check engine Ram ProMaster 2015 Diesel Supplement

[x] Cancel search | Manufacturer: RAM, Model Year: 2015, Model line: ProMaster, Model: Ram ProMaster 2015Pages: 130, PDF Size: 0.59 MB

Page 100 of 130

spraying water from a garden hose vertically down the

face of the A/C condenser (if equipped) or the back of the

radiator core.

Check the engine cooling system hoses for brittle rubber,

cracking, tears, cuts and tightness of the connection at the

coolant recovery bottle and radiator. Inspect the entire

system for leaks.

With the engine at normal operating temperature (but

not running), check the cooling system pressure cap for

proper vacuum sealing by draining a small amount of

engine coolant (antifreeze) from the radiator drain cock.

The radiator drain cock is located in the lower radiator

tank. If the cap is sealing properly, the engine coolant

(antifreeze) will begin to drain from the coolant expan-

sion bottle. DO NOT REMOVE THE COOLANT PRES-

SURE CAP WHEN THE COOLING SYSTEM IS HOT.Cooling System — Drain Flush And Refill

If the engine coolant (antifreeze) is dirty or contains a

considerable amount of sediment, clean and flush with a

reliable cooling system cleaner. Follow with a thorough

rinsing to remove all deposits and chemicals. Properly

dispose of old engine coolant (antifreeze).

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

Selection Of Coolant

Refer to “Fluids, Lubricants, And Genuine Parts” in

“Maintaining Your Vehicle” for further information.

98 MAINTAINING YOUR VEHICLE

Page 103 of 130

•Mixing engine coolant (antifreeze) types is not recom-

mended and can result in cooling system damage. If

HOAT and OAT coolant are mixed in an emergency,

have a authorized dealer drain, flush, and refill with

OAT coolant (conforming to MS.90032) as soon as

possible.

Cooling System Pressure Cap

The cap must be fully tightened to prevent loss of engine

coolant (antifreeze), and to ensure that the engine coolant

(antifreeze) will return to the radiator from the coolant

expansion bottle.

The cap should be inspected and cleaned if there is any

accumulation of foreign material on the sealing surfaces.

WARNING!

• Do not open hot engine cooling system. Never add

engine coolant (antifreeze) when the engine is

overheated. Do not loosen or remove the cap to cool

an overheated engine. Heat causes pressure to

build up in the cooling system. To prevent scalding

or injury, do not remove the pressure cap while the

system is hot or under pressure.

• Do not use a pressure cap other than the one

specified for your vehicle. Personal injury or en-

gine damage may result.

Disposal Of Used Engine Coolant

Used ethylene glycol-based engine coolant (antifreeze) is

a regulated substance requiring proper disposal. Check

with your local authorities to determine the disposal

rules for your community. To prevent ingestion by ani-

mals or children, do not store ethylene glycol-based

6

MAINTAINING YOUR VEHICLE 101

Page 104 of 130

engine coolant (antifreeze) in open containers or allow it

to remain in puddles on the ground. If ingested by a child

or pet, seek emergency assistance immediately. Clean up

any ground spills immediately.

Points To Remember

NOTE:When the vehicle is stopped after a few miles/

kilometers of operation, you may observe vapor coming

from the front of the engine compartment. This is nor-

mally a result of moisture from rain, snow, or high

humidity accumulating on the radiator and being vapor-

ized when the thermostat opens, allowing hot engine

coolant (antifreeze) to enter the radiator.

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

• Do not overfill the coolant expansion bottle. •

Check the coolant freeze point in the radiator and in the

coolant expansion bottle. If engine coolant (antifreeze)

needs to be added, the contents of the coolant expansion

bottle must also be protected against freezing.

• If frequent engine coolant (antifreeze) additions are

required, the cooling system should be pressure tested

for leaks.

• Maintain engine coolant (antifreeze) concentration at a

minimum of 50% OAT coolant (conforming to

MS.90032) and distilled water for proper corrosion

protection of your engine which contains aluminum

components.

