Brake service RAM PROMASTER 2023 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2023, Model line: PROMASTER, Model: RAM PROMASTER 2023Pages: 296, PDF Size: 12.31 MB

Page 209 of 296

IN CASE OF EMERGENCY207

If the tire inflates to the recommended pressure or

is at least 26 psi (1.8 bar) within 15 minutes:

NOTE:If the tire becomes overinflated, push the Deflation

Button to reduce the tire pressure to the recom -

mended inflation pressure before continuing.

1. Push the Power Button to turn the Tire

Service Kit off.

2. Remove the speed limit label from the

Tire Service Kit and place sticker on the

steering wheel.

3. Immediately disconnect the Sealant Hose from the valve stem, reinstall the cap on the

fitting at the end of the hose, and place the Tire

Service Kit in the vehicle storage location.

Drive Vehicle: Immediately after injecting sealant

and inflating the tire, drive the vehicle

5 miles (8 km) or 10 minutes to ensure distribution of the Tire Service Kit Sealant

within the tire. Do not exceed 50 mph (80 km/h). After Driving:

Pull over to a safe location and turn on the

vehicle’s Hazard Warning Flashers.

Verify that the valve stem (on the wheel with

the deflated tire) is in a position that is near to

the ground. This will allow the Tire Service Kit

Hose to reach the valve stem and keep the Tire

Service Kit flat on the ground. This will provide

the best positioning of the kit when injecting the

sealant into the deflated tire and running the

air pump. Move the vehicle as necessary to

place the valve stem in this position before

proceeding.

Place the transmission in PARK (P) and cycle the

ignition in the OFF position.

Apply the parking brake.

NOTE:

If tire has improper inflation follow these next steps:

1. Uncoil the Sealant Hose, and then remove the

cap from the fitting at the end of the hose.

2. Place the Tire Service Kit flat on the

ground next to the deflated tire.

3. Remove the cap from the valve stem, and then screw the fitting at the end of the Sealant Hose

onto the valve stem.

4. Uncoil the Power Plug and insert the

plug into the vehicle's 12 Volt power

outlet.

5. Uncoil the Hose and screw the fitting at

the end of the hose onto the valve stem.

6. Turn the Mode Select Knob and turn to

the Air Mode position.

7. Check the pressure in the tire by reading the Pressure Gauge.

If tire pressure is less than 19 psi (1.3 bar):

The tire is too badly damaged. Do not attempt to

drive the vehicle further. Call for assistance.WARNING!

The Tire Service Kit is not a permanent flat tire

repair. Have the tire inspected and repaired or

replaced after using the Tire Service Kit. Do not

exceed 50 mph (80 km/h) until the tire is repaired

or replaced. Failure to follow this warning can result

in injuries that are serious or fatal to you, your

passengers, and others around you. Have the tire

checked as soon as possible at an authorized dealer.

7

23_VF_OM_EN_USC_t.book Page 207

Page 213 of 296

IN CASE OF EMERGENCY211

SEALING A TIRE WITH TIRE SERVICE KIT

(A) Whenever You Stop To Use Tire Service Kit:

1. Pull over to a safe location and turn on the

vehicle’s Hazard Warning Flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near to

the ground. This will allow the Tire Service Kit

Hoses (3) and (5) to reach the valve stem and

keep the Tire Service Kit flat on the ground. This will provide the best positioning of the kit

when injecting the sealant into the deflated

tire and running the air pump. Move the

vehicle as necessary to place the valve stem in

this position before proceeding.

3. Place the transmission in PARK (P) (auto transmission) or in Gear (manual transmission)

and place the ignition in the OFF position.

4. Apply the parking brake.

(B) Setting Up To Use Tire Service Kit:

1. Push in the Mode Select Knob (2) and turn to the Sealant Mode position.

2. Uncoil the Sealant Hose (3) and then remove the cap from the fitting at the end of the hose.

3. Place the Tire Service Kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the Sealant Hose

(3) onto the valve stem.

5. Uncoil the Power Plug (7) and insert the plug into the vehicle’s 12 Volt power outlet.

NOTE:Do not remove foreign objects (e.g., screws or

nails) from the tire.

(C) Injecting Tire Service Kit Sealant Into

The Deflated Tire:

Always start the engine before turning ON the

Tire Service Kit.

NOTE:Manual transmission vehicles must have the

parking brake engaged and the gear selector in

NEUTRAL.

After pushing the Power Button (1), the sealant

(white fluid) will flow from the Sealant Bottle (4)

through the Sealant Hose (3) and into the tire.

