instrument cluster RAM CHASSIS CAB 2022 Repair Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2022, Model line: CHASSIS CAB, Model: RAM CHASSIS CAB 2022Pages: 428, PDF Size: 20.18 MB

Page 158 of 428

156STARTING AND OPERATING

(Continued)

ParkSense system might not detect an obstacle

behind or in front of the fascia/bumper, or it

could provide a false indication that an obstacle

is behind or in front of the fascia/bumper.

Use the ParkSense switch to turn the ParkSense

system off if obstacles such as bicycle carriers,

trailer hitches, etc. are placed within 18 inches

(45 cm) of the rear fascia/bumper. Failure to do

so can result in the system misinterpreting a

close obstacle as a sensor problem, causing the

“Front/Rear ParkSense Unavailable Service

Required” message to be appear in the instru

-

ment cluster display.

LANESENSE — IF EQUIPPED

LANESENSE OPERATION

The LaneSense system is operational at speeds

above 37 mph (60 km/h) and below 112 mph

(180 km/h). It uses a forward looking camera to

detect lane markings and measure vehicle

position within the lane boundaries.

When both lane markings are detected and the

driver drifts out of the lane (no turn signal has been

applied) OR the driver departs the lane on the

opposite side of the applied turn signal (if the left

turn signal is applied and the vehicle departs to the

right), the LaneSense system provides a haptic

warning in the form of torque applied to the

steering wheel, as well as a visual warning in the

instrument cluster display to prompt the driver to

remain within the lane boundaries.

The driver may manually override the haptic

warning by applying torque to the steering wheel at

any time.

When only a single lane marking is detected and

the driver drifts across that lane marking (no turn

signal applied), the LaneSense system provides a

visual warning through the instrument cluster

display to prompt the driver to remain within the

lane.

When only a single lane marking is detected, a

haptic (torque) warning will not be provided.

WARNING!

Drivers must be careful when backing up even

when using ParkSense. Always check carefully

behind your vehicle, look behind you, and be

sure to check for pedestrians, animals, other

vehicles, obstructions, and blind spots before

backing up. You are responsible for safety and

must continue to pay attention to your

surroundings. Failure to do so can result in

serious injury or death.

Before using ParkSense, it is strongly recom -

mended that the ball mount and hitch ball

assembly be disconnected from the vehicle

when the vehicle is not used for towing.

Failure to do so can result in injury or damage

to vehicles or obstacles because the hitch ball

will be much closer to the obstacle than the

rear fascia when the vehicle sounds the

continuous tone. Also, the sensors could

detect the ball mount and hitch ball assembly,

depending on its size and shape, giving a false

indication that an obstacle is behind the

vehicle.

CAUTION!

ParkSense is only a parking aid and it is

unable to recognize every obstacle, including

small obstacles. Parking curbs might be

temporarily detected or not detected at all.

Obstacles located above or below the sensors

will not be detected when they are in close

proximity.

The vehicle must be driven slowly when using

ParkSense in order to be able to stop in time

when an obstacle is detected. It is recom -

mended that the driver looks over his/her

shoulder when using ParkSense.

WARNING!

22_DPF_OM_EN_USC_t.book Page 156

Page 159 of 428

STARTING AND OPERATING157

NOTE:When operating conditions have been met, the

LaneSense system will monitor if the driver’s

hands are on the steering wheel and provide an

audible and visual warning to the driver if removed.

The system will cancel if the driver does not return

their hands to the wheel.

TURNING LANESENSE ON OR OFF

The LaneSense button is located on the

switch panel below the Uconnect display.

NOTE:If your vehicle is equipped with a 12–inch

Uconnect Display screen, the LaneSense button is

located above the display.

To turn the LaneSense system on, push the

LaneSense button (LED turns off). A “LaneSense

On” message is shown in the instrument cluster

display.

To turn the LaneSense system off, push the

LaneSense button again (LED turns on).

