oil RAM CHASSIS CAB 2020 Workshop Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: CHASSIS CAB, Model: RAM CHASSIS CAB 2020Pages: 516, PDF Size: 16.57 MB

Page 351 of 516

SERVICING AND MAINTENANCE349

Synthetic Engine Oils

You may use synthetic engine oils provided the

recommended oil quality requirements are met,

and the recommended maintenance intervals

for oil and filter changes are followed.

Synthetic engine oils which do not have both the

engine oil certification mark and the correct SAE

viscosity grade number should not be used.

Materials Added To Engine Oil

The manufacturer strongly recommends

against the addition of any additives (other than

leak detection dyes) to the engine oil. Engine oil

is an engineered product and its performance

may be impaired by supplemental additives.

Disposing Of Used Engine Oil And Oil Filters

Care should be taken in disposing of used

engine oil and oil filters from your vehicle. Used

oil and oil filters, indiscriminately discarded, can

present a problem to the environment. Contact

an authorized dealer, service station or govern -

mental agency for advice on how and where

used oil and oil filters can be safely discarded in

your area.

Engine Oil Filter

The engine oil filter should be replaced with a

new filter at every engine oil change.

Engine Oil Filter Selection

This manufacturer's engines have a full-flow

type disposable oil filter. Use a filter of this type

for replacement. The quality of replacement

filters varies considerably. Only high quality

filters should be used to ensure most efficient

service. Mopar engine oil filters are high quality

oil filters and are recommended.

Engine Air Cleaner Filter

Refer to the “Maintenance Plan” in this section

for the proper maintenance intervals.

NOTE:

Be sure to follow the “Severe Duty Conditions”

maintenance interval if applicable. Engine Air Cleaner Filter Selection

The quality of replacement engine air cleaner

filters varies considerably. Only high quality

filters should be used to ensure most efficient

service. Mopar engine air cleaner filters are a

high quality filter and are recommended.

Engine Air Cleaner Filter Inspection And

Replacement — Gas Engine

Inspect engine air cleaner filter for dirt and or

debris, if you find evidence of either dirt or

debris you should change your air cleaner filter.

WARNING!

The air induction system (air cleaner, hoses,

etc.) can provide a measure of protection in

the case of engine backfire. Do not remove

the air induction system (air cleaner, hoses,

etc.) unless such removal is necessary for

repair or maintenance. Make sure that no

one is near the engine compartment before

starting the vehicle with the air induction

system (air cleaner, hoses, etc.) removed.

Failure to do so can result in serious personal

injury.

7

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 349

Page 353 of 516

SERVICING AND MAINTENANCE351

3. Remove the air cleaner filter element from

the housing assembly.

Air Cleaner Filter

Engine Air Cleaner Filter Installation

NOTE:

Inspect and clean the housing if dirt or debris is

present before replacing the air filter element.

1. Install the air cleaner filter element into the housing assembly with the air cleaner filter

inspection surface facing downward.

2. Install the air cleaner cover onto the housing assembly locating tabs. 3. Install screws to secure the air cleaner

cover to the housing assembly.

Air Conditioner Maintenance

For best possible performance, your air condi -

tioner should be checked and serviced by an

authorized dealer at the start of each warm

season. This service should include cleaning of

the condenser fins and a performance test.

Drive belt tension should also be checked at

this time.

Refrigerant Recovery And Recycling R-134a

— If Equipped

R-134a Air Conditioning Refrigerant is a hydro -

fluorocarbon (HFC) that is an ozone-friendly

substance. The manufacturer recommends

that air conditioning service be performed by an

authorized dealer or other service facilities

using recovery and recycling equipment.

NOTE:

Use only manufacturer approved A/C system

PAG compressor oil and refrigerants.

1 — Air Cleaner Filter

2 — Air Cleaner Filter Inspection Surface

WARNING!

Use only refrigerants and compressor lubri -

cants approved by the manufacturer for

your air conditioning system. Some unap -

proved refrigerants are flammable and can

explode, injuring you. Other unapproved

refrigerants or lubricants can cause the

system to fail, requiring costly repairs.

Refer to Warranty Information Book, for

further warranty information.

