fuel Ram ProMaster 2015 Diesel Supplement

[x] Cancel search | Manufacturer: RAM, Model Year: 2015, Model line: ProMaster, Model: Ram ProMaster 2015Pages: 130, PDF Size: 0.59 MB

Page 40 of 130

Normal Starting Procedure

The shift lever must be in the NEUTRAL (N) position,

and the brake pedal must be pressed, to allow engine

cranking. Place the shift lever in NEUTRAL (N) and

apply the brake pedal BEFORE turning the key to the

START/AVV position; otherwise, the engine will not

crank and the key must be cycled OFF, then back on,

before cranking is allowed.

Observe the instrument panel cluster lights when starting

the engine.

NOTE:Normal starting of either a cold or a warm

engine is obtained without pumping or pressing the

accelerator pedal.

1. Press and hold the brake pedal.

2. Place the shift lever into the NEUTRAL (N) position while keeping the brake pedal depressed. 3. Turn the ignition switch to the ON/RUN/MAR posi-

tion and watch the instrument panel cluster lights.

CAUTION!

If the “Generic Warning Light” remains on and a

“Service Fuel Filter” message displays, DO NOT

START engine before you drain the water from the

fuel filter housing to avoid engine damage. Please

see your authorized dealer for draining the fuel

filter/water separator and fuel filter replacement.

4. After the Glow Plug light turns off, turn the ignition switch to the AVV (START) position to start the engine.

Do not press the accelerator during starting.

5. If you wish to stop the cranking of the engine prior to the engine starting, release the ignition key so that it

turns back to the ON/RUN position.

38 STARTING AND OPERATING

Page 43 of 130

NOTE:The engine and transmission block heater cord is

a factory installed option. If your vehicle is not equipped,

heater cords are available from your authorized

MOPAR® dealer.

• A 12 Volt heater built into the fuel filter housing aids in

preventing fuel gelling. It is controlled by a built-in

thermostat.

• A Diesel Pre-Heat system both improves engine start-

ing and reduces the amount of white smoke generated

by a warming engine.

NORMAL OPERATION

Observe the following when the diesel engine is operat-

ing.

• All message center lights are off.

• Malfunction Indicator Light (MIL) is off.

• Generic Warning Light is off. •

Engine Oil Pressure telltale is not illuminated.

