steering Ram ProMaster 2020 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: ProMaster, Model: Ram ProMaster 2020Pages: 264, PDF Size: 10.11 MB

Page 78 of 264

76SAFETY

Because air bag sensors measure vehicle

deceleration over time, vehicle speed and

damage by themselves are not good indicators

of whether or not an air bag should have

deployed.

Seat belts are necessary for your protection in

all collisions, and also are needed to help keep

you in position, away from an inflating air bag.

When the ORC detects a collision requiring the

front air bags, it signals the inflator units. A large

quantity of non-toxic gas is generated to inflate

the front air bags.

The steering wheel hub trim cover and the

upper passenger side of the instrument panel

separate and fold out of the way as the air bags

inflate to their full size. The front air bags fully

inflate in less time than it takes to blink your

eyes. The front air bags then quickly deflate

while helping to restrain the driver and front

passenger.Supplemental Side Air Bags

Supplemental Seat-Mounted Side Air Bags

(SABs)

This vehicle is equipped with Supplemental

Seat-Mounted Side Air Bags (SABs).

Supplemental Seat-Mounted Side Air Bags

(SABs) are located in the outboard side of the

front seats. The SABs are marked with “SRS

AIRBAG” or “AIRBAG” on a label or on the seat

trim on the outboard side of the seats.

The SABs may help to reduce the risk of occu -

pant injury during certain side impacts, in addi -

tion to the injury reduction potential provided by

the seat belts and body structure.

Front Supplemental Seat-Mounted Side Air Bag Label

When the SAB deploys, it opens the seam on

the outboard side of the seatback’s trim cover.

The inflating SAB deploys through the seat

seam into the space between the occupant and

the door. The SAB moves at a very high speed

and with such a high force that it could injure

occupants if they are not seated properly, or if

items are positioned in the area where the SAB

inflates. Children are at an even greater risk of

injury from a deploying air bag.

WARNING!

Do not use accessory seat covers or place

objects between you and the Side Air Bags;

the performance could be adversely affected

and/or objects could be pushed into you,

causing serious injury.

20_VF_OM_EN_US_t.book Page 76

Page 81 of 264

SAFETY79

NOTE:

Air bag covers may not be obvious in the inte -

rior trim, but they will open during air bag

deployment. Rollover Events

Side Air Bags and seat belt pretensioners are

designed to activate in certain rollover events.

The Occupant Restraint Controller (ORC) deter

-

mines whether deployment in a particular roll-

over event is appropriate, based on the severity

and type of collision. Vehicle damage by itself is

not a good indicator of whether or not Side Air

Bags and seat belt pretensioners should have

deployed.

The Side Air Bags and seat belt pretensioners

will not deploy in all rollover events. The rollover

sensing system determines if a rollover event

may be in progress and whether deployment is

appropriate. In the event the vehicle experi -

ences a rollover or near rollover event, and

deployment is appropriate, the rollover sensing

system will deploy the side air bags and seat

belt pretensioners on both sides of the vehicle.

The SABICs may help reduce the risk of partial

or complete ejection of vehicle occupants

through side windows in certain rollover or side

impact events.

Air Bag System Components

NOTE:

The Occupant Restraint Controller (ORC) moni -

tors the internal circuits and interconnecting

wiring associated with electrical Air Bag System

Components listed below:

Occupant Restraint Controller (ORC)

Air Bag Warning Light

Steering Wheel and Column

Instrument Panel

Driver and Front Passenger Air Bags

Seat Belt Buckle Switch

Supplemental Side Air Bags

Front and Side Impact Sensors

Seat Belt Pretensioners

WARNING!

Side Air Bags need room to inflate. Do not

lean against the door or window. Sit upright

in the center of the seat.

Being too close to the Side Air Bags during

deployment could cause you to be severely

injured or killed.

Relying on the Side Air Bags alone could

lead to more severe injuries in a collision.

The Side Air Bags work with your seat belt

to restrain you properly. In some collisions,

Side Air Bags won’t deploy at all. Always

wear your seat belt even though you have

Side Air Bags.4

20_VF_OM_EN_US_t.book Page 79

Page 83 of 264

SAFETY81

(Continued)

NOTE:

After an accident, remember to cycle the igni -

tion to the STOP (OFF/LOCK) position and

remove the key from the ignition switch to avoid

draining the battery. Carefully check the vehicle

for fuel leaks in the engine compartment and on

the ground near the engine compartment and

fuel tank before resetting the system and

starting the engine. If there are no fuel leaks or

damage to the vehicle electrical devices (e.g.

headlights) after an accident, reset the Fuel Cut

Off Switch by following the procedure described

below. If you have any doubt, contact an autho -

rized dealer.

