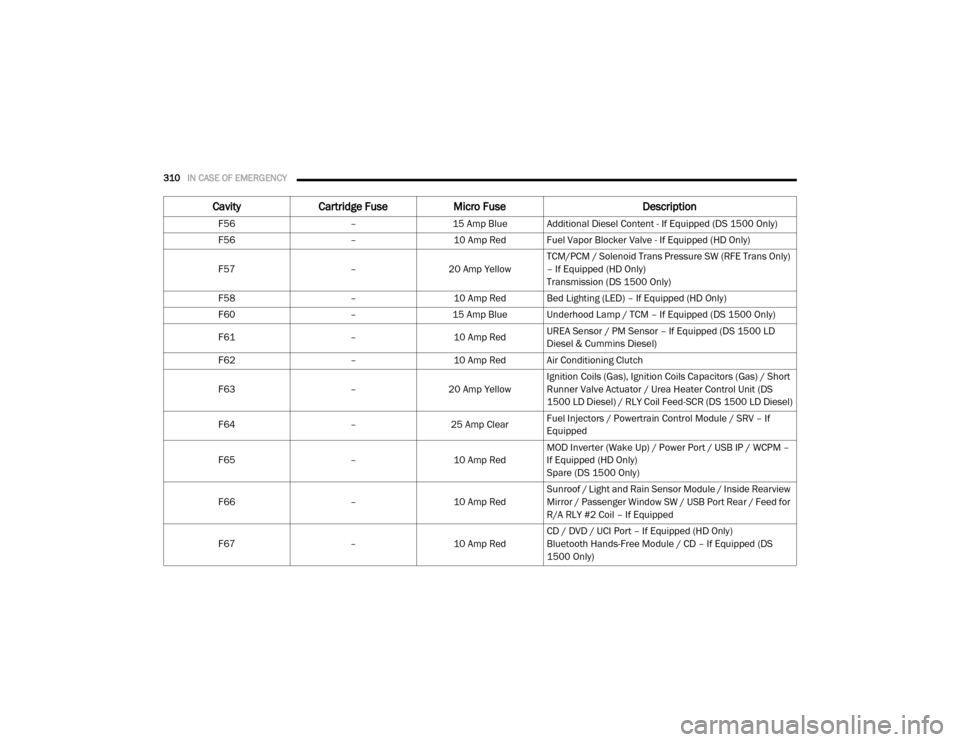

310IN CASE OF EMERGENCY

F56 –15 Amp Blue Additional Diesel Content - If Equipped (DS 1500 Only)

F56 –10 Amp Red Fuel Vapor Blocker Valve - If Equipped (HD Only)

F57 –20 Amp Yellow TCM/PCM / Solenoid Trans Pressure SW (RFE Trans Only)

– If Equipped (HD Only)

Transmission (DS 1500 Only)

F58 –10 Amp Red Bed Lighting (LED) – If Equipped (HD Only)

F60 –15 Amp Blue Underhood Lamp / TCM – If Equipped (DS 1500 Only)

F61 –10 Amp RedUREA Sensor / PM Sensor – If Equipped (DS 1500 LD

Diesel & Cummins Diesel)

F62 –10 Amp Red Air Conditioning Clutch

F63 –20 Amp Yellow Ignition Coils (Gas), Ignition Coils Capacitors (Gas) / Short

Runner Valve Actuator / Urea Heater Control Unit (DS

1500 LD Diesel) / RLY Coil Feed-SCR (DS 1500 LD Diesel)

F64 –25 Amp ClearFuel Injectors / Powertrain Control Module / SRV – If

Equipped

F65 –10 Amp RedMOD Inverter (Wake Up) / Power Port / USB IP / WCPM –

If Equipped (HD Only)

Spare (DS 1500 Only)

F66 –10 Amp RedSunroof / Light and Rain Sensor Module / Inside Rearview

Mirror / Passenger Window SW / USB Port Rear / Feed for

R/A RLY #2 Coil – If Equipped

F67 –10 Amp RedCD / DVD / UCI Port – If Equipped (HD Only)

Bluetooth Hands-Free Module / CD – If Equipped (DS

1500 Only)

Cavity

Cartridge Fuse Micro Fuse Description

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 310

Page 317 of 516

IN CASE OF EMERGENCY315

(Continued)

4500/5500 Models

These vehicles do not come equipped with a

jack.

NOTE:

Jacking and tire changing on 4500/

5500 models should be performed by an autho -

rized dealer, or knowledgeable service

personnel with the appropriate heavy duty

equipment, like a tire service company.

Preparations For Jacking

1. Park the vehicle on a firm, level surface. Avoid ice or slippery areas.

2. Place the gear selector into PARK. On four-wheel drive vehicles, shift the transfer

case to the 4L position.

