flat tire RAM CHASSIS CAB 2019 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2019, Model line: CHASSIS CAB, Model: RAM CHASSIS CAB 2019Pages: 607, PDF Size: 12.68 MB

Page 395 of 607

IN CASE OF EMERGENCY 393

Jack Warning Label 1. If equipped, remove the spare wheel, jack, and tools from

storage.

2. Using the lug wrench, loosen, but do not remove, the lug

nuts by turning them counterclockwise one turn while

the wheel is still on the ground.• To assure that spare tires, flat or inflated, are securely

stowed, spares must be stowed with the valve stem

facing the ground. WARNING! (Continued) CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the Jacking

Instructions for this vehicle.

6

Page 396 of 607

394 IN CASE OF EMERGENCY

3. When changing the front wheel, assemble the jack driver

to the jack and connect the jack driver to the extension

tube. Place the jack under the axle as close to the tire as

possible with the jack driver extending to the front.

Connect the extension tubes and lug wrench.

Front Jacking Locations

When changing a rear wheel, assemble the jack driver to

the jack and connect the jack driver to the extension tubes.

Securely place the jack under the sway bar bracket (unless

both tires are flat on one side, then place jack under shock

bracket) facing forward in vehicle. Connect the extension

tubes and lug wrench. Rear Jacking Location

Before raising the wheel off the ground, make sure that

the jack will not damage surrounding truck parts and

adjust the jack position as required.

NOTE:

If the jack will not lower by turning the dial (thumbwheel) by

hand, it may be necessary to use the jack driver in order to

lower the jack.

4. By rotating the lug wrench clockwise, raise the vehicle

until the wheel just clears the surface.

Page 397 of 607

IN CASE OF EMERGENCY 395

5. Remove the lug nuts and pull the wheel off. Install the

spare wheel and lug nuts with the cone shaped end of the

nuts toward the wheel on single rear wheel (SRW)

models. On dual rear wheel models (DRW) the lug nuts

are a two-piece assembly with a flat face. Lightly tighten

the nuts. To avoid risk of forcing the vehicle off the jack,

do not fully tighten the nuts until the vehicle has been

lowered.

6. Using the lug wrench, finish tightening the nuts using a

crisscross pattern. For the proper lug nut torque specifica -

tions refer to “Wheel And Tire Torque Specifications” in

“Technical Specifications.” If in doubt about the correct

tightness, have them checked with a torque wrench by an

authorized dealer or at a service station. 7. Install wheel center cap (if equipped) and remove wheel

blocks. Do not install chrome or aluminum wheel center

caps on the spare wheel. This may result in cap damage.

8. Lower the jack to its fully closed position. If the jack will

not lower by turning the dial (thumbwheel) by hand, it

may be necessary to use the jack driver in order to lower

the jack. Stow the replaced tire, jack, and tools as previ -

ously described.

9. Adjust the tire pressure when possible.WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire. WARNING!

A loose tire or jack thrown forward in a collision or hard

stop, could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided.