Fuel Cut Off Switch Reset Procedure

In order to reset the Fuel Cut Off Switch after an

event push the “A” Button located underneath

the instrument panel on the passenger side. Fuel Cut Off Switch

Maintaining Your Air Bag System

WARNING!

If, after an accident, you smell fuel or see

leaks from the fuel system, do not reset the

Fuel Cut Off Switch to avoid the risk of fire.

Before resetting the Fuel Cut Off Switch,

carefully check for fuel leaks or damage to

the vehicle electrical devices (e.g.

headlights).

WARNING!

Modifications to any part of the air bag

system could cause it to fail when you need

it. You could be injured if the air bag system

is not there to protect you. Do not modify

the components or wiring, including adding

any kind of badges or stickers to the

steering wheel hub trim cover or the upper

passenger side of the instrument panel. Do

not modify the front bumper, vehicle body

structure, or add aftermarket side steps or

running boards.

It is dangerous to try to repair any part of

the air bag system yourself. Be sure to tell

anyone who works on your vehicle that it

has an air bag system.

4

20_VF_OM_EN_US_t.book Page 81

Page 104 of 264

102STARTING AND OPERATING

Torque Converter Clutch

A feature designed to improve fuel economy

has been included in the automatic transmis -

sion on your vehicle. A clutch within the torque

converter engages automatically at calibrated

speeds. This may result in a slightly different

feeling or response during normal operation in

the upper gears. When the vehicle speed drops

or during some accelerations, the clutch auto -

matically disengages.

NOTE:

The torque converter clutch will not engage

until the transmission fluid and engine

coolant are warm [usually after 1 to 3 miles

(2 to 5 km) of driving]. Because the engine

speed is higher when the torque converter

clutch is not engaged, it may seem as if the

transmission is not shifting into Overdrive

when cold. This is normal. Using the Elec -

tronic Range Select (ERS) shift control, when

the transmission is sufficiently warm, will

demonstrate that the transmission is able to

shift into and out of Overdrive.

If the vehicle has not been driven for several

days, the first few seconds of operation after

shifting the transmission into gear may seem

sluggish. This is due to the fluid partially

draining from the torque converter into the

transmission. This condition is normal and

will not cause damage to the transmission.

The torque converter will refill within five

seconds after starting the engine.

POWER STEERING

The standard power steering system will give

you good vehicle response and increased ease

of maneuverability in tight spaces. The system

will provide mechanical steering capability if

power assist is lost.

If for some reason the power assist is inter -

rupted, it will still be possible to steer your

vehicle. Under these conditions, you will

observe a substantial increase in steering

effort, especially at very low vehicle speeds and

during parking maneuvers. NOTE:

Increased noise levels at the end of the

steering wheel travel are considered normal

and do not indicate that there is a problem

with the power steering system.

Upon initial start-up in cold weather, the

power steering pump may make noise for a

short amount of time. This is due to the cold,

thick fluid in the steering system. This noise

should be considered normal, and it does not

in any way damage the steering system.

CAUTION!

Prolonged operation of the steering system at

the end of the steering wheel travel will

increase the steering fluid temperature and it

should be avoided when possible. Damage to

the power steering pump may occur.

20_VF_OM_EN_US_t.book Page 102

Page 105 of 264

STARTING AND OPERATING103

Power Steering Fluid Check

Checking the power steering fluid level at a

defined service interval is not required. The fluid

should be checked at every oil change if a leak

is suspected, abnormal noises are apparent,

and/or the system is not functioning as antici -

pated. Coordinate inspection efforts through an

authorized dealer. If necessary, add fluid to restore to the proper

indicated level. With a clean cloth, wipe any

spilled fluid from all surfaces. Refer to “Fluids

And Lubricants” in “Technical Specifications”

for further information.