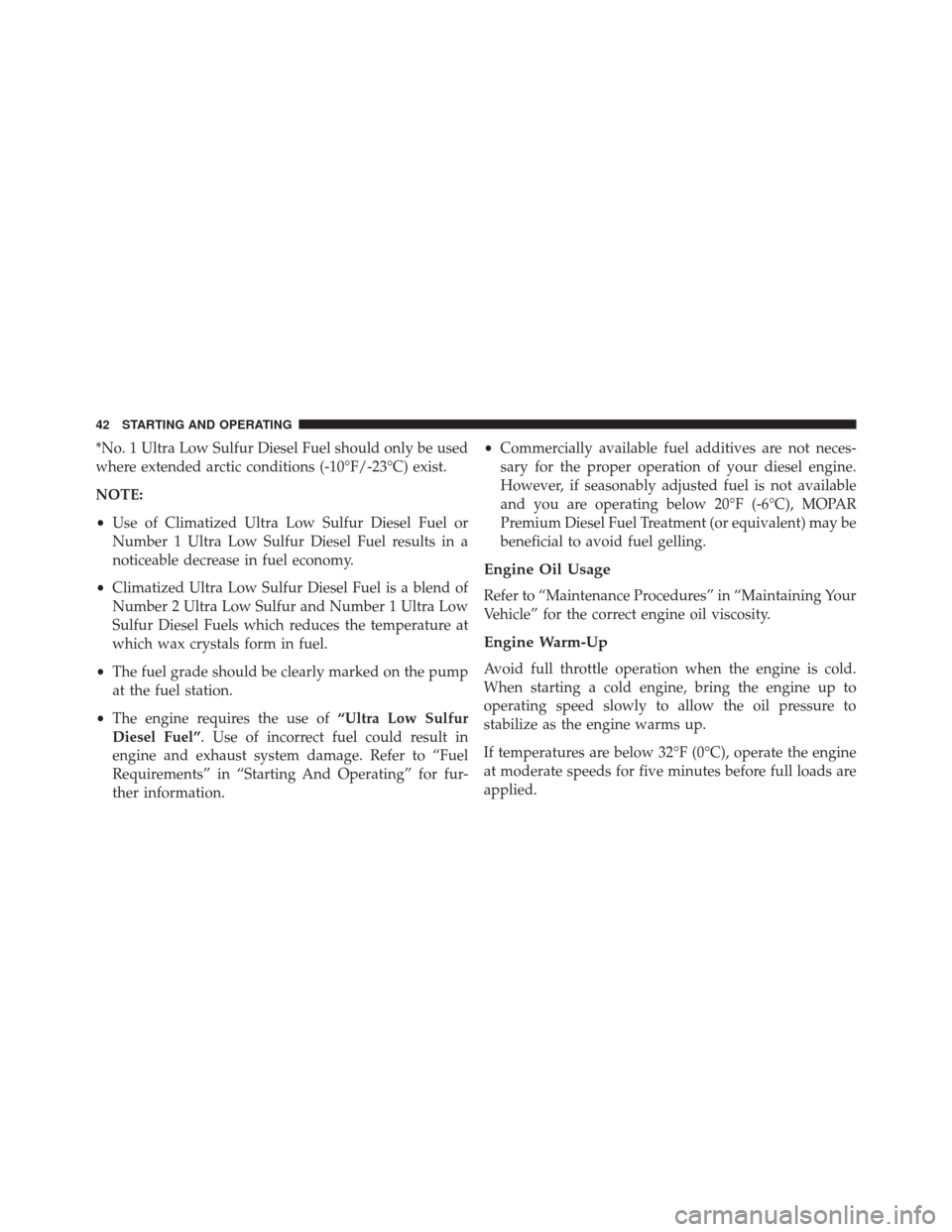

Cold Weather Precautions

Operation in ambient temperature below 32°F (0°C) may

require special considerations. The following charts sug-

gest these options:

Fuel Operating Range

NOTE: Use “Ultra Low Sulfur Diesel Fuels” ONLY.

Fuel Operating Range Chart

5

STARTING AND OPERATING 41

Page 44 of 130

*No. 1 Ultra Low Sulfur Diesel Fuel should only be used

where extended arctic conditions (-10°F/-23°C) exist.

NOTE:

•Use of Climatized Ultra Low Sulfur Diesel Fuel or

Number 1 Ultra Low Sulfur Diesel Fuel results in a

noticeable decrease in fuel economy.

• Climatized Ultra Low Sulfur Diesel Fuel is a blend of

Number 2 Ultra Low Sulfur and Number 1 Ultra Low

Sulfur Diesel Fuels which reduces the temperature at

which wax crystals form in fuel.

• The fuel grade should be clearly marked on the pump

at the fuel station.

• The engine requires the use of “Ultra Low Sulfur

Diesel Fuel”. Use of incorrect fuel could result in

engine and exhaust system damage. Refer to “Fuel

Requirements” in “Starting And Operating” for fur-

ther information. •

Commercially available fuel additives are not neces-

sary for the proper operation of your diesel engine.

However, if seasonably adjusted fuel is not available

and you are operating below 20°F (-6°C), MOPAR

Premium Diesel Fuel Treatment (or equivalent) may be

beneficial to avoid fuel gelling.

Engine Oil Usage

Refer to “Maintenance Procedures” in “Maintaining Your

Vehicle” for the correct engine oil viscosity.

Engine Warm-Up

Avoid full throttle operation when the engine is cold.

When starting a cold engine, bring the engine up to

operating speed slowly to allow the oil pressure to

stabilize as the engine warms up.

If temperatures are below 32°F (0°C), operate the engine

at moderate speeds for five minutes before full loads are

applied.

42 STARTING AND OPERATING

Page 45 of 130

Engine Idling

Avoid prolonged idling, long periods of idling may be

harmful to your engine because combustion chamber tem-

peratures can drop so low that the fuel may not burn

completely. Incomplete combustion allows carbon and var-

nish to form on piston rings, cylinder head valves, and

injector nozzles. Also, the unburned fuel can enter the

crankcase, diluting the oil and causing rapid wear to the

engine.