The air conditioning system contains refrig -

erant under high pressure. To avoid risk of

personal injury or damage to the system,

adding refrigerant or any repair requiring

lines to be disconnected should be done by

an experienced technician.

CAUTION!

Do not use chemical flushes in your air

conditioning system as the chemicals can

damage your air conditioning components.

Such damage is not covered by the New

Vehicle Limited Warranty.

7

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 351

Page 354 of 516

352SERVICING AND MAINTENANCE

Refrigerant Recovery And Recycling

R-1234yf — If Equipped

R-1234yf Air Conditioning Refrigerant is a

hydrofluoroolefin (HFO) that is endorsed by the

Environmental Protection Agency and is an

ozone-friendly substance with a low

global-warming potential. The manufacturer

recommends that air conditioning service be

performed by an authorized dealer using

recovery and recycling equipment.

NOTE:

Use only manufacturer approved A/C system

PAG compressor oil, and refrigerants.

Cabin Filter Replacement (A/C Air Filter)

Refer to the “Maintenance Plan” for the proper

maintenance intervals. The cabin air filter is located in the fresh air inlet

behind the glove compartment. Perform the

following procedure to replace the filter:

1. Open the glove compartment and remove

all contents.

2. With the glove compartment door open, remove the glove compartment tension

tether and tether clip by sliding the clip

toward the face of the glove compartment

door. Lift the clip out of glove compartment

door and release into dash panel.

Right Side Of Glove Compartment

3. There are travel stops on both sides of the

glove compartment. Push inward on right

side of the glove compartment travel stop to

disengage the stop. Then pull the right of

the glove compartment outward (away from

the hinge) to disengaging the right side of

the compartment from the hinge. Continue

by removing the left side from the hinge by

slightly lowering the compartment while

pulling outward until it is completely disen -

gaged from the hinge.

Glove Compartment

WARNING!

Do not remove the cabin air filter while the

vehicle is running, or while the ignition is in

the ACC or ON/RUN mode. With the cabin air

filter removed and the blower operating, the

blower can contact hands and may propel dirt

and debris into your eyes, resulting in

personal injury.

1 — Glove Compartment Door

2 — Glove Compartment Tension Tether

1 — Glove Compartment Travel Stop

2 — Glove Compartment Tension Tether

3 — Glove Compartment Door

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 352

Page 358 of 516

356SERVICING AND MAINTENANCE

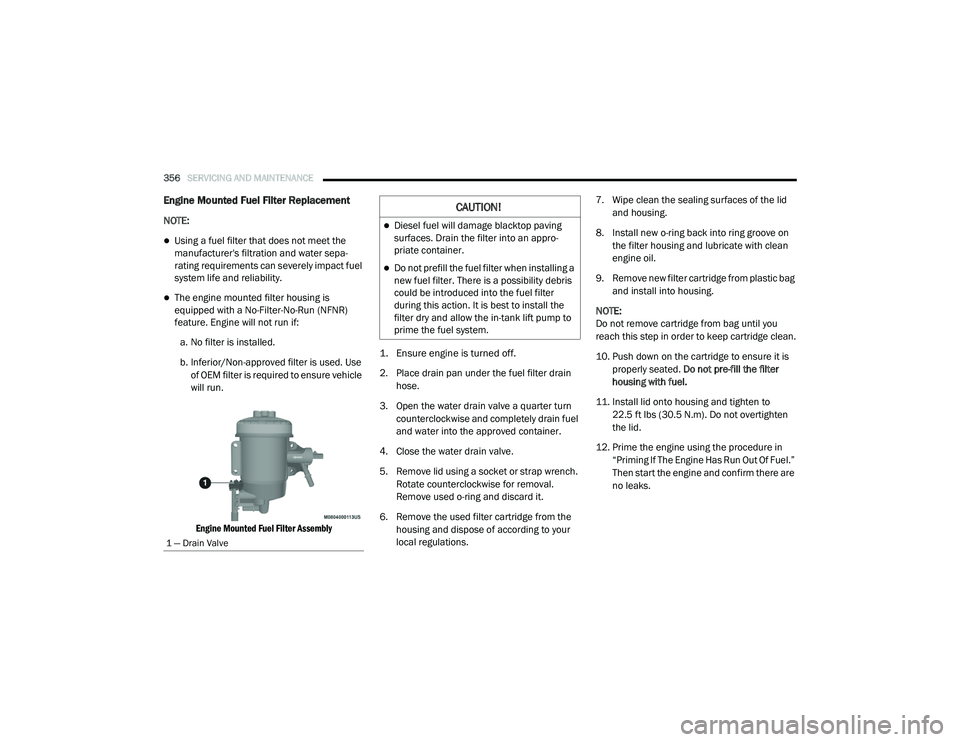

Engine Mounted Fuel Filter Replacement

NOTE:

Using a fuel filter that does not meet the

manufacturer's filtration and water sepa -

rating requirements can severely impact fuel

system life and reliability.

The engine mounted filter housing is

equipped with a No-Filter-No-Run (NFNR)

feature. Engine will not run if:

a. No filter is installed.

b. Inferior/Non-approved filter is used. Use of OEM filter is required to ensure vehicle

will run.

Engine Mounted Fuel Filter Assembly

1. Ensure engine is turned off.

2. Place drain pan under the fuel filter drain

hose.

3. Open the water drain valve a quarter turn counterclockwise and completely drain fuel

and water into the approved container.

4. Close the water drain valve.

5. Remove lid using a socket or strap wrench. Rotate counterclockwise for removal.

Remove used o-ring and discard it.

6. Remove the used filter cartridge from the housing and dispose of according to your

local regulations. 7. Wipe clean the sealing surfaces of the lid

and housing.

8. Install new o-ring back into ring groove on the filter housing and lubricate with clean

engine oil.

9. Remove new filter cartridge from plastic bag and install into housing.

NOTE:

Do not remove cartridge from bag until you

reach this step in order to keep cartridge clean.

10. Push down on the cartridge to ensure it is properly seated. Do not pre-fill the filter

housing with fuel.

11. Install lid onto housing and tighten to 22.5 ft lbs (30.5 N.m). Do not overtighten

the lid.

12. Prime the engine using the procedure in “Priming If The Engine Has Run Out Of Fuel.”

Then start the engine and confirm there are

no leaks.

1 — Drain Valve

CAUTION!

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appro-

priate container.

Do not prefill the fuel filter when installing a

new fuel filter. There is a possibility debris

could be introduced into the fuel filter

during this action. It is best to install the

filter dry and allow the in-tank lift pump to

prime the fuel system.

