check engine RAM PROMASTER CITY 2022 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2022, Model line: PROMASTER CITY, Model: RAM PROMASTER CITY 2022Pages: 260, PDF Size: 8.45 MB

Page 182 of 260

180IN CASE OF EMERGENCY

Insert the power plug into the vehicle power outlet

socket. Start the vehicle engine. Push the Tire Service Kit power button on. The

electric compressor will be turned on, sealant and

air will inflate the tire.

Minimum 26 psi (1.8 bar) of pressure should be

reached within 20 minutes. If the pressure has not

been reached, turn off and remove the Tire Service

Kit, drive the vehicle 30 feet (10 meters) back and

forth, to better distribute the sealant inside the

tire.

Attach the clear flexible filling tube of the

compressor directly to the tire valve and repeat the

inflation process.

When the correct pressure has been reached,

start driving the vehicle to uniformly distribute the

sealant inside the tire. After 10 minutes, stop and

check the tire pressure. If the pressure is below

19 psi (1.3 bar), do not drive the vehicle, as the

tire is too damaged, contact the nearest

authorized dealer.

If the pressure is at 19 psi (1.3 bar) or above

repeat the inflation process to reach the correct

tire pressure and continue driving.

Peel off the warning label from the bottle and place

it on the dashboard as a reminder to the driver that

a tire has been treated with Tire Service Kit.

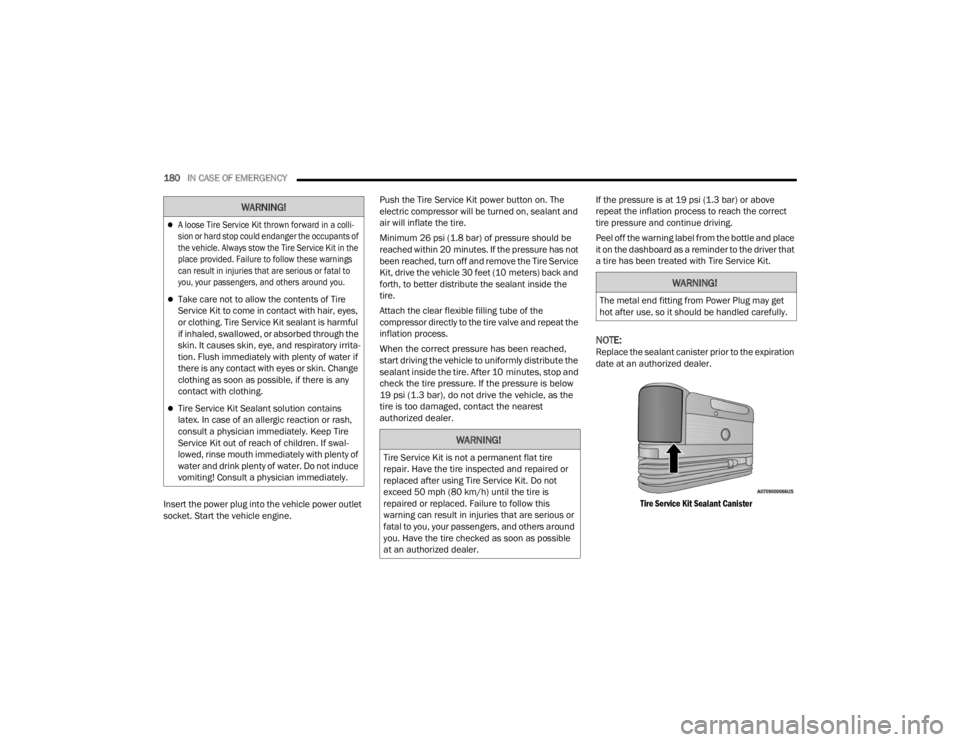

NOTE:Replace the sealant canister prior to the expiration

date at an authorized dealer.

