lock RAM PROMASTER 2022 Repair Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2022, Model line: PROMASTER, Model: RAM PROMASTER 2022Pages: 268, PDF Size: 13.26 MB

Page 183 of 268

IN CASE OF EMERGENCY181

Wheel Blocked Example

NOTE:Passengers should not remain in the vehicle when

the vehicle is being lifted or raised.

JACK LOCATION — IF EQUIPPED

Depending on vehicle trim level, the jack and jack

tools are stored under the front passenger seat in

a box, or strapped behind the driver seat in a tool

bag. Tools may vary.

Jack Kit Location

To release the jack kit from its storage location,

turn the lock knob a quarter turn counterclockwise

to the unlock position.

Lock Knob

CAUTION!

Do not force lock knob over limit. Damage to

lock knob may occur.

1 — Unlock Position

2 — Lock Position

7

22_VF_OM_EN_USC_t.book Page 181

Page 185 of 268

IN CASE OF EMERGENCY183

Winch Location

The winch mechanism is located under the

rear of the vehicle in between the right rear tire

and spare tire.

Winch Extension

2. Rotate the wheel wrench handle counter

-

clockwise until the spare tire is on the ground

with enough cable slack to allow you to pull it

out from under the vehicle.

Lowering Spare Tire

3. Pull the spare tire out from under the vehicle to gain access to the spare tire retainer.

Spare Tire

4. Lift the spare tire with one hand to give clearance to tilt the retainer at the end of

the cable.

Lifting Spare Tire

CAUTION!

The winch mechanism is designed for use with

the jack wrench extension tool only. Use of air

wrench or power tool may damage the winch.

7

22_VF_OM_EN_USC_t.book Page 183

Page 186 of 268

184IN CASE OF EMERGENCY

(Continued)

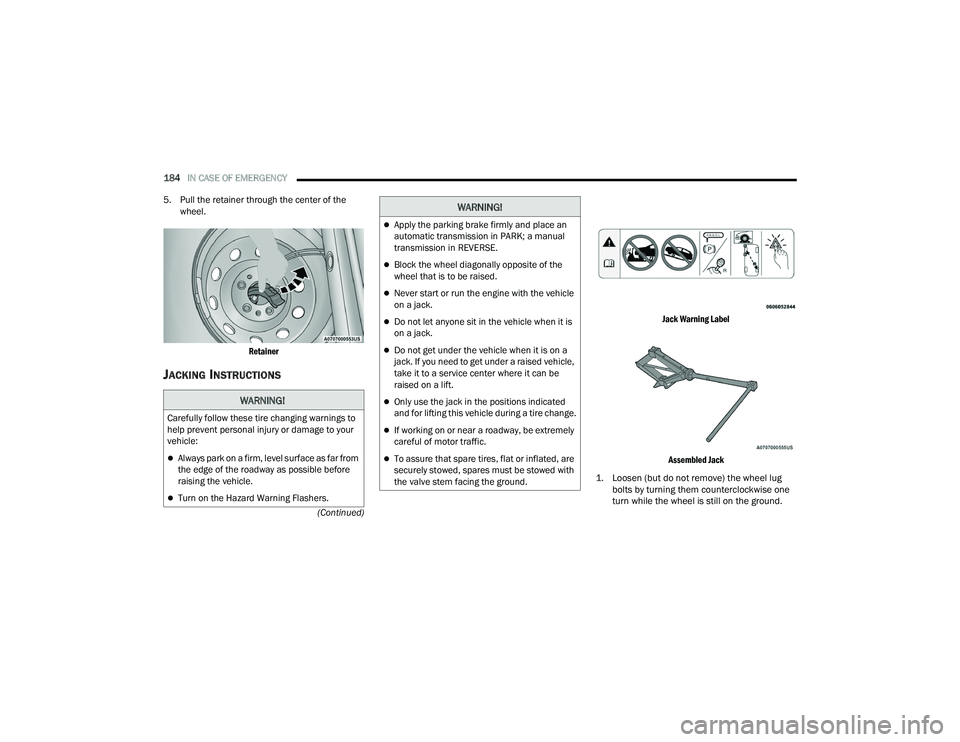

5. Pull the retainer through the center of the

wheel.

Retainer

JACKING INSTRUCTIONS

Jack Warning Label

Assembled Jack

1. Loosen (but do not remove) the wheel lug bolts by turning them counterclockwise one

turn while the wheel is still on the ground.

WARNING!

Carefully follow these tire changing warnings to

help prevent personal injury or damage to your

vehicle:

Always park on a firm, level surface as far from

the edge of the roadway as possible before

raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and place an

automatic transmission in PARK; a manual

transmission in REVERSE.