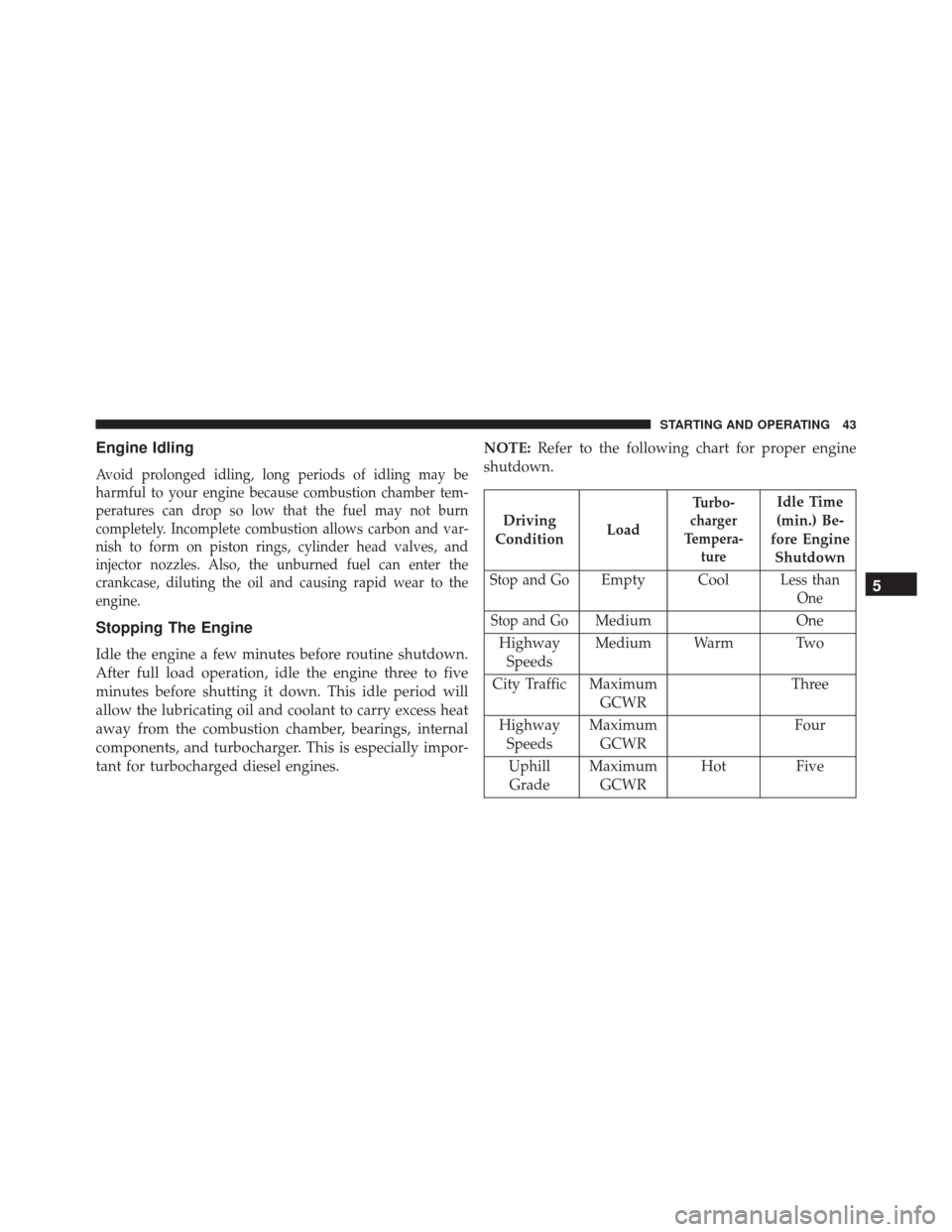

Stopping The Engine

Idle the engine a few minutes before routine shutdown.

After full load operation, idle the engine three to five

minutes before shutting it down. This idle period will

allow the lubricating oil and coolant to carry excess heat

away from the combustion chamber, bearings, internal

components, and turbocharger. This is especially impor-

tant for turbocharged diesel engines.NOTE:

Refer to the following chart for proper engine

shutdown.