• Make sure that the coolant expansion bottle overflow

hoses are not kinked or obstructed.

• Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean.

102 MAINTAINING YOUR VEHICLE

Page 105 of 130

•Do not change the thermostat for Summer or Winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory engine coolant (antifreeze)

performance, poor gas mileage, and increased emis-

sions.

Brake System

Brake Master Cylinder — Brake Fluid Level Check

The fluid level of the master cylinder should be checked

when performing under the hood service, or immedi-

ately if the “Brake System Warning Light” indicates

system failure.

The brake master cylinder has a translucent plastic

reservoir. On the outboard side of the reservoir, there is a

“MAX” mark and a “MIN” mark. The fluid level must be

kept within these two marks. Do not add fluid above the

full mark because leakage may occur at the cap. With disc brakes, the fluid level can be expected to fall as

the brake linings wear. However, an unexpected drop in

fluid level may be caused by a leak and a system check

should be conducted.

Refer to “Fluids, Lubricants, And Genuine Parts” in

“Maintaining Your Vehicle” for further information.

WARNING!

•

Use only manufacturer’s recommended brake

fluid. Refer to “Fluids, Lubricants, and Genuine

Parts” in “Maintaining Your Vehicle” for further

information. Using the wrong type of brake fluid

can severely damage your brake system and/or

impair its performance. The proper type of brake

fluid for your vehicle is also identified on the

original factory installed hydraulic master cylinder

reservoir.

(Continued)

6

MAINTAINING YOUR VEHICLE 103

Page 106 of 130

WARNING!(Continued)

•To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that has

been in a tightly closed container. Keep the master

cylinder reservoir cap secured at all times. Brake

fluid in a open container absorbs moisture from the

air resulting in a lower boiling point. This may

cause it to boil unexpectedly during hard or pro-

longed braking, resulting in sudden brake failure.

This could result in a accident.

•

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts, causing the

brake fluid to catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

•Do not allow petroleum based fluid to contaminate

the brake fluid. Brake seal components could be

damaged, causing partial or complete brake failure.

This could result in an accident.

Automated Manual Transmission

Checking Fluid Levels

To check the gear oil and check/replace the hydraulic

clutch operating system fluid, contact only your autho-

rized dealer.

NOTE: Do not add or use leak detection dye in the

hydraulic clutch operating system fluid.

WARNING!

Used gear oil contains substances that are hazardous

for the environment. It is advisable to have oil

changed by your authorized dealer where used oil

will be disposed of according to the law.

104 MAINTAINING YOUR VEHICLE

Page 114 of 130

MAINTENANCE SCHEDULE — DIESEL ENGINE

Your vehicle is equipped with an automatic oil change

indicator system. The oil change indicator system will

remind you that it is time to take your vehicle in for

scheduled maintenance.

Based on engine operation conditions, the oil change

indicator message will illuminate in the instrument clus-

ter. This means that service is required for your vehicle.

Operating conditions such as frequent short-trips, trailer

tow, and extremely hot or cold ambient temperatures will

influence when the “Oil Change Required” message is

displayed. Severe Operating Conditions can cause the

change oil message to illuminate as early as 3,500 miles

(5,600 km) since last reset. Have your vehicle serviced as

soon as possible, within the next 500 miles (805 km).

Your authorized dealer will reset the oil change indicator

message after completing the scheduled oil change. If a

scheduled oil change is performed by someone otherthan your authorized dealer, the message can be reset by

referring to the steps described under “Electronic Vehicle

Information Center (EVIC)” in “Understanding Your

Instrument Panel” for further information.

NOTE:

Under no circumstances should oil change inter-

vals exceed 18,500 miles (29,773 km) or twelve months,

whichever comes first.

