service indicator RAM CHASSIS CAB 2022 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2022, Model line: CHASSIS CAB, Model: RAM CHASSIS CAB 2022Pages: 428, PDF Size: 20.18 MB

Page 331 of 428

SERVICING AND MAINTENANCE329

MAINTENANCE PLAN – GASOLINE ENGINE

Refer to the maintenance plan on the following pages for required maintenance. More frequent maintenance may be needed in severe conditions, such as dusty

areas and very short trip driving. In some extreme conditions, additional maintenance not specified in the maintenance schedule may be required.

NOTE:Using white lithium grease, lubricate the door hinge pivot joints twice a year to prevent premature wear.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

Change oil and filter.

Rotate the tires. Rotate at the first sign of irregular wear, even if it occurs before the oil indicator system turns on.

Inspect engine cooling system protection and hoses.

Inspect exhaust system.

Inspect engine air cleaner filter if using in dusty or off-road conditions. Replace the engine air cleaner filter, if necessary.

Inspect battery and clean and tighten terminals as required.

Inspect the CV/Universal joints.

Inspect automatic transmission fluid if equipped with dipstick.

Inspect brake pads, shoes, rotors, drums, hoses and parking brake.

Inspect front end, and lubricate — If equipped with serviceable fittings.

Inspect and replace the Evaporative System Fresh Air Filter as necessary, replacement may be more frequent if vehicle is operated in extreme dusty condi-

tions.8

22_DPF_OM_EN_USC_t.book Page 329

Page 334 of 428

332SERVICING AND MAINTENANCE

SCHEDULED SERVICING — DIESEL ENGINE

Required Maintenance Intervals

Refer to the maintenance plan on the following

pages for the required maintenance intervals.

More frequent maintenance may be needed in

severe conditions, such as dusty areas and very

short trip driving. In some extreme conditions,

additional maintenance not specified in the

maintenance schedule may be required.

At Each Stop For Fuel

Check the engine oil level at least 30 minutes after

a fully warmed engine is shut off. Checking the oil

level while the vehicle is on level ground will

improve the accuracy of the oil level reading. Add

oil only when the level is at or below the ADD or

MIN mark.

Once A Month

Inspect the batteries, and clean and tighten the

terminals as required.

Check the fluid levels of the coolant reservoir,

brake master cylinder, and automatic transmis -

sion, and add as needed. At Each Oil Change

Change the engine oil filter.

Inspect the exhaust system.

Check the tire inflation pressures and look for

unusual wear or damage. Rotate at the first sign

of irregular wear.

Inspect engine air cleaner filter. Replace the

engine air cleaner filter, if necessary.

Inspect the CV/Universal joints.

Check the coolant level, hoses, and clamps.

Inspect front end, and lubricate — If equipped

with serviceable fittings.

Inspect and replace the Evaporative System

Fresh Air Filter as necessary, replacement may

be more frequent if vehicle is operated in

extreme dusty conditions.

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.

NOTE:Using white lithium grease, lubricate the door

hinge pivot joints twice a year to prevent

premature wear.

OIL CHANGE INDICATOR SYSTEM —

D

IESEL ENGINE

Your vehicle is equipped with an engine oil change

indicator system. This system will alert you when it

is time to change your engine oil by displaying the

words “Oil Change Due” in your instrument cluster

display. The engine oil change indicator system is

duty cycle based, which means the engine oil

change interval may fluctuate depending on your

personal driving style. Failure to change the engine

oil per the maintenance schedule can result in

internal engine damage.

An authorized dealer will reset the oil change

indicator message after completing the scheduled

oil change. If a scheduled oil change is performed

by someone other than an authorized dealer, the

message can be reset by referring to the steps

described under Instrument Cluster Display

Ú page 81.

Replace the engine oil and oil filter every

15,000 miles (24,000 km) or 12 months, or

sooner if prompted by the oil change indicator

system. Under no circumstances should oil change

intervals exceed 15,000 miles (24,000 km) or 12 months, whichever comes first.CAUTION!

Failure to perform the required maintenance

items may result in damage to the vehicle.

22_DPF_OM_EN_USC_t.book Page 332

Page 335 of 428

SERVICING AND MAINTENANCE333

NOTE:

Under no circumstances should oil change inter -

vals exceed 15,000 miles (24,000 km) or

12 months or 500 hours, whichever comes first.

It is recommended that every 3,000 miles

(4,800 km), check the engine oil level at least

30 minutes after a fully warmed engine is shut

off. Checking the oil level while the vehicle is on

level ground will improve the accuracy of the oil

level reading. Add oil only when the level is at or

below the ADD or MIN mark.