Tire Service Kit Sealant Canister

A loose Tire Service Kit thrown forward in a colli -

sion or hard stop could endanger the occupants of

the vehicle. Always stow the Tire Service Kit in the

place provided. Failure to follow these warnings

can result in injuries that are serious or fatal to

you, your passengers, and others around you.

Take care not to allow the contents of Tire

Service Kit to come in contact with hair, eyes,

or clothing. Tire Service Kit sealant is harmful

if inhaled, swallowed, or absorbed through the

skin. It causes skin, eye, and respiratory irrita -

tion. Flush immediately with plenty of water if

there is any contact with eyes or skin. Change

clothing as soon as possible, if there is any

contact with clothing.

Tire Service Kit Sealant solution contains

latex. In case of an allergic reaction or rash,

consult a physician immediately. Keep Tire

Service Kit out of reach of children. If swal -

lowed, rinse mouth immediately with plenty of

water and drink plenty of water. Do not induce

vomiting! Consult a physician immediately.

WARNING!

WARNING!

Tire Service Kit is not a permanent flat tire

repair. Have the tire inspected and repaired or

replaced after using Tire Service Kit. Do not

exceed 50 mph (80 km/h) until the tire is

repaired or replaced. Failure to follow this

warning can result in injuries that are serious or

fatal to you, your passengers, and others around

you. Have the tire checked as soon as possible

at an authorized dealer.

WARNING!

The metal end fitting from Power Plug may get

hot after use, so it should be handled carefully.

22_VM_OM_EN_USC_t.book Page 180

Page 191 of 260

189

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indicator

system will remind you that it is time to take your

vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent short-trips,

trailer tow, extended engine idle time, extremely

hot or cold ambient temperatures will influence

when the “Oil Change Required” message is

displayed. Have your vehicle serviced as soon as

possible, within the next 500 miles (805 km).An authorized dealer will reset the oil change

indicator message after completing the scheduled

oil change. If a scheduled oil change is performed

by someone other than an authorized dealer, to

reset the message Ú

page 41.

NOTE:Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km), 350

hours of engine run time or 12 months, whichever

comes first. The 350 hours of engine run or idle

time is generally only a concern for fleet

customers. Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual wear

or damage. Rotate tires at the first sign of irreg

-

ular wear, even if it occurs before the oil indi -

cator system turns on.

Check the fluid levels of the coolant reservoir

and brake master cylinder, fill as needed.

Check function of all interior and exterior lights.

8

22_VM_OM_EN_USC_t.book Page 189

Page 196 of 260

194SERVICING AND MAINTENANCE

(Continued)

CHECKING OIL LEVEL

To ensure proper engine lubrication, the engine oil

must be maintained at the correct level. Check the

oil level at regular intervals, such as every fuel

stop. The best time to check the engine oil level is

about five minutes after a fully warmed up engine

is shut off.

Checking the oil while the vehicle is on level ground

will improve the accuracy of the oil level readings.

There are four possible dipstick types:

Crosshatched zone.

Crosshatched zone marked SAFE.

Crosshatched zone marked with MIN at the low

end of the range and MAX at the high end of the

range.

Crosshatched zone marked with dimples at the

MIN and the MAX ends of the range.

NOTE:Always maintain the oil level within the crosshatch

markings on the dipstick.

Adding 1 quart (1 liter) of oil when the reading is at

the low end of the dipstick range will raise the oil

level to the high end of the range marking.

ADDING WASHER FLUID

The windshield and rear window washers share the

same fluid reservoir. The fluid reservoir is located

in the front of the engine compartment. Be sure to

check the fluid level in the reservoir at regular

intervals. Fill the reservoir with windshield washer

solvent (not radiator antifreeze) and operate the

system for a few seconds to flush out the residual

water.

When refilling the washer fluid reservoir, take

some washer fluid and apply it to a cloth or towel

and wipe clean the wiper blades, this will help

blade performance.