6

Page 398 of 607

396 IN CASE OF EMERGENCY

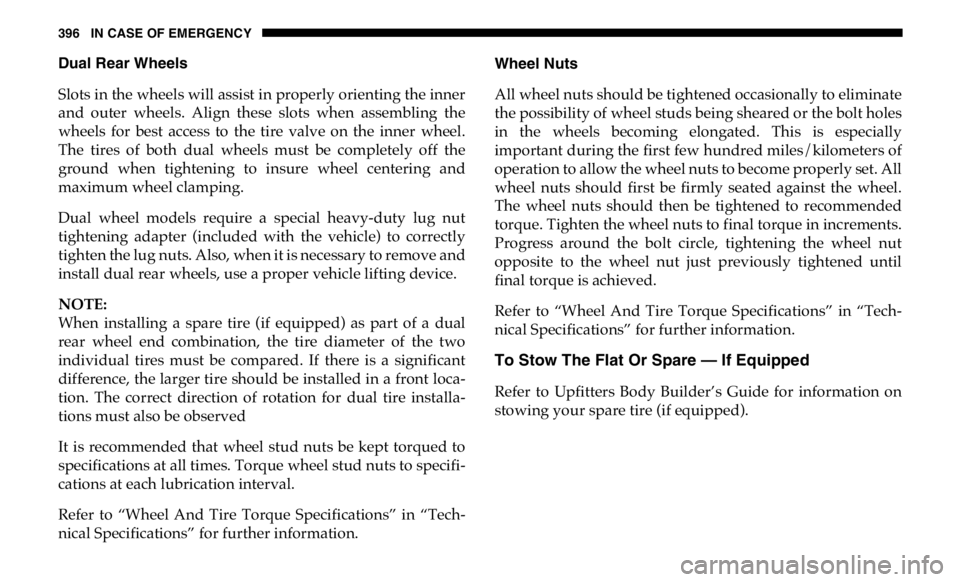

Dual Rear Wheels

Slots in the wheels will assist in properly orienting the inner

and outer wheels. Align these slots when assembling the

wheels for best access to the tire valve on the inner wheel.

The tires of both dual wheels must be completely off the

ground when tightening to insure wheel centering and

maximum wheel clamping.

Dual wheel models require a special heavy-duty lug nut

tightening adapter (included with the vehicle) to correctly

tighten the lug nuts. Also, when it is necessary to remove and

install dual rear wheels, use a proper vehicle lifting device.

NOTE:

When installing a spare tire (if equipped) as part of a dual

rear wheel end combination, the tire diameter of the two

individual tires must be compared. If there is a significant

difference, the larger tire should be installed in a front loca -

tion. The correct direction of rotation for dual tire installa -

tions must also be observed

It is recommended that wheel stud nuts be kept torqued to

specifications at all times. Torque wheel stud nuts to specifi -

cations at each lubrication interval.

Refer to “Wheel And Tire Torque Specifications” in “Tech -

nical Specifications” for further information. Wheel Nuts

All wheel nuts should be tightened occasionally to eliminate

the possibility of wheel studs being sheared or the bolt holes

in the wheels becoming elongated. This is especially

important during the first few hundred miles/kilometers of

operation to allow the wheel nuts to become properly set. All

wheel nuts should first be firmly seated against the wheel.

The wheel nuts should then be tightened to recommended

torque. Tighten the wheel nuts to final torque in increments.

Progress around the bolt circle, tightening the wheel nut

opposite to the wheel nut just previously tightened until

final torque is achieved.

Refer to “Wheel And Tire Torque Specifications” in “Tech -

nical Specifications” for further information.

To Stow The Flat Or Spare — If Equipped

Refer to Upfitters Body Builder’s Guide for information on

stowing your spare tire (if equipped).

