fuel pressure Ram 5500 Chassis Cab 2016 Diesel Supplement

[x] Cancel search | Manufacturer: RAM, Model Year: 2016, Model line: 5500 Chassis Cab, Model: Ram 5500 Chassis Cab 2016Pages: 338, PDF Size: 1.63 MB

Page 218 of 338

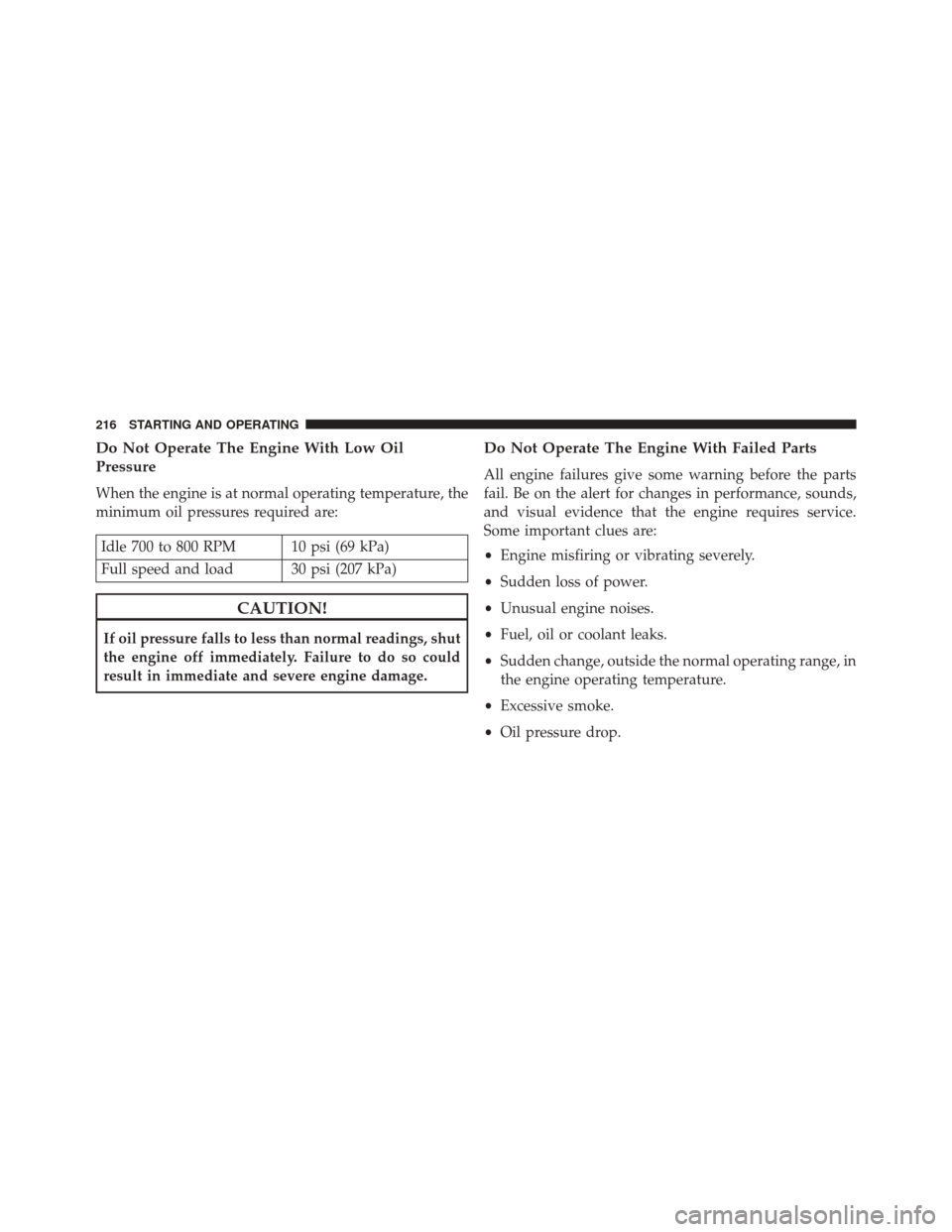

Do Not Operate The Engine With Low Oil

Pressure

When the engine is at normal operating temperature, the

minimum oil pressures required are:

Idle 700 to 800 RPM 10 psi (69 kPa)

Full speed and load 30 psi (207 kPa)

CAUTION!