To prevent freeze-up of your windshield washer

system in cold weather, select a solution or mixture

that meets or exceeds the temperature range of

your climate. This rating information can be found

on most washer fluid containers.MAINTENANCE-FREE BATTERY

Your vehicle is equipped with a maintenance-free

battery. You will never have to add water, and

periodic maintenance is not required.

CAUTION!

Overfilling or underfilling the crankcase will

cause aeration or loss of oil pressure. This could

damage your engine.

WARNING!

Commercially available windshield washer

solvents are flammable. They could ignite and

burn you. Care must be exercised when filling or

working around the washer solution.

WARNING!

Battery fluid is a corrosive acid solution and

can burn or even blind you. Do not allow

battery fluid to contact your eyes, skin, or

clothing. Do not lean over a battery when

attaching clamps. If acid splashes in eyes or

on skin, flush the area immediately with large

amounts of water Úpage 181.

Battery gas is flammable and explosive. Keep

flame or sparks away from the battery. Do not

use a booster battery or any other booster

source with an output greater than 12 Volts.

Do not allow cable clamps to touch each

other.

22_VM_OM_EN_USC_t.book Page 194

Page 198 of 260

196SERVICING AND MAINTENANCE

Synthetic Engine Oils

Your engine was designed for synthetic engine oils,

only use synthetic API approved engine oils.

Synthetic engine oils which do not have both the

engine oil certification mark and the correct SAE

viscosity grade number should not be used.

Materials Added To Engine Oil

The manufacturer strongly recommends against

the addition of any additives (other than leak

detection dyes) to the engine oil. Engine oil is an

engineered product and its performance may be

impaired by supplemental additives.

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used engine

oil and oil filters from your vehicle. Used oil and oil

filters, indiscriminately discarded, can present a

problem to the environment. Contact an

authorized dealer, service station or governmental

agency for advice on how and where used oil and

oil filters can be safely discarded in your area.

ENGINE OIL FILTER

The engine oil filter should be replaced with a new

filter at every engine oil change.

Engine Oil Filter Selection

A full-flow type disposable oil filter should be used

for replacement. The quality of replacement filters

varies considerably. Only high quality Mopar®

certified filters should be used.

ENGINE AIR CLEANER FILTER

For the proper maintenance intervals Úpage 190.

NOTE:Be sure to follow the Severe Duty Conditions main -

tenance interval if applicable Ú page 189.Engine Air Cleaner Filter Selection

The quality of replacement filters varies

considerably. Only high quality Mopar® certified

filters should be used.

AIR CONDITIONER MAINTENANCE

For best possible performance, your air conditioner

should be checked and serviced by an authorized

dealer at the start of each warm season. This

service should include cleaning of the condenser

fins and a performance test. Drive belt tension

should also be checked at this time.

CAUTION!

Do not use chemical flushes in your engine oil as

the chemicals can damage your engine. Such

damage is not covered by the New Vehicle

Limited Warranty.

WARNING!

The air induction system (air cleaner, hoses,

etc.) can provide a measure of protection in the

case of engine backfire. Do not remove the air

induction system (air cleaner, hoses, etc.) unless

such removal is necessary for repair or

maintenance. Make sure that no one is near the

engine compartment before starting the vehicle

with the air induction system (air cleaner, hoses,

etc.) removed. Failure to do so can result in

serious personal injury.

WARNING!

Use only refrigerants and compressor lubri

-

cants approved by FCA for your air condi -

tioning system. Some unapproved refrigerants

are flammable and can explode, injuring you.

Other unapproved refrigerants or lubricants

can cause the system to fail, requiring costly

repairs. Refer to Warranty Information Book,

for further warranty information.

The air conditioning system contains refrig -

erant under high pressure. To avoid risk of

personal injury or damage to the system,

adding refrigerant or any repair requiring lines

to be disconnected should be done by an

experienced technician.

22_VM_OM_EN_USC_t.book Page 196

Page 201 of 260

SERVICING AND MAINTENANCE199

NOTE:Intentional tampering with emissions control

systems can result in civil penalties being

assessed against you.

