torque Ram 4500 Chassis Cab 2018 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 4500 Chassis Cab, Model: Ram 4500 Chassis Cab 2018Pages: 298, PDF Size: 5.88 MB

Page 69 of 298

WARNING!

If you continue operating the vehicle when

the Transmission Temperature Warning

Light is illuminated you could cause the

fluid to boil over, come in contact with hot

engine or exhaust components and cause a

fire.

CAUTION!

Continuous driving with the Transmission

Temperature Warning Light illuminated

will eventually cause severe transmission

damage or transmission failure.

Yellow Indicator Lights

— Rear Fog Indicator — If Equipped

This indicator will illuminate when the rear

fog lights are on.

— TOW/HAUL Indicator Light

This light will illuminate when TOW/HAUL

mode is selected.

— Cargo Light — If Equipped

The cargo light will illuminate when the cargo

light is activated by pushing the cargo light

button on the headlight switch.

— 4WD Low Indicator Light —

If Equipped

This light alerts the driver that the vehicle is

in the four-wheel drive LOW mode. The front

and rear driveshafts are mechanically locked

together forcing the front and rear wheels to

rotate at the same speed. Low range provides

a greater gear reduction ratio to provide in-

creased torque at the wheels.

Refer to “Four-Wheel Drive Operation — If

Equipped” in “Starting And Operating” for

further information on four-wheel drive op-

eration and proper use.

– 4WD Indicator Light —

If Equipped

This light alerts the driver that the vehicle is

in the four-wheel drive mode, and the front

and rear driveshafts are mechanically locked

together forcing the front and rear wheels to

rotate at the same speed.

— 2WD Indicator Light —

If Equipped

This light alerts the driver that the vehicle is

in the two-wheel drive mode.

— Wait To Start Light — If Equipped

The “Wait To Start” telltale will illuminate for

approximately two seconds when the ignition

is turned to the RUN position. It’s duration

may be longer based on colder operating

conditions. Vehicle will not initiate start until

telltale is no longer displayed. Refer to

“Starting The Engine” in “Starting And Op-

erating” for further information.

NOTE:

The “Wait To Start” telltale may not illumi-

nate if the intake manifold temperature is

warm enough.

— Water In Fuel Indicator Light —

If Equipped

The “Water In Fuel Indicator Light” will illu-

minate when there is water detected in the

fuel filters. If this light remains on, DO NOT

start the vehicle before you drain the water

from the fuel filters to prevent engine dam-

67

Page 134 of 298

Electronically Shifted Transfer

Case (Four-Position Switch) —

If Equipped

The electronic shift transfer case is operated

by the 4WD Control Switch (Transfer Case

Switch), which is located on the instrument

panel.This electronically shifted transfer case pro-

vides four mode positions: • Two-Wheel Drive High Range (2WD)

• Four-Wheel Drive Lock High Range (4WD

LOCK)

• Four-Wheel Drive Low Range (4WD LOW)

• Neutral (NEUTRAL)

For additional information on the appropriate

use of each transfer case mode position, see

the information below:

2WD

Rear Wheel Drive High Range — This range is

for normal street and highway driving on dry,

hard surfaced roads.

4WD LOCK

Four-Wheel Drive Lock High Range — This

range maximizes torque to the front drive-

shaft, forcing the front and rear wheels to

rotate at the same speed. This range provides

additional traction for loose, slippery road

surfaces only.

4WD LOW

Four-Wheel Drive Low Range — This range

provides low speed four-wheel drive. It maxi-

mizes torque to the front driveshaft, forcing

Four-Position/Part Time Transfer Case

STARTING AND OPERATING

132

Page 135 of 298

the front and rear wheels to rotate at the same

speed. This range provides additional trac-

tion and maximum pulling power for loose,

slippery road surfaces only. Do not exceed

25 mph (40 km/h).

NEUTRAL (N)

Neutral — This range disengages both the

front and rear driveshafts from the pow-

ertrain. To be used for flat towing behind

another vehicle. Refer to “Recreational Tow-

ing” in this section for further information.

WARNING!

You or others could be injured or killed if

you leave the vehicle unattended with the

transfer case in the NEUTRAL position

without first fully engaging the parking

brake. The transfer case NEUTRAL posi-

tion disengages both the front and rear

drive shafts from the powertrain and will

allow the vehicle to roll, even if the trans-

mission is in PARK. The parking brake

should always be applied when the driver

is not in the vehicle.This electronically shifted transfer case is

designed to be driven in the two-wheel drive

position (2WD) for normal street and highway

conditions on dry, hard surfaced roads.