If oil pressure falls to less than normal readings, shut

the engine off immediately. Failure to do so could

result in immediate and severe engine damage.

Do Not Operate The Engine With Failed Parts

All engine failures give some warning before the parts

fail. Be on the alert for changes in performance, sounds,

and visual evidence that the engine requires service.

Some important clues are:

•Engine misfiring or vibrating severely.

• Sudden loss of power.

• Unusual engine noises.

• Fuel, oil or coolant leaks.

• Sudden change, outside the normal operating range, in

the engine operating temperature.

• Excessive smoke.

• Oil pressure drop.

216 STARTING AND OPERATING

Page 255 of 338

microbes form “slime” that will clog the fuel filtration

system and lines. Drain condensation from the supply

tank and change the line filter on a regular basis.

NOTE:When a diesel engine is allowed to run out of

fuel, air is pulled into the fuel system.

If the vehicle will not start, refer to “Maintenance

Procedures/Priming If The Engine Has Run Out Of Fuel”

in “Maintaining Your Vehicle” for further information.

WARNING!

Do not open the high pressure fuel system with the

engine running. Engine operation causes high fuel

pressure. High pressure fuel spray can cause serious

injury or death.

Diesel Exhaust Fluid Storage

Diesel Exhaust Fluid (DEF) is considered a very stable

product with a long shelf life. If DEF is kept in tempera-

tures between 10° and 90°F (-12° and 32°C), it will last a

minimum of one year.

DEF is subject to freezing at the lowest temperatures. For

example, DEF may freeze at temperatures at or below

12° F (-11° C). The system has been designed to operate in

this environment.

NOTE: When working with DEF, it is important to know

that:

•

Any containers or parts that come into contact with DEF

must be DEF compatible (plastic or stainless steel). Cop-

per, brass, aluminum, iron or non-stainless steel should be

avoided as they are subject to corrosion by DEF.

• If DEF is spilled, it should be wiped up completely.

5

STARTING AND OPERATING 253

Page 288 of 338

5. Remove lid using a socket or strap wrench. Rotatecounterclockwise for removal. Remove used o-ring

and discard it.

6. Remove the used filter cartridge from the housing and dispose of according to your local regulations.

7. Wipe clean the sealing surfaces of the lid and housing.

8. Install new o-ring back into ring groove on the filter housing and lubricate with clean engine oil.

NOTE: WIF sensor is re-usable. Service kit comes with

new o-ring for filter canister and WIF sensor.Priming If The Engine Has Run Out Of Fuel

WARNING!

Do not open the high pressure fuel system with the

engine running. Engine operation causes high fuel

pressure. High pressure fuel spray can cause serious

injury or death.

1. Add a substantial amount of fuel to the tank, approxi- mately 2 to 5 gal (8L to 19L).

2. Turn ignition switch to the start position to engage starter for one second, return ignition switch to run

position. This will activate in tank fuel pump for

approximately 15 seconds. Repeat this process twice.

3. Start the engine using the “Normal Starting” proce- dure. Refer to “Starting Procedures” in “Starting and

Operating” for further information.

286 MAINTAINING YOUR VEHICLE

Page 290 of 338

•Use of biodiesel mixture in excess of 20% can nega-

tively impact the fuel filter’s ability to separate water

from the fuel, resulting in high pressure fuel system

corrosion or damage.

• Ethanol blends are not recommended or approved for

use with your Cummins diesel engine.

• In addition, commercially available fuel additives are

not necessary for the proper operation of your Cum-

mins diesel engine.

Intervention Regeneration Strategy — Message

Process Flow

The Cummins diesel engine meets all EPA Heavy Duty

Diesel Engine Emissions Standards, resulting in one of

the lowest emitting diesel engines ever produced.

To achieve these emissions standards, your vehicle is

equipped with a state-of-the-art engine and exhaust

system. The engine and exhaust after-treatment system work together to achieve the EPA Heavy Duty Diesel

Engine Emissions Standards. These systems are seam-

lessly integrated into your vehicle and managed by the

Cummins Powertrain Control Module (PCM). The PCM

manages engine combustion to allow the exhaust sys-

tem’s catalyst to trap and burn Particulate Matter (PM)

pollutants, with no input or interaction on your part.

