wheel bolts Ram ProMaster City 2018 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: ProMaster City, Model: Ram ProMaster City 2018Pages: 180, PDF Size: 7.52 MB

Page 62 of 180

NOTE:

• Air bag covers may not be obvious in theinterior trim, but they will open during air

bag deployment.

• After any collision, the vehicle should be taken to an authorized dealer immediately.

Enhanced Accident Response System

In the event of an impact, if the communica-

tion network remains intact, and the power

remains intact, depending on the nature of

the event, the ORC will determine whether to

have the Enhanced Accident Response Sys-

tem perform the following functions:

• Cut off fuel to the engine.

• Flash hazard lights as long as the batteryhas power or until the hazard light button is

pressed. The hazard lights can be deacti-

vated by pressing the hazard light button.

• Turn on the interior lights, which remain on as long as the battery has power or for

15 minutes from the intervention of the

Enhanced Accident Response System.

• Unlock the power door locks.

Enhanced Accident Response System Reset

Procedure

In order to reset the Enhanced Accident Re-

sponse System functions after an event, the

ignition switch must be changed from igni-

tion START or ON/RUN to ignition OFF. Care-

fully check the vehicle for fuel leaks in the

engine compartment and on the ground near

the engine compartment and fuel tank before

resetting the system and starting the engine.

Maintaining Your Air Bag System

WARNING!

• Modifications to any part of the air bag system could cause it to fail when you

need it. You could be injured if the air

bag system is not there to protect you.

Do not modify the components or wiring,

including adding any kind of badges or

stickers to the steering wheel hub trim

cover or the upper right side of the

instrument panel. Do not modify the

front bumper, vehicle body structure, or

add aftermarket side steps or running

boards.

WARNING!

• It is dangerous to try to repair any part ofthe air bag system yourself. Be sure to

tell anyone who works on your vehicle

that it has an air bag system.

• Do not attempt to modify any part of your

air bag system. The air bag may inflate

accidentally or may not function prop-

erly if modifications are made. Take your

vehicle to an authorized dealer for any

air bag system service. If your seat, in-

cluding your trim cover and cushion,

needs to be serviced in any way (includ-

ing removal or loosening/tightening of

seat attachment bolts), take the vehicle

to your authorized dealer. Only manufac-

turer approved seat accessories may be

used. If it is necessary to modify the air

bag system for persons with disabilities,

contact your authorized dealer.

SAFETY

60

Page 80 of 180

Periodic Safety Checks You

Should Make Outside The Vehicle

Tires

Examine tires for excessive tread wear and

uneven wear patterns. Check for stones,

nails, glass, or other objects lodged in the

tread or sidewall. Inspect the tread for cuts

and cracks. Inspect sidewalls for cuts,

cracks, and bulges. Check the wheel bolts for

tightness. Check the tires (including spare)

for proper cold inflation pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam

indicator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and lock-

ing.

Fluid Leaks

Check area under the vehicle after overnight

parking for fuel, coolant, oil, or other fluid

leaks. Also, if gasoline fumes are detected or

if fuel, or brake fluid leaks are suspected. The

cause should be located and corrected imme-

diately.

SAFETY

78

Page 98 of 180

WARNING!

• If working on or near a roadway, beextremely careful of motor traffic.

• To assure that spare tires, flat or in-

flated, are securely stowed, spares must

be stowed with the valve stem facing the

ground.

• The stowed spare tire should always be

checked for security by pushing on it

with your hand , at the location under

the rear bumper, behind the vehicle. The

spare tire should not move when fully

secured by the winch under the vehicle.

CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those indi-

cated in the Jacking Instructions for this

vehicle.

1. Loosen (but do not remove) the wheel lug bolts with the wrench handle by turning

them to the left one turn while the wheel

is still on the ground. 2. There are two jack engagement locations

on each side of the vehicle body.

NOTE:

Place the jack underneath the jack engage-

ment location that is closest to the flat tire.

WARNING!

Being under a jacked-up vehicle is danger-

ous. The vehicle could slip off the jack and

fall on you. You could be crushed. Never

get any part of your body under a vehicle

that is on a jack. If you need to get under a

raised vehicle, take it to a service center

where it can be raised on a lift.

CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those indi-

cated in the Jacking Instructions for this

vehicle.

Jack Warning Label

IN CASE OF EMERGENCY

96

Page 99 of 180

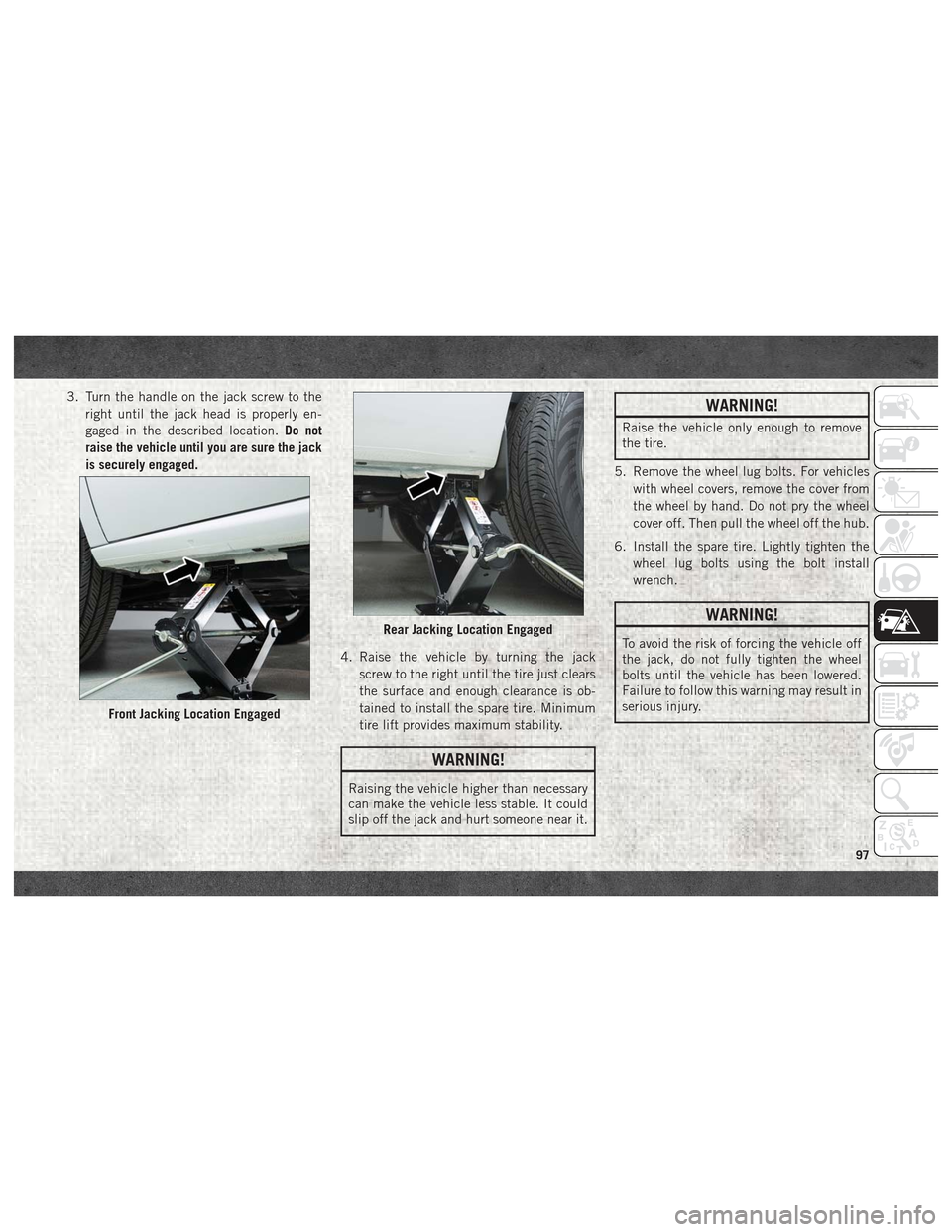

3. Turn the handle on the jack screw to theright until the jack head is properly en-

gaged in the described location. Do not

raise the vehicle until you are sure the jack

is securely engaged.

