light RAM PROMASTER 2023 Owners Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2023, Model line: PROMASTER, Model: RAM PROMASTER 2023Pages: 296, PDF Size: 12.31 MB

Page 197 of 296

IN CASE OF EMERGENCY195

SOS Call System Limitations

Vehicles sold in Mexico DO NOT have SOS Call

system capabilities.

SOS or other emergency line operators in Mexico

may not answer or respond to SOS system calls. If the SOS Call system detects a malfunction,

any of the following may occur at the time the

malfunction is detected, and at the beginning of

each ignition cycle:

The overhead console lights located within the

SOS and ASSIST buttons will continuously illumi

-

nate red.

The Device Screen will display the following

message: “Vehicle device requires service.

Please contact an authorized dealer.”

An In-Vehicle Audio message will state “Vehicle

device requires service. Please contact an

authorized dealer.” Even if the SOS Call system is fully functional,

factors beyond FCA US LLC’s control may prevent

or stop the SOS Call system operation. These

include, but are not limited to, the following

factors:

The ignition is in the OFF position

The vehicle’s electrical systems are not intact

The SOS Call system software and/or hardware

are damaged during a crash

The vehicle battery loses power or becomes

disconnected during a vehicle crash

LTE (voice/data) or 4G (data) network and/or

Global Positioning Satellite signals are unavail

-

able or obstructed

Equipment malfunction at the SOS operator

facility

Operator error by the SOS operator

LTE (voice/data) or 4G (data) network congestion

Weather

Buildings, structures, geographic terrain, or

tunnels

The SOS Call system is embedded into the

vehicle’s electrical system. Do not add after -

market electrical equipment to the vehicle’s elec -

trical system. This may prevent your vehicle from

sending a signal to initiate an emergency call.

To avoid interference that can cause the SOS Call

system to fail, never add aftermarket equipment

(e.g., two-way mobile radio, CB radio, data

recorder, etc.) to your vehicle’s electrical system

or modify the antennas on your vehicle. IF YOUR

VEHICLE LOSES BATTERY POWER FOR ANY

REASON (INCLUDING DURING OR AFTER AN ACCI -

DENT), THE UCONNECT FEATURES, APPS AND

SERVICES, AMONG OTHERS, WILL NOT OPERATE.

Modifications to any part of the SOS Call

system could cause the air bag system to fail

when you need it. You could be injured if the

air bag system is not there to help protect you.

WARNING!

WARNING!

Ignoring the overhead console light could

mean you will not have SOS Call services.

If the overhead console light is illuminated,

have an authorized dealer service the SOS

Call system immediately.

The Occupant Restraint Control module turns

on the air bag Warning Light on the instrument

panel if a malfunction in any part of the

system is detected. If the Air Bag Warning

Light is illuminated, have an authorized dealer

service the Occupant Restraint Control system

immediately.

7

23_VF_OM_EN_USC_t.book Page 195

Page 204 of 296

202IN CASE OF EMERGENCY

3. Place the wrench handle and lug bolt adapter on the jack screw and turn clockwise until the

jack head is properly engaged in the described

location. Do not raise the vehicle until you are

sure the jack is securely engaged.

4. Raise the vehicle by turning the jack screw clockwise, using the wrench handle and lug

bolt adapter. Raise the vehicle only until the

tire just clears the surface and enough

clearance is obtained to install the spare tire.

Minimum tire lift provides maximum stability. 5. Remove the wheel lug bolts. For vehicles with

wheel covers, remove the cover from the

wheel by hand. Do not pry the wheel cover off.

Then pull the wheel off the hub.

6. Install the spare tire. Lightly tighten the wheel lug bolts.

Mounting Spare Tire

NOTE:Do not install the wheel cover on the spare tire.

7. Lower the vehicle by turning the jack screw left, making sure it is securely on the ground.

Tighten the lug nuts/bolts in a star pattern

until each nut/bolt has been tightened twice.

Ensure that the socket is fully engaged on

the lug nut/bolt (do not insert it halfway)

Úpage 269.

Torque Patterns

8. Lower the jack to its fully-closed position.

9. Stow the damaged wheel/spare tire by reinstalling the wheel retainer and using the

cable winch mechanism to securely tighten

under the vehicle before driving.WARNING!

Being under a jacked-up vehicle is dangerous.