Once A Month Or Before A Long Trip:

• Check engine oil level

• Check windshield washer fluid level

• Check the tire inflation pressures and look for unusual

wear or damage

• Check the fluid levels of the coolant reservoir, brake

master cylinder, and power steering and fill as needed

• Check function of all interior and exterior lights

112 MAINTENANCE SCHEDULE

Page 117 of 130

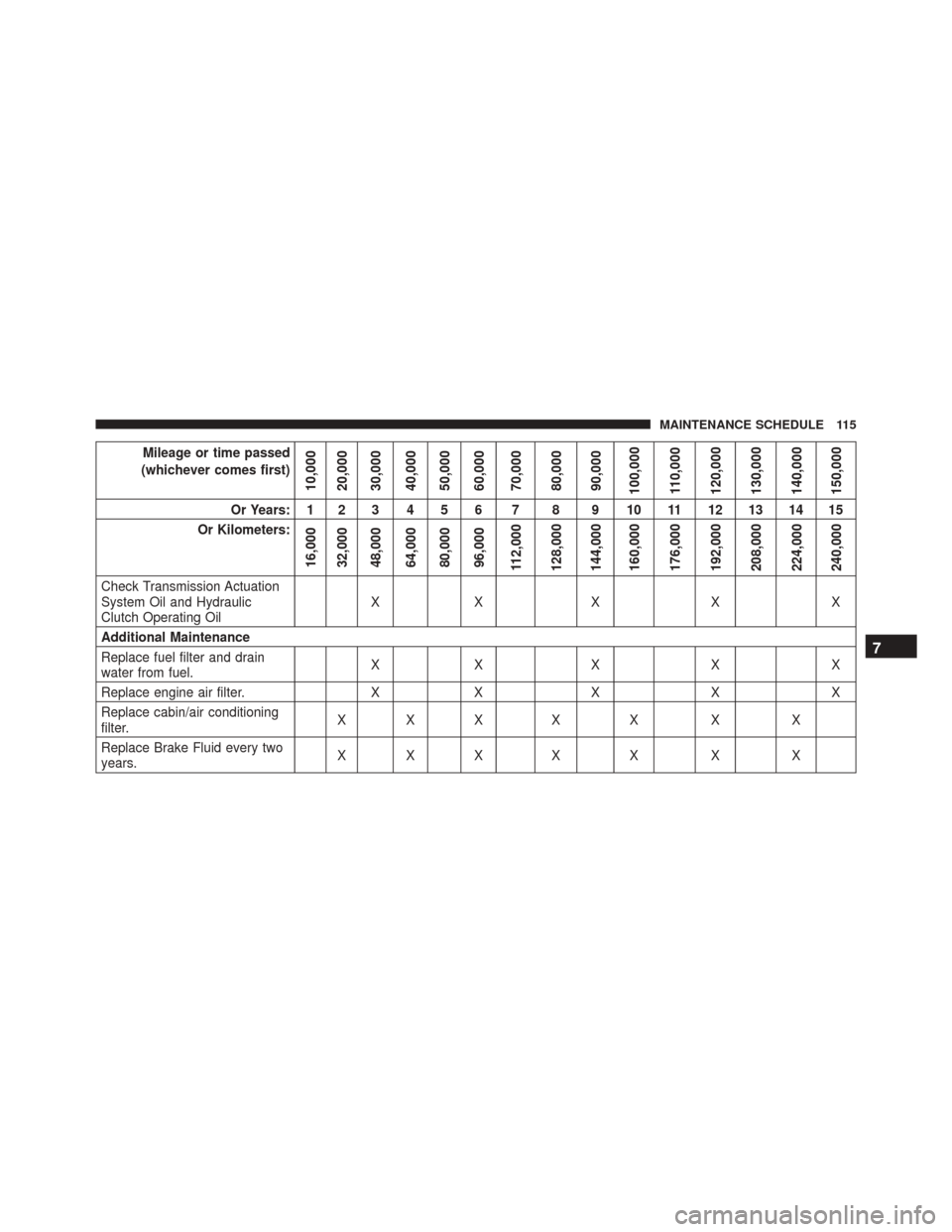

Mileage or time passed

(whichever comes first)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Check Transmission Actuation