When additional traction is required, the

transfer case 4WD LOCK and 4WD LOW po-

sitions can be used to maximize torque to the

front driveshaft, forcing the front and rear

wheels to rotate at the same speed. This is

accomplished by rotating the 4WD Control

Switch to the desired position.

Refer to “Shifting Procedure” in the “Start-

ing And Operating” section of your Owner’s

Manual

locatedat

www.mopar.com/en-us/care/owners-manual.html

(U.S. Residents) or www.owners.mopar.ca

(Canadian Residents) for specific shifting in-

structions.

SPEED CONTROL

When engaged, the Speed Control takes over

accelerator operations at speeds greater than

25 mph (40 km/h). The Speed Control buttons are located on the

right side of the steering wheel.

Speed Control Buttons

1 — Push Cancel

2 — Push On/Off

3 — Push Resume/Accel

4 — Push Set/Decel

133

Page 165 of 298

4. By rotating the lug wrench clockwise,raise the vehicle until the wheel just

clears the surface.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

5. Remove the lug nuts and pull the wheel off. Install the spare wheel and lug nuts

with the cone shaped end of the nuts

toward the wheel on single rear wheel

(SRW) models. On dual rear wheel models

(DRW) the lug nuts are a two-piece assem-

bly with a flat face. Lightly tighten the

nuts. To avoid risk of forcing the vehicle

off the jack, do not fully tighten the nuts

until the vehicle has been lowered.

6. Using the lug wrench, finish tightening the nuts using a crisscross pattern. For

the proper lug nut torque specifications

refer to “Wheel And Tire Torque Specifi-

cations” in “Technical Specifications.” If

in doubt about the correct tightness, have them checked with a torque wrench by an

authorized dealer or at a service station.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided.

7. Install wheel center cap (if equipped) and remove wheel blocks. Do not install

chrome or aluminum wheel center caps

on the spare wheel. This may result in cap

damage.

8. Lower the jack to its fully closed position. If the jack will not lower by turning the

dial (thumbwheel) by hand, it may be

necessary to use the jack driver in order to

lower the jack. Stow the replaced tire,

jack, and tools as previously described.

9. Adjust the tire pressure when possible.

To Stow The Flat Or Spare —

If Equipped

Refer to Upfitters Body Builders Guide for

information on stowing your spare tire (if

equipped).

Hub Caps/Wheel Covers —

If Equipped

The hub caps must be removed before raising

the vehicle off the ground.

CAUTION!

Use extreme caution when removing the

front and rear center caps. Damage can

occur to the center cap and/or the wheel if

screwdriver type tools are used. A pulling

motion, not a pry off motion, is recom-

mended to remove the caps.

For single rear wheel (SRW) models, use the

flat blade on the end of the lug wrench to pull

the hub cap off. Insert the blade end into the

pull off notch and carefully pull the hub cap

off with a back and forth motion.

