oil RAM CHASSIS CAB 2023 Workshop Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2023, Model line: CHASSIS CAB, Model: RAM CHASSIS CAB 2023Pages: 444, PDF Size: 20.51 MB

Page 373 of 444

SERVICING AND MAINTENANCE371

(Continued)

To guarantee optimum performance of the system,

keep the surfaces of the charge air cooler,

condenser and radiator clean and free of debris.

Periodically check the hoses leading to and from

the charge air cooler for cracks or loose clamps

resulting in loss of pressure and reduced engine

performance.

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically Ú

page 344.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked when performing under the hood service

or immediately if the Brake System Warning Light

indicates system failure.

If necessary, add fluid to bring level within the

designated marks on the side of the reservoir of

the brake master cylinder. Be sure to clean the top

of the master cylinder area before removing cap.

With disc brakes the fluid level can be expected to

fall as the brake linings wear. However, an

unexpected drop in fluid level may be caused by a

leak and a system check should be conducted.

For further information Ú page 421.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting

or riding on the brake pedal can result in

abnormally high brake temperatures, excessive

lining wear, and possible brake damage. You

would not have your full braking capacity in an

emergency.

WARNING!

Use only manufacturer's recommended brake

fluid Úpage 421. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep

the master cylinder reservoir cap secured at

all times. Brake fluid in an open container

absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This

could result in a collision.

Overfilling the brake fluid reservoir can result

in spilling brake fluid on hot engine parts,

causing the brake fluid to catch fire. Brake

fluid can also damage painted and vinyl

surfaces, care should be taken to avoid its

contact with these surfaces.

Do not allow petroleum based fluid to contam -

inate the brake fluid. Brake seal components

could be damaged, causing partial or

complete brake failure. This could result in a

collision.

WARNING!

8

23_DPF_OM_EN_USC_t.book Page 371

Page 374 of 444

372SERVICING AND MAINTENANCE

AUTOMATIC TRANSMISSION

Special Additives

The manufacturer strongly recommends against

using any special additives in the transmission.

Automatic Transmission Fluid (ATF) is an

engineered product and its performance may be

impaired by supplemental additives. Therefore, do

not add any fluid additives to the transmission. The

only exception to this policy is the use of special

dyes for diagnosing fluid leaks in 6-speed

transmissions. Avoid using transmission sealers as

they may adversely affect seals.

Fluid Level Check — 8-Speed Transmission

The fluid level is preset at the factory and does not

require adjustment under normal operating

conditions. Routine fluid level checks are not

required, therefore the transmission has no

dipstick. An authorized dealer can check your

transmission fluid level using special service tools. If you notice fluid leakage or transmission

malfunction, visit an authorized dealer

immediately to have the transmission fluid level

checked. Operating the vehicle with an improper

fluid level can cause severe transmission damage.

Fluid Level Check — 6-Speed Transmission

It is best to check the fluid level when the

transmission is at normal operating temperature

(158-176°F / 70-80°C). This normally occurs

after at least 15 miles (25 km) of driving. At normal

operating temperature the fluid cannot be held

comfortably between the fingertips. You can read

the transmission sump temperature in the

instrument cluster screen Ú page 89.

Use the following procedure to check the

transmission fluid level properly:

1. Monitor the transmission temperature using the instrument cluster display, and operate

the vehicle as required to reach the normal

operating temperature. If the transmission is

not functioning properly, or the vehicle cannot be driven, see the following Note and Caution

about checking the fluid level at colder

temperatures.

2. Park the vehicle on level ground.

3. Run the engine at normal idle speed for at least 60 seconds, and leave the engine

running for the rest of this procedure.

4. Fully apply the parking brake, and press the brake pedal.

5. Place the gear selector momentarily into each gear position (allowing time for the

transmission to fully engage in each position),

ending with the transmission in PARK.

6. Remove the dipstick, wipe it clean and reinsert it until seated.

7. Remove the dipstick again and note the fluid level on both sides. The fluid level reading is

only valid if there is a solid coating of oil on

both sides of the dipstick. Note that the holes

in the dipstick will be full of fluid if the actual

level is at or above the hole. The fluid level

should be between the “HOT” (upper)

reference holes on the dipstick at normal

operating temperature. If the fluid level is low,

add fluid through the dipstick tube to bring it to

the proper level. Do not overfill. Use ONLY the

specified fluid Ú page 421. After adding any

quantity of oil through the dipstick tube, wait a

CAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage your

transmission components. Such damage is not

covered by the New Vehicle Limited Warranty.

CAUTION!