System Oil and Hydraulic

Clutch Operating Oil XX X X X

Additional Maintenance

Replace fuel filter and drain

water from fuel. XX X X X

Replace engine air filter. X X X X X

Replace cabin/air conditioning

filter. XXX X X X X

Replace Brake Fluid every two

years. XXX X X X X

7

MAINTENANCE SCHEDULE 115

Page 124 of 130

Adding Engine Coolant (Antifreeze).............99

Adding Fuel ..............................66

Air bag Light .............................17

Air Cleaner, Engine (Engine Air Cleaner Filter) .....92

Antifreeze (Engine Coolant) ...............98, 105

Disposal ............................. .101

Anti-Lock Warning Light .....................17

Automated Manual Transmission Fluid Type ........................... .109

Battery .................................96

Brake Fluid ............................ .109

Brake System ........................... .103

Fluid Check .......................... .103

Master Cylinder ....................... .103

Warning Light ..........................17

Capacities, Fluid ......................... .105Caps, Filler

Oil (Engine) ............................91

Radiator (Coolant Pressure) ................101

Check Engine Light (Malfunction Indicator Light) . . .17

Coolant Pressure Cap (Radiator Cap) ...........101

Cooling System ...........................97

Adding Coolant (Antifreeze) ................99

Coolant Capacity ...................... .105

Coolant Level ...........................97

Disposal of Used Coolant .................101

Drain, Flush, and Refill ....................98

Points to Remember .....................102

Pressure Cap ......................... .101

Radiator Cap ......................... .101

Selection of Coolant (Antifreeze) .......98, 105, 106

Cruise Light ..............................17

Diesel Exhaust Fluid (DEF) ..................106

Diesel Fuel .......................... .60, 106

122 INDEX

Page 125 of 130

Diesel Fuel Requirements.................60, 106

Bulk Storage of .........................67

Diesel Fuel System, Re-Priming ................94

Disposal Antifreeze (Engine Coolant) ................101

Draining Fuel/Water Separator Filter ............93

Electronic Speed Control (Cruise Control) .........12

Electronic Vehicle Information Center (EVIC) ......30

Engine ..................................88

Air Cleaner ............................92

Block Heater ...........................45

Break-In Recommendations ..................8

Compartment ...........................88

Coolant (Antifreeze) .....................106

Fuel Requirements ..................... .105

Identification ...........................88

Idling ................................43

Oil........................... .90, 105, 106Oil Filler Cap

...........................91

Oil Selection .......................... .105

Filters Air Cleaner ............................92

Engine Fuel ............................93

Engine Oil ......................... .92, 106

Engine Oil Disposal ......................92

Flashers Turn Signal ............................17

Fluid Capacities ......................... .105

Fluid Level Checks Brake ............................... .103

Fluids, Lubricants and Genuine Parts ...........106

Fog Lights ...............................17

Fuel ................................ .60, 66

Adding ...............................66

Diesel ......................... .60, 66, 106

Filter ............................ .93, 106

8

INDEX 123

Page 126 of 130

Gauge................................17

Light .................................17

Requirements ...................... .60, 105

Specifications ...........................62

Tank Capacity ......................... .105

Gauges Fuel .................................17

Odometer .............................17

Speedometer ...........................17

Tachometer ............................17

Gear Ranges ..............................48

General Maintenance .......................17

Gross Axle Weight Rating ....................73

Gross Vehicle Weight Rating ..................72

Hitches Trailer Towing ..........................76 Information Center, Vehicle

...................30

Instrument Cluster ...................... .16, 17

Intervention Regeneration Strategy ..............96

Lights Airbag ................................17

Anti-Lock .............................17

Brake Warning ..........................17

Check Engine (Malfunction Indicator) ..........17

Cruise ................................17

Engine Temperature Warning ................17

Fog ..................................17

High Beam ............................17

High Beam Indicator ......................17

Instrument Cluster .......................17

Low Fuel ..............................17

Oil Pressure ............................17

Seat Belt Reminder .......................17

Tire Pressure Monitoring (TPMS) .............17

124 INDEX