NOTE:The LaneSense system will retain the last system

state (on or off) from the last ignition cycle when

the ignition is changed to the ON/RUN position.

LANESENSE WARNING MESSAGE

The LaneSense system will indicate the current

lane drift condition through the instrument cluster

display.

When the LaneSense system is on, the lane lines

are gray when both of the lane boundaries have

not been detected and the LaneSense telltale

is solid white.

System ON (Gray Lines) With White Telltale

Left Lane Departure — Only Left Lane Detected

When the LaneSense system is on, the Lane-

Sense Telltale is solid white when only the

left lane marking has been detected and the

system is ready to provide visual warnings in the

instrument cluster display if an unintentional

lane departure occurs on the left side.

When the LaneSense system senses the lane

has been approached and is in a lane departure

situation, the visual warning in the instrument

cluster display will show the left lane line

flashing yellow (on/off). The LaneSense telltale changes from solid white to flashing yellow.

Lane Crossed (Flashing Yellow Lane Line) With Yellow Telltale

NOTE:The LaneSense system operates with similar

behavior for a right lane departure when only the

right lane marking has been detected.

4

22_DPF_OM_EN_USC_t.book Page 157

Page 160 of 428

158STARTING AND OPERATING

Left Lane Departure — Both Lane Lines Detected

When the LaneSense system is on, and both the

lane markings have been detected, the system

is "armed" to provide visual warnings in the

instrument cluster display and a torque warning

in the steering wheel if an unintentional lane

departure occurs. The lane lines turn from gray

to white and the LaneSense telltale is solid

green.

Lanes Sensed (White Lines) With Green Telltale

When the LaneSense system senses a lane drift

situation, the left lane line turns solid yellow.

The LaneSense telltale changes from solid

green to solid yellow. At this time torque is

applied to the steering wheel in the opposite

direction of the lane boundary. For example: If approaching the left side of the

lane the steering wheel will turn to the right.

Lane Approached (Solid Yellow Lane Line) With Solid Yellow Telltale

When the LaneSense system senses the lane

has been approached and is in a lane departure

situation, the left lane line flashes yellow (on/

off). The LaneSense telltale changes from

solid yellow to flashing yellow. At this time

torque is applied to the steering wheel in the

opposite direction of the lane boundary. For example: If approaching the left side of the

lane the steering wheel will turn to the right.

Lane Crossed (Flashing Yellow Lane Line) With Flashing Yellow Telltale

NOTE:The LaneSense system operates with similar

behavior for a right lane departure.

CHANGING LANESENSE STATUS

The LaneSense system has settings to adjust the

intensity (Low/Medium/High) of the torque

warning and the warning zone sensitivity (Early/

Medium/Late) that you can configure through the

Uconnect system Ú page 191.

NOTE:

When enabled the system operates above

37 mph (60 km/h) and below 112 mph

(180 km/h).

22_DPF_OM_EN_USC_t.book Page 158

Page 171 of 428

STARTING AND OPERATING169

REFUELING THE VEHICLE— GASOLINE

ENGINE

NOTE:When the fuel nozzle “clicks” or shuts off the fuel

tank is full.

NOTE:Tighten the gas cap a quarter turn until you hear

one click. This is an indication that the cap is

properly tightened.

If the gas cap is not tightened properly, the

Malfunction Indicator Light will come on. Be sure

the gas cap is tightened every time the vehicle is

refueled.

LOOSE FUEL FILLER CAP MESSAGE

If the vehicle diagnostic system determines that

the fuel filler cap is loose, improperly installed, or damaged, a loose gASCAP indicator will display in

the instrument cluster telltale display area

Ú

page 81. Tighten the fuel filler cap properly and

push the RIGHT button to turn off the message. If

the problem continues, the message will appear

the next time the vehicle is started.

REFUELING THE VEHICLE — DIESEL ENGINE

NOTE:

When the fuel nozzle “clicks” or shuts off, the

fuel tank is full.

Tighten the fuel filler cap until you hear a

“clicking” sound. This is an indication that the

fuel filler cap is properly tightened.