In unusual situations involving grossly

malfunctioning engine operation, a scorching odor

may suggest severe and abnormal catalyst

overheating. If this occurs, stop the vehicle, turn off

the engine and allow it to cool. Service, including a

tune-up to manufacturer's specifications, should

be obtained immediately.

To minimize the possibility of catalytic converter

damage:

Do not interrupt the ignition when the transmis -

sion is in gear and the vehicle is in motion.

Do not try to start the vehicle by pushing or

towing the vehicle.

Do not idle the engine with any ignition compo -

nents disconnected or removed, such as when

diagnostic testing, or for prolonged periods

during very rough idle or malfunctioning oper -

ating conditions.

COOLING SYSTEM Engine Coolant Checks

Check the engine coolant (antifreeze) protection

every 12 months (before the onset of freezing

weather, where applicable). If the engine coolant is

dirty, the system should be drained, flushed, and

refilled with fresh Organic Additive Technology

(OAT) coolant (conforming to MS.90032) by an

authorized dealer. Check the front of the A/C

condenser for any accumulation of bugs, leaves,

etc. If dirty, clean by gently spraying water from a

garden hose vertically down the face of the

condenser.

Check the engine cooling system hoses for brittle

rubber, cracking, tears, cuts, and tightness of the

connection at the coolant recovery bottle and

radiator. Inspect the entire system for leaks. DO

NOT REMOVE THE COOLANT PRESSURE CAP

WHEN THE COOLING SYSTEM IS HOT.WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from your

radiator. If you see or hear steam coming from

under the hood, do not open the hood until the

radiator has had time to cool. Never open a

cooling system pressure cap when the radi -

ator or coolant bottle is hot.

Keep hands, tools, clothing, and jewelry away

from the radiator cooling fan when the hood is

raised. The fan starts automatically and may

start at any time, whether the engine is

running or not.

When working near the radiator cooling fan,

disconnect the fan motor lead or turn the igni -

tion to the OFF position. The fan is tempera -

ture controlled and can start at any time the

ignition is in the ON position.

8

22_VM_OM_EN_USC_t.book Page 199

Page 203 of 260

SERVICING AND MAINTENANCE201

Some vehicles require special tools to add

coolant properly. Failure to fill these systems

properly could lead to severe internal engine

damage. If any coolant is needed to be added to

the system, please contact a local authorized

dealer.

Mixing engine coolant types is not recom -

mended and can result in cooling system

damage. If HOAT and OAT coolant are mixed in

an emergency, have an authorized dealer drain,

flush, and refill with OAT coolant (conforming to

MS.90032) as soon as possible.

Cooling System Pressure Cap

The cap must be fully tightened to prevent loss of

engine coolant, and to ensure that engine coolant

will return to the radiator from the coolant recovery

tank.

The cap should be inspected and cleaned if there

is any accumulation of foreign material on the

sealing surfaces.

The image on the coolant system

pressure cap is a reminder that the

radiator contains hot engine coolant

under pressure.Disposal Of Used Coolant

Used ethylene glycol-based coolant is a regulated

substance requiring proper disposal. Check with

your local authorities to determine the disposal

rules for your community. To prevent ingestion, do

not store ethylene glycol-based coolant in open

containers or allow it to remain in puddles on the

ground, clean up immediately. If ingested, seek

emergency assistance immediately.

Coolant Level

The coolant expansion bottle provides a quick

visual method for determining that the coolant

level is adequate. With the engine OFF and cold,

the level of the engine coolant in the bottle should

be between the “MIN” and “MAX” marks.

The radiator normally remains completely full, so

there is no need to remove the radiator/coolant

pressure cap unless checking for engine coolant

freeze point or replacing coolant. Advise an

authorized dealer of this. As long as the engine

operating temperature is satisfactory, the coolant

only needs to be checked once a month.