NOTE:Sealant may leak out through the puncture in

the tire.

If the sealant (white fluid) does not flow within

0 – 10 seconds through the Sealant Hose (3):

1. Push the Power Button (1) to turn Off the Tire Service Kit. Disconnect the Sealant Hose (3)

from the valve stem. Make sure the valve

stem is free of debris. Reconnect the Sealant

Hose (3) to the valve stem. Check that the

Mode Select Knob (2) is in the Sealant Mode

position and not Air Mode. Push the Power

Button (1) to turn On the Tire Service Kit.

2. Connect the Power Plug (7) to a different 12 Volt power outlet in your vehicle or another

vehicle, if available. Make sure the engine is

running before turning ON the Tire Service Kit.

Take care not to allow the contents of Tire

Service Kit to come in contact with hair, eyes,

or clothing. Tire Service Kit sealant is harmful

if inhaled, swallowed, or absorbed through the

skin. It causes skin, eye, and respiratory irrita -

tion. Flush immediately with plenty of water if

there is any contact with eyes or skin. Change

clothing as soon as possible, if there is any

contact with clothing.

Tire Service Kit Sealant solution contains

latex. In case of an allergic reaction or rash,

consult a physician immediately. Keep Tire

Service Kit out of reach of children. If swal -

lowed, rinse mouth immediately with plenty of

water and drink plenty of water. Do not induce

vomiting! Consult a physician immediately.

WARNING!

7

23_VF_OM_EN_USC_t.book Page 211

Page 218 of 296

216IN CASE OF EMERGENCY

4. Disconnect the opposite end of the positive (+)

jumper cable from the remote positive (+) post

of the discharged vehicle, and reinstall the

protective cap.

5. Close the cover of the Front Power Distribution Center.

If frequent jump starting is required to start your

vehicle you should have the battery and charging

system inspected at an authorized dealer.

BATTERY LOCATION

There are two remote jump starting posts under

the hood which is the recommended jump start

location. If access to the battery is needed, an

access panel on the driver’s side floor will allow for

battery access.

Battery Access Panel

Battery Location

IF YOUR ENGINE OVERHEATS

If the vehicle is overheating, it will need to be

serviced by an authorized dealer.

In any of the following situations, you can reduce

the potential for overheating by taking the

appropriate action.

On the highways — slow down.

In city traffic — while stopped, place the trans -

mission in NEUTRAL (N), but do not increase the

engine idle speed while preventing vehicle

motion with the brakes.

NOTE:There are steps that you can take to slow down an

impending overheat condition:

If your Air Conditioner (A/C) is on, turn it off.

The A/C system adds heat to the engine cooling

system and turning the A/C off can help remove

this heat.

You can also turn the temperature control to

maximum heat, the mode control to floor and

the blower control to high. This allows the heater

core to act as a supplement to the radiator and

aids in removing heat from the engine cooling

system.

CAUTION!

Accessories plugged into the vehicle power

outlets draw power from the vehicle’s battery,

even when not in use (i.e., cellular devices, etc.).

Eventually, if plugged in long enough without

engine operation, the vehicle’s battery will

discharge sufficiently to degrade battery life

and/or prevent the engine from starting.

23_VF_OM_EN_USC_t.book Page 216

Page 219 of 296

IN CASE OF EMERGENCY217

GEAR SELECTOR OVERRIDE

If a malfunction occurs and the gear selector

cannot be moved out of the PARK (P) position, you

can use the following procedure to temporarily

move the gear selector:

1. Turn the engine OFF.

2. Firmly apply the parking brake.

3. Using a small screwdriver or similar tool,

remove the shifter boot material of the gear

selector by pulling up to carefully separate the

gear selector bezel and boot assembly from

the console.

Shifter Boot And Bezel

4. Press and maintain firm pressure on the brake

pedal.

5. Insert the screwdriver or similar tool into the gear selector override release and push down

while depressing the shifter button at the

same time.

Gear Selector Override Release Lever

6. Move the gear selector to the NEUTRAL (N) position.

7. The vehicle may then be started in NEUTRAL.

8. Reinstall the shifter boot and bezel.

WARNING!

You or others can be badly burned by hot engine

coolant (antifreeze) or steam from your radiator.

If you see or hear steam coming from under the

hood, do not open the hood until the radiator

has had time to cool. Never try to open a cooling

system pressure cap when the radiator or

coolant bottle is hot.

CAUTION!