Make sure that the fuel filler cap is tightened

each time the vehicle is refueled.

The inlet for the engine air intake is located

behind the passenger side headlamp and

receives air through the grille.

CAUTION!

Damage to the fuel system or emissions

control system could result from using an

improper fuel tank filler tube cap (fuel filler

cap). A poorly fitting cap could let impurities

into the fuel system. Also, a poorly-fitted after

-

market cap can cause the Malfunction Indi -

cator Light (MIL) to illuminate due to fuel

vapors escaping from the system.

A poorly fitting fuel filler cap may cause the

MIL to turn on.

To avoid fuel spillage and overfilling, do not

“top off” the fuel tank after filling.

WARNING!WARNING!

Never have any smoking materials lit in or

near the vehicle when the gas cap is removed

or the tank is being filled.

Never add fuel to the vehicle when the engine

is running. This is in violation of most state

and federal fire regulations and may cause

the MIL to turn on.

WARNING!

A fire may result if gasoline is pumped into a

portable container that is inside of a vehicle. You

could be burned. Always place gas containers on

the ground while filling.

CAUTION!

To avoid fuel spillage and overfilling, do not “top

off” the fuel tank after filling.

WARNING!

A fire may result if gasoline is pumped into a

portable container that is inside of a vehicle. You

could be burned. Always place gas containers on

the ground while filling.

4

22_DPF_OM_EN_USC_t.book Page 169

Page 172 of 428

170STARTING AND OPERATING

DIESEL EXHAUST FLUID

Your vehicle is equipped with a Selective Catalytic

Reduction (SCR) system to meet the very stringent

diesel emissions standards required by the

Environmental Protection Agency.

The purpose of the SCR system is to reduce levels

of NOx (oxides of nitrogen emitted from engines)

that are harmful to our health and the environment

to a near-zero level. A small quantity of Diesel

Exhaust Fluid (DEF) is injected into the exhaust

upstream of a catalyst where, when vaporized, it

converts smog-forming nitrogen oxides (NOx) into

harmless nitrogen (N2) and water vapor (H2O), two

natural components of the air we breathe. You can

operate with the comfort that your vehicle is

contributing to a cleaner, healthier world

environment for this and generations to come.

System Overview

This vehicle is equipped with a Diesel Exhaust Fluid

(DEF) injection system and a Selective Catalytic

Reduction (SCR) catalyst to meet the emission

requirements.

The DEF injection system consists of the following

components:

DEF tank

DEF pump

DEF injector

Electronically-heated DEF lines

DEF control module

NOx sensors

Temperature sensors

SCR catalyst

UQS Sensor

For system messages and warnings Ú page 81.

NOTE:

Your vehicle is equipped with a DEF injection

system. You may occasionally hear an audible

clicking noise. This is normal operation.

The DEF pump will run for a period of time after

engine shutdown to purge the DEF system. This

is normal operation.

Diesel Exhaust Fluid Storage

Diesel Exhaust Fluid (DEF) is considered a very

stable product with a long shelf life. If DEF is kept

in temperatures between 10° and 90°F (-12° and

32°C), it will last a minimum of one year.

DEF is subject to freezing at the lowest

temperatures. For example, DEF may freeze at

temperatures at or below 12°F (-11°C). The

system has been designed to operate in this

environment.

NOTE:When working with DEF, it is important to know

that:

Any containers or parts that come into contact

with DEF must be DEF compatible (plastic or

stainless steel). Copper, brass, aluminum, iron

or non-stainless steel should be avoided as they

are subject to corrosion by DEF.

If DEF is spilled, it should be wiped up

completely.

Adding Diesel Exhaust Fluid (DEF)

The DEF gauge (located on the instrument cluster)

will display the level of DEF remaining in the tank

Úpage 81.

NOTE:

Driving conditions (altitude, vehicle speed, load,

etc.) will effect the amount of DEF that is used in

your vehicle.