Page 408 of 607

406 IN CASE OF EMERGENCY

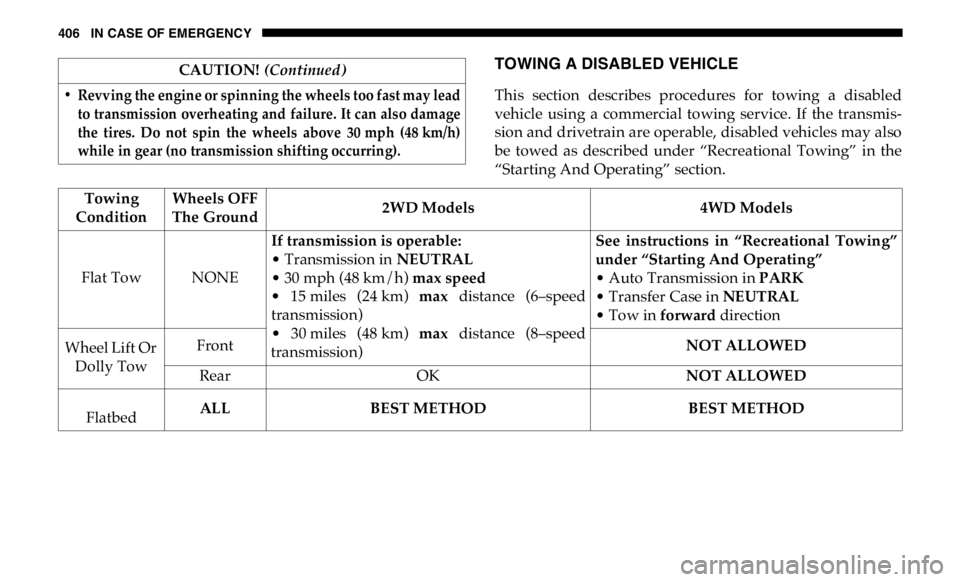

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled

vehicle using a commercial towing service. If the transmis -

sion and drivetrain are operable, disabled vehicles may also

be towed as described under “Recreational Towing” in the

“Starting And Operating” section.• Revving the engine or spinning the wheels too fast may lead

to transmission overheating and failure. It can also damage

the tires. Do not spin the wheels above 30 mph (48 km/h)

while in gear (no transmission shifting occurring). CAUTION! (Continued)

Towing

Condition Wheels OFF

The Ground 2WD Models 4WD Models

Flat Tow NONE If transmission is operable:

• Transmission in NEUTRAL

• 30 mph (48 km/h) max speed

• 15 miles (24 km) max distance (6–speed

transmission)

• 30 miles (48 km) max distance (8–speed

transmission) See instructions in “Recreational Towing”

under “Starting And Operating”

• Auto Transmission in PARK

• Transfer Case in NEUTRAL

• Tow in forward direction

Wheel Lift Or

Dolly Tow Front NOT ALLOWED

Rear OK NOT ALLOWED

Flatbed ALL BEST METHOD BEST METHOD

Page 413 of 607

SERVICING AND MAINTENANCE 411

Once A Month Or Before A Long Trip:

• Check engine oil level.

• Check windshield washer fluid level.

• Check the tire inflation pressures and look for unusual

wear or damage. Rotate at the first sign of irregular wear.

• Check the fluid levels of the coolant reservoir, brake

master cylinder, power steering and automatic transmis -

sion (six-speed only), and fill as needed.

• Check function of all interior and exterior lights. Maintenance Plan

Required Maintenance

Refer to the maintenance plan on the following pages for

required maintenance.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

• Change oil and filter.

• Rotate the tires. Rotate at the first sign of irregular wear, even if it occurs before the oil indicator system turns on.

• Inspect engine cooling system protection and hoses.

• Inspect exhaust system.

• Inspect engine air cleaner if using in dusty or off-road conditions.

• Inspect battery and clean and tighten terminals as required.

• Inspect automatic transmission fluid if equipped with dipstick.

• Inspect brake pads, shoes, rotors, drums, hoses and park brake.