Severe service (high ambient temperature,

short trips, heavy loading, trailer towing,

off-road, or law enforcement use) may reduce

oil change intervals. If models configured with optional B20 capability

are operated with greater than 5% levels of

biodiesel, the oil change interval must not exceed

12,500 miles (20,000 km) or 400 hours,

whichever comes first under any circumstances.

See the Fuel Requirements section for more

information regarding operation with biodiesel

blend (B6-B20) fuel meeting ASTM specification

D-7467.

PERFORM SERVICE INDICATOR —

D

IESEL ENGINE

Your vehicle will require emissions maintenance at

a set interval. To help remind you when this

maintenance is due, the instrument cluster will

display “Perform Service”. When the “Perform

Service” message is displayed on the instrument

cluster it is necessary to have the emissions

maintenance performed. Emissions maintenance

may include replacing the Closed Crankcase

Ventilation (CCV) filter element. The procedure for

clearing and resetting the “Perform Service”

indicator message is located in the appropriate

Service Information.

8

22_DPF_OM_EN_USC_t.book Page 333

Page 336 of 428

334SERVICING AND MAINTENANCE

MAINTENANCE PLAN — DIESEL ENGINE

Inspection and service should also be performed anytime a malfunction is observed or suspected. Retain all receipts.

Mileage or time passed (whichever

comes first):

7,500

15,000

22,500

30,000

37,500

45,000

52,500

60,000

67,500

75,000

82,500

90,000

97,500

105,000

112,500

120,000

127,500

135,000

142,500

150,000

Or Months: 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120

Or Kilometers:

12,000

24,000

36,000

48,000

60,000

72,000

84,000

96,000

108,000

120,000

132,000

144,000

156,000

168,000

180,000

192,000

204,000

216,000

228,000

240,000

Change engine oil every 15,000 miles

(24,000 km) or 12 months or 500

hours or sooner if prompted by the oil

change indicator system, whichever

comes first.

1

X X X X X X X X X X

Additional Inspections

Check the Diesel Exhaust Fluid (DEF)

tank, refill if necessary. X X X X X X X X X X X X X X X X X X X X

Rotate the tires. X X X X X X X X X X X X X X X X X X X X

Inspect the CV/Universal joints. X X X X X X X X X X X X X X X X X X X X

Inspect front end, and lubricate — If

equipped with serviceable fittings. X X X X X X X X X X X X X X X X X X X X

In s

pect engine air cleaner filter,

replace if necessary.

2X X X X X X X X X X

22_DPF_OM_EN_USC_t.book Page 334

Page 343 of 428

SERVICING AND MAINTENANCE341

PRESSURE WASHING

Cleaning the engine compartment with a high

pressure washer is not recommended.

VEHICLE MAINTENANCE

An authorized dealer has the qualified service

personnel, special tools, and equipment to

perform all service operations in an expert

manner. Service Manuals are available which

include detailed service information for your

vehicle. Refer to these Service Manuals before

attempting any procedure yourself.

NOTE:Intentional tampering with emissions control

systems may void your warranty and could result in

civil penalties being assessed against you.

ENGINE OIL

Engine Oil Selection— Gasoline Engine

Use only the manufacturer's recommended fluid

Úpage 404.

NOTE:Hemi engines (6.4L) at times can tick right after

startup and then quiet down after approximately

30 seconds. This is normal and will not harm the

engine. This characteristic can be caused by short

drive cycles. For example, if the vehicle is started

then shut off after driving a short distance. Upon

restarting, you may experience a ticking sound.

Other causes could be if the vehicle is unused for

an extended period of time, incorrect oil, extended

oil changes or extended idling. If the engine

continues to tick or if the Malfunction Indicator

Light (MIL) comes on, see the nearest authorized

dealer.

Engine Oil Selection — Diesel Engine

Use only the manufacturer's recommended fluid

Úpage 404.

CAUTION!

It is essential when replacing the cables on

the battery that the positive cable is attached

to the positive post and the negative cable is

attached to the negative post. Battery posts

are marked positive (+) and negative (-) and

are identified on the battery case. Cable

clamps should be tight on the terminal posts

and free of corrosion.

If a “fast charger” is used while the battery is

in the vehicle, disconnect both vehicle battery

cables before connecting the charger to the

battery. Do not use a “fast charger” to provide

starting voltage.

CAUTION!

Precautions have been taken to safeguard all

parts and connections however, the pressures

generated by these machines is such that

complete protection against water ingress

cannot be guaranteed.