3. Turn on the Hazard Warning flashers.

4. Apply the parking brake. 5. Turn the ignition OFF.

6. Block both the front and rear of the wheel

diagonally opposite the jacking position. For

example, if the driver’s front wheel is being

changed, block the passenger’s rear wheel.

Wheel Blocked

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being jacked.

Jacking Instructions 4500 And 5500 Series

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic. Pull far

enough off the road to avoid being hit when

operating the jack or changing the wheel.

WARNING!

Carefully follow these tire changing warnings

to help prevent personal injury or damage to

your vehicle:

Always park on a firm, level surface as far

from the edge of the roadway as possible

before raising the vehicle.

Turn on the Hazard Warning flashers.

Apply the parking brake firmly and set the

transmission in PARK.

Block the wheel diagonally opposite the

wheel to be raised.

Never start or run the engine with the

vehicle on a jack.

Do not let anyone sit in the vehicle when it

is on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised

vehicle, take it to a service center where it

can be raised on a lift.

6

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 315

Page 318 of 516

316IN CASE OF EMERGENCY

Jack Warning Label

1. If equipped, remove the spare wheel, jack,

and tools from storage.

2. Using the lug wrench, loosen, but do not remove, the lug nuts by turning them coun -

terclockwise one turn while the wheel is still

on the ground.

3. When changing the front wheel, assemble the jack driver to the jack and connect the

jack driver to the extension tube. Place the

jack under the axle as close to the tire as

possible with the jack driver extending to

the front. Connect the extension tubes and

lug wrench.

Front Jacking Locations

When changing a rear wheel, assemble the

jack driver to the jack and connect the jack

driver to the extension tubes. Securely

place the jack under the sway bar bracket (unless both tires are flat on one side, then

place jack under shock bracket) facing for

-

ward in vehicle. Connect the extension

tubes and lug wrench.

Rear Jacking Location

Before raising the wheel off the ground,

make sure that the jack will not damage

surrounding truck parts and adjust the jack

position as required.

NOTE:

If the jack will not lower by turning the dial

(thumbwheel) by hand, it may be necessary to

use the jack driver in order to lower the jack.

4. By rotating the lug wrench clockwise, raise the vehicle until the wheel just clears the

surface.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire

change.

If working on or near a roadway, be

extremely careful of motor traffic.

To assure that spare tires, flat or inflated,

are securely stowed, spares must be

stowed with the valve stem facing the

ground.

CAUTION!

Do not attempt to raise the vehicle by jacking

on locations other than those indicated in the

Jacking Instructions for this vehicle.

WARNING! (Continued)

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 316

Page 319 of 516

IN CASE OF EMERGENCY317

5. Remove the lug nuts and pull the wheel off.

Install the spare wheel and lug nuts with the

cone shaped end of the nuts toward the

wheel on Single Rear-Wheel (SRW) models.

On Dual Rear-Wheel models (DRW) the lug

nuts are a two-piece assembly with a flat

face. Lightly tighten the nuts. To avoid risk

of forcing the vehicle off the jack, do not

fully tighten the nuts until the vehicle has

been lowered.

6. Using the lug wrench, finish tightening the nuts using a crisscross pattern. For the

proper lug nut torque specifications refer to

“Wheel And Tire Torque Specifications” in

“Technical Specifications.” If in doubt about

the correct tightness, have them checked

with a torque wrench by an authorized

dealer or at a service station. 7. Install wheel center cap (if equipped) and

remove wheel blocks. Do not install chrome

or aluminum wheel center caps on the

spare wheel. This may result in cap damage.

8. Lower the jack to its fully closed position. If the jack will not lower by turning the dial

(thumbwheel) by hand, it may be necessary

to use the jack driver in order to lower the

jack. Stow the replaced tire, jack, and tools

as previously described.

9. Adjust the tire pressure when possible.

10. After 25 miles (40 km), check the lug nut torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

Dual Rear Wheels

Slots in the wheels will assist in properly

orienting the inner and outer wheels. Align

these slots when assembling the wheels for

best access to the tire valve on the inner wheel.

The tires of both dual wheels must be

completely off the ground when tightening to

insure wheel centering and maximum wheel

clamping.

Dual wheel models require a special heavy-duty

lug nut tightening adapter (included with the

vehicle) to correctly tighten the lug nuts. Also,

when it is necessary to remove and install dual

rear wheels, use a proper vehicle lifting device.

NOTE:

When installing a spare tire (if equipped) as part

of a dual rear wheel end combination, the tire

diameter of the two individual tires must be

compared. If there is a significant difference,

the larger tire should be installed in a front loca-

tion. The correct direction of rotation for dual

tire installations must also be observed.WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off

the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided.