If a transmission fluid leak occurs, visit an

authorized dealer immediately. Severe

transmission damage may occur. An authorized

dealer has the proper tools to adjust the fluid

level accurately.

23_DPF_OM_EN_USC_t.book Page 372

Page 375 of 444

SERVICING AND MAINTENANCE373

minimum of two minutes for the oil to fully

drain into the transmission before rechecking

the fluid level.

NOTE:If it is necessary to check the transmission below

the operating temperature, the fluid level should

be between the two “COLD” (lower) holes on the

dipstick with the fluid at 60-70°F / 16-21°C. Only

use the COLD region of the dipstick as a rough

reference when setting the fluid level after a trans -

mission service or fluid change. Re-check the fluid

level, and adjust as required, once the trans -

mission reaches normal operating temperature.

8. Reinsert the dipstick. Check for leaks. Release the parking brake.

NOTE:If it is necessary to check the transmission below

the operating temperature, the fluid level should

be between the two COLD (lower) holes on the

dipstick with the fluid at 68-86°F / 20-30°C. Only

use the COLD region of the dipstick as a rough

reference when setting the fluid level after a trans -

mission service or fluid change. Re-check the fluid

level, and adjust as required, once the trans -

mission reaches normal operating temperature.

Fluid And Filter Changes — 8-Speed

Transmission

Under normal operating conditions, the fluid

installed at the factory will provide satisfactory

lubrication for the life of the vehicle.

Routine fluid and filter changes are not required.

However, change the fluid and filter if the fluid

becomes contaminated (with water, etc.), or if the

transmission is disassembled for any reason.

Fluid And Filter Changes — 6-Speed

Transmission

For the proper maintenance intervals Úpage 344.

In addition, change the fluid and filters if the fluid

becomes contaminated (with water, etc.), or if the

transmission is disassembled for any reason.

Selection Of Lubricant

It is important to use the proper transmission fluid

to ensure optimum transmission performance and

life. Use only the manufacturer’s specified

transmission fluid Ú page 421. It is important to

maintain the transmission fluid at the correct level

using the recommended fluid. No chemical flushes

should be used in any transmission; only the

approved lubricant should be used.

CAUTION!

If the fluid temperature is below 50°F (10°C) it

may not register on the dipstick. Do not add fluid

until the temperature is elevated enough to

produce an accurate reading. Run the engine at

idle, in PARK, to warm the fluid.

CAUTION!

If the fluid temperature is below 50°F (10°C) it

may not register on the dipstick. Do not add fluid

until the temperature is elevated enough to

produce an accurate reading. Run the engine at

idle, in PARK, to warm the fluid.

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may cause

deterioration in transmission shift quality and/or

torque converter shudder, and (for 6-speed

transmissions) will require more frequent fluid

and filter changes Ú page 421.

8

23_DPF_OM_EN_USC_t.book Page 373

Page 376 of 444

374SERVICING AND MAINTENANCE

REAR AXLE AND 4X4 FRONT DRIVING

A

XLE FLUID LEVEL

For normal service, periodic fluid level checks are

not required. When the vehicle is serviced for other

reasons the exterior surfaces of the axle assembly

should be inspected. If gear oil leakage is

suspected, inspect the fluid level with the vehicle

in a level position.

When checking the fluid level, the vehicle should

be in a level position. The fluid level at room

temperature should be as follows:

3500 Front Axle: ¼ inch ± ¼ inch (6.4 mm ±

6.4 mm) below the bottom of the fill hole.

3500 Rear Axle: ¼ inch ± ¼ inch (6.4 mm ±

6.4 mm) below the bottom of the fill hole.

4500/5500 Front Axle: ¼ inch +/- ¼ inch

(6.4 mm ± 6.4 mm) below the bottom of the fill

hole.

4500/5500 Rear Axle: 1/8 inch +/- 1/8 inch (3.2 mm +/- 3.2 mm) below the bottom of the fill

hole.

Drain And Refill

On 4500/5500 vehicles, remove the lower bolt to

drain the axle fluid.

4500/5500 Rear Axle Plugs

For the proper maintenance intervals Úpage 344.

Lubricant Selection

For further information Ú page 421.

NOTE:The presence of water in the gear lubricant will

result in corrosion and possible failure of differ -

ential components. Operation of the vehicle in

water, as may be encountered in some off-highway

types of service, will require draining and refilling

the axle to avoid damage.

Limited-Slip Differentials DO REQUIRE limited slip

oil additive (friction modifiers).

NOTE:Slight noise and mild shuddering may be evident

while turning a vehicle with limited slip differential

on concrete or dry pavement. These conditions

should be considered normal operation of the

limited slip differential.