4. Raise the vehicle by turning the jackscrew to the right until the tire just clears

the surface and enough clearance is ob-

tained to install the spare tire. Minimum

tire lift provides maximum stability.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

WARNING!

Raise the vehicle only enough to remove

the tire.

5. Remove the wheel lug bolts. For vehicles with wheel covers, remove the cover from

the wheel by hand. Do not pry the wheel

cover off. Then pull the wheel off the hub.

6. Install the spare tire. Lightly tighten the wheel lug bolts using the bolt install

wrench.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not fully tighten the wheel

bolts until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

Front Jacking Location Engaged

Rear Jacking Location Engaged

97

Page 100 of 180

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.

7. Lower the vehicle by turning the jack screw to the left. 8. Refer to “Torque Specifications” in

“Technical Specifications” for proper

wheel lug bolt torque.

9. Lower the jack to its fully-closed position.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

10. Stow the cable and wheel spacer before driving the vehicle. Refer to “Vehicles

With Alloy Wheels” in this section for

instructions on stowing alloy wheels.

11. Stow the jack and tools under the driv- er’s seat.

12. Check the spare tire pressure as soon as possible. Correct the tire pressure, as

required.

13. When you place the spare tire back on the winch or if you carry the tire in need

of repair on the winch, always check that

the tire is properly secured under the vehicle by pushing on the stowed tire

under the rear bumper at the back of the

vehicle. If the tire has motion when

pushed, use the tools to retighten the

winch until a loud click is heard.

Vehicles With Alloy Wheels

For stowing a damaged tire on vehicles with

alloy wheels, remove the adapter bracket and

bolts from the storage bag in the glove com-

partment and follow the steps below:

1. Take the adapter and fit the plastic spacer

between the spring and the flange of the

bracket (The adapter bracket is sold sepa-

rately through the dealer).

2. The plastic fin must be directed down- wards and perfectly coincide with the

flange cut part; fit the bracket in the

adapter, fold the bracket up and secure it

to the adapter with the fastening knob.

3. Position the tire vertically and lay the mounted adapter on the inner part of the

rim, using the supplied bolts fasten the

wheel to the adapter using the bolt install

wrench.

4. Tighten the bolts with the wrench handle.

Mounting Spare Tire

IN CASE OF EMERGENCY

98

Page 101 of 180

5. Rotate the winch mechanism clockwiseuntil the wheel is properly stowed under

the vehicle and until the wench makes

three audible noises.

6. Reach underneath and shake tire by hand to confirm that it is secure. The tire should

not move. If the tire is still loose and/or

three audible noises are not heard, place

and secure damaged wheel into the ve-

hicle and seek dealer assistance for the

winch mechanism.

This is for temporary use only.

