light Ram ProMaster 2019 Repair Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2019, Model line: ProMaster, Model: Ram ProMaster 2019Pages: 332, PDF Size: 3.66 MB

Page 158 of 332

While audible signals are emitted, the audio system is not

muted.

The audible signal is turned off immediately if the distance

increases. The tone cycle remains constant if the distance

measured by the inner sensors is constant. If this condition

occurs for the external sensors, the signal is turned off after

three seconds (stopping warnings during maneuvers par-

allel to walls).

ParkSense Rear Park Assist Failure Indications

A malfunction of the ParkSense Rear Park Assist sensors or

system is indicated, during REVERSE gear engagement, by

the instrument panel warning icon.The warning icon is illuminated and a message is

displayed in the instrument cluster display (if

equipped). Refer to “Warning Lights And Mes-

sages” in “Getting To Know Your Instrument

Panel” for further information.

The sensors and wiring are tested continuously when the

ignition is in the ON/RUN position. Failures are indicated

immediately if they occur when the system is ON.

Even if the system is able to identify that a specific sensor

is in failure condition, the instrument cluster display shall

indicate that the ParkSense Rear Park Assist system is unavailable, without reference to the sensor in failure

condition. If even a single sensor fails, the entire system

must be disabled. The system is turned off automatically.

Cleaning The ParkSense System

Clean the Rear Park Assist sensors with water, car wash

soap and a soft cloth. Do not use rough or hard cloths. In

washing stations, clean sensors quickly keeping the vapor

jet/high pressure washing nozzles at least 4 inches (10 cm)

from the sensors. Do not scratch or poke the sensors.

Otherwise, you could damage the sensors.

ParkSense Rear Park Assist System Usage

Precautions

NOTE:

•

Ensure that the outer surface and the underside of the

rear bumper is clean and clear of snow, ice, mud, dirt or

other obstruction to keep the Rear Park Assist system

operating properly.

• Jackhammers, large trucks, and other vibrations could

affect the performance of Rear Park Assist.

• Clean the Rear Park Assist sensors regularly, taking care

not to scratch or damage them. The sensors must not be

covered with ice, snow, slush, mud, dirt or debris.

156 STARTING AND OPERATING

Page 160 of 332

If it’s necessary to keep the ball mount and hitch ball

assembly mounted for a long period, it is possible to filter

out the ball mount and hitch ball assembly presence in

sensor field of view. The filtering operation must be

performed only by an authorized dealer.

PARKVIEW REAR BACK UP CAMERA

Your vehicle is equipped with the ParkView Rear Back Up

Camera that allows you to see an on-screen image of the

rear surroundings of your vehicle whenever the gear

selector is put into REVERSE and/or when the rear doors

are opened. The image will be displayed on the touch-

screen display along with a caution note to “check entire

surroundings” across the top of the screen. After five

seconds this note will disappear. The ParkView Rear Back

Up Camera is located on the top rear of the vehicle below

the center light.When the vehicle is shifted out of REVERSE and/or when

the rear doors are closed, the rear camera mode is exited

and the navigation or audio screen appears again.

Rear Back Up Camera Location

158 STARTING AND OPERATING

Page 162 of 332

REFUELING THE VEHICLE

The gas cap is located behind the fuel filler door on the left

side of the vehicle. If the gas cap is lost or damaged, be sure

the replacement cap is for use with this vehicle.

WARNING!

•Never have any smoking materials lit in or near the

vehicle when the fuel door is open or the tank is

being filled.

(Continued)

WARNING! (Continued)

•Never add fuel when the engine is running. This is

in violation of most state and federal fire regulations

and may cause the “Malfunction Indicator Light” to

turn on.

• A fire may result if fuel is pumped into a portable

container that is inside of a vehicle. You could be

burned. Always place fuel containers on the ground

while filling.

CAUTION!

• Damage to the fuel system or emissions control

system could result from using an improper fuel

tank filler tube cap.

• A poorly fitting fuel filler cap could let impurities

into the fuel system.

• A poorly fitting fuel filler cap may cause the “Mal-

function Indicator Light (MIL)” to turn on.

• To avoid fuel spillage and overfilling, do not “top

off” the fuel tank after filling. When the fuel nozzle

“clicks” or shuts off, the fuel tank is full.

