brake light Ram ProMaster 2016 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2016, Model line: ProMaster, Model: Ram ProMaster 2016Pages: 448, PDF Size: 3.28 MB

Page 244 of 448

The system’s pump motor runs during an ABS stop to

provide regulated hydraulic pressure. The pump motor

makes a low humming noise during operation, which is

normal.

The ABS includes an amber ABS Warning Light. When

the light is illuminated, the ABS is not functioning. The

system reverts to standard non-anti-lock brakes. Turning

the ignition Off and On again may reset the ABS if the

fault detected was only momentary.

WARNING!

•Pumping the Anti-Lock Brakes will diminish their

effectiveness and may lead to a collision. Pumping

makes the stopping distance longer. Just press

firmly on your brake pedal when you need to slow

down or stop.

(Continued)

WARNING! (Continued)

•The Anti-Lock Brake System (ABS) cannot prevent

the natural laws of physics from acting on the

vehicle, nor can it increase braking or steering

efficiency beyond that afforded by the condition of

the vehicle brakes and tires or the traction afforded.

• The ABS cannot prevent collisions, including those

resulting from excessive speed in turns, following

another vehicle too closely, or hydroplaning.

• The capabilities of an ABS-equipped vehicle must

never be exploited in a reckless or dangerous

manner, which could jeopardize the user’s safety or

the safety of others.

When you are in a severe braking condition involving the

use of the ABS, you will experience some pedal drop as

the vehicle comes to a stop. This is the result of the

system reverting to the base brake system.

242 STARTING AND OPERATING

Page 245 of 448

Engagement of the ABS may be accompanied by a

pulsing sensation. You may also hear a clicking noise.

These occurrences are normal and indicate that the

system is functioning properly.

Traction Control System (TCS)

The Traction Control System (TCS) monitors the amount

of wheel spin of each of the driven wheels. If wheel spin

is detected, brake pressure is applied to the slipping

wheel(s) and engine power is reduced, to provide en-

hanced acceleration and stability. A feature of the TCS

system, Brake Limited Differential (BLD), functions simi-

lar to a limited slip differential and controls the wheel

spin across a driven axle. If one wheel on a driven axle is

spinning faster than the other, the system will apply the

brake of the spinning wheel. This will allow more engine

torque to be applied to the wheel that is not spinning.

This feature remains active even if the ESC is in the

“Partial Off” mode.The “ESC Activation/Malfunction Indicator Light” (in

the instrument cluster) will start to flash as soon as the

tires lose traction and the wheels begin to spin. This

indicates that the TCS is active. If the indicator light

flashes during acceleration, ease up on the accelerator

and apply as little throttle as possible. Be sure to adapt

your speed and driving to the prevailing road conditions,

and do not switch off the ESC or TCS.

WARNING!

•

The TCS cannot prevent the natural laws of physics

from acting on the vehicle, nor can it increase the

traction afforded.

• The TCS cannot prevent collisions, including those

resulting from excessive speed in turns, or hydro-

planing.

(Continued)

5

STARTING AND OPERATING 243

Page 250 of 448

The “ESC Activation/Malfunction Indicator Light” also

flashes when TCS is active. If the “ESC Activation/

Malfunction Indicator Light” begins to flash during ac-

celeration, ease up on the accelerator and apply as little

throttle as possible. Be sure to adapt your speed and

driving to the prevailing road conditions.

NOTE:

•The “ESC Activation/Malfunction Indicator Light”

and the “ESC OFF Indicator Light” come on momen-

tarily each time the ignition switch is turned ON.

• Each time the ignition is turned ON, the ESC system

will be ON even if it was turned off previously.

• The ESC system will make buzzing or clicking sounds

when it is active. This is normal; the sounds will stop

when ESC becomes inactive following the maneuver

that caused the ESC activation. The “ESC OFF Indicator Light” indicates the

Electronic Stability Control (ESC) is off.

Trailer Sway Control (TSC)

TSC uses sensors in the vehicle to recognize an exces-

sively swaying trailer and will take the appropriate

actions to attempt to stop the sway. The system may

reduce engine power and apply the brake of the appro-

priate wheel(s) to counteract the sway of the trailer. TSC

will become active automatically once an excessively

swaying trailer is recognized. Note that TSC cannot stop

all trailers from swaying. Always use caution when

towing a trailer and follow the trailer tongue weight

recommendations. Refer to “Trailer Towing” in this sec-

tion for further information. When TSC is functioning,

the “ESC Activation/Malfunction Indicator Light” will

flash, the engine power may be reduced and you may

feel the brakes being applied to individual wheels to

248 STARTING AND OPERATING

Page 252 of 448

WARNING!

There may be situations on minor hills with a loaded

vehicle, or while pulling a trailer, when the system

will not activate and slight rolling may occur. This

could cause a collision with another vehicle or object.

