water pump RAM CHASSIS CAB 2022 Owners Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2022, Model line: CHASSIS CAB, Model: RAM CHASSIS CAB 2022Pages: 428, PDF Size: 20.18 MB

Page 172 of 428

170STARTING AND OPERATING

DIESEL EXHAUST FLUID

Your vehicle is equipped with a Selective Catalytic

Reduction (SCR) system to meet the very stringent

diesel emissions standards required by the

Environmental Protection Agency.

The purpose of the SCR system is to reduce levels

of NOx (oxides of nitrogen emitted from engines)

that are harmful to our health and the environment

to a near-zero level. A small quantity of Diesel

Exhaust Fluid (DEF) is injected into the exhaust

upstream of a catalyst where, when vaporized, it

converts smog-forming nitrogen oxides (NOx) into

harmless nitrogen (N2) and water vapor (H2O), two

natural components of the air we breathe. You can

operate with the comfort that your vehicle is

contributing to a cleaner, healthier world

environment for this and generations to come.

System Overview

This vehicle is equipped with a Diesel Exhaust Fluid

(DEF) injection system and a Selective Catalytic

Reduction (SCR) catalyst to meet the emission

requirements.

The DEF injection system consists of the following

components:

DEF tank

DEF pump

DEF injector

Electronically-heated DEF lines

DEF control module

NOx sensors

Temperature sensors

SCR catalyst

UQS Sensor

For system messages and warnings Ú page 81.

NOTE:

Your vehicle is equipped with a DEF injection

system. You may occasionally hear an audible

clicking noise. This is normal operation.

The DEF pump will run for a period of time after

engine shutdown to purge the DEF system. This

is normal operation.

Diesel Exhaust Fluid Storage

Diesel Exhaust Fluid (DEF) is considered a very

stable product with a long shelf life. If DEF is kept

in temperatures between 10° and 90°F (-12° and

32°C), it will last a minimum of one year.

DEF is subject to freezing at the lowest

temperatures. For example, DEF may freeze at

temperatures at or below 12°F (-11°C). The

system has been designed to operate in this

environment.

NOTE:When working with DEF, it is important to know

that:

Any containers or parts that come into contact

with DEF must be DEF compatible (plastic or

stainless steel). Copper, brass, aluminum, iron

or non-stainless steel should be avoided as they

are subject to corrosion by DEF.

If DEF is spilled, it should be wiped up

completely.

Adding Diesel Exhaust Fluid (DEF)

The DEF gauge (located on the instrument cluster)

will display the level of DEF remaining in the tank

Úpage 81.

NOTE:

Driving conditions (altitude, vehicle speed, load,

etc.) will effect the amount of DEF that is used in

your vehicle.

Another factor is that outside temperature can

affect DEF consumption. In cold conditions,

12°F (-11°C) and below, the DEF gauge needle

can stay on a fixed position and may not move

for extended periods of time. This is a normal

function of the system.

There is an electric heater inside the DEF tank

that automatically works when necessary. If the

DEF supply does freeze, the truck will operate

normally until it thaws.

22_DPF_OM_EN_USC_t.book Page 170

Page 173 of 428

STARTING AND OPERATING171

(Continued)

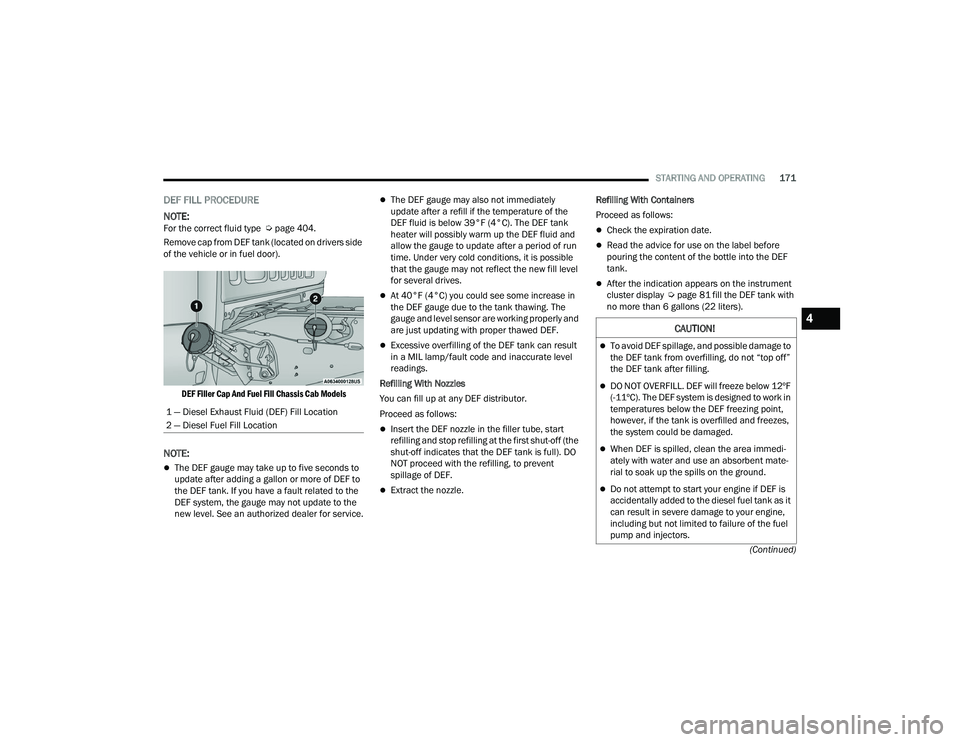

DEF FILL PROCEDURE

NOTE:

For the correct fluid type Ú page 404.