163

Page 211 of 298

TECHNICAL SPECIFICATIONS

WHEEL AND TIRE TORQUE

SPECIFICATIONS..............210

Torque Specifications ...........210

Dual Rear Wheels ..............211

FLUID CAPACITIES — GAS ENGINE . . .213 FLUID CAPACITIES — 6.7L CUMMINS

DIESEL ENGINE

...............213

FLUIDS AND LUBRICANTS —

GAS ENGINE ................ .214Engine.....................214

Chassis ....................216

FLUIDS AND LUBRICANTS —

6.7L DIESEL ENGINES ...........216

Engine.....................216

Chassis ....................218

MOPAR ACCESSORIES ...........219

Authentic Accessories By Mopar .....219

TECHNICAL SPECIFICATIONS

209

Page 212 of 298

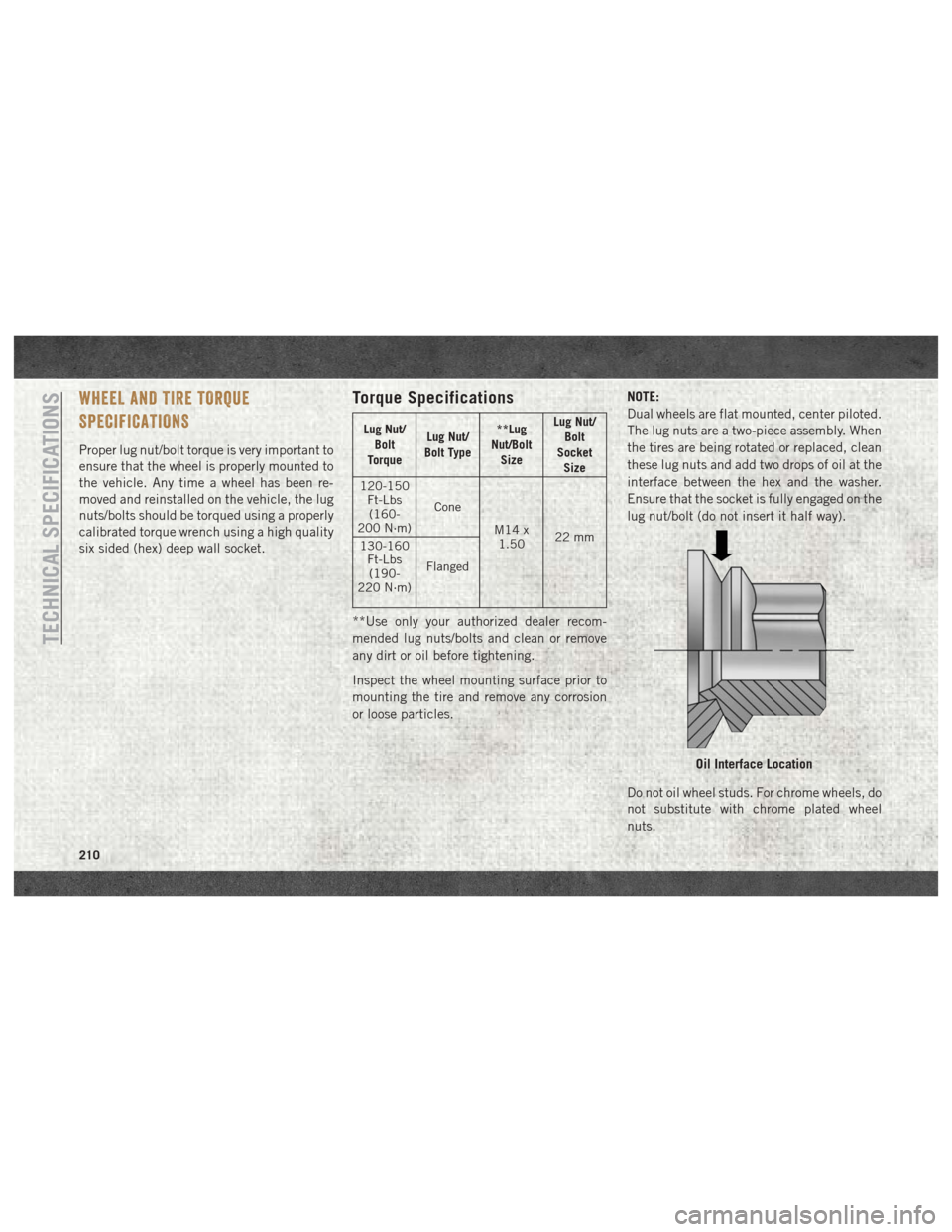

WHEEL AND TIRE TORQUE

SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been re-

moved and reinstalled on the vehicle, the lug

nuts/bolts should be torqued using a properly

calibrated torque wrench using a high quality

six sided (hex) deep wall socket.

Torque Specifications

Lug Nut/Bolt

Torque Lug Nut/

Bolt Type **Lug

Nut/Bolt Size Lug Nut/

Bolt

Socket Size

120-150 Ft-Lbs(160-

200 N·m) Cone

M14 x1.50 22 mm

130-160

Ft-Lbs(190-

220 N·m) Flanged

**Use only your authorized dealer recom-

mended lug nuts/bolts and clean or remove

any dirt or oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion

or loose particles. NOTE:

Dual wheels are flat mounted, center piloted.

The lug nuts are a two-piece assembly. When

the tires are being rotated or replaced, clean

these lug nuts and add two drops of oil at the

interface between the hex and the washer.

Ensure that the socket is fully engaged on the

lug nut/bolt (do not insert it half way).

Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel

nuts.