Fuel Filler Cap

160 STARTING AND OPERATING

Page 168 of 332

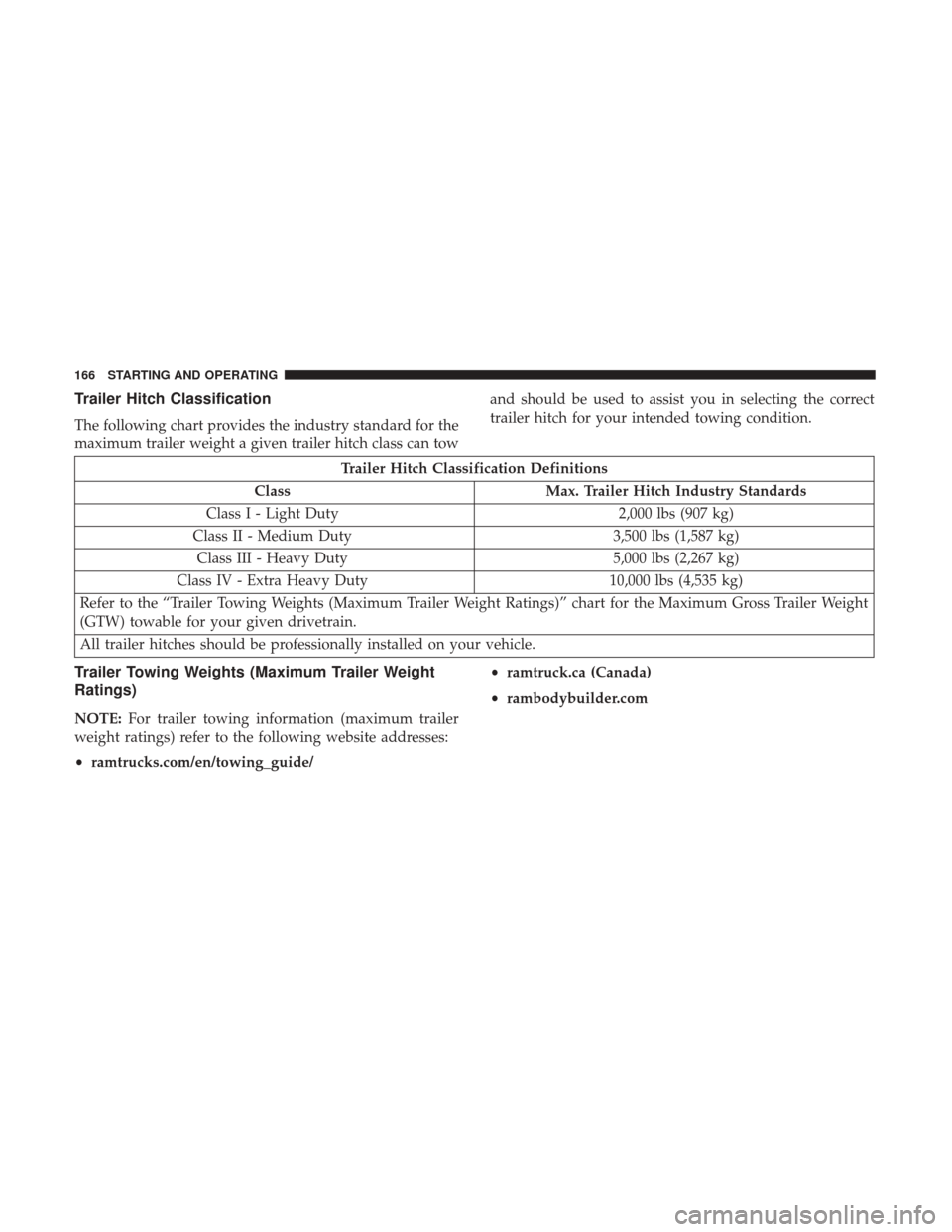

Trailer Hitch Classification

The following chart provides the industry standard for the

maximum trailer weight a given trailer hitch class can towand should be used to assist you in selecting the correct

trailer hitch for your intended towing condition.

Trailer Hitch Classification Definitions

Class Max. Trailer Hitch Industry Standards

Class I - Light Duty 2,000 lbs (907 kg)

Class II - Medium Duty 3,500 lbs (1,587 kg)

Class III - Heavy Duty 5,000 lbs (2,267 kg)

Class IV - Extra Heavy Duty 10,000 lbs (4,535 kg)

Refer to the “Trailer Towing Weights (Maximum Trailer Weight Ratings)” chart for the Maximum Gross Trailer Weight

(GTW) towable for your given drivetrain.