Remove cap from DEF tank (located on drivers side

of the vehicle or in fuel door).

DEF Filler Cap And Fuel Fill Chassis Cab Models

NOTE:

The DEF gauge may take up to five seconds to

update after adding a gallon or more of DEF to

the DEF tank. If you have a fault related to the

DEF system, the gauge may not update to the

new level. See an authorized dealer for service.

The DEF gauge may also not immediately

update after a refill if the temperature of the

DEF fluid is below 39°F (4°C). The DEF tank

heater will possibly warm up the DEF fluid and

allow the gauge to update after a period of run

time. Under very cold conditions, it is possible

that the gauge may not reflect the new fill level

for several drives.

At 40°F (4°C) you could see some increase in

the DEF gauge due to the tank thawing. The

gauge and level sensor are working properly and

are just updating with proper thawed DEF.

Excessive overfilling of the DEF tank can result

in a MIL lamp/fault code and inaccurate level

readings.

Refilling With Nozzles

You can fill up at any DEF distributor.

Proceed as follows:

Insert the DEF nozzle in the filler tube, start

refilling and stop refilling at the first shut-off (the

shut-off indicates that the DEF tank is full). DO

NOT proceed with the refilling, to prevent

spillage of DEF.

Extract the nozzle. Refilling With Containers

Proceed as follows:

Check the expiration date.

Read the advice for use on the label before

pouring the content of the bottle into the DEF

tank.

After the indication appears on the instrument

cluster display

Úpage 81 fill the DEF tank with

no more than 6 gallons (22 liters).

1 — Diesel Exhaust Fluid (DEF) Fill Location

2 — Diesel Fuel Fill Location

CAUTION!

To avoid DEF spillage, and possible damage to

the DEF tank from overfilling, do not “top off”

the DEF tank after filling.

DO NOT OVERFILL. DEF will freeze below 12ºF

(-11ºC). The DEF system is designed to work in

temperatures below the DEF freezing point,

however, if the tank is overfilled and freezes,

the system could be damaged.

When DEF is spilled, clean the area immedi -

ately with water and use an absorbent mate -

rial to soak up the spills on the ground.

Do not attempt to start your engine if DEF is

accidentally added to the diesel fuel tank as it

can result in severe damage to your engine,

including but not limited to failure of the fuel

pump and injectors.

4

22_DPF_OM_EN_USC_t.book Page 171

Page 350 of 428

348SERVICING AND MAINTENANCE

station, or government agency for advice on recy -

cling programs and for where used fluids and

filters can be properly disposed of in your area.

Drain the fuel/water separator filters when the

“Water In Fuel Indicator Light” is ON. Within

10 minutes of vehicle shutdown, turn the engine

mounted filter drain valve (located on the side of

the filter assembly) counterclockwise a quarter

turn, and turn the under body mounted filter drain

valve (located on the bottom of the filter assembly)

counterclockwise 1 full turn. Then turn the ignition

switch to the ON position, and allow any

accumulated water to drain. Leave the drain valve

open until all water and contaminants have been

removed. When clean fuel is visible, close the drain

valve following these guidelines:

1. Rotate the drain clockwise to close until you feel resistance from the internal seal.

2. Continue turning the drain half of a turn to properly compress the seal.

NOTE:Over-compression of the seal due to overtightening

of the drain will damage the seal, cause a leak, and

require the entire sensor to be replaced.

3. Turn the ignition switch to OFF. The sensor drain should not be overtightened

during normal service operations to avoid internal

damage and future fuel leaks. The drain should be

closed and secured without the use of tools.

If more than a couple ounces/milliliters of fuel

have been drained, follow the directions

Ú

page 350

ENGINE MOUNTED FUEL FILTER

R

EPLACEMENT

NOTE:

Using a fuel filter that does not meet the manu -

facturer's filtration and water separating

requirements can severely impact fuel system

life and reliability.

The engine mounted filter housing is equipped

with a No-Filter-No-Run (NFNR) feature. Engine

will not run if:

No filter is installed.

Inferior/Non-approved filter is used. Use of

OEM filter is required to ensure vehicle will

run.

Engine Mounted Fuel Filter Assembly

1 — Drain Valve

CAUTION!

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appropriate

container.

Do not prefill the fuel filter when installing a

new fuel filter. There is a possibility debris

could be introduced into the fuel filter during

this action. It is best to install the filter dry and

allow the in-tank lift pump to prime the fuel

system.