WARNING!

You can be badly injured working on or around a

motor vehicle. Only do service work for which

you have the knowledge and the proper

equipment. If you have any doubt about your

ability to perform a service job, take your vehicle

to a competent mechanic.

8

22_DPF_OM_EN_USC_t.book Page 341

Page 349 of 428

SERVICING AND MAINTENANCE347

along a rib (not across) are not normal. Any belt

with cracks running along a rib must be replaced.

Also have the belt replaced if it has excessive wear,

frayed cords or severe glazing.

Accessory Belt (Serpentine Belt)

Conditions that would require replacement:

Rib chunking (one or more ribs has separated

from belt body)

Rib or belt wear

Longitudinal belt cracking (cracks between two

ribs)

Belt slips

“Groove jumping" (belt does not maintain

correct position on pulley)

Belt broken (note: identify and correct problem

before new belt is installed)

Noise (objectionable squeal, squeak, or rumble

is heard or felt while drive belt is in operation)

Some conditions can be caused by a faulty

component such as a belt pulley. Belt pulleys

should be carefully inspected for damage and

proper alignment.

Belt replacement on some models requires the

use of special tools, we recommend having your

vehicle serviced at an authorized dealer.

DRAINING FUEL/WATER SEPARATOR

F

ILTER

There are two fuel filter assemblies. One is located

on the driver's side of the engine. The best access

to this water drain valve is from under the hood.

The second one is on the under body, located in

front of the rear axle above the drive shaft on

pick-up models. The second filter location is on the

frame behind the front axle. The best access to this

water drain valve is from under the vehicle. If water is detected in the water separator while the

engine is running, or while the ignition switch is in

the ON position, the “Water In Fuel Indicator Light”

will illuminate and an audible chime will be heard

five times. At this point you should stop the engine

and drain the water from both of the filters.

If the “Water In Fuel Indicator Light” comes on and

a single chime is heard while you are driving, or

with the ignition switch in the ON position, there

may be a problem with your water separator wiring

or sensor. See an authorized dealer for service.

Upon proper draining of the water from both fuel

filters, the “Water In Fuel Indicator Light” will

remain illuminated for approximately 10 seconds.

If the water was drained while the engine was

running, the “Water In Fuel Indicator Light” may

remain on for approximately three minutes.

NOTE:Care should be taken in disposing of used fluids

from your vehicle. Used fluids, indiscriminately

discarded, can present a problem to the envi

-

ronment. Contact an authorized dealer, service

CAUTION!

Do not drain the fuel/water separator filter

when the engine is running.

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appropriate

container.

CAUTION!

If the “Water In Fuel Indicator Light” remains on,

DO NOT START the engine before you drain water

from the fuel filters to avoid engine damage.

8

22_DPF_OM_EN_USC_t.book Page 347

Page 350 of 428

348SERVICING AND MAINTENANCE

station, or government agency for advice on recy -

cling programs and for where used fluids and

filters can be properly disposed of in your area.

Drain the fuel/water separator filters when the

“Water In Fuel Indicator Light” is ON. Within

10 minutes of vehicle shutdown, turn the engine

mounted filter drain valve (located on the side of

the filter assembly) counterclockwise a quarter

turn, and turn the under body mounted filter drain

valve (located on the bottom of the filter assembly)

counterclockwise 1 full turn. Then turn the ignition

switch to the ON position, and allow any

accumulated water to drain. Leave the drain valve

open until all water and contaminants have been

removed. When clean fuel is visible, close the drain

valve following these guidelines:

1. Rotate the drain clockwise to close until you feel resistance from the internal seal.

2. Continue turning the drain half of a turn to properly compress the seal.

NOTE:Over-compression of the seal due to overtightening

of the drain will damage the seal, cause a leak, and

require the entire sensor to be replaced.

3. Turn the ignition switch to OFF. The sensor drain should not be overtightened

during normal service operations to avoid internal

damage and future fuel leaks. The drain should be

closed and secured without the use of tools.

If more than a couple ounces/milliliters of fuel

have been drained, follow the directions

Ú

page 350

ENGINE MOUNTED FUEL FILTER

R

EPLACEMENT

NOTE:

Using a fuel filter that does not meet the manu -

facturer's filtration and water separating

requirements can severely impact fuel system

life and reliability.

The engine mounted filter housing is equipped

with a No-Filter-No-Run (NFNR) feature. Engine

will not run if:

No filter is installed.

Inferior/Non-approved filter is used. Use of

OEM filter is required to ensure vehicle will

run.