Oil Interface Location

TECHNICAL SPECIFICATIONS

210

Page 213 of 298

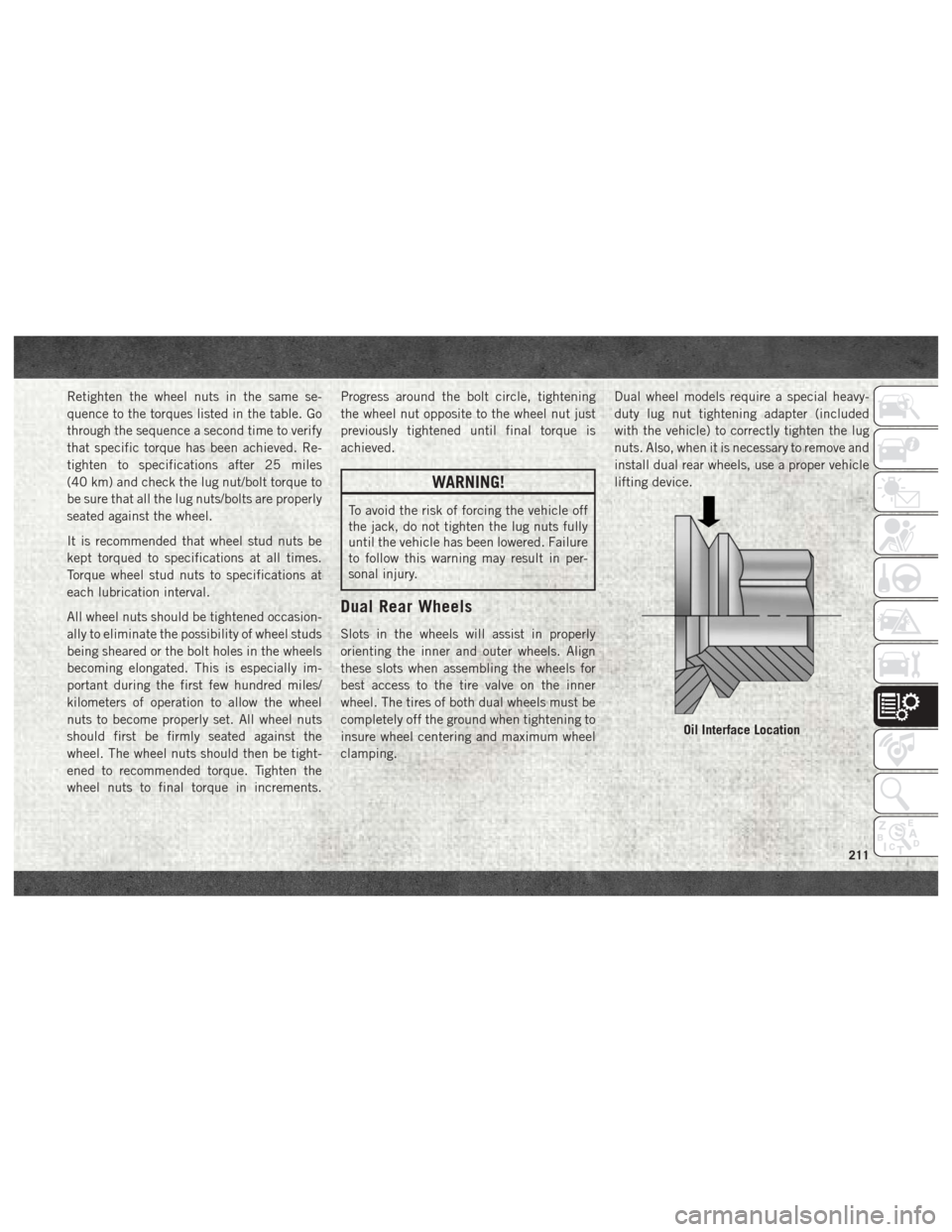

Retighten the wheel nuts in the same se-

quence to the torques listed in the table. Go

through the sequence a second time to verify

that specific torque has been achieved. Re-

tighten to specifications after 25 miles

(40 km) and check the lug nut/bolt torque to

be sure that all the lug nuts/bolts are properly

seated against the wheel.

It is recommended that wheel stud nuts be

kept torqued to specifications at all times.

Torque wheel stud nuts to specifications at

each lubrication interval.

All wheel nuts should be tightened occasion-

ally to eliminate the possibility of wheel studs

being sheared or the bolt holes in the wheels

becoming elongated. This is especially im-

portant during the first few hundred miles/

kilometers of operation to allow the wheel

nuts to become properly set. All wheel nuts

should first be firmly seated against the

wheel. The wheel nuts should then be tight-

ened to recommended torque. Tighten the

wheel nuts to final torque in increments.Progress around the bolt circle, tightening

the wheel nut opposite to the wheel nut just

previously tightened until final torque is

achieved.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the lug nuts fully

until the vehicle has been lowered. Failure

to follow this warning may result in per-

sonal injury.