6

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 317

Page 326 of 516

324IN CASE OF EMERGENCY

Follow these steps to activate the Manual Park

Release:

1. Firmly apply the parking brake.

2. Using a small screwdriver or similar tool,

remove the Manual Park Release access

cover, which is just above the parking brake

release handle, below and to the left of the

steering column.

3. Press and maintain firm pressure on the brake pedal.

4. Using the screwdriver or similar tool, push the Manual Park Release lever locking tab

(just below the middle of the lever) upwards.

5. While holding the locking tab in the disen -

gaged position, pull the tether strap to

rotate the lever rearward, until it locks in

place pointing towards the driver's seat.

Release the locking tab and verify that the

Manual Park Release lever is locked in the

released position. 6. The vehicle is now out of PARK and can be

towed. Release the parking brake only when

the vehicle is securely connected to a tow

vehicle.

To Reset The Manual Park Release:

1. Push the locking tab to the right, to unlock the lever.

2. Rotate the Manual Park Release lever forward to its original position, until the

locking tab snaps into place to secure the

lever.

3. Pull gently on the tether strap to confirm that the lever is locked in its stowed posi-

tion.

4. Re-install the access cover.FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or

snow, it can often be moved using a rocking

motion. Turn the steering wheel right and left to

clear the area around the front wheels. Then

shift back and forth between DRIVE (D) and

REVERSE (R), while gently pressing the acceler -

ator. Use the least amount of accelerator pedal

pressure that will maintain the rocking motion,

without spinning the wheels or racing the

engine.

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 324

Page 357 of 516

SERVICING AND MAINTENANCE355

If water is detected in the water separator while

the engine is running, or while the ignition

switch is in the ON position, the “Water In Fuel

Indicator Light” will illuminate and an audible

chime will be heard five times. At this point you

should stop the engine and drain the water from

both of the filters.

If the “Water In Fuel Indicator Light” comes on

and a single chime is heard while you are

driving, or with the ignition switch in the ON

position, there may be a problem with your

water separator wiring or sensor. See an autho -

rized dealer for service. Upon proper draining of the water from both

fuel filters, the “Water In Fuel Indicator Light”

will remain illuminated for approximately 10

seconds. If the water was drained while the

engine was running, the “Water In Fuel Indicator

Light” may remain on for approximately three

minutes.

NOTE:

Care should be taken in disposing of used fluids

from your vehicle. Used fluids, indiscriminately

discarded, can present a problem to the envi

-

ronment. Contact an authorized dealer, service

station, or government agency for advice on

recycling programs and for where used fluids

and filters can be properly disposed of in your

area.

Drain the fuel/water separator filters when the

“Water In Fuel Indicator Light” is ON. Within

10 minutes of vehicle shutdown, turn the

engine mounted filter drain valve (located on

the side of the filter assembly) counterclock -

wise quarter turn, and turn the under body

mounted filter drain valve (located on the

bottom of the filter assembly) counterclockwise

wise 1 full turn. Then turn the ignition switch to the ON position, and allow any accumulated

water to drain. Leave the drain valve open until

all water and contaminants have been

removed. When clean fuel is visible, close the

drain valve following these guidelines:

1. Rotate the drain clockwise to close until

you feel resistance from the internal seal.

2. Continue turning the drain half of a turn to properly compress the seal.

NOTE:

Over-compression of the seal due to over-tight -

ening of the drain will damage the seal, cause a

leak, and require the entire sensor to be

replaced.

3. Turn the ignition switch to OFF.

The sensor drain should not be over-tightened

during normal service operations to avoid

internal damage and future fuel leaks. The

drain should be closed and secured without the

use of tools.

If more than a couple ounces/milliliters of fuel

have been drained, follow the directions for

“Priming If The Engine Has Run Out Of Fuel.”

CAUTION!

Do not drain the fuel/water separator filter

when the engine is running.

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appro-

priate container.

CAUTION!

If the “Water In Fuel Indicator Light” remains

on, DO NOT START the engine before you

drain water from the fuel filters to avoid

engine damage.

7

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 355

Page 358 of 516

356SERVICING AND MAINTENANCE

Engine Mounted Fuel Filter Replacement

NOTE:

Using a fuel filter that does not meet the

manufacturer's filtration and water sepa -

rating requirements can severely impact fuel

system life and reliability.

The engine mounted filter housing is

equipped with a No-Filter-No-Run (NFNR)

feature. Engine will not run if:

a. No filter is installed.

b. Inferior/Non-approved filter is used. Use of OEM filter is required to ensure vehicle

will run.

Engine Mounted Fuel Filter Assembly

1. Ensure engine is turned off.

2. Place drain pan under the fuel filter drain

hose.