Engine Mounted Fuel Filter Assembly

1 — Drain Valve

CAUTION!

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appropriate

container.

Do not prefill the fuel filter when installing a

new fuel filter. There is a possibility debris

could be introduced into the fuel filter during

this action. It is best to install the filter dry and

allow the in-tank lift pump to prime the fuel

system.

22_DPF_OM_EN_USC_t.book Page 348

Page 374 of 428

372SERVICING AND MAINTENANCE

Exterior Bulbs

Bulb Name Bulb Number

Low Beam (Halogen Reflector Headlamp) H11LL

High Beam (Halogen Reflector Headlamp) 9005LL

Low & High Beam (LED Reflector Headlamp) LED (Serviced at an authorized dealer)

Low & High Beam (LED Projector Headlamp) LED (Serviced at an authorized dealer)

Turn Signal / Front Position (Halogen Reflector Headlamp) 7444NA

Turn Signal (LED Projector Headlamp) LED (Serviced at an authorized dealer)

Front Position (LED Headlamps) LED (Serviced at an authorized dealer)

Turn Signal (LED Reflector Headlamp) 7444NA

Front Side Marker (Headlamps) LED (Serviced at an authorized dealer)

Front Fog Lamps (Halogen Reflector Headlamp) H11LL

Front Fog Lamps (LED Headlamp) LED (Serviced at an authorized dealer)

Side Indicators (Front And Side View Mirror) LED (Serviced at an authorized dealer)

Center High Mounted Stop Lamp (CHMSL) 921

Cab Roof Marker Lamps 194NA

Box Off Tail Lamps – Stop/Turn/Tail/License Plate 1157

Box Off Tail Lamps – Back Up 1156

22_DPF_OM_EN_USC_t.book Page 372

Page 387 of 428

SERVICING AND MAINTENANCE385

condition, please replace the TPMS sensor as it is

not designed to be reused when driven under Run

Flat mode 14 psi (96 kPa) condition.

NOTE:TPMS Sensor must be replaced after driving the

vehicle on a flat tire condition.

It is not recommended driving a vehicle loaded at

full capacity or to tow a trailer while a tire is in the

Run Flat mode.

See the Tire Pressure Monitoring System section

for more information.

Tire Spinning

When stuck in mud, sand, snow, or ice conditions,

do not spin your vehicle's wheels above 30 mph

(48 km/h) or for longer than 30 seconds

continuously without stopping.

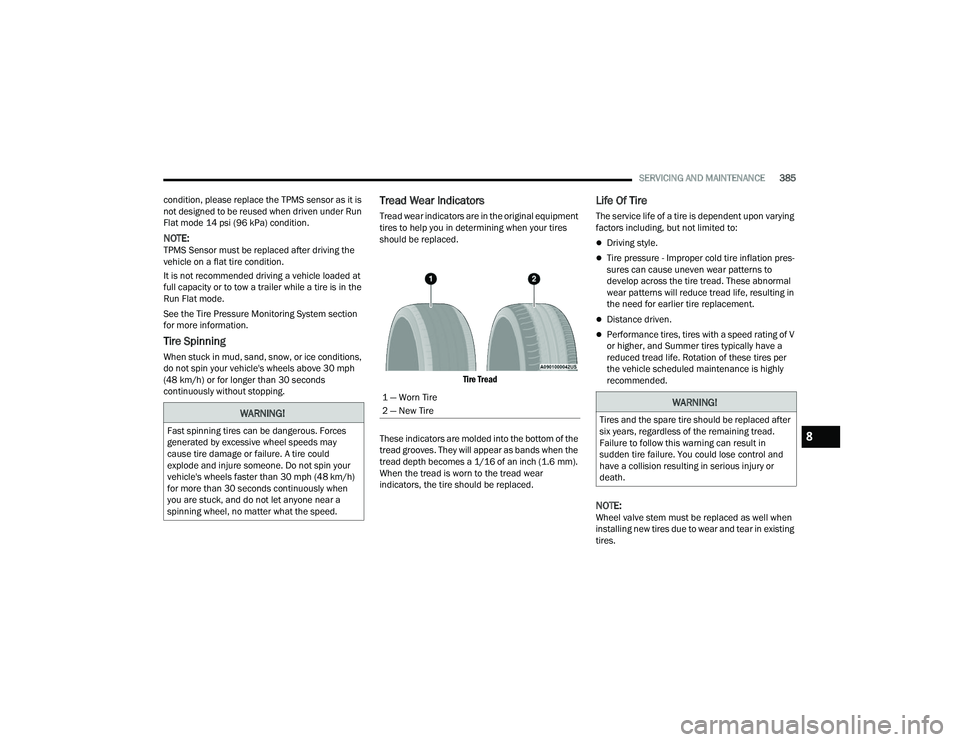

Tread Wear Indicators

Tread wear indicators are in the original equipment

tires to help you in determining when your tires

should be replaced.