The vehicle could slip off the jack and fall on

you. You could be crushed. Never get any part of

your body under a vehicle that is on a jack. If you

need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off the

jack and hurt someone near it. Raise the vehicle

only enough to remove the tire.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

CAUTION!

Be sure to mount the spare tire with the valve

stem facing outward. The vehicle could be

damaged if the spare tire is mounted incorrectly.

23_VF_OM_EN_USC_t.book Page 202

Page 223 of 296

221

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indicator

system will remind you that it is time to take your

vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil change

indicator message will illuminate in the instrument

cluster. This means that service is required for your

vehicle. Operating conditions such as frequent

short-trips, trailer tow, and extremely hot or cold

ambient temperatures will influence when the “Oil

Change Required” message is displayed. Have the

vehicle serviced as soon as possible, within the next

500 miles (805 km).

An authorized dealer will reset the oil change

indicator message after completing the scheduled

oil change. If a scheduled oil change is performed

by someone other than an authorized dealer, the

message can be reset by referring to the steps

described under Instrument Cluster Display

Ú

page 57.

NOTE:Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for fleet

customers. Once A Month Or Before A Long Trip:

Check engine oil level

Check windshield washer fluid level

Check the tire pressures and look for unusual

wear or damage. Rotate at the first sign of irreg

-

ular wear, even if it occurs before the oil indi -

cator system turns on

Check the fluid levels of the coolant reservoir,

and brake master cylinder and fill as needed

Check function of all interior and exterior lights

8

23_VF_OM_EN_USC_t.book Page 221

Page 228 of 296

226SERVICING AND MAINTENANCE

(Continued)

CHECKING OIL LEVEL

To ensure proper engine lubrication, the engine oil

must be maintained at the correct level. Check the

oil level at regular intervals, such as every fuel

stop. The best time to check the engine oil level is

about five minutes after a fully warmed up engine

is shut off.

Checking the oil while the vehicle is on level ground

will improve the accuracy of the oil level readings.

There are four possible dipstick types:

Crosshatched zone.

Crosshatched zone marked SAFE.

Crosshatched zone marked with MIN at the low

end of the range and MAX at the high end of the

range.

Crosshatched zone marked with dimples at the

MIN and the MAX ends of the range.

NOTE:Always maintain the oil level within the crosshatch

markings on the dipstick.

Adding 1 qt (1 L) of oil when the reading is at the

low end of the dipstick range will raise the oil level

to the high end of the range marking.

ADDING WASHER FLUID

The fluid reservoir is located in the engine

compartment and should be checked at regular

intervals. Fill the reservoir with windshield washer

solvent (not radiator antifreeze) and operate the

system for a few seconds to flush out any residual

water.

The washer fluid reservoir will hold a full gallon of

fluid when the Low Washer Fluid Light illuminates.

WARNING!

Never smoke while working in the engine

compartment: gas and flammable vapors may

be present, with the risk of fire.

Be very careful when working in the engine

compartment when the engine is hot: you may

get burned. Do not get too close to the radiator

cooling fan: the electric fan may start; danger

of injury. Scarves, ties and other loose clothing

might be pulled by moving parts.

CAUTION!

Be careful not to confuse the various types of

fluids while topping up: they are not compatible

with each other! Topping up with an unsuitable

fluid could severely damage your car.

The oil level must never exceed the MAX mark.

Always top up using engine oil of the same

specifications as that already in the engine.

If the engine oil is being topped up, wait for the

engine to cool down before loosening the filler

cap, particularly for vehicles with aluminum

caps (if equipped). WARNING: risk of burns!

Overfilling or underfilling the crankcase will

cause aeration or loss of oil pressure. This

could damage your engine.

CAUTION!

CAUTION!

Overfilling or underfilling the crankcase will

cause aeration or loss of oil pressure. This could

damage your engine.

WARNING!

Commercially available windshield washer

solvents are flammable. They could ignite and

burn you. Care must be exercised when filling or

working around the washer solution.

23_VF_OM_EN_USC_t.book Page 226

Page 237 of 296

SERVICING AND MAINTENANCE235

If an examination of your engine compartment

shows no evidence of radiator or hose leaks, the

vehicle may be safely driven. The vapor will soon

dissipate.

Do not overfill the coolant expansion bottle.