Driving with a hot cooling system could damage

your vehicle. If the temperature gauge reads

HOT (H), pull over and stop the vehicle. Idle the

vehicle with the air conditioner turned off until

the pointer drops back into the normal range.

If the pointer remains on HOT (H), and you

hear continuous chimes, turn the engine off

immediately and call for service.

7

23_VF_OM_EN_USC_t.book Page 217

Page 221 of 296

IN CASE OF EMERGENCY219

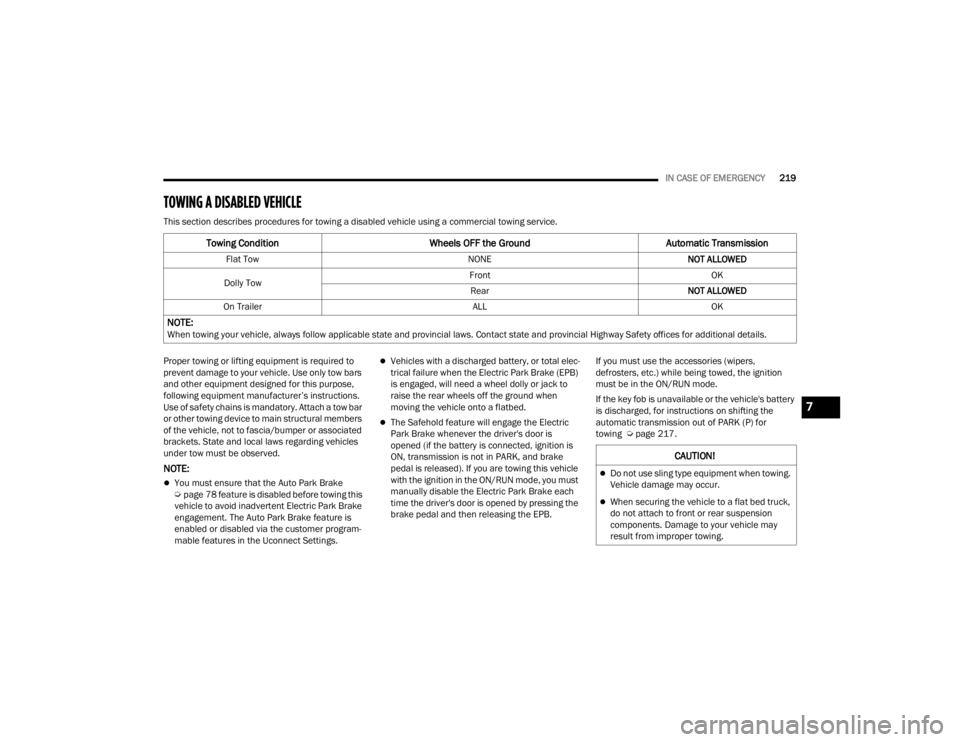

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled vehicle using a commercial towing service.

Proper towing or lifting equipment is required to

prevent damage to your vehicle. Use only tow bars

and other equipment designed for this purpose,

following equipment manufacturer’s instructions.

Use of safety chains is mandatory. Attach a tow bar

or other towing device to main structural members

of the vehicle, not to fascia/bumper or associated

brackets. State and local laws regarding vehicles

under tow must be observed.

NOTE:

You must ensure that the Auto Park Brake

Úpage 78 feature is disabled before towing this

vehicle to avoid inadvertent Electric Park Brake

engagement. The Auto Park Brake feature is

enabled or disabled via the customer program -

mable features in the Uconnect Settings.

Vehicles with a discharged battery, or total elec -

trical failure when the Electric Park Brake (EPB)

is engaged, will need a wheel dolly or jack to

raise the rear wheels off the ground when

moving the vehicle onto a flatbed.

The Safehold feature will engage the Electric

Park Brake whenever the driver's door is

opened (if the battery is connected, ignition is

ON, transmission is not in PARK, and brake

pedal is released). If you are towing this vehicle

with the ignition in the ON/RUN mode, you must

manually disable the Electric Park Brake each

time the driver's door is opened by pressing the

brake pedal and then releasing the EPB. If you must use the accessories (wipers,

defrosters, etc.) while being towed, the ignition

must be in the ON/RUN mode.

If the key fob is unavailable or the vehicle's battery

is discharged, for instructions on shifting the

automatic transmission out of PARK (P) for

towing Ú

page 217.