TRANSFER CASE

Fluid Level Check

This fluid level can be checked by removing the

filler plug. The fluid level should be to the bottom

edge of the filler plug hole with the vehicle in a level

position.

Drain And Refill

For the proper maintenance intervals Úpage 344.

Selection Of Lubricant

Use only the manufacturer's recommended fluid

Úpage 421.

NOISE CONTROL SYSTEM REQUIRED

M

AINTENANCE & WARRANTY

All vehicles built over 10,000 lb (4,535 kg) Gross

Vehicle Weight Rating and manufactured for sale

and use in the United States are required to

comply with the Federal Government's Exterior

Noise Regulations. These vehicles can be

identified by the Noise Emission Control Label

located in the operator's compartment.

1 — 4500/5500 Rear Axle Fluid Fill Plug

2 — 4500/5500 Rear Axle Fluid Drain Plug

23_DPF_OM_EN_USC_t.book Page 374

Page 383 of 444

SERVICING AND MAINTENANCE381

F41 –10 Amp RedAct Grille Shutter / Dam *

F42 –20 Amp YellowHorn

F43 –15 Amp BlueHeated Strng Wheel *

F44 –10 Amp RedDiagnostic Port

F45 ––Spare

F46 –10 Amp RedUpfitters Relay Coils *

F47 ––Spare

F48 ––Spare

F49 –15 Amp BlueIP Cluster / CSG

F50 –20 Amp YellowAir Suspension Mod *

F51 –10 Amp RedIGN Mod / KINMod / RFHub

F52 –5 Amp TanBatt Snsr

F53 –20 Amp YellowTrlr Tow – Lt Turn/Stop

F54 –20 Amp YellowNon-Memory Adj Pedals *

F55 –10 Amp RedFwd Utility Lamps

F56 –10 Amp RedVBV

F57 –20 Amp YellowTCM / PCM / Trans PRSR SW

F58 –10 Amp RedBed Lighting

F59 ––Spare

F60 ––Spare

Cavity Cartridge Fuse Micro FuseDescription

* If Equipped

8

23_DPF_OM_EN_USC_t.book Page 381

Page 384 of 444

382SERVICING AND MAINTENANCE

F61 –10 Amp RedNH3 Sensor / PM Sensor *

F62 –10 Amp RedA/C Clutch

F63 –20 Amp YellowIgnition Coils / CAPS

F64 –25 Amp ClearFuel Injectors / PCM *

F65 –10 Amp RedRVDMP / MOD BLE *

F66 –10 Amp RedSunroof / USB RR * / RR Mirror/

Passenger Wind SW

F67 –10 Amp RedUCI / TRLR 360 Cam/ Tach *

F68 –10 Amp RedAEB RACAM HTR *

F69 –15 Amp BlueSCR Mod 12 Volt *

F70 –30 Amp GreenFuel Pump Mtr / Fuel Htr RLY

F71 –25 Amp ClearAmp / Act Noise Cnsl

F72 ––Spare

F73 –20 Amp YellowFuel Transfer Pump *

F74 –10 Amp RedBackup Alarm

F75 –10 Amp RedSCR RLY / ATMM *

F76 –10 Amp RedElectronic Stability Control (ESC) *

F77 –10 Amp RedDTCM / TCM / FAD MOD / STOM

F78 –15 Amp BlueECM / PCM / IRCM / AUX Relay

Feed / HRLS

F79 –15 Amp BlueID / Clearance Lt

Cavity Cartridge Fuse Micro FuseDescription

* If Equipped

23_DPF_OM_EN_USC_t.book Page 382

Page 388 of 444

386SERVICING AND MAINTENANCE

Replacing Exterior Bulbs

BASE QUAD: LOW BEAM HEADLAMP, HIGH

BEAM HEADLAMP, FRONT PARK AND TURN —

IF EQUIPPED

Low Beam

See the following steps to replace:

1. Open the hood.

2. Disconnect and isolate the negative battery

cable.

3. Reach into the front wheel house ahead of the front wheel, remove the fastener, and lift the

cover over the access hole in the front of the

wheel house splash shield. Access to the rear

of the lamp can be gained through this access

hole.

Splash Shield Access Cover

4. Reach through the access hole of the wheel

house splash shield and disengage the bulb

access cover by rotating counterclockwise.

Bulb Access Cover

5. Disconnect the internal lamp wiring harness connector from the low beam bulb. 6. Rotate the bulb counterclockwise a quarter

turn to unlock the bulb from the lamp.