3. Open the water drain valve a quarter turn counterclockwise and completely drain fuel

and water into the approved container.

4. Close the water drain valve.

5. Remove lid using a socket or strap wrench. Rotate counterclockwise for removal.

Remove used o-ring and discard it.

6. Remove the used filter cartridge from the housing and dispose of according to your

local regulations. 7. Wipe clean the sealing surfaces of the lid

and housing.

8. Install new o-ring back into ring groove on the filter housing and lubricate with clean

engine oil.

9. Remove new filter cartridge from plastic bag and install into housing.

NOTE:

Do not remove cartridge from bag until you

reach this step in order to keep cartridge clean.

10. Push down on the cartridge to ensure it is properly seated. Do not pre-fill the filter

housing with fuel.

11. Install lid onto housing and tighten to 22.5 ft lbs (30.5 N.m). Do not overtighten

the lid.

12. Prime the engine using the procedure in “Priming If The Engine Has Run Out Of Fuel.”

Then start the engine and confirm there are

no leaks.

1 — Drain Valve

CAUTION!

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appro-

priate container.

Do not prefill the fuel filter when installing a

new fuel filter. There is a possibility debris

could be introduced into the fuel filter

during this action. It is best to install the

filter dry and allow the in-tank lift pump to

prime the fuel system.

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 356

Page 359 of 516

SERVICING AND MAINTENANCE357

Underbody Mounted Fuel Filter

Replacement

NOTE:

Using a fuel filter that does not meet the

manufacturer's filtration and water sepa -

rating requirements can severely impact fuel

system life and reliability.

The underbody mounted filter housing will

cause the engine not to run if:

a. No filter is installed.

Underbody Mounted Fuel Filter Assembly

1. Ensure engine is turned off.

2. Place drain pan under the fuel filter drain

hose.

3. Open the water drain valve one full turn counterclockwise and completely drain fuel

and water into the approved container.

4. Close the water drain valve. 5. Remove lid using a socket or strap wrench.

Rotate counterclockwise for removal.

Remove used o-ring and discard it.

6. Remove the used filter cartridge from the housing and dispose of according to your

local regulations.

7. Wipe clean the sealing surfaces of the lid and housing.

8. Install new o-ring back into ring groove on the filter housing and lubricate with clean

engine oil.

NOTE:

Water In Fuel (WIF) sensor is re-usable. Service

kit comes with new o-ring for filter canister and

WIF sensor.

1 — Drain Valve

CAUTION!

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appro-

priate container.

Do not prefill the fuel filter when installing a

new fuel filter. There is a possibility debris

could be introduced into the fuel filter

during this action. It is best to install the

filter dry and allow the in-tank lift pump to

prime the fuel system.

7

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 357

Page 362 of 516

360SERVICING AND MAINTENANCE

Body Lubrication

Locks and all body pivot points, including such

items as seat tracks, door hinge pivot points

and rollers, liftgate, tailgate, decklid, sliding

doors and hood hinges, should be lubricated

periodically with a lithium based grease, such

as Mopar Spray White Lube to ensure quiet,

easy operation and to protect against rust and

wear. Prior to the application of any lubricant,

the parts concerned should be wiped clean to

remove dust and grit; after lubricating excess,

oil and grease should be removed. Particular

attention should also be given to hood latching

components to ensure proper function. When

performing other underhood services, the hood

latch, release mechanism and safety catch

should be cleaned and lubricated.

The external lock cylinders should be lubricated

twice a year, preferably in the Autumn and

Spring. Apply a small amount of a high quality

lubricant, such as Mopar Lock Cylinder Lubri -

cant directly into the lock cylinder.

Windshield Wiper Blades

Clean the rubber edges of the wiper blades and

the windshield periodically with a sponge or soft

cloth and a mild nonabrasive cleaner. This will

remove accumulations of salt or road film.

Operation of the wipers on dry glass for long

periods may cause deterioration of the wiper

blades. Always use washer fluid when using the

wipers to remove salt or dirt from a dry wind -

shield.

Avoid using the wiper blades to remove frost or

ice from the windshield. Keep the blade rubber

out of contact with petroleum products such as

engine oil, gasoline, etc.

NOTE:

Life expectancy of wiper blades varies

depending on geographical area and frequency

of use. Poor performance of blades may be

present with chattering, marks, water lines or

wet spots. If any of these conditions are

present, clean the wiper blades or replace as

necessary. The wiper blades and wiper arms should be

inspected periodically, not just when wiper

performance problems are experienced. This

inspection should include the following points:

Wear or uneven edges

Foreign material

Hardening or cracking

Deformation or fatigue

If a wiper blade or wiper arm is damaged,

replace the affected wiper arm or blade with a

new unit. Do not attempt to repair a wiper arm

or blade that is damaged.

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 360