brake light Ram ProMaster 2014 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2014, Model line: ProMaster, Model: Ram ProMaster 2014Pages: 410, PDF Size: 2.83 MB

Page 216 of 410

WARNING!(Continued)

•Do not leave the Key Fob in or near the vehicle or

in a location accessible to children. A child could

operate power windows, other controls, or move

the vehicle.

• Be sure the parking brake is fully disengaged

before driving; failure to do so can lead to brake

failure and a collision.

• Always fully apply the parking brake when leav-

ing your vehicle, or it may roll and cause damage or

injury. Also be certain to leave a manual transmis-

sion in REVERSE or first (1st) gear. Failure to do so

may allow the vehicle to roll and cause damage or

injury.

CAUTION!

If the Brake Warning Light remains on with the

parking brake released, a brake system malfunction

is indicated. Have the brake system serviced by an

authorized dealer immediately.

BRAKE SYSTEM

In the event power assist is lost for any reason (for

example; repeated brake applications with the engine

off), the brakes will still function. The effort required to

brake the vehicle will be significantly more than that

required with the power system operating.

If either of the two hydraulic systems loses normal

capability, the remaining system will still function with

some loss of braking effectiveness. This will be evident by

increased pedal travel during application, greater pedal

214 STARTING AND OPERATING

Page 217 of 410

force required to slow or stop, and activation of the

Brake Warning Light and the ABS Warning Light during

brake use.

Four-Wheel Anti-Lock Brake System (ABS)

The Four-Wheel ABS is designed to aid the driver in

maintaining vehicle control under adverse braking con-

ditions. The system operates with a separate computer to

modulate hydraulic pressure, to prevent wheel lock-up

and to help avoid skidding on slippery surfaces.

The system’s pump motor runs during an ABS stop to

provide regulated hydraulic pressure. The pump motor

makes a low humming noise during operation, which is

normal.

The ABS includes an amber ABS Warning Light. When

the light is illuminated, the ABS is not functioning.

The system reverts to standard non-anti-lock brakes.Turning the ignition Off and On again may reset the ABS

if the fault detected was only momentary.

WARNING!

•

Pumping the Anti-Lock Brakes will diminish their

effectiveness and may lead to a collision. Pumping

makes the stopping distance longer. Just press

firmly on your brake pedal when you need to slow

down or stop.

• The Anti-Lock Brake System (ABS) cannot prevent

the natural laws of physics from acting on the

vehicle, nor can it increase braking or steering

efficiency beyond that afforded by the condition of

the vehicle brakes and tires or the traction afforded.

• The ABS cannot prevent collisions, including those

resulting from excessive speed in turns, following

another vehicle too closely, or hydroplaning.

(Continued)

5

STARTING AND OPERATING 215

Page 219 of 410

functions similarly to a limited-slip differential, and

controls the wheel spin across a driven axle. If one wheel

on a driven axle is spinning faster than the other, the

system will apply the brake of the spinning wheel. This

will allow more engine torque to be applied to the wheel

that is not spinning. This feature remains active even if

the ESC is in the “Partial Off” mode.

The “ESC Activation/Malfunction Indicator Light” (in

the instrument cluster) will start to flash as soon as the

tires lose traction and the wheels begin to spin. This

indicates that the TCS is active. If the indicator light

flashes during acceleration, ease up on the accelerator

and apply as little throttle as possible. Be sure to adapt

your speed and driving to the prevailing road conditions,

and do not switch off the ESC or TCS.WARNING!

•The TCS cannot prevent the natural laws of physics

from acting on the vehicle, nor can it increase the

traction afforded.

• The TCS cannot prevent collisions, including those

resulting from excessive speed in turns, or hydro-

planing.

• The capabilities of a TCS-equipped vehicle must

never be exploited in a reckless or dangerous

manner, which could jeopardize the user’s safety or

the safety of others.

5

STARTING AND OPERATING 217

Page 224 of 410

NOTE:

•The “ESC Activation/Malfunction Indicator Light”

and the “ESC OFF Indicator Light” come on momen-

tarily each time the ignition switch is turned ON.

• Each time the ignition is turned ON, the ESC system

will be ON even if it was turned off previously.

• The ESC system will make buzzing or clicking sounds

when it is active. This is normal; the sounds will stop

when ESC becomes inactive following the maneuver

that caused the ESC activation.

The “ESC OFF Indicator Light” indicates the

Electronic Stability Control (ESC) is off.Trailer Sway Control (TSC)

TSC uses sensors in the vehicle to recognize an exces-

sively swaying trailer and will take the appropriate

actions to attempt to stop the sway. The system may

reduce engine power and apply the brake of the appro-

priate wheel(s) to counteract the sway of the trailer. TSC

will become active automatically once an excessively

swaying trailer is recognized. Note that TSC cannot stop

all trailers from swaying. Always use caution when

towing a trailer and follow the trailer tongue weight

recommendations. Refer to “Trailer Towing” in this sec-

tion for further information. When TSC is functioning,

the “ESC Activation/Malfunction Indicator Light” will

flash, the engine power may be reduced and you may

feel the brakes being applied to individual wheels to

attempt to stop the trailer from swaying. TSC is disabled

when the ESC system is in the “Partial Off” mode.