Driving

Condition Load

Turbo-

charger

Tempera- tureIdle Time

(min.) Be-

fore Engine Shutdown

Stop and GoEmpty CoolLess than One

Stop and GoMedium One

Highway Speeds Medium Warm Two

City Traffic Maximum GCWR Three

Highway Speeds Maximum

GCWR Four

Uphill Grade Maximum

GCWR Hot Five

5

STARTING AND OPERATING 43

Page 47 of 130

Do Not Operate The Engine With Failed Parts

All engine failures give some warning before the parts

fail. Be on the alert for changes in performance, sounds,

and visual evidence that the engine requires service.

Some important clues are:

•engine misfiring or vibrating severely

• sudden loss of power

• unusual engine noises

• fuel, oil or coolant leaks

• sudden change, outside the normal operating range, in

the engine operating temperature

• excessive smoke

• oil pressure drop

ENGINE BLOCK/TRANSMISSION HEATER — IF

EQUIPPED

To ensure reliable starting/operating at these tempera-

tures, use of an externally powered electric engine block/

transmission heater (available from your authorized

dealer) is recommended.

The engine block heater warms engine coolant and

permits quicker starts in cold weather. The transmission

heaters warm gearbox oil and hydraulic actuation system

oil to operate in cold weather. Connect the heater cord to

a ground-fault interrupter protected 110–115 Volt AC

electrical outlet with a grounded, three-wire extension

cord.

Its use is recommended for environments that routinely

fall below -10°F (-23°C). It should be used when the

vehicle has not been running overnight or longer periods

5

STARTING AND OPERATING 45

Page 62 of 130

Towing The Vehicle

•The manufacturer recommends towing your vehicle

with all four wheels OFFthe ground using a flatbed.

• Automated Manual transmission vehicles can also be

flat towed (all four wheels on the ground) with the

transmission in NEUTRAL. Ensure the transmission is

in NEUTRAL (N) (by checking that the vehicle moves

when pushed) and tow in the same way as a normal

vehicle with a manual transmission.

CAUTION!

• DO NOT flat tow any disabled vehicle if condition

is related to the clutch, transmission or driveline.

Additional damage to the drivetrain could result.

• Towing this vehicle in violation of the above re-

quirements can cause severe engine, transmission,

(Continued)

CAUTION! (Continued)

or drivetrain damage. Damage from improper tow-

ing is not covered under the New Vehicle Limited

Warranty.

If it is not possible to shift the transmission to NEUTRAL

(N), do not flat tow the vehicle and contact your autho-

rized dealer.

FUEL REQUIREMENTS

Use good quality diesel fuel from a reputable supplier in

your vehicle. Federal law requires that you must fuel this

vehicle with Ultra Low Sulfur Highway Diesel fuel

(15 ppm Sulfur maximum) and prohibits the use of Low

Sulfur Highway Diesel fuel (500 ppm Sulfur maximum)

to avoid damage to the emissions control system.

60 STARTING AND OPERATING

Page 63 of 130

For most year-round service, No. 2 diesel fuel meeting

ASTM (formerly known as the American Society for

Testing and Materials) specification D-975 Grade S15 will

provide good performance.

If the vehicle is exposed to extreme cold (below 20°F or

-7°C), or is required to operate at colder-than-normal

conditions for prolonged periods, use climatized No. 2

diesel fuel or dilute the No. 2 diesel fuel with 50% No. 1

diesel fuel. This will provide better protection from fuel

gelling or wax-plugging of the fuel filter.

WARNING!

Do not use alcohol or gasoline as a fuel blending

agent. They can be unstable under certain conditions

and hazardous or explosive when mixed with diesel

fuel.Diesel fuel is seldom completely free of water. If water is

detected in the water separator while the engine is

running or while the ignition switch is in the ON/RUN

position, the “Generic Warning Light” will illuminate

and the specific message, “Service Fuel Filter” will ap-

pear in the Electronic Vehicle Information Center (EVIC).

If this occurs you should stop the engine and drain the

water from the filter housing.