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 356

Page 359 of 516

SERVICING AND MAINTENANCE357

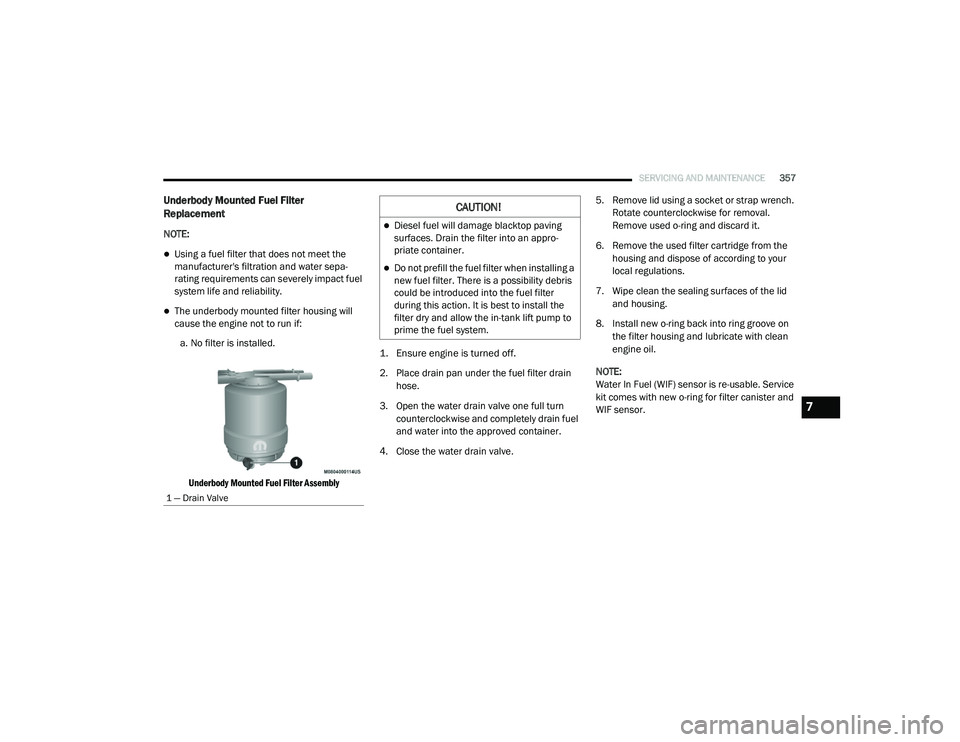

Underbody Mounted Fuel Filter

Replacement

NOTE:

Using a fuel filter that does not meet the

manufacturer's filtration and water sepa -

rating requirements can severely impact fuel

system life and reliability.

The underbody mounted filter housing will

cause the engine not to run if:

a. No filter is installed.

Underbody Mounted Fuel Filter Assembly

1. Ensure engine is turned off.

2. Place drain pan under the fuel filter drain

hose.

3. Open the water drain valve one full turn counterclockwise and completely drain fuel

and water into the approved container.

4. Close the water drain valve. 5. Remove lid using a socket or strap wrench.

Rotate counterclockwise for removal.

Remove used o-ring and discard it.

6. Remove the used filter cartridge from the housing and dispose of according to your

local regulations.

7. Wipe clean the sealing surfaces of the lid and housing.

8. Install new o-ring back into ring groove on the filter housing and lubricate with clean

engine oil.

NOTE:

Water In Fuel (WIF) sensor is re-usable. Service

kit comes with new o-ring for filter canister and

WIF sensor.

1 — Drain Valve

CAUTION!

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appro-

priate container.

Do not prefill the fuel filter when installing a

new fuel filter. There is a possibility debris

could be introduced into the fuel filter

during this action. It is best to install the

filter dry and allow the in-tank lift pump to

prime the fuel system.

7

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 357

Page 362 of 516

360SERVICING AND MAINTENANCE

Body Lubrication

Locks and all body pivot points, including such

items as seat tracks, door hinge pivot points

and rollers, liftgate, tailgate, decklid, sliding

doors and hood hinges, should be lubricated

periodically with a lithium based grease, such

as Mopar Spray White Lube to ensure quiet,

easy operation and to protect against rust and

wear. Prior to the application of any lubricant,

the parts concerned should be wiped clean to

remove dust and grit; after lubricating excess,

oil and grease should be removed. Particular

attention should also be given to hood latching

components to ensure proper function. When

performing other underhood services, the hood

latch, release mechanism and safety catch

should be cleaned and lubricated.

The external lock cylinders should be lubricated

twice a year, preferably in the Autumn and

Spring. Apply a small amount of a high quality

lubricant, such as Mopar Lock Cylinder Lubri -

cant directly into the lock cylinder.

Windshield Wiper Blades

Clean the rubber edges of the wiper blades and

the windshield periodically with a sponge or soft

cloth and a mild nonabrasive cleaner. This will

remove accumulations of salt or road film.

Operation of the wipers on dry glass for long

periods may cause deterioration of the wiper

blades. Always use washer fluid when using the

wipers to remove salt or dirt from a dry wind -

shield.

Avoid using the wiper blades to remove frost or

ice from the windshield. Keep the blade rubber

out of contact with petroleum products such as

engine oil, gasoline, etc.

NOTE:

Life expectancy of wiper blades varies

depending on geographical area and frequency

of use. Poor performance of blades may be

present with chattering, marks, water lines or

wet spots. If any of these conditions are

present, clean the wiper blades or replace as

necessary. The wiper blades and wiper arms should be

inspected periodically, not just when wiper

performance problems are experienced. This

inspection should include the following points:

Wear or uneven edges

Foreign material

Hardening or cracking

Deformation or fatigue

If a wiper blade or wiper arm is damaged,

replace the affected wiper arm or blade with a

new unit. Do not attempt to repair a wiper arm

or blade that is damaged.

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 360

Page 364 of 516

362SERVICING AND MAINTENANCE

Installing The Front Wipers

1. Lift the wiper arm off of the glass, until the

wiper arm is in the full up position.