All trailer hitches should be professionally installed on your vehicle.

Trailer Towing Weights (Maximum Trailer Weight

Ratings)

NOTE: For trailer towing information (maximum trailer

weight ratings) refer to the following website addresses:

• ramtrucks.com/en/towing_guide/ •

ramtruck.ca (Canada)

• rambodybuilder.com

166 STARTING AND OPERATING

Page 172 of 332

WARNING!

•Do not connect trailer brakes to your vehicle’s hy-

draulic brake lines. It can overload your brake sys-

tem and cause it to fail. You might not have brakes

when you need them and could have an accident.

• Towing any trailer will increase your stopping dis-

tance. When towing, you should allow for additional

space between your vehicle and the vehicle in front

of you. Failure to do so could result in an accident.

CAUTION!

If the trailer weighs more than 1,000 lbs (453 kg)

loaded, it should have its own brakes and they should

be of adequate capacity. Failure to do this could lead to

accelerated brake lining wear, higher brake pedal

effort, and longer stopping distances.

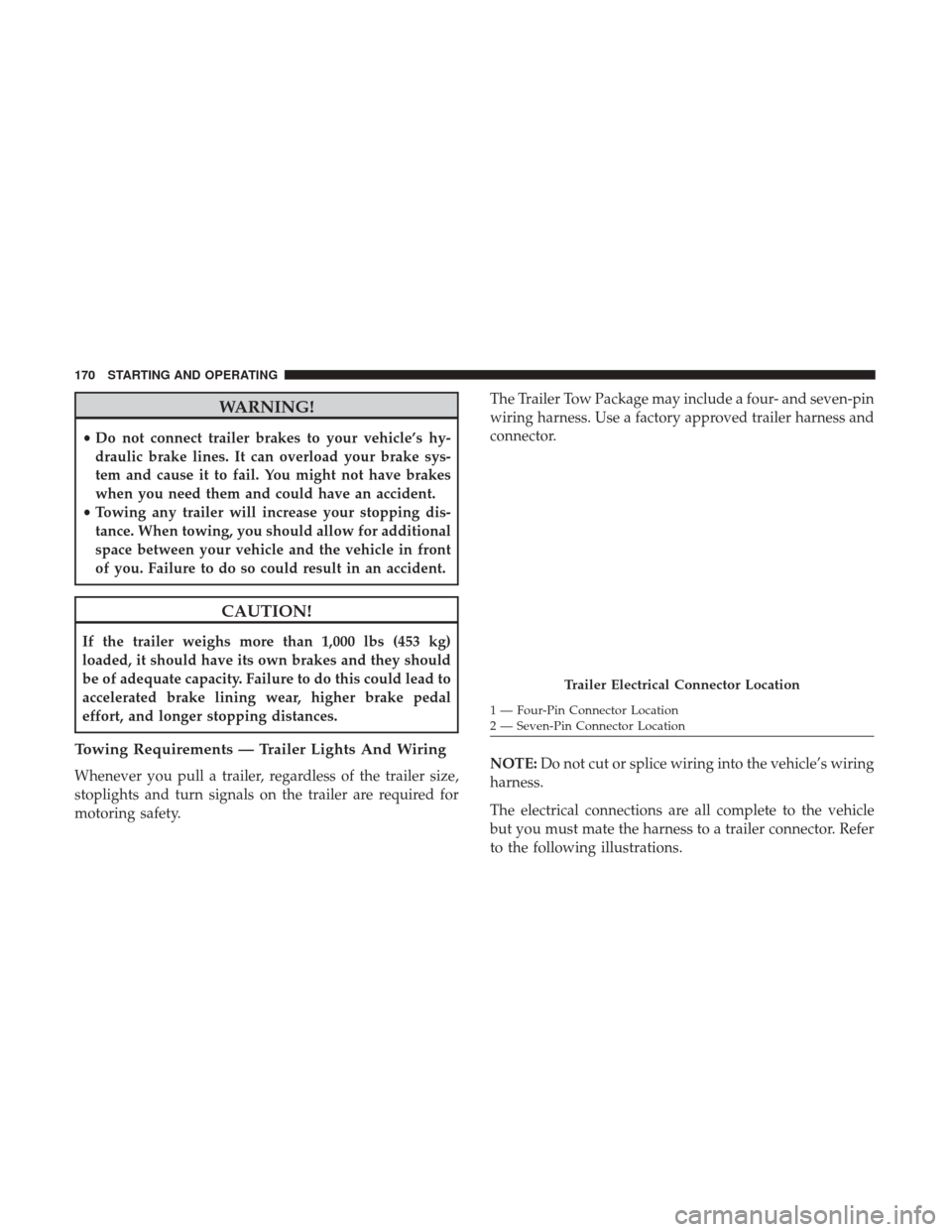

Towing Requirements — Trailer Lights And Wiring

Whenever you pull a trailer, regardless of the trailer size,

stoplights and turn signals on the trailer are required for

motoring safety. The Trailer Tow Package may include a four- and seven-pin

wiring harness. Use a factory approved trailer harness and

connector.

NOTE:

Do not cut or splice wiring into the vehicle’s wiring

harness.

The electrical connections are all complete to the vehicle

but you must mate the harness to a trailer connector. Refer

to the following illustrations.

Trailer Electrical Connector Location

1 — Four-Pin Connector Location

2 — Seven-Pin Connector Location

170 STARTING AND OPERATING

Page 174 of 332

Automatic Transmission

The DRIVE range can be selected when towing. The

transmission controls include a drive strategy to avoid

frequent shifting when towing. However, if frequent shift-

ing does occur while in DRIVE, select TOW/HAUL mode

or select a lower gear range (using the Electronic Range

Select (ERS) shift control).

NOTE:Using TOW/HAUL mode or selecting a lower

gear range (using the ERS shift control) while operating the

vehicle under heavy loading conditions will improve per-

formance and extend transmission life by reducing exces-

sive shifting and heat build up. This action will also