7. Pull the bulb straight out from the housing.

8. Reverse the procedure for installation of new bulb and covers.

High Beam

See the following steps to replace:

1. Open the hood.

2. Disconnect and isolate the negative battery cable.

Bulb Access Cover

3. Look under the hood and behind the headlamp to find the high beam bulb access

cover.

4. Reach behind the headlamp and disengage the access cover by rotating counterclockwise.

CAUTION!

Do not contaminate the bulb glass by touching

it with your fingers or by allowing it to contact

other oily surfaces. Shortened bulb life will

result.

Always use the correct bulb size and type for

replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp,

the bulb socket, or the lamp wiring.

23_DPF_OM_EN_USC_t.book Page 386

Page 389 of 444

SERVICING AND MAINTENANCE387

5. Disconnect the internal lamp wiring harness connector from the high beam bulb.

6. Rotate the bulb counterclockwise a quarter turn to unlock the bulb from the lamp.

7. Pull the bulb straight out from the housing.

8. Reverse the procedure for installation of new bulb and covers.

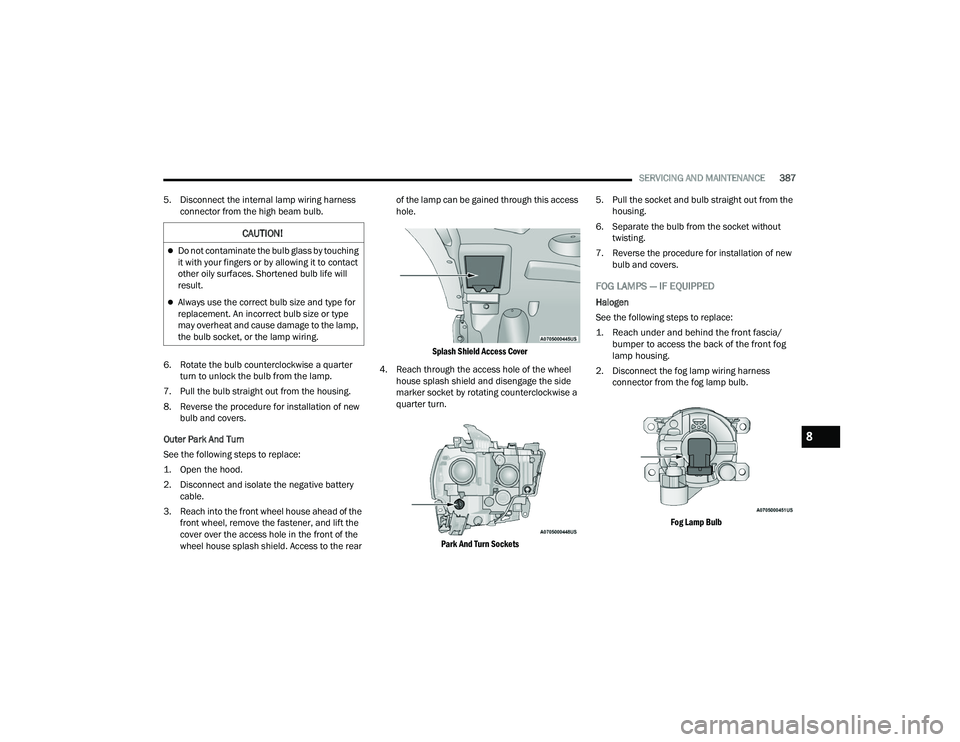

Outer Park And Turn

See the following steps to replace:

1. Open the hood.

2. Disconnect and isolate the negative battery cable.

3. Reach into the front wheel house ahead of the front wheel, remove the fastener, and lift the

cover over the access hole in the front of the

wheel house splash shield. Access to the rear of the lamp can be gained through this access

hole.

Splash Shield Access Cover

4. Reach through the access hole of the wheel house splash shield and disengage the side

marker socket by rotating counterclockwise a

quarter turn.

Park And Turn Sockets

5. Pull the socket and bulb straight out from the

housing.

6. Separate the bulb from the socket without twisting.

7. Reverse the procedure for installation of new bulb and covers.

FOG LAMPS — IF EQUIPPED

Halogen

See the following steps to replace:

1. Reach under and behind the front fascia/bumper to access the back of the front fog

lamp housing.

2. Disconnect the fog lamp wiring harness connector from the fog lamp bulb.

Fog Lamp Bulb

CAUTION!

Do not contaminate the bulb glass by touching

it with your fingers or by allowing it to contact

other oily surfaces. Shortened bulb life will

result.