2. Position the wiper blade under the hook on the tip of the wiper arm with the wiper

locking tab open.

3. Insert the receiver bracket on the wiper assembly into the hook on the tip of the arm

through the opening in the wiper blade

under the locking tab.

4. Slide the wiper blade up into the hook on the wiper arm until it is latched (engage -

ment will be accompanied by an audible

click). Fold down the latch release tab and

snap it into its locked position.

5. Gently lower the wiper blade onto the glass.

Exhaust System

The best protection against carbon monoxide

entry into the vehicle body is a properly main -

tained engine exhaust system.

If you notice a change in the sound of the

exhaust system; or if the exhaust fumes can be

detected inside the vehicle; or when the under -

side or rear of the vehicle is damaged; have an

authorized technician inspect the complete exhaust system and adjacent body areas for

broken, damaged, deteriorated, or misposi

-

tioned parts. Open seams or loose connections

could permit exhaust fumes to seep into the

passenger compartment. In addition, have the

exhaust system inspected each time the vehicle

is raised for lubrication or oil change. Replace

as required.

Under normal operating conditions, the cata-

lytic converter will not require maintenance.

However, it is important to keep the engine

properly tuned to ensure proper catalyst opera-

tion and prevent possible catalyst damage.

WARNING!

Exhaust gases can injure or kill. They

contain carbon monoxide (CO), which is

colorless and odorless. Breathing it can

make you unconscious and can eventually

poison you. To avoid breathing CO, refer to

“Safety Tips” in “Safety” for further informa -

tion.

A hot exhaust system can start a fire if you

park over materials that can burn. Such

materials might be grass or leaves coming

into contact with your exhaust system. Do

not park or operate your vehicle in areas

where your exhaust system can contact

anything that can burn.

CAUTION!

The catalytic converter requires the use of

unleaded fuel only. Leaded gasoline will

destroy the effectiveness of the catalyst as

an emissions control device and may seri -

ously reduce engine performance and

cause serious damage to the engine.

Damage to the catalytic converter can

result if your vehicle is not kept in proper

operating condition. In the event of engine

malfunction, particularly involving engine

misfire or other apparent loss of perfor -

mance, have your vehicle serviced

promptly. Continued operation of your

vehicle with a severe malfunction could

cause the converter to overheat, resulting

in possible damage to the converter and

vehicle.

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 362

Page 369 of 516

SERVICING AND MAINTENANCE367

(Continued)

Brake System

In order to ensure brake system performance,

all brake system components should be

inspected periodically. Refer to the “Mainte -

nance Plan” in this section for the proper main -

tenance intervals.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked when performing under the hood

service or immediately if the brake system

warning lamp indicates system failure.

If necessary, add fluid to bring level within the

designated marks on the side of the reservoir of

the brake master cylinder. Be sure to clean the

top of the master cylinder area before removing

cap. With disc brakes the fluid level can be expected

to fall as the brake linings wear. However, an

unexpected drop in fluid level may be caused by

a leak and a system check should be

conducted.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your foot

resting or riding on the brake pedal can result

in abnormally high brake temperatures,

excessive lining wear, and possible brake

damage. You would not have your full braking

capacity in an emergency.WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri

-

cants” in “Technical Specifications” for

further information. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory

installed hydraulic master cylinder reser -

voir.

To avoid contamination from foreign matter

or moisture, use only new brake fluid or

fluid that has been in a tightly closed

container. Keep the master cylinder reser -

voir cap secured at all times. Brake fluid in

a open container absorbs moisture from

the air resulting in a lower boiling point. This

may cause it to boil unexpectedly during

hard or prolonged braking, resulting in

sudden brake failure. This could result in a

collision.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

WARNING! (Continued)

7

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 367

Page 371 of 516

SERVICING AND MAINTENANCE369

Use the following procedure to check the trans -

mission fluid level properly:

1. Monitor the transmission temperature using the instrument cluster display, and

operate the vehicle as required to reach

the normal operating temperature. If the

transmission is not functioning properly, or

the vehicle cannot be driven, see the NOTE

and CAUTION below about checking the

fluid level at colder temperatures.