Check the coolant freeze point in the radiator

and in the coolant expansion bottle. If engine

coolant needs to be added, the contents of the

coolant expansion bottle must also be protected

against freezing.

If frequent engine coolant additions are

required, the cooling system should be pressure

tested for leaks.

Maintain engine coolant concentration at a

minimum of 50% OAT coolant (conforming to

MS.90032) and distilled water for proper corro -

sion protection of your engine which contains

aluminum components.

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning, keep

the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever neces -

sary, install ONLY the correct type thermostat.

Other designs may result in unsatisfactory

engine cooling performance, poor gas mileage,

and increased emissions.

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically Ú page 222.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked when performing under the hood service

or immediately if the Brake System Warning Light

indicates system failure. If necessary, add fluid to

bring level within the designated marks on the side

of the reservoir of the brake master cylinder. Be

sure to clean the top of the master cylinder area

before removing cap. With disc brakes the fluid

level can be expected to fall as the brake linings

wear. However, an unexpected drop in fluid level

may be caused by a leak and a system check

should be conducted Ú page 273.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting or

riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You would not have your full

braking capacity in an emergency.

WARNING!

Use only the manufacturer recommended

brake fluid Úpage 273. Using the wrong type

of brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep

the master cylinder reservoir cap secured at

all times. Brake fluid in an open container

absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure.

This could result in a collision.

Overfilling the brake fluid reservoir can result

in spilling brake fluid on hot engine parts,

causing the brake fluid to catch fire. Brake

fluid can also damage painted and vinyl

surfaces, care should be taken to avoid its

contact with these surfaces.

Do not allow petroleum-based fluid to contami -

nate the brake fluid. Brake seal components could

be damaged, causing partial or complete brake

failure. This could result in a collision.

8

23_VF_OM_EN_USC_t.book Page 235

Page 244 of 296

242SERVICING AND MAINTENANCE

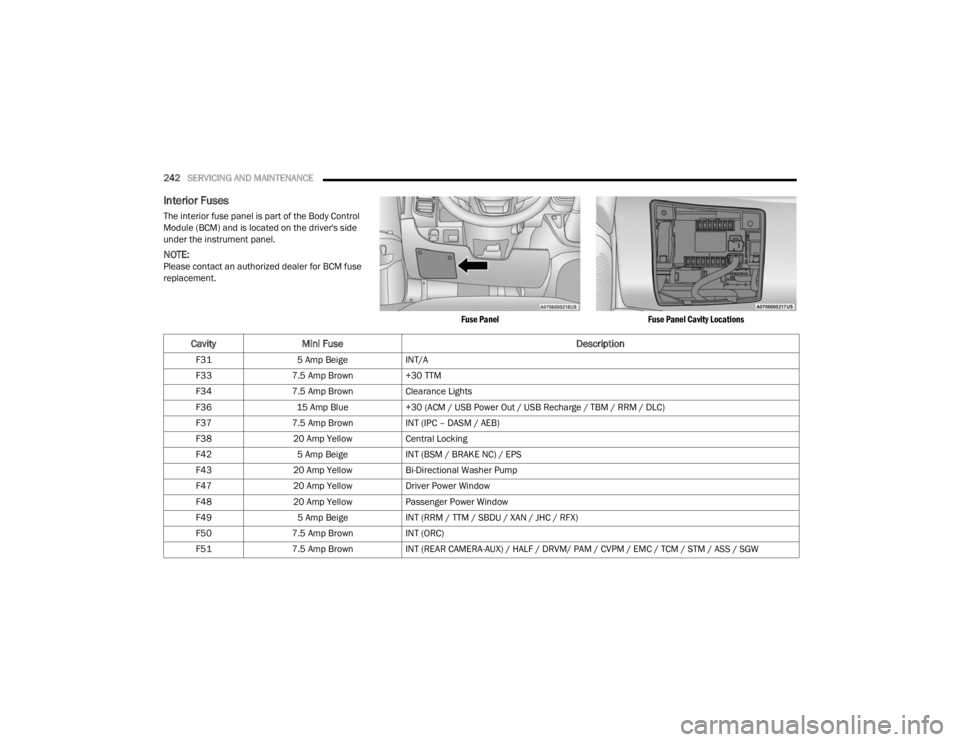

Interior Fuses

The interior fuse panel is part of the Body Control

Module (BCM) and is located on the driver's side

under the instrument panel.