Always use the correct bulb size and type for

replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp,

the bulb socket, or the lamp wiring.

8

23_DPF_OM_EN_USC_t.book Page 387

Page 390 of 444

388SERVICING AND MAINTENANCE

3. Rotate the bulb counterclockwise a quarter turn to unlock the bulb from the housing.

4. Pull the bulb straight out from the housing.

5. Reverse the procedure to install the bulb and cover.

CENTER HIGH MOUNTED STOP LAMP (CHMSL)

WITH CARGO LAMP

See the following steps to replace:

1. Remove the two screws holding the housing/lens to the body as shown.

CHMSL Mounting Screw Locations

2. Separate the connector holding the housing

and wiring harness to the body.

CHMSL Connector Location

3. Turn the desired bulb socket a quarter turn and remove the socket and bulb from housing.

4. Pull the desired bulb straight from the socket.

Outside Bulbs: Cargo Lamps

Inside Bulb: Center High Mounted Stop

Lamp

5. Reverse the procedure for installation of bulbs and housing.

CAB TOP CLEARANCE LAMPS — IF EQUIPPED

See the following steps to replace:

1. Remove the two screws from the top of the lamp.

Removing Rear Screw From Clearance Lamp

2. Rotate the bulb socket a quarter turn and pull it from the lamp assembly.

CAUTION!

Do not contaminate the bulb glass by touching it

with your fingers or by allowing it to contact other

oily surfaces. Shortened bulb life will result.

CAUTION!

Do not contaminate the bulb glass by touching it

with your fingers or by allowing it to contact other

oily surfaces. Shortened bulb life will result.

23_DPF_OM_EN_USC_t.book Page 388

Page 402 of 444

400SERVICING AND MAINTENANCE

NOTE:Wheel valve stem must be replaced as well when

installing new tires due to wear and tear in existing

tires.

Keep dismounted tires in a cool, dry place with as

little exposure to light as possible. Protect tires

from contact with oil, grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance of

many characteristics. They should be inspected

regularly for wear and correct cold tire inflation

pressures. The manufacturer strongly

recommends that you use tires equivalent to the

originals in size, quality and performance when

replacement is needed Úpage 399. Refer to the

Tire And Loading Information Placard or the

Vehicle Certification Label for the size designation

of your tire. The Load Index and Speed Symbol for

your tire will be found on the original equipment

tire sidewall.

For more information relating to the Load Index

and Speed Symbol of a tire Ú page 389.

It is recommended to replace the two front tires or

two rear tires as a pair. Replacing just one tire can

seriously affect your vehicle’s handling. If you ever

replace a wheel, make sure that the wheel’s

specifications match those of the original wheels. It is recommended you contact an authorized tire

dealer or original equipment dealer with any

questions you may have on tire specifications or

capability. Failure to use equivalent replacement

tires may adversely affect the safety, handling, and

ride of your vehicle.

TIRE TYPES

All Season Tires — If Equipped

All Season tires provide traction for all seasons

(Spring, Summer, Autumn, and Winter). Traction

levels may vary between different all season tires.

All season tires can be identified by the M+S, M&S,

M/S or MS designation on the tire sidewall. Use all

season tires only in sets of four; failure to do so

may adversely affect the safety and handling of

your vehicle.

Summer Or Three Season Tires —

If Equipped

Summer tires provide traction in both wet and dry

conditions, and are not intended to be driven in

snow or on ice. If your vehicle is equipped with

Summer tires, be aware these tires are not

designed for Winter or cold driving conditions.

Install Winter tires on your vehicle when ambient

temperatures are less than 40°F (5°C) or if roads

are covered with ice or snow. For more

information, contact an authorized dealer.

WARNING!

Do not use a tire, wheel size, load rating, or

speed rating other than that specified for your

vehicle. Some combinations of unapproved

tires and wheels may change suspension

dimensions and performance characteristics,

resulting in changes to steering, handling, and

braking of your vehicle. This can cause unpre

-

dictable handling and stress to steering and

suspension components. You could lose

control and have a collision resulting in

serious injury or death. Use only the tire and

wheel sizes with load ratings approved for

your vehicle.

Never use a tire with a smaller load index or

capacity, other than what was originally

equipped on your vehicle. Using a tire with a

smaller load index could result in tire over -

loading and failure. You could lose control and

have a collision.

Failure to equip your vehicle with tires having

adequate speed capability can result in

sudden tire failure and loss of vehicle control.

CAUTION!

Replacing original tires with tires of a different

size may result in false speedometer and

odometer readings.

23_DPF_OM_EN_USC_t.book Page 400