Always remember the driver is responsible for brak-

ing the vehicle.

Towing With HSA

HSA will provide assistance when starting on a grade

when pulling a trailer.

WARNING!

•If you use a trailer brake controller with your

trailer, your trailer brakes may be activated and

deactivated with the brake switch. If so, when the

(Continued)

WARNING! (Continued)

brake pedal is released, there may not be enough

brake pressure to hold the vehicle and trailer on a

hill and this could cause a collision with another

vehicle or object behind you. In order to avoid

rolling down the hill while resuming acceleration,

manually activate the trailer brake prior to releas-

ing the brake pedal. Always remember the driver is

responsible for braking the vehicle.

• HSA is not a parking brake. If you stop the vehicle

on a hill without putting the transmission in PARK

and using the parking brake, it will roll down the

hill and could cause a collision with another ve-

hicle or object. Always remember to use the park-

ing brake while parking on a hill, and that the

driver is responsible for braking the vehicle.

250 STARTING AND OPERATING

Page 303 of 448

CAUTION!

If the trailer weighs more than 1,000 lbs (454 kg)

loaded, it should have its own brakes and they

should be of adequate capacity. Failure to do this

could lead to accelerated brake lining wear, higher

brake pedal effort, and longer stopping distances.

Towing Requirements — Trailer Lights And Wiring

Whenever you pull a trailer, regardless of the trailer size,

stoplights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may include a four- and seven-

pin wiring harness. Use a factory approved trailer har-

ness and connector.

5

STARTING AND OPERATING 301

Page 378 of 448

•Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean.

• Do not change the thermostat for Summer or Winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory engine coolant (antifreeze)

performance, poor gas mileage, and increased emis-

sions.

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically.

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting or

riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You would not have your full

braking capacity in an emergency.

Master Cylinder — Brake Fluid Level Check

The fluid level in the master cylinder should be checked

when performing underhood services, or immediately if

the “Brake System Warning Light” indicates system

failure.

Clean the top of the master cylinder area before removing

the cap. Add fluid to bring the level up to the top of the

“FULL” mark on the side of the master cylinder reservoir.