222 STARTING AND OPERATING

Page 226 of 410

WARNING!

There may be situations on minor hills with a loaded

vehicle, or while pulling a trailer, when the system

will not activate and slight rolling may occur. This

could cause a collision with another vehicle or object.

Always remember the driver is responsible for brak-

ing the vehicle.

Towing With HSA

HSA will provide assistance when starting on a grade

when pulling a trailer.

WARNING!

•If you use a trailer brake controller with your

trailer, your trailer brakes may be activated and

deactivated with the brake switch. If so, when the

(Continued)

WARNING! (Continued)

brake pedal is released, there may not be enough

brake pressure to hold the vehicle and trailer on a

hill and this could cause a collision with another

vehicle or object behind you. In order to avoid

rolling down the hill while resuming acceleration,

manually activate the trailer brake prior to releas-

ing the brake pedal. Always remember the driver is

responsible for braking the vehicle.

• HSA is not a parking brake. If you stop the vehicle

on a hill without putting the transmission in PARK

and using the parking brake, it will roll down the

hill and could cause a collision with another ve-

hicle or object. Always remember to use the park-

ing brake while parking on a hill, and that the

driver is responsible for braking the vehicle.

224 STARTING AND OPERATING

Page 269 of 410

WARNING!

•An improperly adjusted Weight Distributing Hitch

system may reduce handling, stability, braking

performance, and could result in a collision.

•

Weight Distributing Systems may not be compatible

with Surge Brake Couplers. Consult with your hitch

and trailer manufacturer or a reputable Recreational

Vehicle dealer for additional information.

Trailer Hitch Classification

The following chart provides the industry standard for

the maximum trailer weight a given trailer hitch class can

tow and should be used to assist you in selecting the

correct trailer hitch for your intended towing condition.

Trailer Hitch Classification Definitions

Class Max. Trailer Hitch

Industry Standards

Class I - Light Duty 2,000 lbs (907 kg)

Class II - Medium Duty 3,500 lbs (1 587 kg) Class III - Heavy Duty 5,000 lbs (2 268 kg)

Class IV - Extra Heavy Duty 10,000 lbs (4 540 kg)

Refer to the “Trailer Towing Weights (Maximum

Trailer Weight Ratings)” chart for the Maximum

Gross Trailer Weight (GTW) towable for your given

drivetrain.

All trailer hitches should be professionally installed

on your vehicle.

5

STARTING AND OPERATING 267

Page 278 of 410

CAUTION!

If the trailer weighs more than 1,000 lbs (454 kg)

loaded, it should have its own brakes and they

should be of adequate capacity. Failure to do this

could lead to accelerated brake lining wear, higher

brake pedal effort, and longer stopping distances.

Towing Requirements — Trailer Lights And Wiring

Whenever you pull a trailer, regardless of the trailer size,

stoplights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may include a four- and seven-

pin wiring harness. Use a factory approved trailer har-

ness and connector.NOTE:Do not cut or splice wiring into the vehicles

wiring harness.

Trailer Electrical Connector Location

1 — Four-Pin Connector Location

2 — Seven-Pin Connector Location

276 STARTING AND OPERATING

Page 347 of 410

Master Cylinder — Brake Fluid Level Check

The fluid level in the master cylinder should be checked

when performing underhood services, or immediately if

the “Brake System Warning Light” indicates system

failure.

Clean the top of the master cylinder area before removing

the cap. Add fluid to bring the level up to the top of the

“FULL” mark on the side of the master cylinder reservoir.

Overfilling of fluid is not recommended because it may

cause leaking in the system.

Add enough fluid to bring the level up to the require-

ments described on the brake fluid reservoir. With disc

brakes, fluid level can be expected to fall as the brake

pads wear. However, low fluid level may be caused by a

leak and a checkup may be needed.Use only manufacturer’s recommended brake fluid. Re-

fer to “Fluids, Lubricants, and Genuine Parts” in “Main-

taining Your Vehicle” for further information.

WARNING!

•

Use only manufacturer’s recommended brake

fluid. Refer to “Fluids, Lubricants, and Genuine

Parts” in “Maintaining Your Vehicle” for further

information. Using the wrong type of brake fluid

can severely damage your brake system and/or

impair its performance. The proper type of brake

fluid for your vehicle is also identified on the

original factory installed hydraulic master cylinder

reservoir.