Towing Condition Wheels OFF the Ground Automatic Transmission

Flat Tow NONENOT ALLOWED

Dolly Tow Front

OK

Rear NOT ALLOWED

On Trailer ALLOK

NOTE:When towing your vehicle, always follow applicable state and provincial laws. Contact state and provincial Highway Safety offices for additional details.

CAUTION!

Do not use sling type equipment when towing.

Vehicle damage may occur.

When securing the vehicle to a flat bed truck,

do not attach to front or rear suspension

components. Damage to your vehicle may

result from improper towing.

7

23_VF_OM_EN_USC_t.book Page 219

Page 223 of 296

221

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indicator

system will remind you that it is time to take your

vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil change

indicator message will illuminate in the instrument

cluster. This means that service is required for your

vehicle. Operating conditions such as frequent

short-trips, trailer tow, and extremely hot or cold

ambient temperatures will influence when the “Oil

Change Required” message is displayed. Have the

vehicle serviced as soon as possible, within the next

500 miles (805 km).

An authorized dealer will reset the oil change

indicator message after completing the scheduled

oil change. If a scheduled oil change is performed

by someone other than an authorized dealer, the

message can be reset by referring to the steps

described under Instrument Cluster Display

Ú

page 57.

NOTE:Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for fleet

customers. Once A Month Or Before A Long Trip:

Check engine oil level

Check windshield washer fluid level

Check the tire pressures and look for unusual

wear or damage. Rotate at the first sign of irreg

-

ular wear, even if it occurs before the oil indi -

cator system turns on

Check the fluid levels of the coolant reservoir,

and brake master cylinder and fill as needed

Check function of all interior and exterior lights

8

23_VF_OM_EN_USC_t.book Page 221

Page 226 of 296

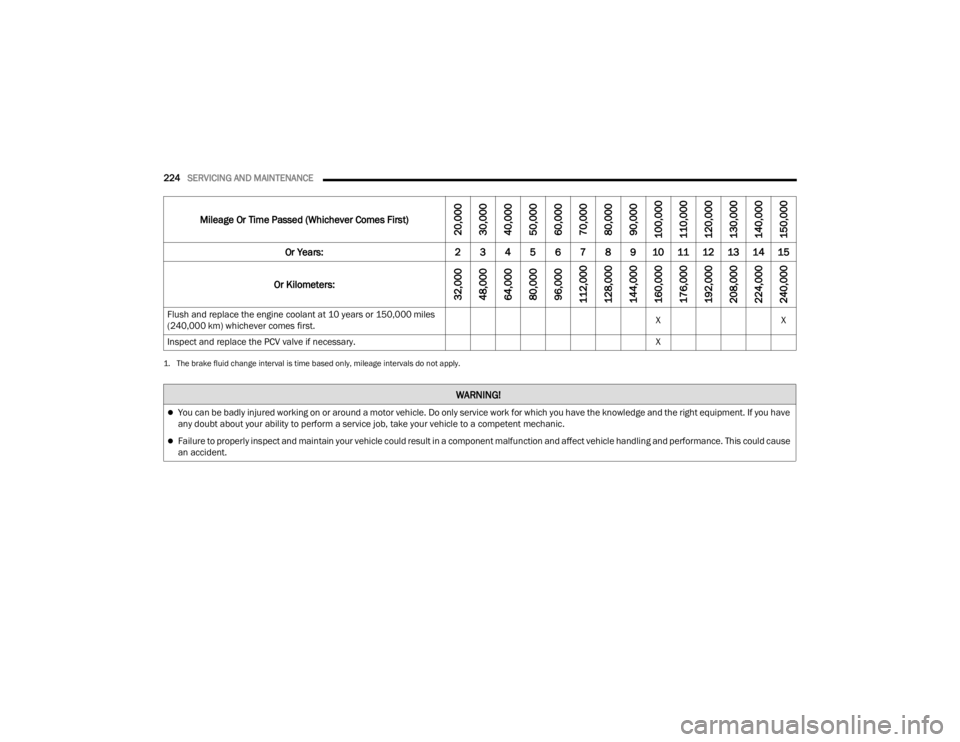

224SERVICING AND MAINTENANCE

Flush and replace the engine coolant at 10 years or 150,000 miles

(240,000 km) whichever comes first. X

X

Inspect and replace the PCV valve if necessary. X

1. The brake fluid change interval is time based only, mileage intervals do not apply.

WARNING!

You can be badly injured working on or around a motor vehicle. Do only service work for which you have the knowledge and the right equipment. If you have

any doubt about your ability to perform a service job, take your vehicle to a competent mechanic.