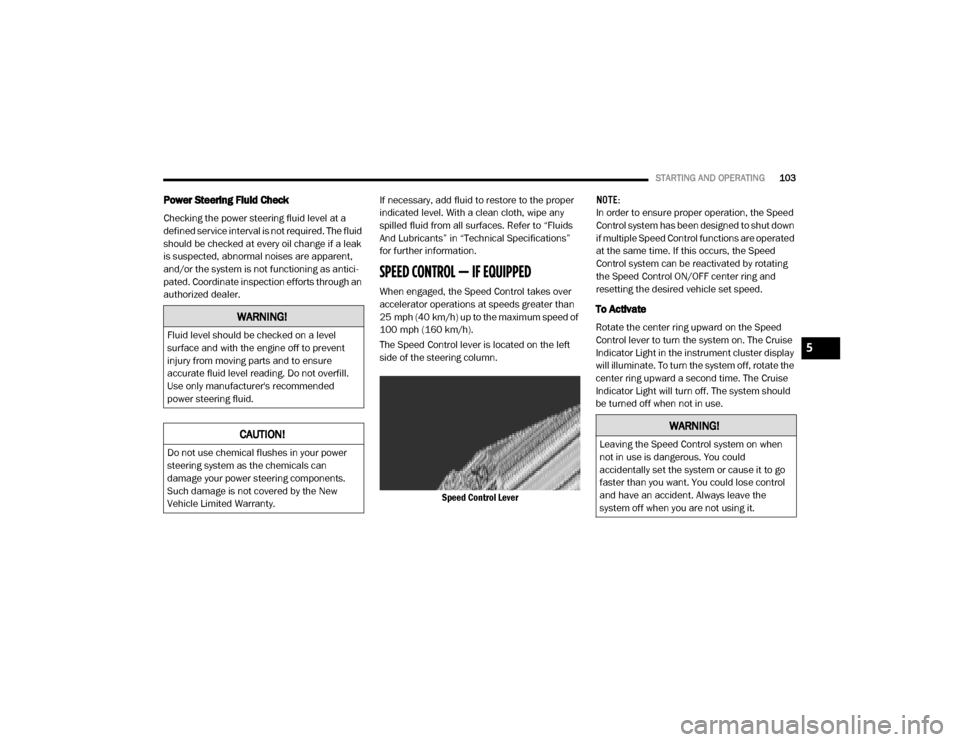

SPEED CONTROL — IF EQUIPPED

When engaged, the Speed Control takes over

accelerator operations at speeds greater than

25 mph (40 km/h) up to the maximum speed of

100 mph (160 km/h).

The Speed Control lever is located on the left

side of the steering column.

Speed Control Lever NOTE:

In order to ensure proper operation, the Speed

Control system has been designed to shut down

if multiple Speed Control functions are operated

at the same time. If this occurs, the Speed

Control system can be reactivated by rotating

the Speed Control ON/OFF center ring and

resetting the desired vehicle set speed.

To Activate

Rotate the center ring upward on the Speed

Control lever to turn the system on. The Cruise

Indicator Light in the instrument cluster display

will illuminate. To turn the system off, rotate the

center ring upward a second time. The Cruise

Indicator Light will turn off. The system should

be turned off when not in use.WARNING!

Fluid level should be checked on a level

surface and with the engine off to prevent

injury from moving parts and to ensure

accurate fluid level reading. Do not overfill.

Use only manufacturer's recommended

power steering fluid.

CAUTION!

Do not use chemical flushes in your power

steering system as the chemicals can

damage your power steering components.

Such damage is not covered by the New

Vehicle Limited Warranty.

WARNING!

Leaving the Speed Control system on when

not in use is dangerous. You could

accidentally set the system or cause it to go

faster than you want. You could lose control

and have an accident. Always leave the

system off when you are not using it.

5

20_VF_OM_EN_US_t.book Page 103

Page 116 of 264

114STARTING AND OPERATING

Tongue Weight (TW)

The Tongue Weight (TW) is the downward force

exerted on the hitch ball by the trailer. You must

consider this as part of the load on your vehicle.

Trailer Frontal Area

The frontal area is the maximum height multi -

plied by the maximum width of the front of a

trailer.

Trailer Sway Control

The Trailer Sway Control (TSC) can be a

mechanical telescoping link that can be

installed between the hitch receiver and the

trailer tongue that typically provides adjustable

friction associated with the telescoping motion

to dampen any unwanted trailer swaying

motions while traveling. If equipped, the electronic TSC recognizes a

swaying trailer and automatically applies indi

-

vidual wheel brakes and/or reduces engine

power to attempt to eliminate the trailer sway.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer

tongue weight, just as if it were luggage located

at a hitch ball or some other connecting point of

the vehicle. These kinds of hitches are the most

popular on the market today and they are

commonly used to tow small and medium sized

trailers.