When additional engine coolant is needed to

maintain the proper level, only OAT coolant that

meets the requirements of the manufacturer

Material Standard MS.90032 should be added to

the coolant bottle. Do not overfill.WARNING!

Do not open a hot engine cooling system.

Never add engine coolant (antifreeze) when

the engine is overheated. Do not loosen or

remove the cap to cool an overheated engine.

Heat causes pressure to build up in the

cooling system. To prevent scalding or injury,

do not remove the pressure cap while the

system is hot or under pressure.

Do not use a pressure cap other than the one

specified for your vehicle. Personal injury or

engine damage may result.

8

22_VM_OM_EN_USC_t.book Page 201

Page 204 of 260

202SERVICING AND MAINTENANCE

(Continued)

Cooling System Notes

NOTE:When the vehicle is stopped after a few miles/kilo-

meters of operation, you may observe vapor

coming from the front of the engine compartment.

This is normally a result of moisture from rain,

snow, or high humidity accumulating on the

radiator and being vaporized when the thermostat

opens, allowing hot engine coolant to enter the

radiator.

If an examination of your engine compartment

shows no evidence of radiator or hose leaks, the

vehicle may be safely driven. The vapor will soon

dissipate.

Do not overfill the coolant expansion bottle.

Check the coolant freeze point in the radiator

and in the coolant expansion bottle. If engine

coolant needs to be added, the contents of the

coolant expansion bottle must also be protected

against freezing.

If frequent engine coolant additions are

required, the cooling system should be pressure

tested for leaks.

Maintain engine coolant concentration at a

minimum of 50% OAT coolant (conforming to

MS.90032) and distilled water for proper corro -

sion protection of your engine which contains

aluminum components.

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning, keep

the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever neces -

sary, install ONLY the correct type thermostat.

Other designs may result in unsatisfactory

engine cooling performance, poor gas mileage,

and increased emissions.

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically. For the proper maintenance intervals

Ú page 190.

Brake Master Cylinder

The fluid in the master cylinder should be checked

when performing under hood services or

immediately if the Brake Warning Light is

illuminated.

Be sure to clean the top of the master cylinder area

before removing the cap. If necessary, add fluid to

bring the fluid level up to the requirements

described on the brake fluid reservoir. With disc

brakes, fluid level can be expected to fall as the

brake pads wear. Brake fluid level should be

checked when pads are replaced. However, low

fluid level may be caused by a leak and a checkup

may be needed. Use only the manufacturer

recommended brake fluid Ú page 241.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting

or riding on the brake pedal can result in

abnormally high brake temperatures, excessive

lining wear, and possible brake damage. You

would not have your full braking capacity in an

emergency.

WARNING!

Use only the manufacturer recommended

brake fluid Úpage 241. Using the wrong type

of brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

22_VM_OM_EN_USC_t.book Page 202

Page 209 of 260

SERVICING AND MAINTENANCE207

FUSES

General Information

The fuses protect electrical systems against

excessive current.

When a device does not work, you must check the

fuse element inside the blade fuse for a break/melt.

Also, please be aware that using power outlets for

extended periods of time with the engine off may

result in vehicle battery discharge.