provide better engine braking.

When towing a loaded trailer up steep grades at low

speeds, holding your vehicle in first gear (using the ERS

shift control) can help to avoid transmission overheating.

Tow/Haul Mode

To reduce potential for automatic transmission overheat-

ing, activate TOW/HAUL mode when driving in hilly

areas, or select a lower gear range (using the Electronic

Range Select (ERS) shift control) on more severe grades.

Speed Control — If Equipped

• Do not use on hilly terrain or with heavy loads.

• When using the speed control, if you experience speed

drops greater than 10 mph (16 km/h), disengage until

you can get back to cruising speed.

• Use speed control in flat terrain and with light loads to

maximize fuel efficiency.

Cooling System

To reduce potential for engine and transmission overheat-

ing, take the following actions:

City Driving

• In city traffic — while stopped, place the transmission in

NEUTRAL, but do not increase engine idle speed.

Highway Driving

• Reduce speed.

• Temporarily turn off air conditioning.

172 STARTING AND OPERATING

Page 177 of 332

Driving Through Water

Driving through water more than a few inches/centimeters

deep will require extra caution to ensure safety and pre-

vent damage to your vehicle.

Flowing/Rising Water

WARNING!

Do not drive on or across a road or path where water is

flowing and/or rising (as in storm run-off). Flowing

water can wear away the road or path’s surface and

cause your vehicle to sink into deeper water. Further-

more, flowing and/or rising water can carry your ve-

hicle away swiftly. Failure to follow this warning may

result in injuries that are serious or fatal to you, your

passengers, and others around you.

Shallow Standing Water

Although your vehicle is capable of driving through shal-

low standing water, consider the following Cautions and

Warnings before doing so.

WARNING!

•Driving through standing water limits your vehicle’s

traction capabilities. Do not exceed 5 mph (8 km/h)

when driving through standing water.

• Driving through standing water limits your vehicle’s

braking capabilities, which increases stopping dis-

tances. Therefore, after driving through standing

water, drive slowly and lightly press on the brake

pedal several times to dry the brakes.

• Failure to follow these warnings may result in inju-

ries that are serious or fatal to you, your passengers,

and others around you.