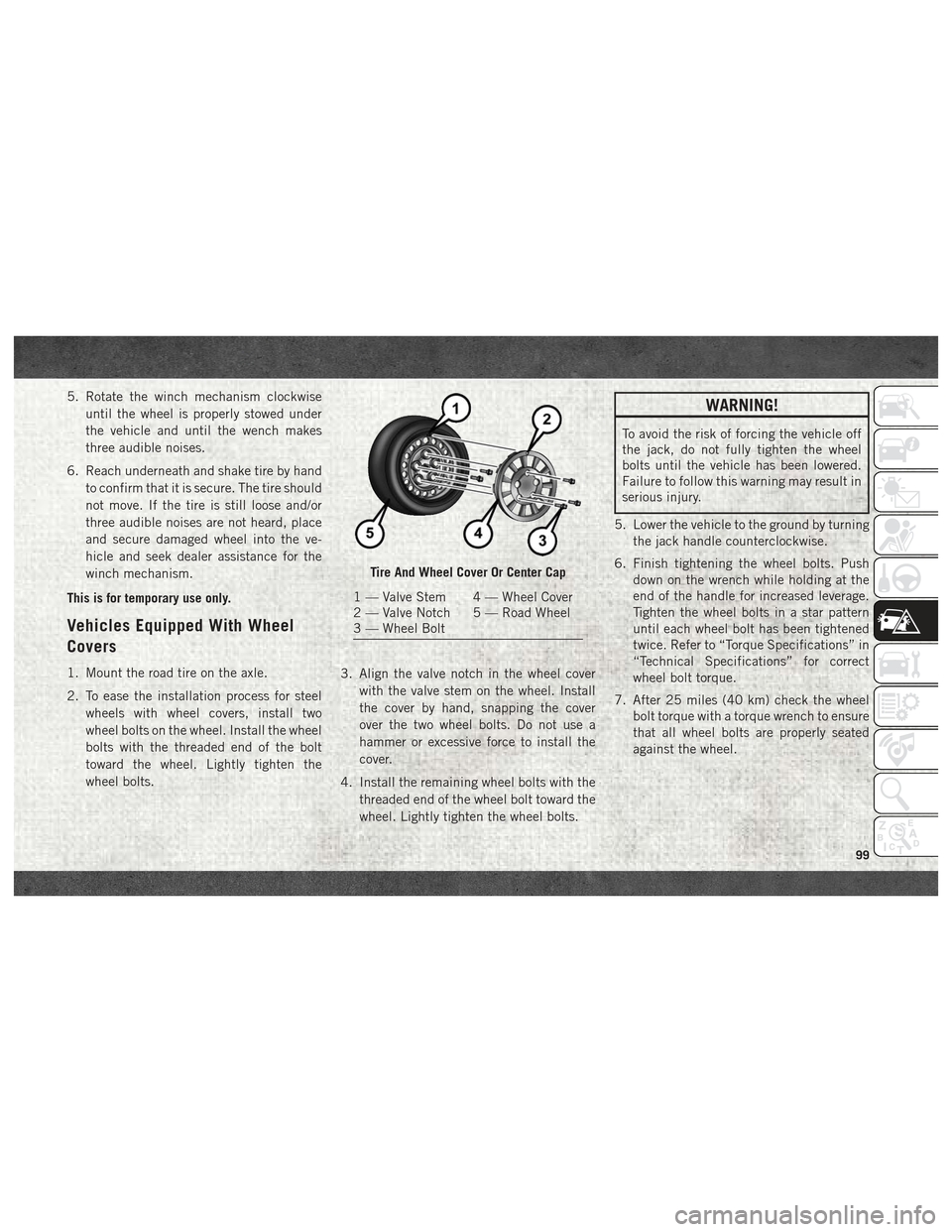

Vehicles Equipped With Wheel

Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two

wheel bolts on the wheel. Install the wheel

bolts with the threaded end of the bolt

toward the wheel. Lightly tighten the

wheel bolts. 3. Align the valve notch in the wheel cover

with the valve stem on the wheel. Install

the cover by hand, snapping the cover

over the two wheel bolts. Do not use a

hammer or excessive force to install the

cover.

4. Install the remaining wheel bolts with the threaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not fully tighten the wheel

bolts until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

6. Finish tightening the wheel bolts. Push down on the wrench while holding at the

end of the handle for increased leverage.

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. Refer to “Torque Specifications” in

“Technical Specifications” for correct

wheel bolt torque.

7. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to ensure

that all wheel bolts are properly seated

against the wheel.