Another factor is that outside temperature can

affect DEF consumption. In cold conditions,

12°F (-11°C) and below, the DEF gauge needle

can stay on a fixed position and may not move

for extended periods of time. This is a normal

function of the system.

There is an electric heater inside the DEF tank

that automatically works when necessary. If the

DEF supply does freeze, the truck will operate

normally until it thaws.

22_DPF_OM_EN_USC_t.book Page 170

Page 173 of 428

STARTING AND OPERATING171

(Continued)

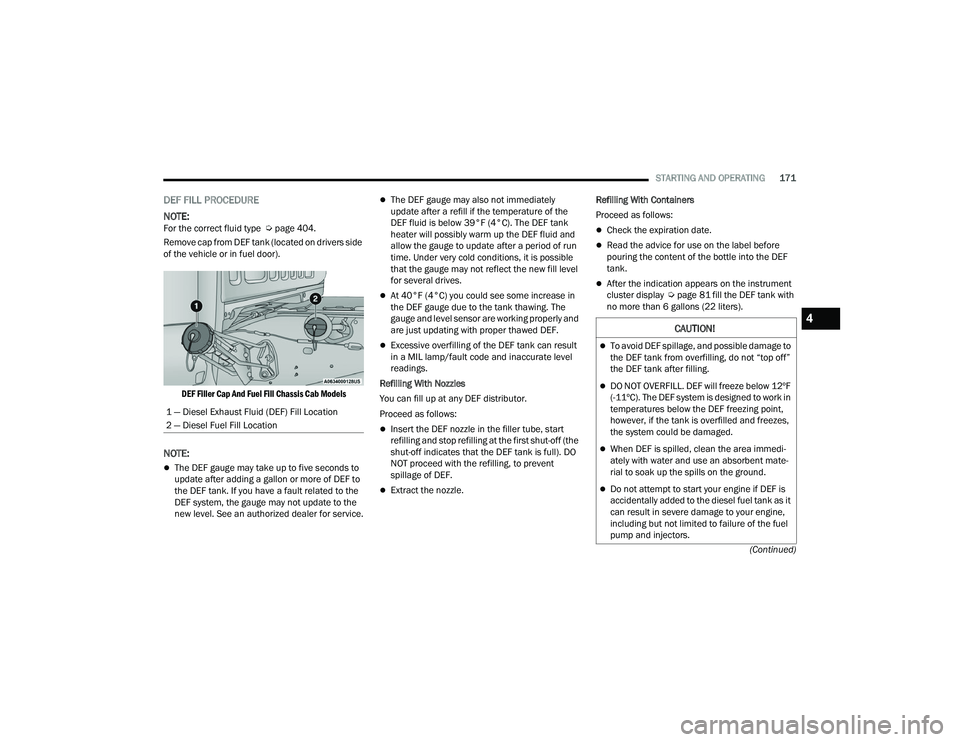

DEF FILL PROCEDURE

NOTE:

For the correct fluid type Ú page 404.

Remove cap from DEF tank (located on drivers side

of the vehicle or in fuel door).

DEF Filler Cap And Fuel Fill Chassis Cab Models

NOTE:

The DEF gauge may take up to five seconds to

update after adding a gallon or more of DEF to

the DEF tank. If you have a fault related to the

DEF system, the gauge may not update to the

new level. See an authorized dealer for service.

The DEF gauge may also not immediately

update after a refill if the temperature of the

DEF fluid is below 39°F (4°C). The DEF tank

heater will possibly warm up the DEF fluid and

allow the gauge to update after a period of run

time. Under very cold conditions, it is possible

that the gauge may not reflect the new fill level

for several drives.

At 40°F (4°C) you could see some increase in

the DEF gauge due to the tank thawing. The

gauge and level sensor are working properly and

are just updating with proper thawed DEF.

Excessive overfilling of the DEF tank can result

in a MIL lamp/fault code and inaccurate level

readings.

Refilling With Nozzles

You can fill up at any DEF distributor.