Weight-Distributing Hitch

A weight-distributing system works by applying

leverage through spring (load) bars. They are

typically used for heavier loads to distribute

trailer tongue weight to the tow vehicle's front

axle and the trailer axle(s). When used in accor -

dance with the manufacturer's directions, it

provides for a more level ride, offering more

consistent steering and brake control thereby

enhancing towing safety. The addition of a fric -

tion/hydraulic sway control also dampens sway

caused by traffic and crosswinds and contrib -

utes positively to tow vehicle and trailer

stability. Trailer sway control and a weight distributing (load equalizing) hitch are recom

-

mended for heavier Tongue Weights (TW) and

may be required depending on vehicle and

trailer configuration/loading to comply with

Gross Axle Weight Rating (GAWR) requirements.

Trailer Hitch Classification

The following chart provides the industry stan -

dard for the maximum trailer weight a given

trailer hitch class can tow and should be used to

assist you in selecting the correct trailer hitch

for your intended towing condition.

WARNING!

It is important that you do not exceed the

maximum front or rear GAWR. A dangerous

driving condition can result if either rating is

exceeded. You could lose control of the

vehicle and have a collision.

WARNING!

An improperly adjusted Weight Distributing

Hitch system may reduce handling,

stability, braking performance, and could

result in a collision.

Weight Distributing Systems may not be

compatible with Surge Brake Couplers.

Consult with your hitch and trailer manufac -

turer or a reputable Recreational Vehicle

dealer for additional information.

20_VF_OM_EN_US_t.book Page 114

Page 118 of 264

116STARTING AND OPERATING

(Continued)

(Continued)

Consider the following items when computing

the weight on the rear axle of the vehicle:

The tongue weight of the trailer.

The weight of any other type of cargo or

equipment put in or on your vehicle.

The weight of the driver and all passengers.

NOTE:

Remember that everything put into or on the

trailer adds to the load on your vehicle. Also,

additional factory-installed options or

dealer-installed options must be considered as

part of the total load on your vehicle. Refer to

the “Tire And Loading Information” placard for

the maximum combined weight of occupants

and cargo for your vehicle.

Towing Requirements

To promote proper break-in of your new vehicle

drivetrain components, the following guidelines

are recommended. Perform the maintenance listed in the “Sched

-

uled Servicing”. Refer to “Scheduled Servicing”

in “Servicing And Maintenance” for the proper

maintenance intervals. When towing a trailer,

never exceed the GAWR or GCWR ratings.

CAUTION!

Do not tow a trailer at all during the first

500 miles (805 km) the new vehicle is driven. The engine, axle or other parts could

be damaged.

Then, during the first 500 miles (805 km) that a trailer is towed, do not drive over

50 mph (80 km/h) and do not make starts

at full throttle. This helps the engine and

other parts of the vehicle wear in at the

heavier loads.

WARNING!

Make certain that the load is secured in the

trailer and will not shift during travel. When

trailering cargo that is not fully secured,

dynamic load shifts can occur that may be

difficult for the driver to control. You could lose

control of your vehicle and have a collision.

When hauling cargo or towing a trailer, do

not overload your vehicle or trailer. Over -

loading can cause a loss of control, poor

performance or damage to brakes, axle,

engine, transmission, steering, suspension,

chassis structure or tires.

CAUTION!

(Continued)

Safety chains must always be used

between your vehicle and trailer. Always

connect the chains to the hook retainers of

the vehicle hitch. Cross the chains under

the trailer tongue and allow enough slack

for turning corners.

Vehicles with trailers should not be parked

on a grade. When parking, apply the

parking brake on the tow vehicle. Put the

tow vehicle transmission in PARK. For

four-wheel drive vehicles, make sure the

transfer case is not in NEUTRAL. Always,

block or "chock" the trailer wheels.

GCWR must not be exceeded.

Total weight must be distributed between

the tow vehicle and the trailer such that the

following four ratings are not exceeded:

GVWR

GTW

GAWR

Tongue weight rating for the trailer

hitch utilized.

WARNING!

(Continued)

20_VF_OM_EN_US_t.book Page 116

Page 130 of 264

128IN CASE OF EMERGENCY

(Continued)

2. Using a suitable tool, flex the housing to lift

the light pod cover away from the unit.

Dome Lamp Light Pod Cover

3. Remove and replace the bulbs as needed.

Dome Lamp Light Bulbs 4. Close the housing cover making sure it

snaps together properly and connect the

lamp.

5. Install overhead console into place making sure to seat the assembly’s forward end

first and then snapping it flush so that the

tension spring is fully seating in the housing.