Block the wheel diagonally opposite of the

wheel that is to be raised.

Never start or run the engine with the vehicle

on a jack.

Do not let anyone sit in the vehicle when it is

on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised vehicle,

take it to a service center where it can be

raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire change.

If working on or near a roadway, be extremely

careful of motor traffic.

To assure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with

the valve stem facing the ground.

WARNING!

22_VF_OM_EN_USC_t.book Page 184

Page 188 of 268

186IN CASE OF EMERGENCY

3. Place the wrench handle and lug bolt adapter on the jack screw and turn clockwise until the

jack head is properly engaged in the described

location. Do not raise the vehicle until you are

sure the jack is securely engaged.

4. Raise the vehicle by turning the jack screw clockwise, using the wrench handle and lug

bolt adapter. Raise the vehicle only until the

tire just clears the surface and enough

clearance is obtained to install the spare tire.

Minimum tire lift provides maximum stability. 5. Remove the wheel lug bolts. For vehicles with

wheel covers, remove the cover from the

wheel by hand. Do not pry the wheel cover off.

Then pull the wheel off the hub.

6. Install the spare tire. Lightly tighten the wheel lug bolts.

Mounting Spare Tire

NOTE:Do not install the wheel cover on the spare tire.

7. Lower the vehicle by turning the jack screw left Úpage 247.

8. Lower the jack to its fully-closed position.

9. Stow the damaged wheel/spare tire with the cable and wheel spacer before driving the

vehicle.

Damaged Wheel Stowage

WARNING!

Being under a jacked-up vehicle is dangerous.

The vehicle could slip off the jack and fall on

you. You could be crushed. Never get any part of

your body under a vehicle that is on a jack. If you

need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off the

jack and hurt someone near it. Raise the vehicle

only enough to remove the tire.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

CAUTION!

Be sure to mount the spare tire with the valve

stem facing outward. The vehicle could be

damaged if the spare tire is mounted incorrectly.

22_VF_OM_EN_USC_t.book Page 186

Page 189 of 268

IN CASE OF EMERGENCY187

10. Install the winch extension and rotate the

wrench handle clockwise until the winch

mechanism operator hears “3 clicks” from the

device to indicate the wheel is properly stowed

under the vehicle.

11. Stow the jack, jack handle and winch handle tools back in the storage compartment.

12. Check the spare tire pressure as soon as possible. Correct the tire pressure, as required.

For vehicles with aluminum wheels:

The center cap must be pushed out from the rear

to install the retainer and stow the tire.

WHEEL COVERS

The wheel covers on the vehicle are held in place

by the wheel lug bolts and can be removed after

the wheel lug bolts are taken off.

TIRE SERVICE KIT — IF EQUIPPED

Small punctures up to 1/4 inch (6 mm) in the tire

tread can be sealed with Tire Service Kit. Foreign

objects (e.g., screws or nails) should not be

removed from the tire. Tire Service Kit can be used

in outside temperatures down to approximately

-4°F (-20°C).

This kit will provide a temporary tire seal, allowing

you to drive your vehicle up to 100 miles (160 km)

with a maximum speed of 50 mph (80 km/h).

TIRE SERVICE KIT STORAGE

Depending on vehicle trim levels, the Tire Service

Kit can be stored in the driver’s door pocket or the

passenger’s side compartment area.

TIRE SERVICE KIT COMPONENTS AND

O

PERATION

Tire Service Kit Components

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the

vehicle. Always stow the jack parts and the spare tire

in the places provided. Have the deflated (flat) tire

repaired or replaced immediately.

CAUTION!

Use a back-and-forth motion to remove the

hub cap. Do not use a twisting motion when

removing the hub cap, damage to the hub cap

finish may occur.

1 — Power Button

2 — Mode Select Knob

3 — Sealant Hose (Clear)

4 — Sealant Bottle

5 — Air Pump Hose (Black)

6 — Sealant Bottle Release Button

7 — Power Plug

8 — Pressure Gauge

9 — Deflation Button

7

22_VF_OM_EN_USC_t.book Page 187

Page 193 of 268

IN CASE OF EMERGENCY191

(D) Drive Vehicle:

Immediately after injecting sealant and inflating the

tire, drive the vehicle 5 miles (8 km) or 10 minutes to

ensure distribution of the Tire Service Kit Sealant within

the tire. Do not exceed 50 mph (80 km/h).

(E) After Driving:

Pull over to a safe location Ú page 189.