NOTE:Please contact an authorized dealer for BCM fuse

replacement.

Fuse PanelFuse Panel Cavity Locations

CavityMini Fuse Description

F315 Amp Beige INT/A

F33 7.5 Amp Brown +30 TTM

F34 7.5 Amp Brown Clearance Lights

F36 15 Amp Blue +30 (ACM / USB Power Out / USB Recharge / TBM / RRM / DLC)

F37 7.5 Amp Brown INT (IPC – DASM / AEB)

F38 20 Amp Yellow Central Locking

F42 5 Amp Beige INT (BSM / BRAKE NC) / EPS

F43 20 Amp Yellow Bi-Directional Washer Pump

F47 20 Amp Yellow Driver Power Window

F48 20 Amp Yellow Passenger Power Window

F49 5 Amp Beige INT (RRM / TTM / SBDU / XAN / JHC / RFX)

F50 7.5 Amp Brown INT (ORC)

F51 7.5 Amp Brown INT (REAR CAMERA-AUX) / HALF / DRVM/ PAM / CVPM / EMC / TCM / STM / ASS / SGW

23_VF_OM_EN_USC_t.book Page 242

Page 248 of 296

246SERVICING AND MAINTENANCE

Replacing Exterior Bulbs

HEADLAMPS LOW BEAM AND HIGH BEAM

See the following steps to replace:

1. Disconnect the negative battery terminal.

2. Remove the headlamp retaining screws.

3. Remove the headlamp assembly from the

vehicle (by moving the headlamp to release

the lower slides from the headlamp mounting

on the vehicle).

4. Disconnect the headlamp harness electrical connector.

5. Remove appropriate plastic cap from the back of the headlamp housing.

6. Detach the wire connector from the bulb.

7. Rotate the bulb counterclockwise and remove it from the reflector.

8. Install a new bulb.

9. Rotate the new bulb clockwise to lock it in place.

10. Reinstall the wire connector.

11. Reinstall the access cap and rotate to lock into place.

12. Connect the headlamp harness electrical connector. 13. Carefully reinstall headlamp in the same

position on the vehicle, so as not to affect

headlamp aiming.

14. Reinstall the headlamp screws.

15. Connect the negative battery terminal.

16. Check lights to make sure they are operating correctly.

FRONT TURN SIGNAL/PARKING LAMPS

See the following steps to replace:

1. Remove one retaining screw on the lower headlamp filler panel. Remove filler panel.

2. Remove two retaining screws on the upper headlamp filler panel. Remove filler panel.

3. Remove one upper retaining screw from the headlamp housing.

4. Remove two lower retaining screws from the headlamp housing.

5. Pull Headlamp forward, disconnect the harness electrical connector and remove the

headlamp assembly from vehicle.

6. Rotate the bulb counterclockwise and remove.

7. Install the bulb into socket, and rotate bulb/ socket clockwise into lamp locking it in place.

8. Carefully reinstall headlamp in the same position on the vehicle, so as not to affect

headlamp aiming. 9. Install the one upper retaining screw on

headlamp housing.

10. Install the two lower retaining screws on headlamp housing.

11. Carefully reinstall the lower headlamp filler panel and one retaining screw.

12. Carefully reinstall the upper headlamp filler panel and two retaining screws.DAYTIME RUNNING LAMP (DRL)/FRONT SIDE

MARKER LAMP

See the following steps to replace:

1. Remove one retaining screw on the lower headlamp filler panel. Remove filler panel.

2. Remove two retaining screws on the upper headlamp filler panel. Remove filler panel.

3. Remove one upper retaining screw from the headlamp housing.

4. Remove two lower retaining screws from the headlamp housing.

5. Pull Headlamp forward, disconnect the harness electrical connector and remove the

headlamp assembly from vehicle.

6. Remove the (DRL), side marker bulb by pulling straight out.

7. Replace lamp as required and lock in place.

8. Reinstall plastic cap.

23_VF_OM_EN_USC_t.book Page 246

Page 249 of 296

SERVICING AND MAINTENANCE247

9. Carefully reinstall headlamp in the same position on the vehicle, as not to affect

headlamp aiming.