6

STARTING AND OPERATING 175

Page 187 of 332

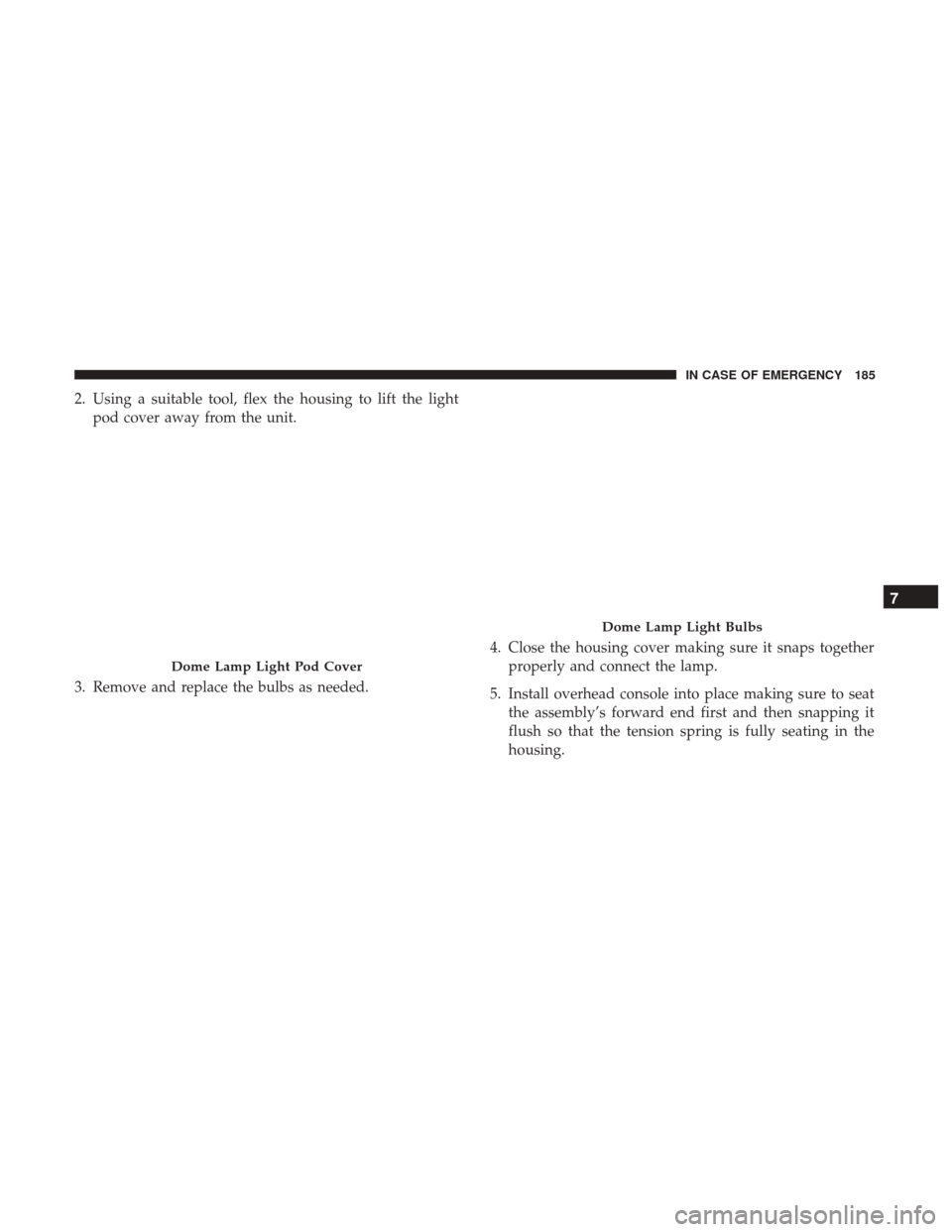

2. Using a suitable tool, flex the housing to lift the lightpod cover away from the unit.

3. Remove and replace the bulbs as needed. 4. Close the housing cover making sure it snaps together

properly and connect the lamp.

5. Install overhead console into place making sure to seat the assembly’s forward end first and then snapping it

flush so that the tension spring is fully seating in the

housing.