Tire Tread

These indicators are molded into the bottom of the

tread grooves. They will appear as bands when the

tread depth becomes a 1/16 of an inch (1.6 mm).

When the tread is worn to the tread wear

indicators, the tire should be replaced.

Life Of Tire

The service life of a tire is dependent upon varying

factors including, but not limited to:

Driving style.

Tire pressure - Improper cold tire inflation pres -

sures can cause uneven wear patterns to

develop across the tire tread. These abnormal

wear patterns will reduce tread life, resulting in

the need for earlier tire replacement.

Distance driven.

Performance tires, tires with a speed rating of V

or higher, and Summer tires typically have a

reduced tread life. Rotation of these tires per

the vehicle scheduled maintenance is highly

recommended.

NOTE:Wheel valve stem must be replaced as well when

installing new tires due to wear and tear in existing

tires.

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may

cause tire damage or failure. A tire could

explode and injure someone. Do not spin your

vehicle's wheels faster than 30 mph (48 km/h)

for more than 30 seconds continuously when

you are stuck, and do not let anyone near a

spinning wheel, no matter what the speed.

1 — Worn Tire

2 — New TireWARNING!

Tires and the spare tire should be replaced after

six years, regardless of the remaining tread.

Failure to follow this warning can result in

sudden tire failure. You could lose control and

have a collision resulting in serious injury or

death.

8

22_DPF_OM_EN_USC_t.book Page 385

Page 401 of 428

TECHNICAL SPECIFICATIONS399

final torque in increments. Progress around the

bolt circle, tightening the wheel nut opposite to the

wheel nut just previously tightened until final

torque is achieved.

FUEL REQUIREMENTS— GASOLINE ENGINE

While operating on gasoline with the required

octane number, hearing a light knocking sound

from the engine is not a cause for concern.

However, if the engine is heard making a heavy

knocking sound, see a dealer immediately. Use of

gasoline with a lower than recommended octane

number can cause engine failure and may void or

not be covered by the New Vehicle Limited

Warranty.

Poor quality gasoline can cause problems such as

hard starting, stalling, and hesitations. If you

experience these symptoms, try another brand of

gasoline before considering service for the vehicle.

6.4L ENGINE

Do not use E-85 flex fuel or ethanol blends greater

than 15% in this engine. This engine is designed to meet all

emissions regulations and provide

satisfactory fuel economy and

performance when using high quality

unleaded gasoline having a posted octane number

of 87 as specified by the (R+M)/2 method.

REFORMULATED GASOLINE

Many areas of the country require the use of

cleaner-burning gasoline referred to as

“reformulated gasoline”. Reformulated gasoline

contains oxygenates and are specifically blended

to reduce vehicle emissions and improve air

quality.

The use of reformulated gasoline is recommended.

Properly blended reformulated gasoline will

provide improved performance and durability of

engine and fuel system components.

MATERIALS ADDED TO FUEL

Besides using unleaded gasoline with the proper

octane rating, gasolines that contain detergents,

corrosion and stability additives are

recommended. Using gasolines that have these

additives will help improve fuel economy, reduce

emissions, and maintain vehicle performance. Designated TOP TIER Detergent Gasoline

contains a higher level of detergents to

further aide in minimizing engine and

fuel system deposits. When available,

the usage of TOP TIER Detergent Gasoline is

recommended. Visit www.toptiergas.com for a list

of TOP TIER Detergent Gasoline Retailers.

Indiscriminate use of fuel system cleaning agents

should be avoided. Many of these materials

intended for gum and varnish removal may contain

active solvents or similar ingredients. These can

harm fuel system gasket and diaphragm materials.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

oxygenates such as ethanol.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the lug nuts/bolts fully until

the vehicle has been lowered. Failure to follow

this warning may result in personal injury.

CAUTION!

DO NOT use E-85, gasoline containing methanol,

or gasoline containing more than 15% ethanol

(E-15). Use of these blends may result in starting

and drivability problems, damage critical fuel

system components, cause emissions to exceed

the applicable standard, and/or cause the

Malfunction Indicator Light to illuminate. Please

observe pump labels as they should clearly

communicate if a fuel contains greater than

15% ethanol (E-15).

9

22_DPF_OM_EN_USC_t.book Page 399