10. Install the one upper retaining screw on the headlamp housing.

11. Install the two lower retaining screws on the headlamp housing.

12. Carefully reinstall the lower headlamp filler panel and one retaining screw.

13. Carefully reinstall the upper headlamp filler panel and two retaining screws.

See an authorized dealer for LED bulb

replacement.

FRONT FOG LAMPS

See the following steps to replace:

1. Turn front wheels inboard to access cover in wheel liner.

2. Open the cover on the front of the wheel liner.

3. Remove connection and replace the bulb.

4. Connect the wire and rotate bulb/socket clockwise into lamp locking it in place.

5. Reinstall the plastic cap and close the cover on the wheel liner. See an authorized dealer for LED bulb

replacement.

FRONT, REAR ROOF LAMPS

See the following steps to replace:

1. Remove two screw and remove the lamp

assembly.

2. Remove the socket bulb by turning counter -

clockwise.

3. Remove bulb and replace as needed.

4. Reinstall the bulb socket and rotate clockwise to lock in place.

5. Reinstall lamp.

REAR TAIL, STOP, BACKUP, TURN SIGNAL AND

REAR SIDE MARKER LAMPS

See the following steps to replace:

1. Open rear doors.

2. Remove the seven (7) fasteners from the rear access cover and remove cover to gain access

to the tail lamp assembly fasteners.

Rear Access Cover

3. Remove the two (2) 17 mm tail lamp assembly fasteners.

4. Disconnect the tail lamp harness connector and remove tail light assembly from the

vehicle.

5. Remove the tail/stop, turn signal, backup and rear side marker bulb/socket by rotating

counterclockwise.

6. Remove the bulb and replace as needed.

7. Reinstall bulb/socket and rotate clockwise to lock in place.

8. Reinstall lamp.

8

23_VF_OM_EN_USC_t.book Page 247

Page 250 of 296

248SERVICING AND MAINTENANCE

Replacing Interior Bulbs

CARGO LAMP

See the following steps to replace:

1. Using a suitable tool, remove either the lamp

above the back door or the sliding door lamp

as needed and disconnect it.

Rear Cargo Lamp Bulb Access

2. Using a suitable tool, pull open the metal bulb access on the back of the housing.

Cargo Lamp Bulb Location

3. Remove and install the replacement bulb.

4. Close the bulb access, connect the lamp and install the lamp into place.

DOME LAMPS

See the following steps to replace:

1. Using a suitable tool, insert the tip at the location shown and press inward to the lamp

to relieve the spring tension. This will allow

you to easily drop the dome lamp assembly

from its bracket and disconnect the lamp.

Dome Lamp Assembly Location

2. Using a suitable tool, flex the housing to lift the light pod cover away from the unit.

Dome Lamp Light Pod Cover

1 — Spring Tension Relief Access

2 — Dome Lamp Assembly

23_VF_OM_EN_USC_t.book Page 248

Page 251 of 296

SERVICING AND MAINTENANCE249

3. Remove and replace the bulbs as needed.

Dome Lamp Light Bulbs

4. Close the housing cover making sure it snaps together properly and connect the lamp.

5. Install overhead console into place making sure to seat the assembly’s forward end first

and then snapping it flush so that the tension

spring is fully seating in the housing.

TIRES

TIRE SAFETY INFORMATION

Tire safety information will cover aspects of

the following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

Tire Markings

Tire Markings

NOTE:

P (Passenger) — Metric tire sizing is based on US

design standards. P-Metric tires have the letter

“P” molded into the sidewall preceding the size

designation. Example: P215/65R15 95H.

European — Metric tire sizing is based on Euro -

pean design standards. Tires designed to this

standard have the tire size molded into the side -

wall beginning with the section width. The letter

"P" is absent from this tire size designation.

Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based on

US design standards. The size designation for

LT-Metric tires is the same as for P-Metric tires

except for the letters “LT” that are molded into

the sidewall preceding the size designation.

Example: LT235/85R16.

Temporary spare tires are designed for tempo -

rary emergency use only. Temporary high pres -

sure compact spare tires have the letter “T” or

“S” molded into the sidewall preceding the size

designation. Example: T145/80D18 103M.

High flotation tire sizing is based on US design

standards and it begins with the tire diameter

molded into the sidewall. Example: 31x10.5

R15 LT.

1 — US DOT Safety Standards

Code (TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and

Temperature Grades

8

23_VF_OM_EN_USC_t.book Page 249