Dome Lamp Light Pod Cover

Dome Lamp Light Bulbs

7

IN CASE OF EMERGENCY 185

Page 193 of 332

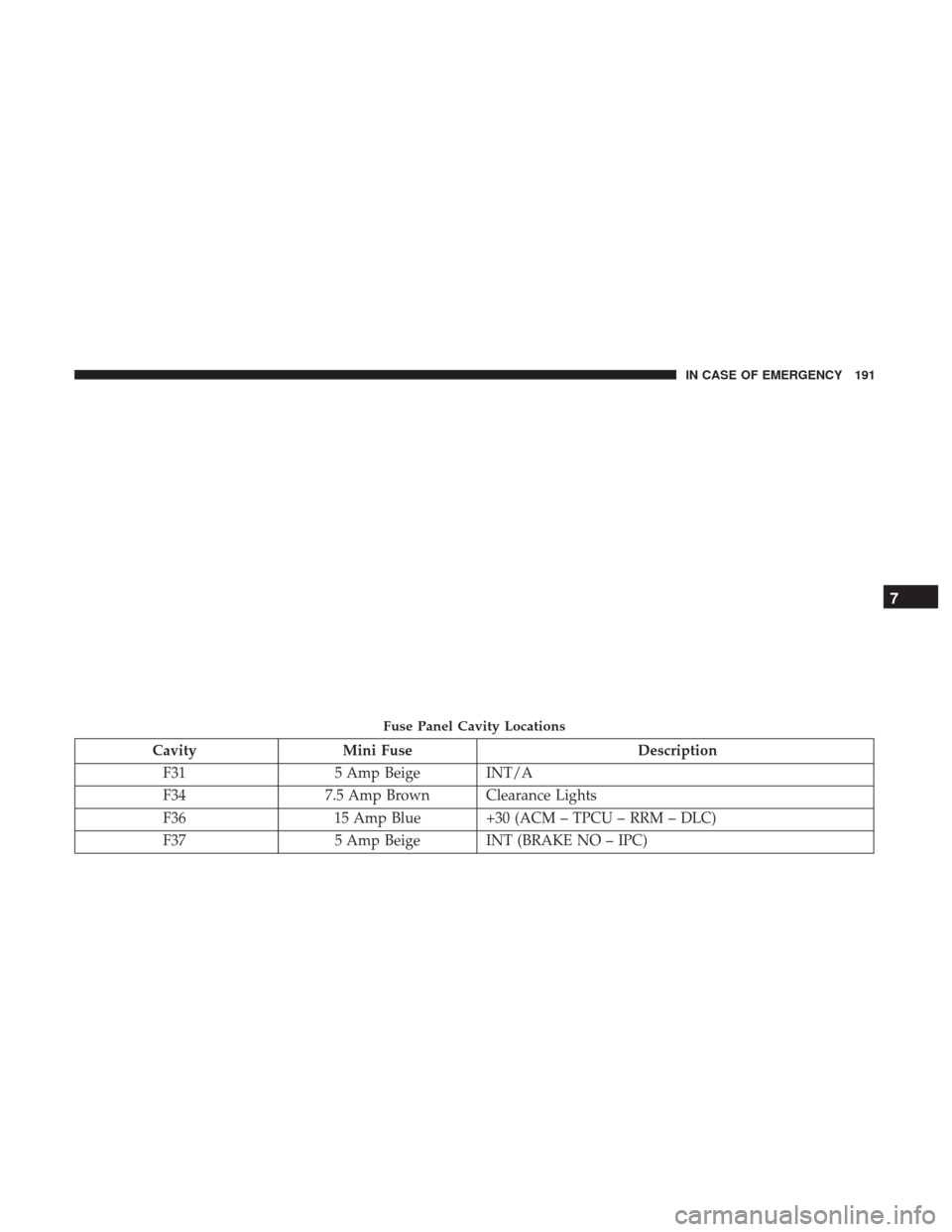

CavityMini Fuse Description

F31 5 Amp Beige INT/A

F34 7.5 Amp Brown Clearance Lights

F36 15 Amp Blue +30 (ACM – TPCU – RRM – DLC)

F37 5 Amp Beige INT (BRAKE NO – IPC)

Fuse Panel Cavity Locations

7

IN CASE OF EMERGENCY 191

Page 206 of 332

3. Place the wrench handle and lug bolt adapter on the jackscrew and turn to the right until the jack head is

properly engaged in the described location. Do not raise

the vehicle until you are sure the jack is securely

engaged.

4. Raise the vehicle by turning the jack screw to the right, using the wrench handle and lug bolt adapter. Raise the

vehicle only until the tire just clears the surface and

enough clearance is obtained to install the spare tire.

Minimum tire lift provides maximum stability.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.

5. Remove the wheel lug bolts. For vehicles with wheel covers, remove the cover from the wheel by hand. Do

not pry the wheel cover off. Then pull the wheel off the

hub.

6. Install the spare tire. Lightly tighten the wheel lug bolts.WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

Mounting Spare Tire

204 IN CASE OF EMERGENCY