Dual Rear Wheels

Slots in the wheels will assist in properly

orienting the inner and outer wheels. Align

these slots when assembling the wheels for

best access to the tire valve on the inner

wheel. The tires of both dual wheels must be

completely off the ground when tightening to

insure wheel centering and maximum wheel

clamping.

Dual wheel models require a special heavy-

duty lug nut tightening adapter (included

with the vehicle) to correctly tighten the lug

nuts. Also, when it is necessary to remove and

install dual rear wheels, use a proper vehicle

lifting device.

Oil Interface Location

211

Page 214 of 298

NOTE:

When installing a spare tire (if equipped) as

part of a dual rear wheel end combination,

the tire diameter of the two individual tires

must be compared. If there is a significant

difference, the larger tire should be installed

in a front location. The correct direction of

rotation for dual tire installations must also

be observed.

These dual rear wheels should be tightened as

follows:It is recommended that wheel stud nuts be

kept torqued to specifications at all times.

Torque wheel stud nuts to specifications at

each lubrication interval.

Wheel Nuts Numbered Sequence (8)

Wheel Nuts Numbered Sequence (10)TECHNICAL SPECIFICATIONS

212

Page 296 of 298

Speed ControlAccel/Decel ...............135

Cancel ..................135

Resume .................135

Speed Control (Cruise Control) ......133

Starting ................120, 121

Engine Block Heater ..........124

Starting Procedures .............121

Starting Procedures (Diesel Engines) . .121

Starting Procedures (Gas Engines) . . . .120

Steering Tilt Column ................28

Wheel, Heated ..............28

Wheel, Tilt .................28

Steering Wheel Mounted Sound System Controls .........257

Storage, Vehicle ................44

Telescoping Steering Column ........28

Temperature Control, Automatic (ATC) . .43

Text Messaging ...............271

Tilt Steering Column .............28

Tire And Loading Information Placard . .196

Tire Markings .................191

Tires ............117, 199, 204, 207

Aging (Life Of Tires) ..........202

Air Pressure ...............199 Changing

.................160

Compact Spare .............204

Dual ................210, 211

General Information .......199, 204

High Speed ...............200

Inflation Pressures ...........200

Jacking ..................160

Life Of Tires ...............202

Load Capacity ..............196

Pressure Monitor System (TPMS) . . .72

Pressure Warning Light .........65

Quality Grading .............207

Radial ..................201

Replacement ..............202

Safety ...............191, 199

Sizes ...................192

Snow Tires ................204

Spare

Tire .........204, 205, 206

Spinning .................201

Tread Wear Indicators .........202

Wheel Nut Torque ........163, 210

Tire Safety Information ...........191

To Open Hood .................44

Towing .................142, 169

Disabled Vehicle ............169

Guide ...................142

Recreational ...............147 Weight

..................142

Towing Vehicle Behind A Motorhome . .147

Trailer Towing ................142

Minimum Requirements .......142

Trailer Towing Guide ............142

Trailer Weight ................142

Transfer Case Electronically Shifted .........132

Fluid ................216, 218

Transmission Automatic ................129

Fluid ................216, 218

Shifting .................128

Transporting Pets ..............115

Tread Wear Indicators ...........202

Turn Signals ...............34, 68

Uconnect 3.0 ................227

Uconnect (Hands-Free Phone) Making A Phone Call ......264, 270

Receiving A Call ............264

Uconnect Phone . . . .264, 269, 270, 271

Uconnect Settings Customer Programmable Features . . .19

Passive Entry Programming .......19

Uconnect Voice Command .....269, 272

Uniform Tire Quality Grades ........207

INDEX

294

Page 297 of 298

Untwisting Procedure, Seat Belt......81

USB Port ...................257

Vehicle Loading ...............196

Vehicle Storage ................44

Vehicle User Guide ICON Symbol Glossary ..........11

In Vehicle Help ..............11

IVH .....................11

Navigation .................11

Operating Instructions ..........11 Searching User Guide

..........11

Voice Command ...............269

Voice Recognition System (VR) .........269, 270, 272

Voltmeter ...................125

Warning Lights (Instrument Cluster Description) .................64

Washers, Windshield .............35

Water Separator, Diesel Fuel .......187

Wheel And Wheel Trim ...........206 Wheel And Wheel Trim Care

........206

Wheel Cover .................163

Wheel Nut Torque ..............163

Window Fogging ................44

Windshield Defroster ............116

Windshield Washers ...........34, 35

Fluid ....................34

Windshield Wipers ..............34

Wipers, Intermittent .............35

Wipers, Rain Sensitive ............35

295