376 MAINTAINING YOUR VEHICLE

Page 397 of 448

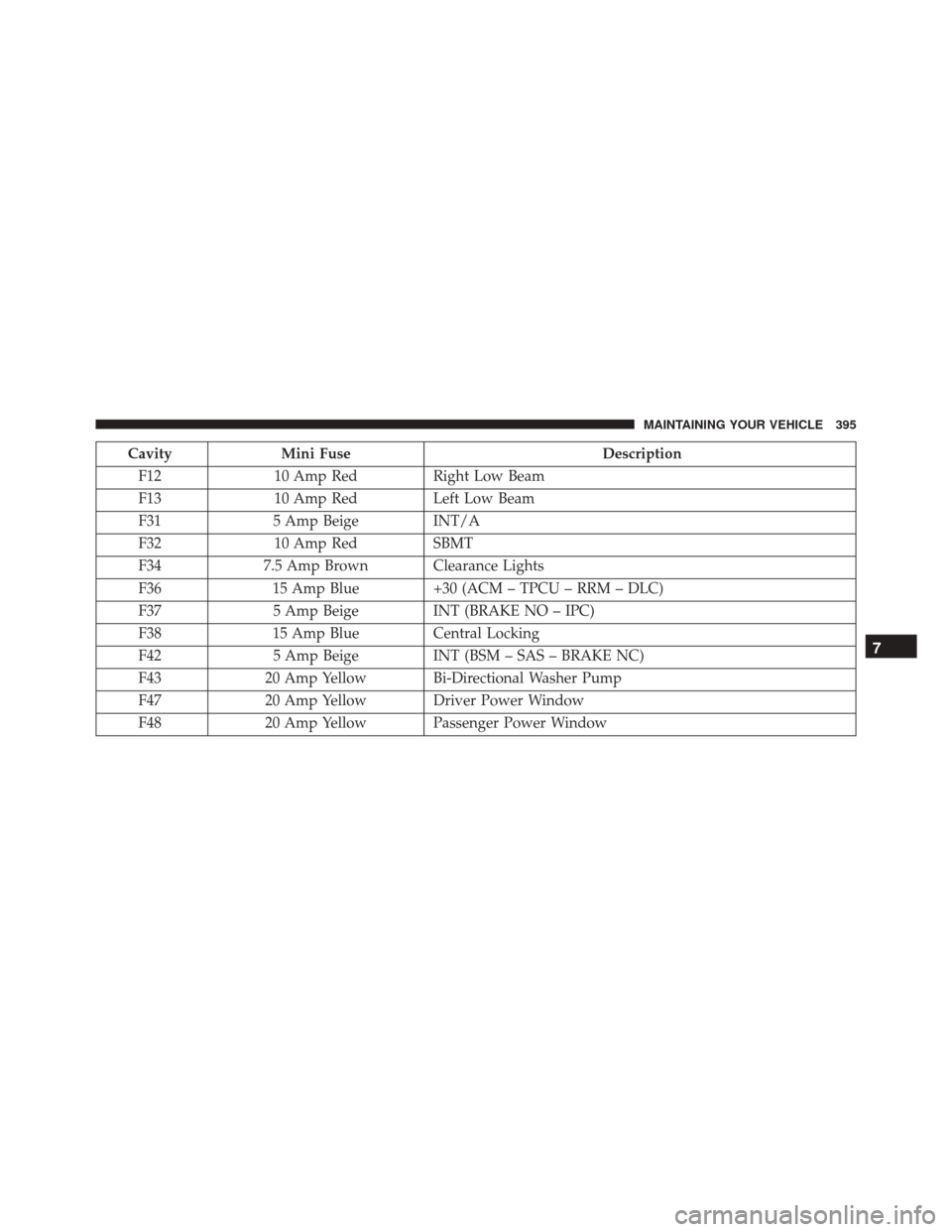

CavityMini Fuse Description

F12 10 Amp Red Right Low Beam

F13 10 Amp Red Left Low Beam

F31 5 Amp Beige INT/A

F32 10 Amp Red SBMT

F34 7.5 Amp Brown Clearance Lights

F36 15 Amp Blue +30 (ACM – TPCU – RRM – DLC)

F37 5 Amp Beige INT (BRAKE NO – IPC)

F38 15 Amp Blue Central Locking

F42 5 Amp Beige INT (BSM – SAS – BRAKE NC)