• Inspect front end, and lubricate — If equipped with serviceable fittings. 7

Page 449 of 607

SERVICING AND MAINTENANCE 447

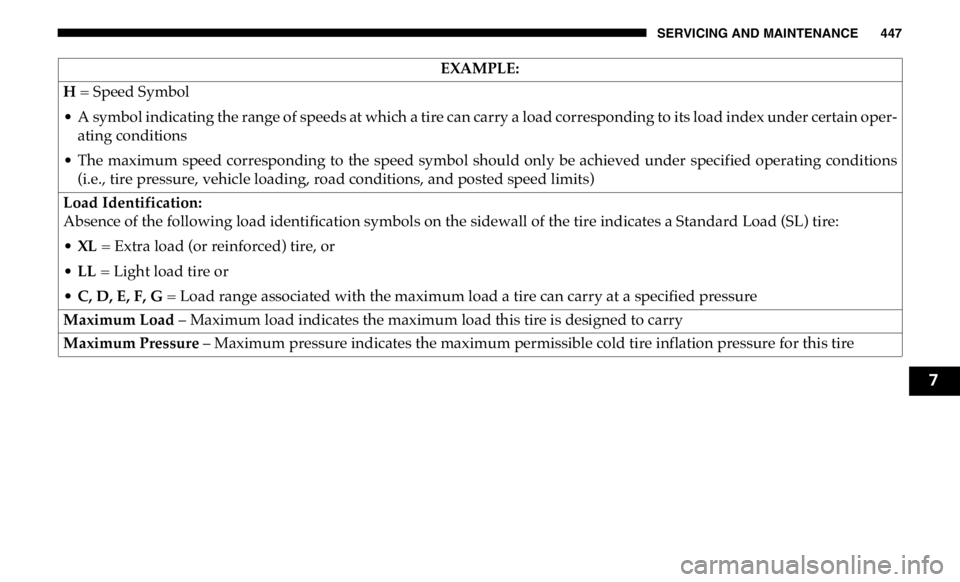

H = Speed Symbol

• A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain oper -

ating conditions

• The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions

(i.e., tire pressure, vehicle loading, road conditions, and posted speed limits)

Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

• XL = Extra load (or reinforced) tire, or

• LL = Light load tire or

• C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire EXAMPLE:

7

Page 451 of 607

SERVICING AND MAINTENANCE 449

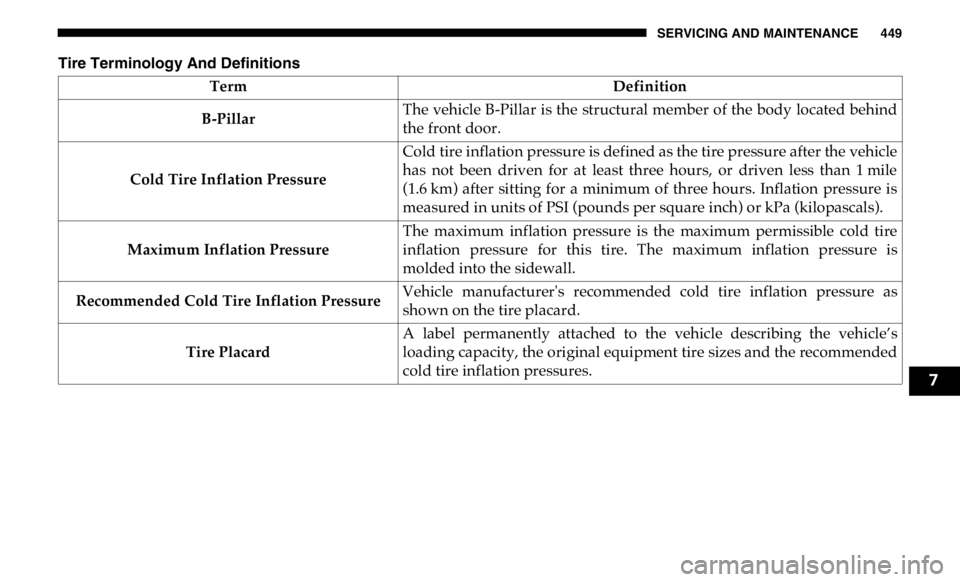

Tire Terminology And Definitions

Term Definition

B-Pillar The vehicle B-Pillar is the structural member of the body located behind

the front door.

Cold Tire Inflation Pressure Cold tire inflation pressure is defined as the tire pressure after the vehicle

has not been driven for at least three hours, or driven less than 1 mile

(1.6 km) after sitting for a minimum of three hours. Inflation pressure is

measured in units of PSI (pounds per square inch) or kPa (kilopascals).

Maximum Inflation Pressure The maximum inflation pressure is the maximum permissible cold tire

inflation pressure for this tire. The maximum inflation pressure is

molded into the sidewall.