FUSESUnderhood Fuses

The Front Power Distribution Center is located

on the driver’s side of the engine compartment.

To access the fuses, remove the cover.

Front Power Distribution Center

The ID number of the electrical component

corresponding to each fuse can be found on the

back of the cover.WARNING!

When replacing a blown fuse, always use

an appropriate replacement fuse with the

same amp rating as the original fuse. Never

replace a fuse with another fuse of higher

amp rating. Never replace a blown fuse with

metal wires or any other material. Do not

place a fuse inside a circuit breaker cavity

or vice versa. Failure to use proper fuses

may result in serious personal injury, fire

and/or property damage.

Before replacing a fuse, make sure that the

ignition is off and that all the other services

are switched off and/or disengaged.

If the replaced fuse blows again, contact an

authorized dealer.

If a general protection fuse for safety

systems (air bag system, braking system),

power unit systems (engine system, trans -

mission system) or steering system blows,

contact an authorized dealer.

WARNING!

(Continued)

20_VF_OM_EN_US_t.book Page 128

Page 151 of 264

IN CASE OF EMERGENCY149

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or

snow, it can often be moved using a rocking

motion. Turn the steering wheel right and left to

clear the area around the front wheels. Shift

back and forth between DRIVE (D) and

REVERSE (R), while gently pressing the acceler -

ator. Use the least amount of accelerator pedal

pressure that will maintain the rocking motion,

without spinning the wheels or racing the

engine. NOTE:

Push the “ESC OFF” switch, to place the Elec

-

tronic Stability Control (ESC) system in “Partial

OFF” mode, before rocking the vehicle. Refer to

“Electronic Brake Control System” in “Safety”

for further information. Once the vehicle has

been freed, push the “ESC OFF” switch again to

restore “ESC ON” mode.

TOWING A DISABLED VEHICLE

This section describes procedures for towing a

disabled vehicle using a commercial towing

service.

CAUTION!

Racing the engine or spinning the wheels may

lead to transmission overheating and failure.

Allow the engine to idle with the transmission

in NEUTRAL for at least one minute after

every five rocking-motion cycles. This will

minimize overheating and reduce the risk of

transmission failure during prolonged efforts

to free a stuck vehicle.

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may

cause damage, or even failure, of the axle

and tires. A tire could explode and injure

someone. Do not spin your vehicle's wheels

faster than 30 mph (48 km/h) or for longer than 30 seconds continuously without

stopping when you are stuck and do not let

anyone near a spinning wheel, no matter

what the speed.

CAUTION!

When “rocking” a stuck vehicle by shifting

between DRIVE and REVERSE, do not spin

the wheels faster than 15 mph (24 km/h), or drivetrain damage may result.

Spinning the wheels too fast may lead to

transmission overheating and failure. It can

also damage the tires. Do not spin the

wheels above 30 mph (48 km/h) while in

gear (no transmission shifting occurring).

6

20_VF_OM_EN_US_t.book Page 149

Page 154 of 264

152

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indi-

cator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate in the

instrument cluster. This means that service is

required for your vehicle. Operating conditions

such as frequent short-trips, trailer tow, and

extremely hot or cold ambient temperatures will

influence when the “Oil Change Required”

message is displayed. Severe Operating Condi-

tions can cause the change oil message to illu -

minate as early as 3,500 miles (5,600 km)

since last reset. Have the vehicle serviced as

soon as possible, within the next 500 miles

(805 km). An authorized dealer will reset the oil change

indicator message after completing the sched

-

uled oil change. If a scheduled oil change is

performed by someone other than an autho -

rized dealer, the message can be reset by refer -

ring to the steps described under “Instrument

Cluster Display” in “Getting To Know Your

Instrument Panel” for further information.

NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty All Models

Change Engine Oil at 4,000 miles (6,500 km) or

350 hours of engine run time if the vehicle is

operated in a dusty and off road environment or

is operated predominately at idle or only very

low engine RPM. This type of vehicle use is

considered Severe Duty. Once A Month Or Before A Long Trip:Check engine oil level

Check windshield washer fluid level

Check the tire inflation pressures and look

for unusual wear or damage. Rotate at the

first sign of irregular wear, even if it occurs

before the oil indicator system turns on

Check the fluid levels of the coolant reservoir,

brake master cylinder, and power steering

and fill as needed

Check function of all interior and exterior

lights

Maintenance Plan

Required Maintenance Intervals

Refer to the maintenance plan on the following

pages for the required maintenance intervals.

20_VF_OM_EN_US_t.book Page 152