Additionally, your vehicle has the ability to alert you to

additional maintenance required on your truck or engine.

Refer to “Electronic Vehicle Information Center (EVIC)”

or “Driver Information Display (DID)” in “Understand-

ing Your Instrument Panel” for further information.

WARNING!

A hot exhaust system can start a fire if you park over

materials that can burn. Such materials might be

(Continued)

288 MAINTAINING YOUR VEHICLE

Page 298 of 338

•Do not change the thermostat for Summer or Winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory engine coolant (antifreeze)

performance, poor gas mileage, and increased emis-

sions.

Charge Air Cooler — Inter-Cooler

The charge air cooler is positioned below the radiator and

the air conditioner condenser. Air enters the engine

through the air cleaner and passes through the turbo-

charger, where it is pressurized. This pressurized air

rapidly reaches high temperature. The air is then directed

through a hose to the charge air cooler and through

another hose to the intake manifold of the engine. The air

entering the engine has been cooled by about 50° to 100°F

(10° to 38°C). This cooling process enables more efficient

burning of fuel resulting in fewer emissions. To guarantee optimum performance of the system, keep

the surfaces of the charge air cooler, condenser and

radiator clean and free of debris. Periodically check the

hoses leading to and from the charge air cooler for cracks

or loose clamps resulting in loss of pressure and reduced

engine performance.

Brake System

Brake Master Cylinder — Brake Fluid Level Check

The fluid level of the master cylinder should be checked

when performing under the hood service, or immedi-

ately if the “Brake System Warning Light” indicates

system failure.

The brake master cylinder has a translucent plastic

reservoir. On the outboard side of the reservoir, there is a

“MAX” mark and a “MIN” mark. The fluid level must be

kept within these two marks. Do not add fluid above the

full mark because leakage may occur at the cap.