(Continued)

7

MAINTAINING YOUR VEHICLE 345

Page 364 of 410

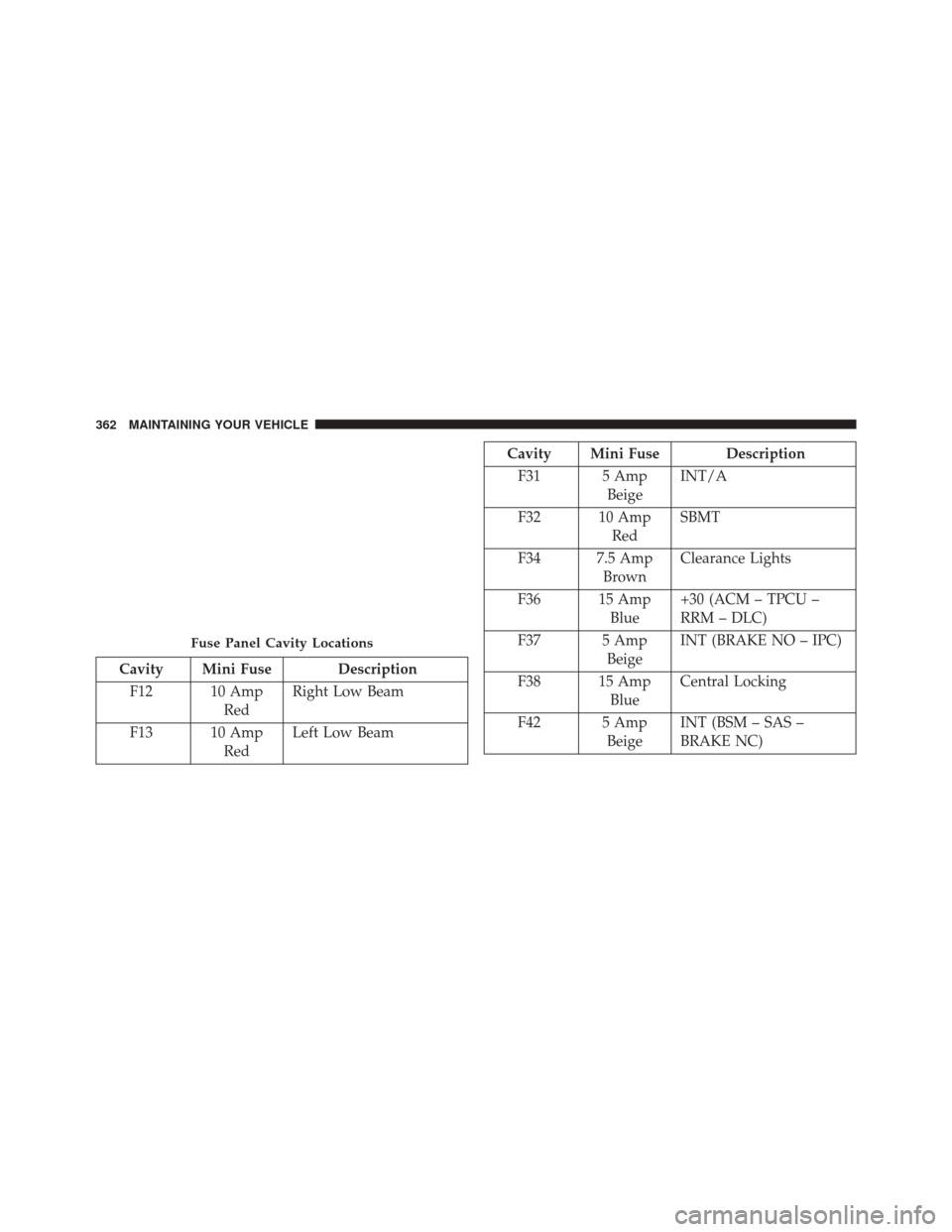

Cavity Mini Fuse DescriptionF12 10 Amp RedRight Low Beam

F13 10 Amp RedLeft Low Beam

Cavity Mini Fuse Description

F31 5 Amp BeigeINT/A

F32 10 Amp RedSBMT

F34 7.5 Amp BrownClearance Lights

F36 15 Amp Blue+30 (ACM – TPCU –

RRM – DLC)

F37 5 Amp BeigeINT (BRAKE NO – IPC)

F38 15 Amp BlueCentral Locking

F42 5 Amp BeigeINT (BSM – SAS –

BRAKE NC)

Fuse Panel Cavity Locations

362 MAINTAINING YOUR VEHICLE

Page 379 of 410

•Check the fluid levels of the coolant reservoir, brake

master cylinder, and power steering and fill as needed

• Check function of all interior and exterior lights

Required Maintenance Intervals

Refer to the maintenance schedules on the following

page for the required maintenance intervals.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

•Change oil and filter.

• Rotate the tires. Rotate at the first sign of irregu-

lar wear, even if it occurs before the oil indicator

system turns on.

• Inspect battery and clean and tighten terminals as

required.

At Every Oil Change Interval As Indicated By

Oil Change Indicator System:

•Inspect brake pads, shoes, rotors, drums, hoses

and park brake.

• Inspect engine cooling system protection and

hoses.

• Inspect exhaust system.

• Inspect engine air cleaner if using in dusty or

off-road conditions.

Maintenance Chart

Refer to the Maintenance Schedules on the following

pages for the required maintenance intervals.

8

M A I

N T

E

N

A

N

C E

S

C

H E

D

U L

E

SMAINTENANCE SCHEDULES 377