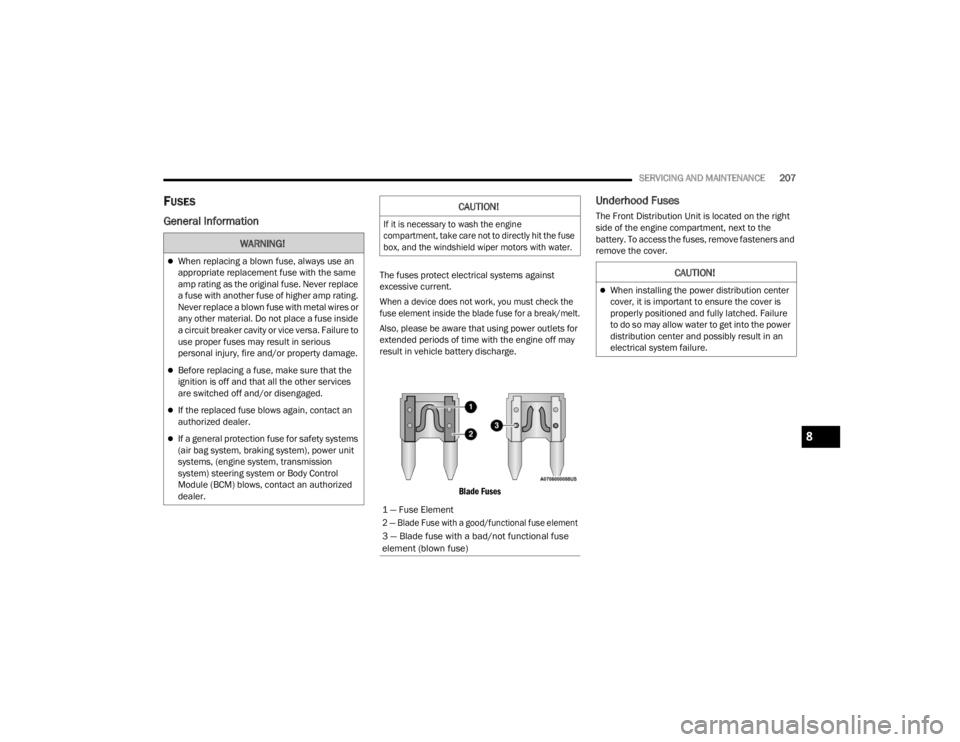

Blade Fuses

Underhood Fuses

The Front Distribution Unit is located on the right

side of the engine compartment, next to the

battery. To access the fuses, remove fasteners and

remove the cover.

WARNING!

When replacing a blown fuse, always use an

appropriate replacement fuse with the same

amp rating as the original fuse. Never replace

a fuse with another fuse of higher amp rating.

Never replace a blown fuse with metal wires or

any other material. Do not place a fuse inside

a circuit breaker cavity or vice versa. Failure to

use proper fuses may result in serious

personal injury, fire and/or property damage.

Before replacing a fuse, make sure that the

ignition is off and that all the other services

are switched off and/or disengaged.

If the replaced fuse blows again, contact an

authorized dealer.

If a general protection fuse for safety systems

(air bag system, braking system), power unit

systems, (engine system, transmission

system) steering system or Body Control

Module (BCM) blows, contact an authorized

dealer.

CAUTION!

If it is necessary to wash the engine

compartment, take care not to directly hit the fuse

box, and the windshield wiper motors with water.

1 — Fuse Element

2 — Blade Fuse with a good/functional fuse element

3 — Blade fuse with a bad/not functional fuse

element (blown fuse)

CAUTION!

When installing the power distribution center

cover, it is important to ensure the cover is

properly positioned and fully latched. Failure

to do so may allow water to get into the power

distribution center and possibly result in an

electrical system failure.