1. Push in the Mode Select Knob (2) and turn to the Air Mode position.

2. Uncoil the power plug and insert the plug into the vehicle's 12 Volt power outlet.

3. Uncoil the Air Pump Hose (5) (black in color) and screw the fitting at the end of hose onto

the valve stem.

4. Check the pressure in the tire by reading the Pressure Gauge (8). If tire pressure is less than 19 psi (1.3 Bar):

The tire is too badly damaged. Do not attempt to

drive the vehicle further. Call for assistance.

If the tire pressure is 19 psi (1.3 Bar) or higher:

1. Push the Power Button (1) to turn on Tire

Service Kit and inflate the tire to the pressure

indicated on the tire and loading information

label on the driver-side door opening.

NOTE:If the tire becomes overinflated, push the Deflation

Button to reduce the tire pressure to the recom -

mended inflation pressure before continuing.

2. Disconnect the Tire Service Kit from the valve stem, reinstall the cap on the valve stem and

unplug from 12 Volt outlet.

3. Place the Tire Service Kit in its proper storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an

authorized dealer or tire service center.

5. Remove the Speed Limit sticker from the instrument panel after the tire has been

repaired.

6. Replace the Sealant Bottle (4) and Sealant Hose (3) assembly at an authorized dealer as

soon as possible Ú page 191.

NOTE:When having the tire serviced, advise the autho -

rized dealer or service center that the tire has been

sealed using the Tire Service Kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (3) (clear in color).

2. Locate the red colored round Sealant Bottle release button at the lower right hand corner

of the kit.

3. Push and hold the Sealant Bottle release button, then pull out the bottle holding the

button.

4. Clean any remaining sealant from the Tire Service Kit housing.

5. Position the new Sealant Bottle (4) in the housing so that the Sealant Hose (3) aligns

with the hose slot in the front of the housing.

Push and hold the Sealant Bottle release

button, then push the bottle into the housing

by holding the button. An audible click will be

heard indicating the bottle is locked into place.

Release the button.

6. Verify that the cap is installed on the fitting at the end of the Sealant Hose (3) and return the

hose to its storage area (located on top of the

housing).

7. Return the Tire Service Kit to its storage location in the vehicle.WARNING!

Tire Service Kit is not a permanent flat tire repair.

Have the tire inspected and repaired or replaced

after using Tire Service Kit. Do not exceed 50 mph

(80 km/h) until the tire is repaired or replaced.

Failure to follow this warning can result in injuries

that are serious or fatal to you, your passengers, and

others around you.

7

22_VF_OM_EN_USC_t.book Page 191

Page 202 of 268

200SERVICING AND MAINTENANCE

Mileage or time passed (whichever comes first)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional Inspections

Inspect the CV/Universal joints. X X X X X X X X X X X X X X

Inspect front suspension, tie rod ends, boot seals, and replace if necessary. X X X X X X X

Inspect the brake pads, replace as necessary. X X X X X X X

Inspect the rear door net block gap, adjust/replace as necessary. XXXXX

Additional Maintenance

Replace the engine air cleaner filter. XXXXX

Inspect the cabin air filter, replace as necessary. X X X X X X X

Replace the Brake Fluid every two years.

1X X X X X X X

Replace the spark plugs.

2X

22_VF_OM_EN_USC_t.book Page 200

Page 209 of 268

SERVICING AND MAINTENANCE207

Removing Air Filter

3. Install the cabin air filter/filter retainer back into the fresh air inlet. When installing the filter

retainer make sure the retainer is fully

engaged.

4. Install the two screws back into the assembly to secure the filter retainer to the fresh air inlet.

BODY LUBRICATION

Locks and all body pivot points, including such

items as seat tracks, door hinge pivot points and

rollers, liftgate, tailgate, decklid, sliding doors and

hood hinges, should be lubricated periodically with

a lithium-based grease, such as Mopar® Spray

White Lube to ensure quiet, easy operation and

to protect against rust and wear. Prior to the

application of any lubricant, the parts concerned

should be wiped clean to remove dust and grit;

after lubricating, excess oil and grease should be

removed. Particular attention should also be given

to hood latching components to ensure proper

function. When performing other underhood

services, the hood latch release mechanism, and

safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated

twice a year, preferably in the Autumn and Spring.

Apply a small amount of a high quality lubricant,

such as Mopar® Lock Cylinder Lubricant directly

into the lock cylinder.

WINDSHIELD WIPER BLADES

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth

and a mild nonabrasive cleaner. This will remove

accumulations of salt or road film.