296 MAINTAINING YOUR VEHICLE

Page 328 of 338

Adding Engine Coolant (Antifreeze)............106

Adding Fuel ..............................80

Air Cleaner, Engine (Engine Air Cleaner Filter) .....94

Antifreeze (Engine Coolant) ..................105

Capacities .............................113

Disposal ............................. .108

Automatic Transmission Fluid Type ............................118

Axle Fluid ..............................118

Battery ................................ .103

Brake Fluid ..............................118

Brake System ............................110

Fluid Check ...........................110

Master Cylinder ........................110

Capacities, Antifreeze (Engine Coolant) ..........113

Capacities, Fluid ..........................113 Caps, Filler

Oil (Engine) ............................93

Radiator (Coolant Pressure) ................108

Charge Air Cooler .........................110

Coolant Pressure Cap (Radiator Cap) ...........108

Cooling System .......................... .104

Adding Coolant (Antifreeze) ...............106

Coolant Capacity .......................113

Coolant Level ......................... .104

Disposal Of Used Coolant .................108

Drain, Flush, And Refill ...................105

Points To Remember .....................109

Pressure Cap ......................... .108

Radiator Cap ......................... .108

Selection Of Coolant (Antifreeze) ........105 , 114

Diesel Fuel ...............................73

Diesel Fuel Requirements ....................73

Bulk Storage Of .........................83

326 INDEX - RAM 1500

Page 332 of 338

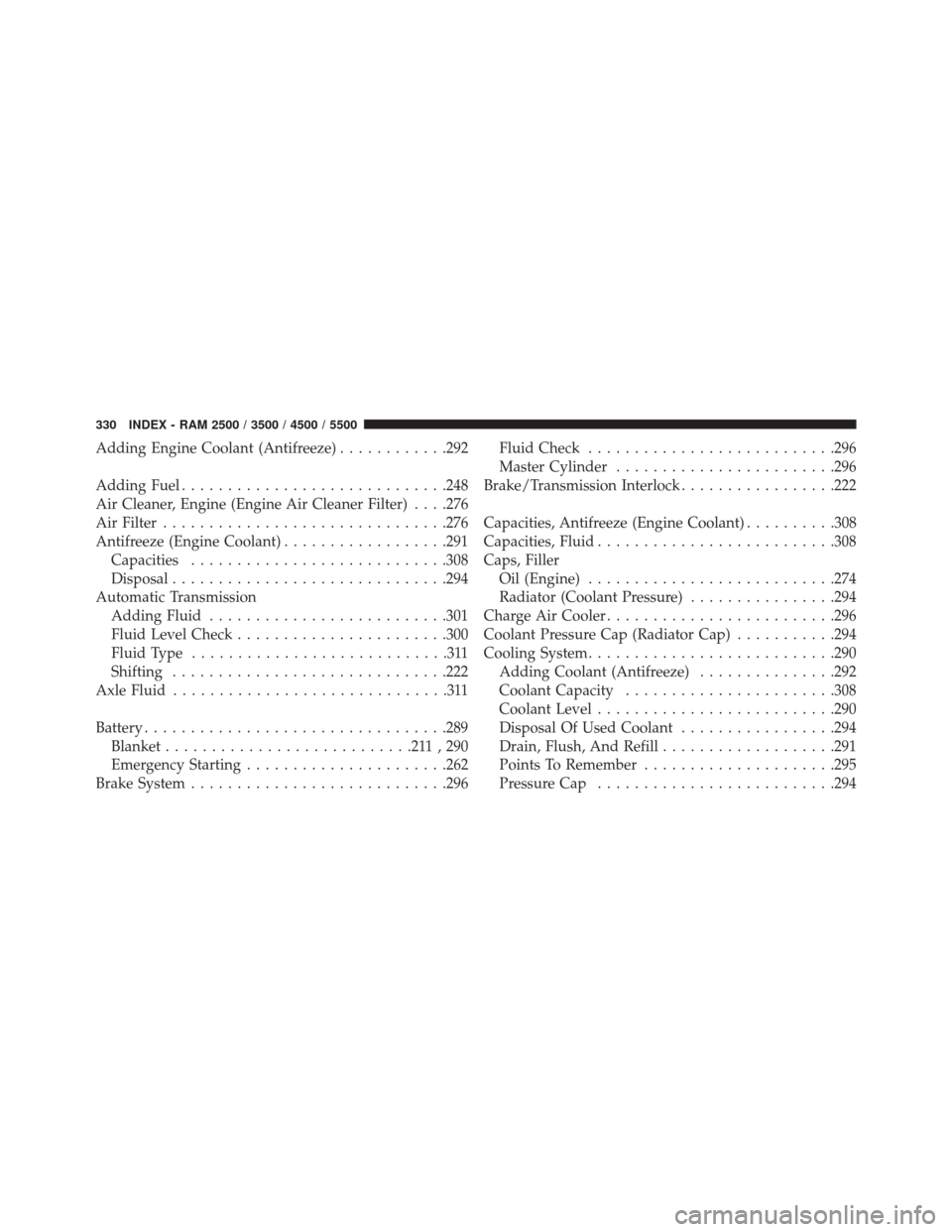

Adding Engine Coolant (Antifreeze)............292

Adding Fuel ............................ .248

Air Cleaner, Engine (Engine Air Cleaner Filter) . . . .276

Air Filter .............................. .276

Antifreeze (Engine Coolant) ..................291

Capacities ........................... .308

Disposal ............................. .294

Automatic Transmission Adding Fluid ......................... .301

Fluid Level Check ...................... .300

Fluid Type ............................311

Shifting ............................. .222

Axle Fluid ..............................311

Battery ................................ .289

Blanket ...........................211,290

Emergency Starting ..................... .262

Brake System ........................... .296Fluid Check

.......................... .296

Master Cylinder ....................... .296

Brake/Transmission Interlock .................222

Capacities, Antifreeze (Engine Coolant) ..........308

Capacities, Fluid ......................... .308

Caps, Filler Oil (Engine) .......................... .274

Radiator (Coolant Pressure) ................294

Charge Air Cooler ........................ .296

Coolant Pressure Cap (Radiator Cap) ...........294

Cooling System .......................... .290

Adding Coolant (Antifreeze) ...............292

Coolant Capacity ...................... .308

Coolant Level ......................... .290

Disposal Of Used Coolant .................294

Drain, Flush, And Refill ...................291

Points To Remember .....................295

Pressure Cap ......................... .294

330 INDEX - RAM 2500 / 3500 / 4500 / 5500