8

22_VM_OM_EN_USC_t.book Page 207

Page 239 of 260

TECHNICAL SPECIFICATIONS237

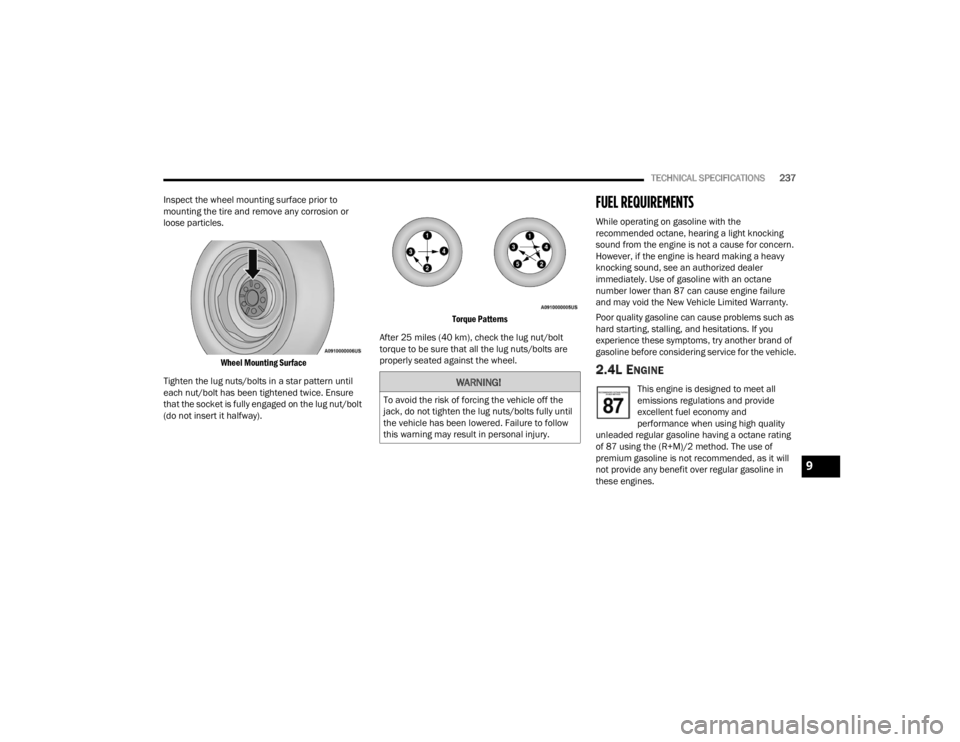

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

Wheel Mounting Surface

Tighten the lug nuts/bolts in a star pattern until

each nut/bolt has been tightened twice. Ensure

that the socket is fully engaged on the lug nut/bolt

(do not insert it halfway).

Torque Patterns

After 25 miles (40 km), check the lug nut/bolt

torque to be sure that all the lug nuts/bolts are

properly seated against the wheel.

FUEL REQUIREMENTS

While operating on gasoline with the

recommended octane, hearing a light knocking

sound from the engine is not a cause for concern.

However, if the engine is heard making a heavy

knocking sound, see an authorized dealer

immediately. Use of gasoline with an octane

number lower than 87 can cause engine failure

and may void the New Vehicle Limited Warranty.

Poor quality gasoline can cause problems such as

hard starting, stalling, and hesitations. If you

experience these symptoms, try another brand of

gasoline before considering service for the vehicle.

2.4L ENGINE

This engine is designed to meet all

emissions regulations and provide

excellent fuel economy and

performance when using high quality

unleaded regular gasoline having a octane rating

of 87 using the (R+M)/2 method. The use of

premium gasoline is not recommended, as it will

not provide any benefit over regular gasoline in

these engines.WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the lug nuts/bolts fully until

the vehicle has been lowered. Failure to follow

this warning may result in personal injury.