Failure to properly inspect and maintain your vehicle could result in a component malfunction and affect vehicle handling and performance. This could cause

an accident.

Mileage Or Time Passed (Whichever Comes First)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

23_VF_OM_EN_USC_t.book Page 224

Page 237 of 296

SERVICING AND MAINTENANCE235

If an examination of your engine compartment

shows no evidence of radiator or hose leaks, the

vehicle may be safely driven. The vapor will soon

dissipate.

Do not overfill the coolant expansion bottle.

Check the coolant freeze point in the radiator

and in the coolant expansion bottle. If engine

coolant needs to be added, the contents of the

coolant expansion bottle must also be protected

against freezing.

If frequent engine coolant additions are

required, the cooling system should be pressure

tested for leaks.

Maintain engine coolant concentration at a

minimum of 50% OAT coolant (conforming to

MS.90032) and distilled water for proper corro -

sion protection of your engine which contains

aluminum components.

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning, keep

the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever neces -

sary, install ONLY the correct type thermostat.

Other designs may result in unsatisfactory

engine cooling performance, poor gas mileage,

and increased emissions.

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically Ú page 222.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked when performing under the hood service

or immediately if the Brake System Warning Light

indicates system failure. If necessary, add fluid to

bring level within the designated marks on the side

of the reservoir of the brake master cylinder. Be

sure to clean the top of the master cylinder area

before removing cap. With disc brakes the fluid

level can be expected to fall as the brake linings

wear. However, an unexpected drop in fluid level

may be caused by a leak and a system check

should be conducted Ú page 273.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting or

riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You would not have your full

braking capacity in an emergency.

WARNING!

Use only the manufacturer recommended

brake fluid Úpage 273. Using the wrong type

of brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep

the master cylinder reservoir cap secured at

all times. Brake fluid in an open container

absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure.

This could result in a collision.

Overfilling the brake fluid reservoir can result

in spilling brake fluid on hot engine parts,

causing the brake fluid to catch fire. Brake

fluid can also damage painted and vinyl

surfaces, care should be taken to avoid its

contact with these surfaces.

Do not allow petroleum-based fluid to contami -

nate the brake fluid. Brake seal components could

be damaged, causing partial or complete brake

failure. This could result in a collision.

8

23_VF_OM_EN_USC_t.book Page 235

Page 271 of 296

269

TECHNICAL SPECIFICATIONS

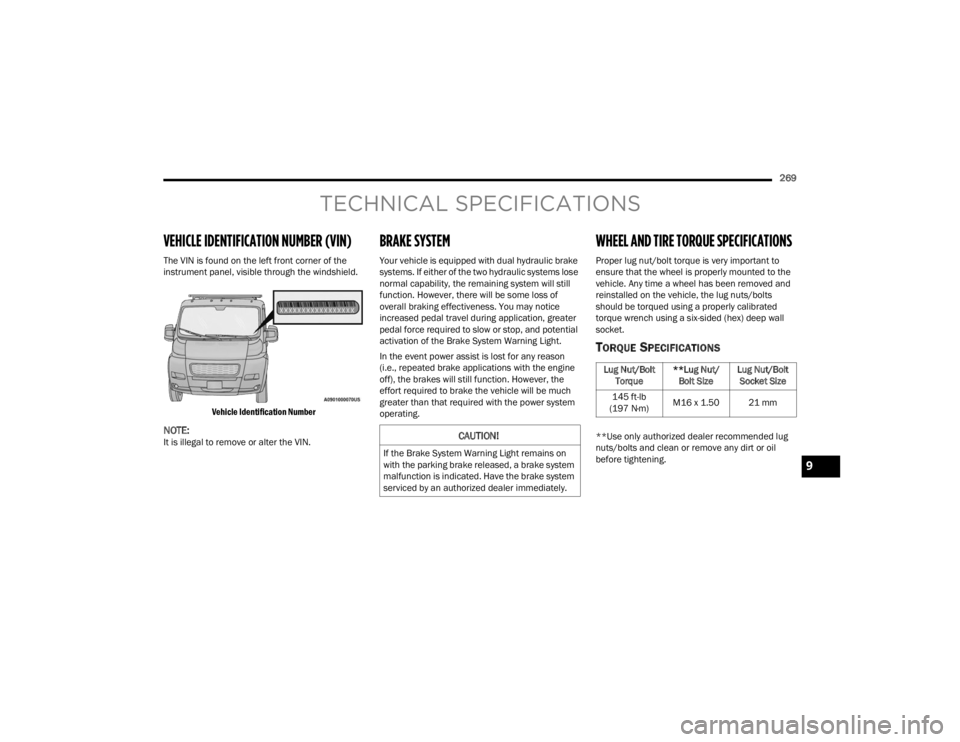

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is found on the left front corner of the

instrument panel, visible through the windshield.