Operation of the wipers on dry glass for long

periods may cause deterioration of the wiper

blades. Always use washer fluid when using the

wipers to remove salt or dirt from a dry windshield.

Avoid using the wiper blades to remove frost or ice

from the windshield. Keep the blade rubber out of

contact with petroleum products such as engine

oil, gasoline, etc.

NOTE:Life expectancy of wiper blades varies depending

on geographical area and frequency of use. If chat -

tering, marks, water lines or wet spots are present,

clean the wiper blades or replace as necessary.

1 — Fresh Air Inlet

2 — Cabin Air Filter

3 — Cabin Air Filter Retainer

8

22_VF_OM_EN_USC_t.book Page 207

Page 220 of 268

218SERVICING AND MAINTENANCE

Interior Fuses

The interior fuse panel is part of the Body Control

Module (BCM) and is located on the driver's side

under the instrument panel.

NOTE:Please contact an authorized dealer for BCM fuse

replacement.

Fuse PanelFuse Panel Cavity Locations

CavityMini Fuse Description

F315 Amp BeigeINT/A

F33 7.5 Amp Brown+30 TTM

F34 7.5 Amp BrownClearance Lights

F36 15 Amp Blue+30 (ACM / USB Power Out / USB Recharge / TBM / RRM / DLC)

F37 7.5 Amp BrownINT (IPC – DASM / AEB)

F38 20 Amp YellowCentral Locking

F42 5 Amp BeigeINT (BSM / BRAKE NC) / EPS

F43 20 Amp YellowBi-Directional Washer Pump

F47 20 Amp YellowDriver Power Window

F48 20 Amp YellowPassenger Power Window

F49 5 Amp BeigeINT (RRM / TTM / SBDU / XAN / JHC / RFX)

F50 7.5 Amp BrownINT (ORC)

22_VF_OM_EN_USC_t.book Page 218

Page 224 of 268

222SERVICING AND MAINTENANCE

Replacing Exterior Bulbs

HEADLAMPS LOW BEAM AND HIGH BEAM

See the following steps to replace:

1. Remove one retaining screw on the lower

headlamp filler panel. Remove filler panel.

2. Remove two retaining screws on the upper headlamp filler panel. Remove filler panel.

3. Remove one upper retaining screw from the headlamp housing.

4. Remove two lower retaining screws from the headlamp housing.

5. Pull Headlamp forward, disconnect harness electrical connector and remove the headlamp

assembly from vehicle.

6. Remove appropriate plastic cap from the back of the headlamp housing.

7. Push down on the upper portion of the socket.

8. Pull the socket outward from reflector.

9. Pull bulb outward from socket.

10. Install new bulb.

11. Push socket back into reflector until it locks back into place.

12. Install access cap.

13. Carefully reinstall headlamp in the same position on the vehicle, so as not to affect

headlamp aiming. 14. Install one upper retaining screw on the

headlamp housing.

15. Install two lower retaining screws on the headlamp housing.

16. Carefully reinstall the lower headlamp filler panel and one retaining screw.

17. Carefully reinstall the upper headlamp filler panel and two retaining screws.

FRONT TURN SIGNAL/PARKING LAMPS

See the following steps to replace:

1. Remove one retaining screw on the lower headlamp filler panel. Remove filler panel.

2. Remove two retaining screws on the upper headlamp filler panel. Remove filler panel.

3. Remove one upper retaining screw from the headlamp housing.

4. Remove two lower retaining screws from the headlamp housing.

5. Pull Headlamp forward, disconnect the harness electrical connector and remove the

headlamp assembly from vehicle.

6. Rotate the bulb counterclockwise and remove.

7. Install the bulb into socket, and rotate bulb/ socket clockwise into lamp locking it in place. 8. Carefully reinstall headlamp in the same

position on the vehicle, so as not to affect

headlamp aiming.

9. Install the one upper retaining screw on headlamp housing.

10. Install the two lower retaining screws on headlamp housing.

11. Carefully reinstall the lower headlamp filler panel and one retaining screw.

12. Carefully reinstall the upper headlamp filler panel and two retaining screws.

DAYTIME RUNNING LAMP (DRL)/FRONT SIDE

MARKER LAMP

See the following steps to replace:

1. Remove one retaining screw on the lower headlamp filler panel. Remove filler panel.

2. Remove two retaining screws on the upper headlamp filler panel. Remove filler panel.

3. Remove one upper retaining screw from the headlamp housing.

4. Remove two lower retaining screws from the headlamp housing.

5. Pull Headlamp forward, disconnect the harness electrical connector and remove the

headlamp assembly from vehicle.

22_VF_OM_EN_USC_t.book Page 222