Proceed as follows:

Insert the DEF nozzle in the filler tube, start

refilling and stop refilling at the first shut-off (the

shut-off indicates that the DEF tank is full). DO

NOT proceed with the refilling, to prevent

spillage of DEF.

Extract the nozzle. Refilling With Containers

Proceed as follows:

Check the expiration date.

Read the advice for use on the label before

pouring the content of the bottle into the DEF

tank.

After the indication appears on the instrument

cluster display

Úpage 81 fill the DEF tank with

no more than 6 gallons (22 liters).

1 — Diesel Exhaust Fluid (DEF) Fill Location

2 — Diesel Fuel Fill Location

CAUTION!

To avoid DEF spillage, and possible damage to

the DEF tank from overfilling, do not “top off”

the DEF tank after filling.

DO NOT OVERFILL. DEF will freeze below 12ºF

(-11ºC). The DEF system is designed to work in

temperatures below the DEF freezing point,

however, if the tank is overfilled and freezes,

the system could be damaged.

When DEF is spilled, clean the area immedi -

ately with water and use an absorbent mate -

rial to soak up the spills on the ground.

Do not attempt to start your engine if DEF is

accidentally added to the diesel fuel tank as it

can result in severe damage to your engine,

including but not limited to failure of the fuel

pump and injectors.

4

22_DPF_OM_EN_USC_t.book Page 171

Page 174 of 428

172STARTING AND OPERATING

Stop filling the DEF tank immediately if DEF

splashes or wells back in the filler neck.

Reinstall cap onto DEF filler tube.

Filling The Def Tank In Cold Climates

Since DEF will begin to freeze at 12°F (-11°C),

your vehicle is equipped with an automatic DEF

heating system. This allows the DEF injection

system to operate properly at temperatures below

12°F (-11°C). If your vehicle is not in operation for

an extended period of time with temperatures

below 12°F (-11°C), the DEF in the tank may

freeze. If the tank is overfilled and freezes, it could

be damaged. Therefore, do not overfill the DEF

tank. Extra care should be taken when filling with

portable containers to avoid overfilling. Note the

level of the DEF gauge in your instrument cluster.

You may safely add a maximum of 2 gallons

(7.5 liters) of DEF from portable containers when

your DEF gauge is reading ½ full.

VEHICLE LOADING

GROSS VEHICLE WEIGHT RATING

(GVWR)

The GVWR is the total permissible weight of your

vehicle including driver, passengers, vehicle,

options and cargo. The label also specifies

maximum capacities of front and rear axle systems

(GAWR). Total load must be limited so GVWR and

front and rear GAWR are not exceeded.

PAYLOAD

The payload of a vehicle is defined as the allowable

load weight a truck can carry, including the weight

of the driver, all passengers, options and cargo.

GROSS AXLE WEIGHT RATING (GAWR)

The GAWR is the maximum permissible load on the

front and rear axles. The load must be distributed

in the cargo area so that the GAWR of each axle is

not exceeded. Each axle GAWR is determined by the components

in the system with the lowest load carrying capacity

(axle, springs, tires or wheels). Heavier axles or

suspension components sometimes specified by

purchasers for increased durability does not

necessarily increase the vehicle's GVWR.

TIRE SIZE

The tire size on the Vehicle Certification Label

represents the actual tire size on your vehicle.

Replacement tires must be equal to the load

capacity of this tire size.

RIM SIZE

This is the rim size that is appropriate for the tire

size listed.

INFLATION PRESSURE

This is the cold tire inflation pressure for your

vehicle for all loading conditions up to full GAWR.

CURB WEIGHT

The curb weight of a vehicle is defined as the total

weight of the vehicle with all fluids, including

vehicle fuel, at full capacity conditions, and with no

occupants or cargo loaded into the vehicle. The

front and rear curb weight values are determined

by weighing your vehicle on a commercial scale

before any occupants or cargo are added.