2. Park the vehicle on level ground.

3. Run the engine at normal idle speed for at least 60 seconds, and leave the engine

running for the rest of this procedure.

4. Fully apply the parking brake, and press the brake pedal.

5. Place the gear selector momentarily into each gear position (allowing time for the

transmission to fully engage in each posi -

tion), ending with the transmission in PARK.

6. Remove the dipstick, wipe it clean and rein -

sert it until seated. 7. Remove the dipstick again and note the

fluid level on both sides. The fluid level

reading is only valid if there is a solid

coating of oil on both sides of the dipstick.

Note that the holes in the dipstick will be full

of fluid if the actual level is at or above the

hole. The fluid level should be between the

“HOT” (upper) reference holes on the

dipstick at normal operating temperature. If

the fluid level is low, add fluid through the

dipstick tube to bring it to the proper level.

Do not overfill. Use ONLY the specified fluid

(refer to "Fluids And Lubricants" in “Tech -

nical Specifications” for fluid specifica -

tions). After adding any quantity of oil

through the dipstick tube, wait a minimum

of two minutes for the oil to fully drain into

the transmission before rechecking the

fluid level.

NOTE:

If it is necessary to check the transmission

below the operating temperature, the fluid level

should be between the two “COLD” (lower)

holes on the dipstick with the fluid at 60-70°F /

16-21°C. Only use the COLD region of the

dipstick as a rough reference when setting the

fluid level after a transmission service or fluid change. Re-check the fluid level, and adjust as

required, once the transmission reaches

normal operating temperature.

8. Reinsert the dipstick. Check for leaks.

Release the parking brake.

NOTE:

If it is necessary to check the transmission

below the operating temperature, the fluid level

should be between the two COLD (lower) holes

on the dipstick with the fluid at 68-86°F /

20-30°C. Only use the COLD region of the

dipstick as a rough reference when setting the

fluid level after a transmission service or fluid

change. Re-check the fluid level, and adjust as

required, once the transmission reaches

normal operating temperature.

CAUTION!

If the fluid temperature is below 50 °F (10

°C) it may not register on the dipstick. Do not

add fluid until the temperature is elevated

enough to produce an accurate reading. Run

the engine at idle, in PARK, to warm the fluid.

7

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 369

Page 373 of 516

SERVICING AND MAINTENANCE371

Lubricant Selection

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

NOTE:

The presence of water in the gear lubricant will

result in corrosion and possible failure of differ -

ential components. Operation of the vehicle in

water, as may be encountered in some

off-highway types of service, will require

draining and refilling the axle to avoid damage.

Limited-Slip Differentials DO REQUIRE limited

slip oil additive (friction modifiers).

NOTE:

Slight noise and mild shuddering may be

evident while turning a vehicle with limited slip

differential on concrete or dry pavement. These

conditions should be considered normal opera -

tion of the limited slip differential.

Transfer Case

Selection Of Lubricant

Use only the manufacturer's recommended

fluid. Refer to “Fluids And Lubricants” in “Tech -

nical Specifications” for further information.

Fluid Level Check

This fluid level can be checked by removing the

filler plug. The fluid level should be to the

bottom edge of the filler plug hole with the

vehicle in a level position.

Drain And Refill

Refer to the “Maintenance Plan” in this section

for the proper maintenance intervals.

Noise Control System Required

Maintenance & Warranty

All vehicles built over 10,000 lbs. (4,535 kg)

Gross Vehicle Weight Rating and manufactured

for sale and use in the United States are

required to comply with the Federal Govern -

ment's Exterior Noise Regulations. These vehi -

cles can be identified by the Noise Emission

Control Label located in the operator's compart -

ment.

Required Maintenance For Noise Control

Systems

The following maintenance services must be

performed every six months or 7,500 miles

(12,000 km) whichever comes first, to ensure

proper operation of the noise control systems.

In addition, inspection and service should be

performed anytime a malfunction is observed or

suspected. Proper maintenance of the entire

vehicle will help the effectiveness of the noise

control systems.

7

2020_RAM_CHASSIS_CAB_OM_USA=GUID-6C67832B-7839-4CCF-BEFC-CDF988F949EA=1=en=.book Page 371