22_DPF_OM_EN_USC_t.book Page 348

Page 351 of 428

SERVICING AND MAINTENANCE349

1. Ensure engine is turned off.

2. Place drain pan under the fuel filter drain hose.

3. Open the water drain valve a quarter turn counterclockwise and completely drain fuel

and water into the approved container.

4. Close the water drain valve.

5. Remove lid using a socket or strap wrench. Rotate counterclockwise for removal. Remove

used o-ring and discard it.

6. Remove the used filter cartridge from the housing and dispose of according to your local

regulations.

7. Wipe clean the sealing surfaces of the lid and housing.

8. Install new o-ring back into ring groove on the filter housing and lubricate with clean engine

oil.

9. Remove new filter cartridge from plastic bag and install into housing.

NOTE:Do not remove cartridge from bag until you reach

this step in order to keep cartridge clean.

10. Push down on the cartridge to ensure it is properly seated. Do not pre-fill the filter

housing with fuel. 11. Install lid onto housing and tighten to 22.5 ft lb

(30.5 N.m). Do not overtighten the lid.

12. Prime the engine, then start the engine and confirm there are no leaks Ú page 350.

UNDERBODY MOUNTED FUEL FILTER

R

EPLACEMENT

NOTE:

Using a fuel filter that does not meet the manu -

facturer's filtration and water separating

requirements can severely impact fuel system

life and reliability.

The underbody mounted filter housing will

cause the engine not to run if:

a. No filter is installed.

Underbody Mounted Fuel Filter Assembly

1. Ensure engine is turned off.

2. Place drain pan under the fuel filter drain hose.

3. Open the water drain valve one full turn

counterclockwise and completely drain fuel

and water into the approved container.

4. Close the water drain valve.

5. Remove lid using a socket or strap wrench. Rotate counterclockwise for removal. Remove

used o-ring and discard it.

6. Remove the used filter cartridge from the housing and dispose of according to your local

regulations.

7. Wipe clean the sealing surfaces of the lid and housing.

1 — Drain Valve

CAUTION!

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appropriate

container.

Do not prefill the fuel filter when installing a

new fuel filter. There is a possibility debris

could be introduced into the fuel filter during

this action. It is best to install the filter dry and

allow the in-tank lift pump to prime the fuel

system.

8

22_DPF_OM_EN_USC_t.book Page 349

Page 352 of 428

350SERVICING AND MAINTENANCE

8. Install new o-ring back into ring groove on the filter housing and lubricate with clean engine

oil.

NOTE:Water In Fuel (WIF) sensor is re-usable. Service kit

comes with new o-ring for filter canister and WIF

sensor.

PRIMING IF THE ENGINE HAS RUN OUT

O

F FUEL

1. Add a substantial amount of fuel to the tank,

approximately 2 to 5 gal (8L to 19L).

2. Three priming cycles must be completed. Turn ignition to the RUN position and wait approxi -

mately 30 seconds. This will activate the in tank

fuel pump. Turn the ignition switch to the off

position, and leave off for at least 30 seconds.

Repeat this procedure three times before

cranking the engine.

3. Start the engine using the “Normal Starting”

procedure Ú page 108.

4. Once the engine starts, allow the engine to idle for a minimum of 30 seconds.

NOTE:The engine may run rough until the air is forced

from all the fuel lines.

NOTE:

A maximum blend of 5% biodiesel, meeting

ASTM specification D-975 may be used with

your Cummins® diesel engine.

A maximum blend of 20% biodiesel, meeting

ASTM specification D-7467 may be used with

your Cummins® diesel engine.

Use of biodiesel mixture in excess of 20% can

negatively impact the fuel filter's ability to sepa -

rate water from the fuel, resulting in high pres -

sure fuel system corrosion or damage.

Ethanol blends are not recommended or

approved for use with your Cummins® diesel

engine.

In addition, commercially available fuel addi -

tives are not necessary for the proper operation

of your Cummins® diesel engine.

INTERVENTION REGENERATION

S

TRATEGY — MESSAGE PROCESS FLOW

The Cummins® diesel engine meets all

Environmental Protection Agency (EPA) Heavy Duty

Diesel Engine Emissions Standards, resulting in

one of the lowest emitting diesel engines ever

produced.

To achieve these emissions standards, your

vehicle is equipped with a state-of-the-art engine

and exhaust system. The engine and exhaust

after-treatment system work together to achieve

WARNING!

Do not open the high pressure fuel system with

the engine running. Engine operation causes

high fuel pressure. High pressure fuel spray can

cause serious injury or death.

CAUTION!

Do not engage the starter motor for more than

15 seconds at a time. Allow two minutes

between the cranking intervals.

WARNING!

Do not use alcohol or gasoline as a fuel blending

agent. They can be unstable under certain

conditions and be hazardous or explosive when

mixed with diesel fuel.

CAUTION!

Due to lack of lubricants in alcohol or gasoline,

the use of these fuels can cause damage to the

fuel system.

22_DPF_OM_EN_USC_t.book Page 350