Never add anything other than DEF to the tank

– especially any form of hydrocarbon such as

diesel fuel, fuel system additives, gasoline, or

any other petroleum-based product. Even a very

small amount of these, less than 100 parts per

million or less than 1 oz. per 78 gallons

(295 liters) will contaminate the entire DEF

system and will require replacement. If owners

use a container, funnel or nozzle when refilling

the tank, it should either be new or one that has

only been used for adding DEF. Mopar®

provides an attachable nozzle with its DEF for

this purpose.

CAUTION!

22_DPF_OM_EN_USC_t.book Page 172

Page 181 of 428

STARTING AND OPERATING179

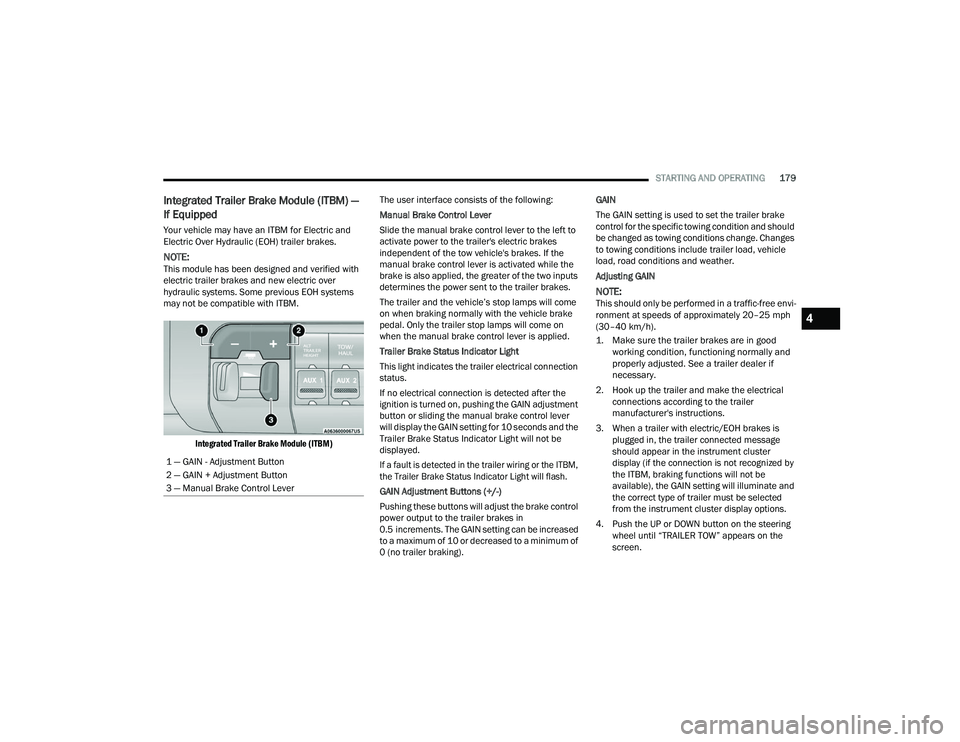

Integrated Trailer Brake Module (ITBM) —

If Equipped

Your vehicle may have an ITBM for Electric and

Electric Over Hydraulic (EOH) trailer brakes.

NOTE:This module has been designed and verified with

electric trailer brakes and new electric over

hydraulic systems. Some previous EOH systems

may not be compatible with ITBM.

Integrated Trailer Brake Module (ITBM)

The user interface consists of the following:

Manual Brake Control Lever

Slide the manual brake control lever to the left to

activate power to the trailer's electric brakes

independent of the tow vehicle's brakes. If the

manual brake control lever is activated while the

brake is also applied, the greater of the two inputs

determines the power sent to the trailer brakes.

The trailer and the vehicle’s stop lamps will come

on when braking normally with the vehicle brake

pedal. Only the trailer stop lamps will come on

when the manual brake control lever is applied.

Trailer Brake Status Indicator Light

This light indicates the trailer electrical connection

status.