9

22_VM_OM_EN_USC_t.book Page 237

Page 248 of 260

246

INDEX

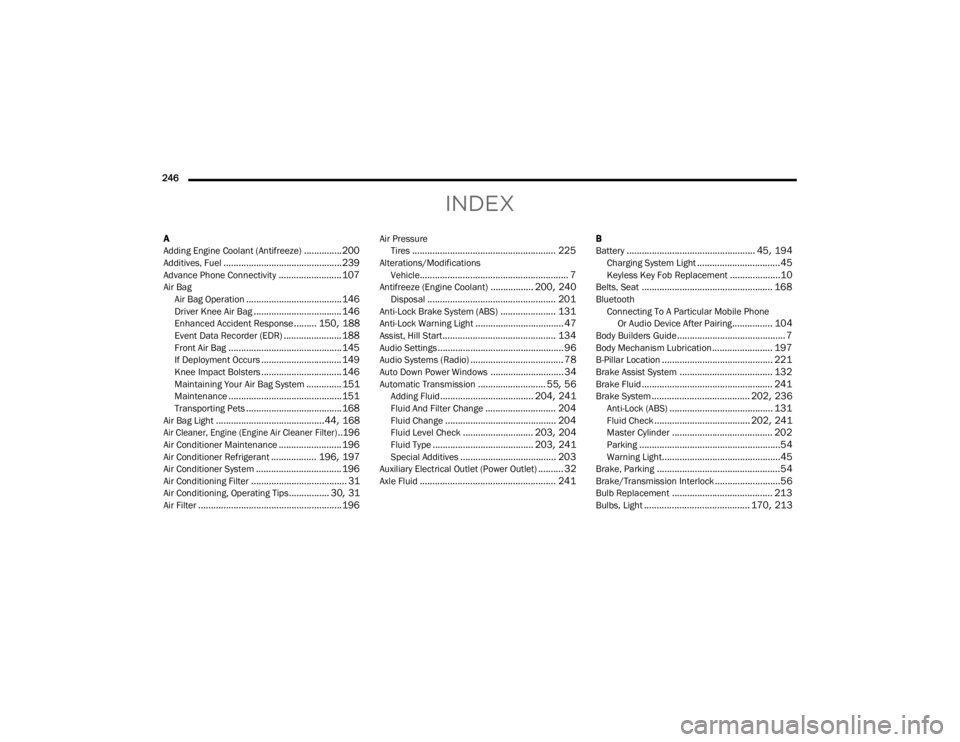

A

Adding Engine Coolant (Antifreeze)............... 200Additives, Fuel............................................... 239Advance Phone Connectivity......................... 107Air BagAir Bag Operation...................................... 146Driver Knee Air Bag................................... 146Enhanced Accident Response......... 150, 188Event Data Recorder (EDR)....................... 188Front Air Bag............................................. 145If Deployment Occurs................................ 149Knee Impact Bolsters................................ 146Maintaining Your Air Bag System.............. 151Maintenance............................................. 151Transporting Pets...................................... 168Air Bag Light........................................... 44, 168

Air Cleaner, Engine (Engine Air Cleaner Filter)..196

Air Conditioner Maintenance......................... 196Air Conditioner Refrigerant.................. 196, 197Air Conditioner System.................................. 196Air Conditioning Filter...................................... 31Air Conditioning, Operating Tips................ 30, 31Air Filter......................................................... 196

Air PressureTires......................................................... 225Alterations/ModificationsVehicle........................................................... 7Antifreeze (Engine Coolant)................. 200, 240Disposal................................................... 201Anti-Lock Brake System (ABS)...................... 131Anti-Lock Warning Light................................... 47Assist, Hill Start............................................. 134Audio Settings.................................................. 96Audio Systems (Radio)..................................... 78Auto Down Power Windows............................. 34Automatic Transmission........................... 55, 56Adding Fluid..................................... 204, 241Fluid And Filter Change............................ 204Fluid Change............................................ 204Fluid Level Check............................ 203, 204Fluid Type........................................ 203, 241Special Additives...................................... 203Auxiliary Electrical Outlet (Power Outlet).......... 32Axle Fluid...................................................... 241

B

Battery................................................... 45, 194Charging System Light.................................45Keyless Key Fob Replacement....................10Belts, Seat.................................................... 168BluetoothConnecting To A Particular Mobile Phone Or Audio Device After Pairing

................ 104Body Builders Guide........................................... 7Body Mechanism Lubrication........................ 197B-Pillar Location............................................ 221Brake Assist System..................................... 132Brake Fluid.................................................... 241Brake System....................................... 202, 236Anti-Lock (ABS)......................................... 131Fluid Check...................................... 202, 241Master Cylinder........................................ 202Parking........................................................54Warning Light...............................................45Brake, Parking.................................................54Brake/Transmission Interlock..........................56Bulb Replacement........................................ 213Bulbs, Light.......................................... 170, 213

22_VM_OM_EN_USC_t.book Page 246