NOTE:

Please see your authorized dealer for draining the

fuel/water separator and fuel filter replacement.

Purchasing good quality fuel and by following the cold

weather advice above, fuel conditioners should not be

required in your vehicle.

NOTE: If available in your area, a high cetane “pre-

mium” diesel fuel may offer improved cold-starting and

warm-up performance.

5

STARTING AND OPERATING 61

Page 64 of 130

CAUTION!

If the “Generic Warning Light” remains on and a

“Service Fuel Filter” message displays, DO NOT

START engine before you drain the water from the

fuel filter housing to avoid engine damage. Please

see your authorized dealer for draining the fuel

filter/water separator and fuel filter replacement.

Fuel Specifications

This diesel engine has been developed to take advantage

of the high energy content and generally lower cost No.

2 Ultra Low Sulfur diesel fuel or No. 2 Ultra Low Sulfur

climatized diesel fuels.NOTE:

•

If you accidentally fill the fuel tank with gasoline on

your diesel vehicle, do not start the engine. Damage to

the engine and fuel system could occur. Please call

your authorized dealer for service.

• A maximum blend of 5% biodiesel meeting ASTM

specification D-975 may be used with your diesel

engine without any adjustments to regular service

schedules.

• Commercially available fuel additives are not neces-

sary for the proper operation of your diesel engine.

• No. 1 Ultra Low Sulfur diesel fuel should only be used

where extended arctic conditions (-10°F or -23°C) exist.

62 STARTING AND OPERATING

Page 65 of 130

Biodiesel Fuel Requirements

A maximum blend of 5% biodiesel meeting ASTM speci-

fication D975 is recommended for use with your diesel

engine. If frequent operation with Biodiesel blends that

are between 6% and 20% (B6–B20) is desired, the main-

tenance schedule is subject to shorter intervals.

The oil and filter change along with fuel filter replace-

ment is subject to shorter intervals when operating your

engine on biodiesel greater than 5%. Do not use biodiesel

greater than 20%.

For regular use of biodiesel blends between 6% and 20%

(B6–B20) it is important that you understand and comply

with these requirements. Refer to the “Maintenance

Chart” in the “Maintenance Schedules” section for fur-

ther direction.

CAUTION!

Failure to comply with Oil Change requirements for

vehicles operating on biodiesel blends between 6%

and 20% (B6–B20) will result in premature engine

wear. Such wear is not covered by the New Vehicle

Limited Warranty.

Biodiesel is a fuel produced from renewable resources

typically derived from animal fat, rapeseed oil (Rapeseed

Methyl Ester (RME) base), or soybean oil (Soy Methyl

Ester (SME or SOME) base).

Biodiesel fuel has inherent limitations which require that

you understand and adhere to the following require-

ments if you use blends of Biodiesel between 6% and 20%

(B6–B20). There are no unique restrictions for the use of

B5.

5

STARTING AND OPERATING 63

Page 66 of 130

CAUTION!

Use of blends greater than 20% is not approved. Use

of blends greater than 20% can result in engine

damage. Such damage is not covered by the New

Vehicle Limited Warranty.

Biodiesel Fuel Properties — Low Ambient

Temperatures

Biodiesel fuel may gel or solidify at low ambient tem-

peratures, which may pose problems for both storage and

operation. Precautions can be necessary at low ambient

temperatures, such as storing the fuel in a heated build-

ing or a heated storage tank, or using cold temperature

additives.

Fuel Quality — Must Comply With ASTM

Standards

The quality of Biodiesel fuel may vary widely. Only fuel

produced by a BQ9000 supplier to the following specifi-

cations may be blended to meet Biodiesel blend B6 – B20

fuel meeting ASTM specification D-7467:

•Petrodiesel fuel meeting ASTM specification D-975

and Biodiesel fuel (B100) meeting ASTM specification

D-6751

Fuel Oxidation Stability — Must Use Fuel Within

Six Months Of Manufacture

Biodiesel fuel has poor oxidation stability which can

result in long term storage problems. Fuel produced to

approved ASTM standards, if stored properly, provides

for protection against fuel oxidation for up to six months.

64 STARTING AND OPERATING