F43 20 Amp Yellow Bi-Directional Washer Pump

F47 20 Amp Yellow Driver Power Window

F48 20 Amp Yellow Passenger Power Window

7

MAINTAINING YOUR VEHICLE 395

Page 413 of 448

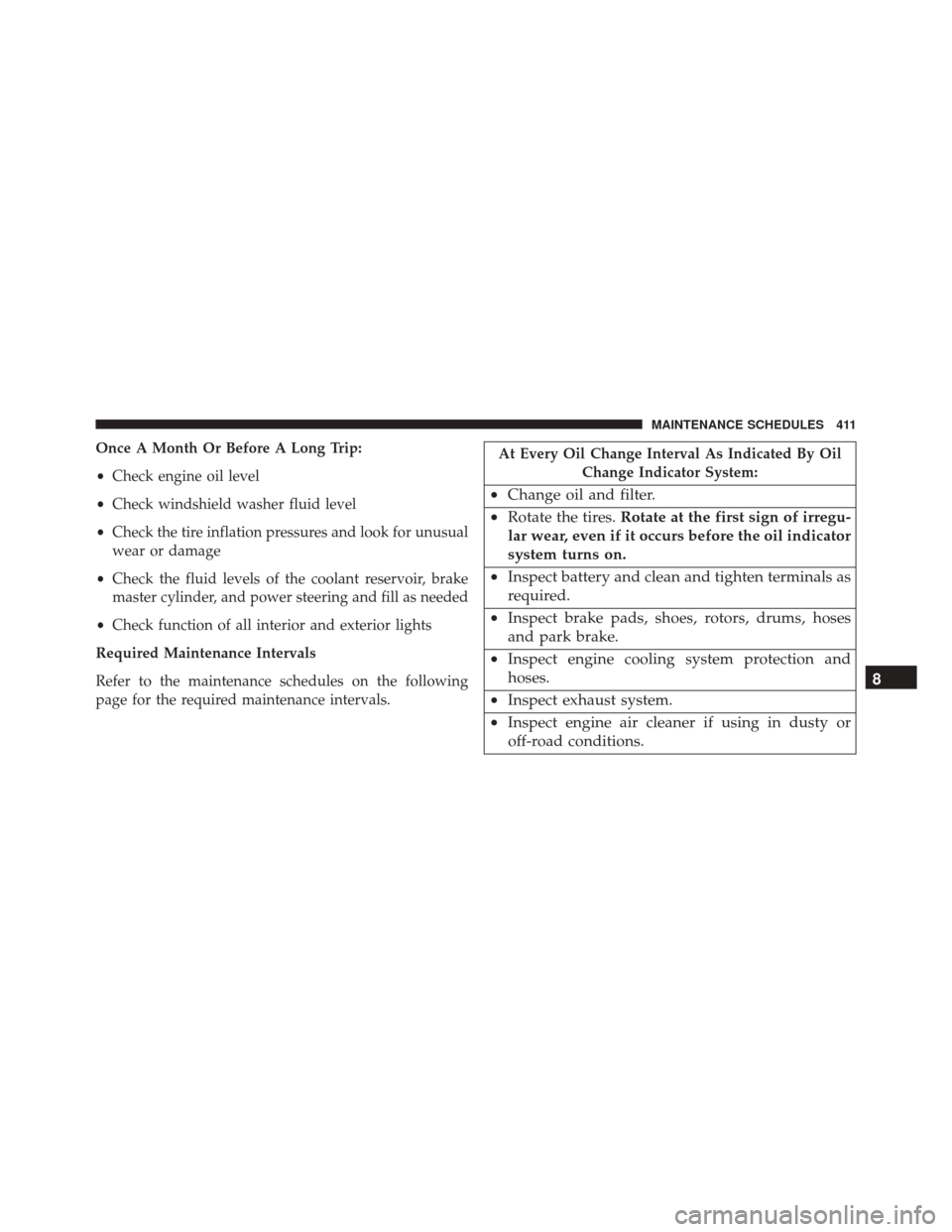

Once A Month Or Before A Long Trip:

•Check engine oil level

• Check windshield washer fluid level

• Check the tire inflation pressures and look for unusual

wear or damage

• Check the fluid levels of the coolant reservoir, brake

master cylinder, and power steering and fill as needed

• Check function of all interior and exterior lights

Required Maintenance Intervals

Refer to the maintenance schedules on the following

page for the required maintenance intervals.At Every Oil Change Interval As Indicated By Oil Change Indicator System:

•Change oil and filter.

• Rotate the tires. Rotate at the first sign of irregu-

lar wear, even if it occurs before the oil indicator

system turns on.

• Inspect battery and clean and tighten terminals as

required.

• Inspect brake pads, shoes, rotors, drums, hoses

and park brake.

• Inspect engine cooling system protection and

hoses.

• Inspect exhaust system.

• Inspect engine air cleaner if using in dusty or

off-road conditions. 8

MAINTENANCE SCHEDULES 411

Page 432 of 448

Adding Engine Coolant (Antifreeze)............372

Adding Fuel ............................ .287

Adding Washer Fluid ..................... .369

Additives, Fuel .......................... .284

AirBag.................................39 Advance Front Air Bag ....................41

Air Bag Operation .......................42

Air Bag Warning Light ....................50

Event Data Recorder (EDR) .................53

FrontAirBag...........................39

If A Deployment Occurs ...................47

Knee Impact Bolsters .....................43

Maintaining Your Air Bag System ............52

Transporting Pets ........................63

Air Bag Deployment ........................39

Air Bag Light ...................... .50, 66, 134

Air Bag Maintenance .......................52

Air Cleaner, Engine (Engine Air Cleaner Filter) . . . .361

Air Conditioner Maintenance .................366Air Conditioning

......................... .204

Air Conditioning Controls ...................204

Air Conditioning Filter .....................367

Air Conditioning Refrigerant .................366

Air Conditioning System .................204, 366

Air Pressure, Tires ........................ .263

Alarm (Security Alarm) ......................15

Alarm System (Security Alarm) ................15

Alterations/Modifications, Vehicle ...............7

Antifreeze (Engine Coolant) ...............371, 405

Disposal ............................. .374

Anti-Lock Brake System (ABS) ................241

Anti-Lock Warning Light ....................155

Appearance Care ........................ .380

Ashtray ............................... .121

Assist, Hill Start ......................... .249

Audio Systems (Radio) .....................199

Auto Down Power Windows ..................24

Automatic Door Locks ......................22

430 INDEX

Page 433 of 448

Automatic Transaxle........................12

Automatic Transmission .................222, 379

Adding Fluid ......................... .379

Fluid And Filter Changes ..................379

Fluid Change ......................... .379

Fluid Level Check ...................... .379

Fluid Type ........................ .378, 408

Gear Ranges .......................... .225

Special Additives ...................... .378

Battery ............................ .135, 364

Charging System Light ...................135

Keyless Transmitter Replacement (RKE) ........19

Belts, Seat ...............................66

Body Builders Guide ........................6

Body Mechanism Lubrication .................368

B-Pillar Location ......................... .257

Brake Assist System ...................... .244

Brake Control System, Electronic ..............241Brake Fluid

............................ .408

Brake, Parking .......................... .239

Brake System ........................ .241, 376

Anti-Lock (ABS) ....................... .241

Fluid Check .......................... .376

Parking ............................. .239

Warning Light ........................ .142

Brake/Transmission Interlock .................224

Bulb Replacement ..................... .399, 401

Bulbs, Light .......................... .68, 399

Camera, Rear ............................112

Capacities, Fluid ......................... .405

Caps, Filler Fuel ................................ .287

Power Steering ........................ .238

Radiator (Coolant Pressure) ................374

Carbon Monoxide Warning ................65, 286

Cargo Light ..............................98

10

INDEX 431