If no electrical connection is detected after the

ignition is turned on, pushing the GAIN adjustment

button or sliding the manual brake control lever

will display the GAIN setting for 10 seconds and the

Trailer Brake Status Indicator Light will not be

displayed.

If a fault is detected in the trailer wiring or the ITBM,

the Trailer Brake Status Indicator Light will flash.

GAIN Adjustment Buttons (+/-)

Pushing these buttons will adjust the brake control

power output to the trailer brakes in

0.5 increments. The GAIN setting can be increased

to a maximum of 10 or decreased to a minimum of

0 (no trailer braking). GAIN

The GAIN setting is used to set the trailer brake

control for the specific towing condition and should

be changed as towing conditions change. Changes

to towing conditions include trailer load, vehicle

load, road conditions and weather.

Adjusting GAIN

NOTE:This should only be performed in a traffic-free envi

-

ronment at speeds of approximately 20–25 mph

(30–40 km/h).

1. Make sure the trailer brakes are in good working condition, functioning normally and

properly adjusted. See a trailer dealer if

necessary.

2. Hook up the trailer and make the electrical connections according to the trailer

manufacturer's instructions.

3. When a trailer with electric/EOH brakes is plugged in, the trailer connected message

should appear in the instrument cluster

display (if the connection is not recognized by

the ITBM, braking functions will not be

available), the GAIN setting will illuminate and

the correct type of trailer must be selected

from the instrument cluster display options.

4. Push the UP or DOWN button on the steering wheel until “TRAILER TOW” appears on the

screen.