Vehicle Identification Number

NOTE:It is illegal to remove or alter the VIN.

BRAKE SYSTEM

Your vehicle is equipped with dual hydraulic brake

systems. If either of the two hydraulic systems lose

normal capability, the remaining system will still

function. However, there will be some loss of

overall braking effectiveness. You may notice

increased pedal travel during application, greater

pedal force required to slow or stop, and potential

activation of the Brake System Warning Light.

In the event power assist is lost for any reason

(i.e., repeated brake applications with the engine

off), the brakes will still function. However, the

effort required to brake the vehicle will be much

greater than that required with the power system

operating.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to the

vehicle. Any time a wheel has been removed and

reinstalled on the vehicle, the lug nuts/bolts

should be torqued using a properly calibrated

torque wrench using a six-sided (hex) deep wall

socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug

nuts/bolts and clean or remove any dirt or oil

before tightening.CAUTION!

If the Brake System Warning Light remains on

with the parking brake released, a brake system

malfunction is indicated. Have the brake system

serviced by an authorized dealer immediately.

Lug Nut/Bolt Torque **Lug Nut/

Bolt Size Lug Nut/Bolt

Socket Size

145 ft-lb

(197 N·m) M16 x 1.50 21 mm

9

23_VF_OM_EN_USC_t.book Page 269

Page 286 of 296

284 Brake/Transmission Interlock

......................... 81Bulb Replacement......................................... 244Bulbs, Light.......................................... 191, 244

C

Camera, Rear...................................... 119, 120Capacities, Fluid............................................ 273Caps, Filler Fuel........................................................... 122Oil (Engine)................................................ 225Radiator (Coolant Pressure)...................... 234Car Washes................................................... 266Carbon Monoxide Warning............................ 192Cargo Area Cover............................................. 51Cargo Compartment........................................ 51Cargo Light...................................................... 36Cellular Phone............................................... 151Certification Label......................................... 123Change Engine Oil — If Equipped

S

.............. 57Change Oil Indicator........................................ 57Changing A Flat Tire....................................... 196Chart, Tire Sizing............................................ 250Check Engine Light (Malfunction

Indicator Light)................................................ 74Checking Your Vehicle For Safety.................. 189Checks, Safety............................................... 189Child Restraint............................................... 185

Child RestraintsBooster Seats........................................... 187Child Seat Installation.............................. 189Infant And Child Restraints....................... 186Older Children And Child Restraints......... 187Clean Air Gasoline......................................... 271CleaningWheels..................................................... 262Climate Control................................................ 40Manual........................................................ 40Rear............................................................. 43Cold Weather Operation.................................. 76Compact Spare Tire...................................... 260Contract, Service.......................................... 277Cooling Pressure Cap (Radiator Cap)............ 234Cooling System............................................. 233Adding Coolant (Antifreeze)...................... 233Coolant Level................................... 233, 234Cooling Capacity....................................... 273Disposal Of Used Coolant......................... 234Drain, Flush, And Refill............................. 233Inspection................................................. 234Points To Remember................................ 234Pressure Cap............................................ 234Radiator Cap............................................ 234Selection Of Coolant (Antifreeze)..... 233, 273Corrosion Protection..................................... 265Cruise Control (Speed Control)................. 87, 88

Cruise Light......................................................72Customer Assistance.................................... 275Customer Programmable Features............... 134Cybersecurity................................................ 133

D

Dealer Service............................................... 227Defroster, Windshield................................... 190Diagnostic System, Onboard............................74Dimmer Control Switch....................................37Dimmer SwitchHeadlight.....................................................34DipsticksAutomatic Transmission........................... 236Oil (Engine)............................................... 226Disable Vehicle Towing................................. 219DisposalAntifreeze (Engine Coolant)...................... 234Door Ajar..........................................................66Door Ajar Light.................................................66Door Locks.......................................................21Automatic....................................................23Doors...............................................................21Driver’s Seat Back Tilt......................................23DrivingThrough Flowing, Rising, Or Shallow Standing Water

.................................................... 131Drowsy Driver Detection................................ 157

23_VF_OM_EN_USC_t.book Page 284