Recommended Cold Tire Inflation Pressure Vehicle manufacturer's recommended cold tire inflation pressure as

shown on the tire placard.

Tire Placard A label permanently attached to the vehicle describing the vehicle’s

loading capacity, the original equipment tire sizes and the recommended

cold tire inflation pressures.

7

Page 452 of 607

450 SERVICING AND MAINTENANCE

Tire Loading And Tire Pressure

NOTE:

The proper cold tire inflation pressure is listed on the

driver’s side B-Pillar or the rear edge of the driver's side

door.

Check the inflation pressure of each tire, including the spare

tire (if equipped), at least monthly and inflate to the recom -

mended pressure for your vehicle.

Example Tire Placard Location (Door) Example Tire Placard Location (B-Pillar)

Page 453 of 607

SERVICING AND MAINTENANCE 451

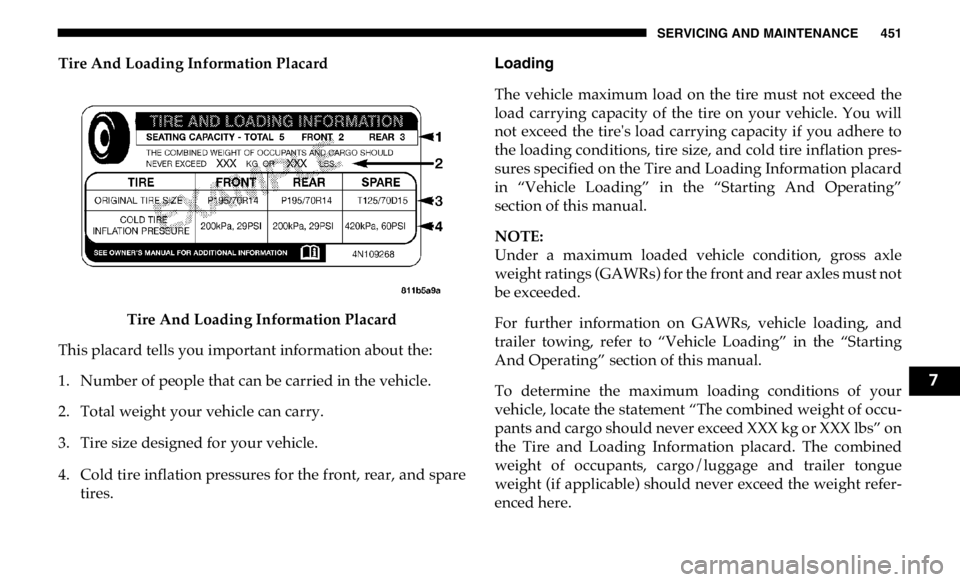

Tire And Loading Information Placard

Tire And Loading Information Placard

This placard tells you important information about the:

1. Number of people that can be carried in the vehicle.

2. Total weight your vehicle can carry.

3. Tire size designed for your vehicle.

4. Cold tire inflation pressures for the front, rear, and spare

tires. Loading

The vehicle maximum load on the tire must not exceed the

load carrying capacity of the tire on your vehicle. You will

not exceed the tire's load carrying capacity if you adhere to

the loading conditions, tire size, and cold tire inflation pres -

sures specified on the Tire and Loading Information placard

in “Vehicle Loading” in the “Starting And Operating”

section of this manual.

NOTE:

Under a maximum loaded vehicle condition, gross axle

weight ratings (GAWRs) for the front and rear axles must not

be exceeded.

For further information on GAWRs, vehicle loading, and

trailer towing, refer to “Vehicle Loading” in the “Starting

And Operating” section of this manual.

To determine the maximum loading conditions of your

vehicle, locate the statement “The combined weight of occu -

pants and cargo should never exceed XXX kg or XXX lbs” on

the Tire and Loading Information placard. The combined

weight of occupants, cargo/luggage and trailer tongue

weight (if applicable) should never exceed the weight refer -

enced here. 7