1 — GAIN - Adjustment Button

2 — GAIN + Adjustment Button

3 — Manual Brake Control Lever

4

22_DPF_OM_EN_USC_t.book Page 179

Page 182 of 428

180STARTING AND OPERATING

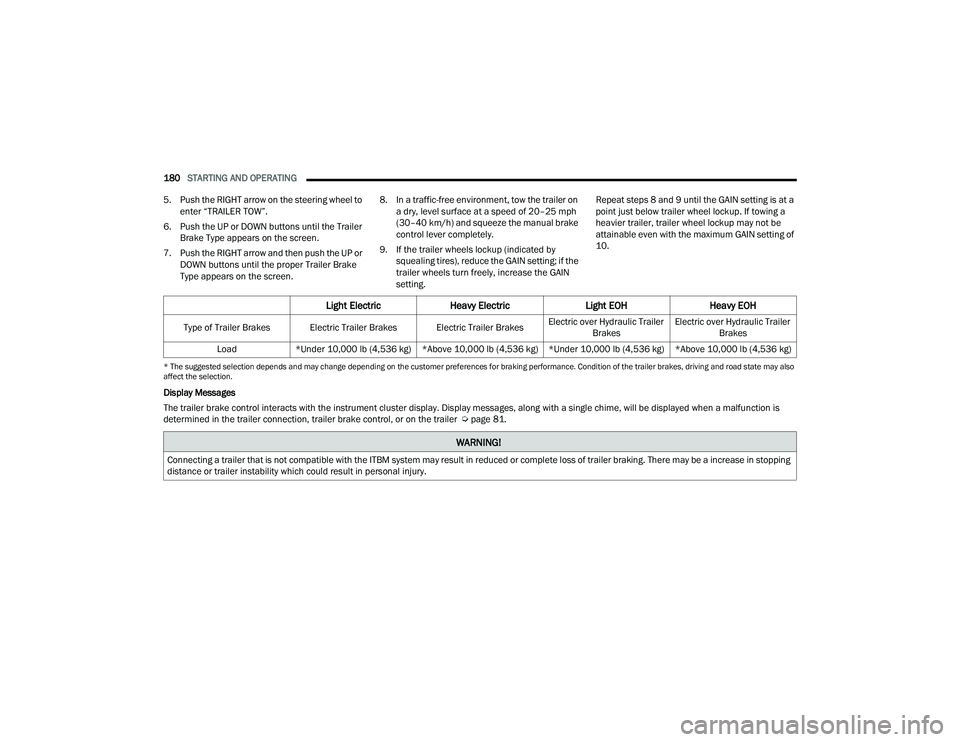

5. Push the RIGHT arrow on the steering wheel to enter “TRAILER TOW”.

6. Push the UP or DOWN buttons until the Trailer Brake Type appears on the screen.

7. Push the RIGHT arrow and then push the UP or DOWN buttons until the proper Trailer Brake

Type appears on the screen. 8. In a traffic-free environment, tow the trailer on

a dry, level surface at a speed of 20–25 mph

(30–40 km/h) and squeeze the manual brake

control lever completely.

9. If the trailer wheels lockup (indicated by squealing tires), reduce the GAIN setting; if the

trailer wheels turn freely, increase the GAIN

setting. Repeat steps 8 and 9 until the GAIN setting is at a

point just below trailer wheel lockup. If towing a

heavier trailer, trailer wheel lockup may not be

attainable even with the maximum GAIN setting of

10.

* The suggested selection depends and may change depending on the customer preferences for braking performance. Condition of the trailer brakes, driving and road state may also

affect the selection.

Display Messages

The trailer brake control interacts with the instrument cluster display. Display messages, along with a single chime, will be displayed when a malfunction is

determined in the trailer connection, trailer brake control, or on the trailer Ú

page 81.

Light ElectricHeavy Electric Light EOHHeavy EOH

Type of Trailer Brakes Electric Trailer Brakes Electric Trailer Brakes Electric over Hydraulic Trailer

Brakes Electric over Hydraulic Trailer

Brakes

Load *Under 10,000 lb (4,536 kg) *Above 10,000 lb (4,536 kg) *Under 10,000 lb (4,536 kg) *Above 10,000 lb (4,536 kg)

WARNING!

Connecting a trailer that is not compatible with the ITBM system may result in reduced or complete loss of trailer braking. There may be a increase in stopping

distance or trailer instability which could result in personal injury.

22_DPF_OM_EN_USC_t.book Page 180

Page 183 of 428

STARTING AND OPERATING181

NOTE:

An aftermarket controller may be available for

use with trailers with air or EOH trailer brake

systems. To determine the type of brakes on

your trailer and the availability of controllers,

check with your trailer manufacturer or dealer.

Removal of the ITBM will cause errors and it

may cause damage to the electrical system and

electronic modules of the vehicle. See an autho -

rized dealer if an aftermarket module is to be

installed.

Towing Requirements — Trailer Lights And

Wiring

Whenever you pull a trailer, regardless of the trailer

size, stoplights and turn signals on the trailer are

required for motoring safety.

The Trailer Tow Package may include a four- and

seven-pin wiring harness. Use a factory approved

trailer harness and connector.

NOTE:Do not cut or splice wiring into the vehicle’s wiring

harness.

The electrical connections are all complete to the

vehicle but you must mate the harness to a trailer

connector. Refer to the following illustrations.

NOTE:

Disconnect trailer wiring connector from the

vehicle before launching a boat (or any other

device plugged into vehicle’s electrical connect)

into water.

Be sure to reconnect once clear from water

area.

Four-Pin Connector Seven-Pin Connector

Trailer Light Check

This feature will run the trailer lights through a

sequence to check the trailer light function. It is

available in the instrument cluster under the

Trailer Tow menu Ú page 85.

CAUTION!

Connecting a trailer that is not compatible with

the ITBM system may result in reduced or

complete loss of trailer braking. There may be a

increase in stopping distance or trailer instability

which could result in damage to your vehicle,

trailer, or other property.

1 — Ground

2 — Park

3 — Left Stop/Turn

4 — Right Stop/Turn

1 — Backup Lamps

2 — Running Lamps

3 — Left Stop/Turn

4 — Ground

5 — Battery

6 — Right Stop/Turn

7 — Electric Brakes

4

22_DPF_OM_EN_USC_t.book Page 181