Tire And Wheel Cover Or Center Cap

1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Road Wheel

3 — Wheel Bolt

99

Page 138 of 180

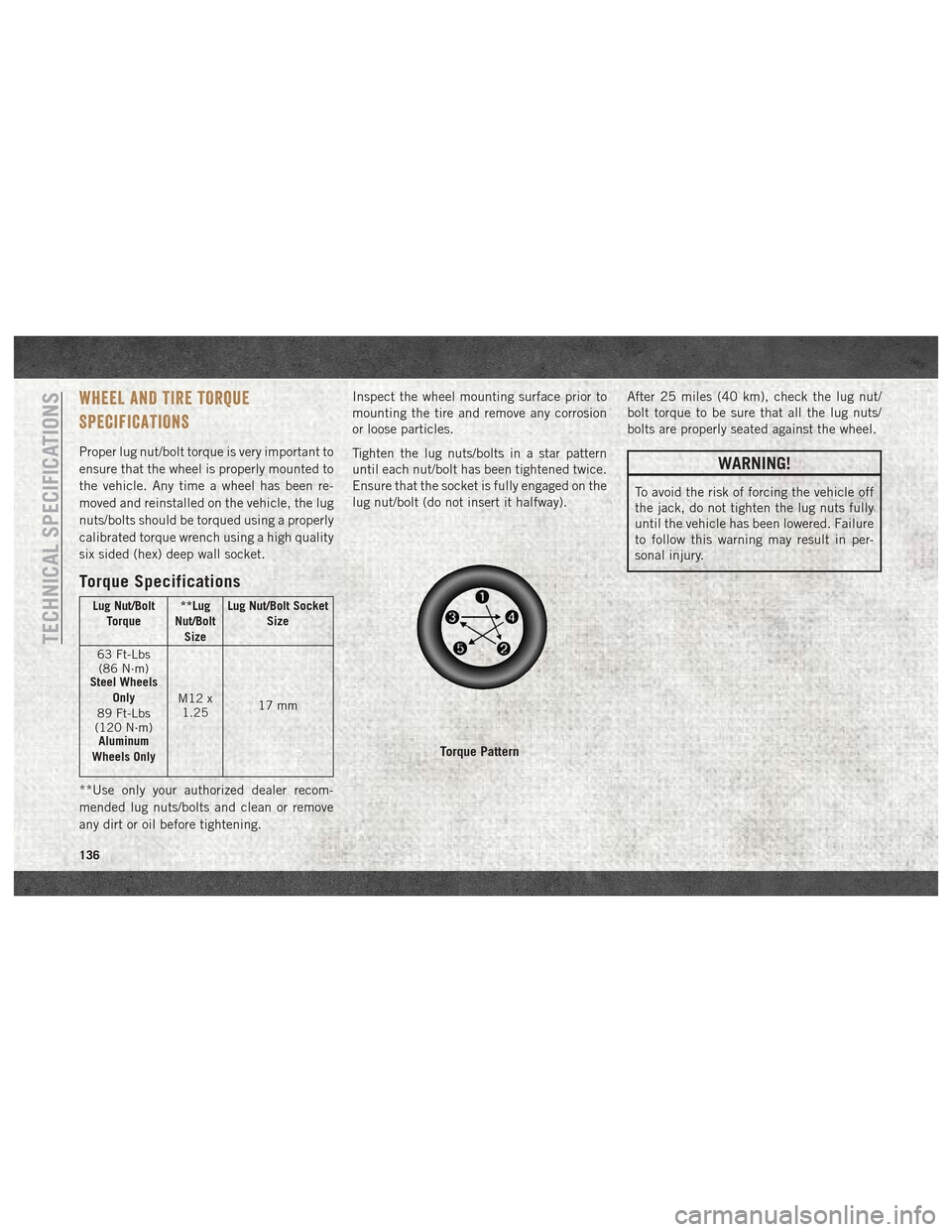

WHEEL AND TIRE TORQUE

SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been re-

moved and reinstalled on the vehicle, the lug

nuts/bolts should be torqued using a properly

calibrated torque wrench using a high quality

six sided (hex) deep wall socket.

Torque Specifications

Lug Nut/BoltTorque **Lug

Nut/Bolt Size Lug Nut/Bolt Socket

Size

63 Ft-Lbs (86 N·m)

Steel Wheels

Only

89 Ft-Lbs

(120 N·m) Aluminum

Wheels Only M12 x

1.25 17 mm

**Use only your authorized dealer recom-

mended lug nuts/bolts and clean or remove

any dirt or oil before tightening. Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion

or loose particles.

Tighten the lug nuts/bolts in a star pattern

until each nut/bolt has been tightened twice.

Ensure that the socket is fully engaged on the

lug nut/bolt (do not insert it halfway).

After 25 miles (40 km), check the lug nut/

bolt torque to be sure that all the lug nuts/

bolts are properly seated against the wheel.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the lug nuts fully

until the vehicle has been lowered. Failure

to follow this warning may result in per-

sonal injury.

Torque Pattern

TECHNICAL SPECIFICATIONS

136