check engine RENAULT CAPTUR 2014 1.G Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2014, Model line: CAPTUR, Model: RENAULT CAPTUR 2014 1.GPages: 244, PDF Size: 5.64 MB

Page 165 of 244

4.7

Frequency of checking coolant level

Check the coolant level regularly

(very severe damage is likely to be

caused to the engine if it runs out of

coolant).

If the level needs to be topped up, only

use products approved by our Technical

Department which ensure:

– protection against freezing;

– an anti-corrosion protection for the cooling system.

Consult your approved dealer at

once if you notice an abnormal or

repeated drop in any of the fluid

levels.

No operations should be

carried out on the cooling

circuit when the engine is

hot.

Risk of burns.

Replacement interval

Refer to the Maintenance Document for

your vehicle.

Coolant level

With the engine switched off and on

level ground, the level when cold must

be between the MINI and MAXI marks

on reservoir 1.

Top this level up when cold before it

reaches the MINI mark.

LEVELS (1/3)

1

When working in the engine

compartment, ensure that

the windscreen wiper stalk

is in the park position.

Risk of injury.

Before performing any

action in the engine com-

partment, the ignition must

be switched off by pressing

the engine stop button (please see

the information on “Starting, stop-

ping the engine” in Section 2).

Page 166 of 244

4.8

Level 2

It is normal for the level to drop as the

brake shoes become worn, but it must

never drop lower than the “MINI" warn-

ing line.

If you wish to check the disc and drum

wear yourself, you should obtain the

document explaining the checking pro-

cedure from the manufacturer’s net-

work or web site.

Topping up

After any operation on the hydraulic cir-

cuit, a specialist must replace the brake

fluid.

Only use fluids approved by our

Technical Department (and taken from

a sealed container).

Replacement interval

Refer to the Maintenance Document for

your vehicle.

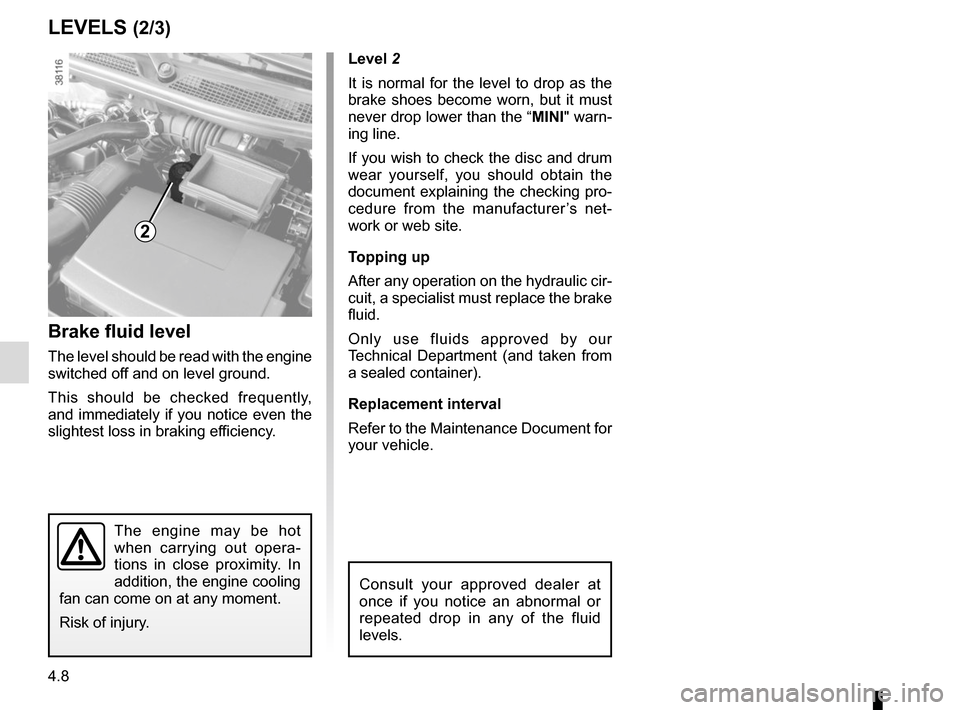

Brake fluid level

The level should be read with the engine

switched off and on level ground.

This should be checked frequently,

and immediately if you notice even the

slightest loss in braking efficiency.

LEVELS (2/3)

2

The engine may be hot

when carrying out opera-

tions in close proximity. In

addition, the engine cooling

fan can come on at any moment.

Risk of injury.

Consult your approved dealer at

once if you notice an abnormal or

repeated drop in any of the fluid

levels.

Page 193 of 244

5.13

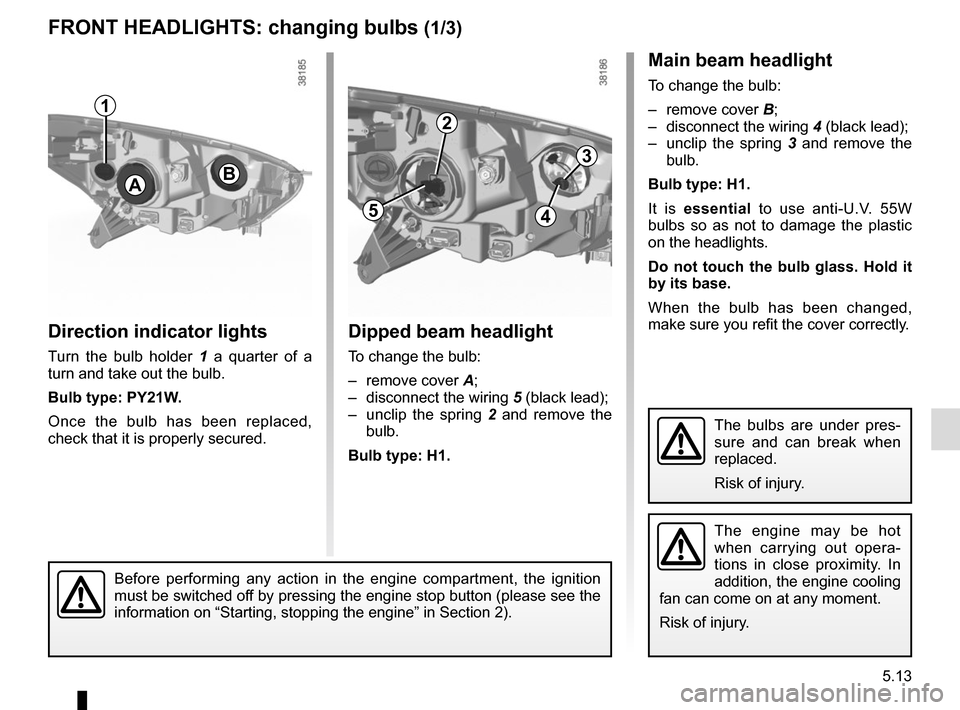

Direction indicator lights

Turn the bulb holder 1 a quarter of a

turn and take out the bulb.

Bulb type: PY21W.

Once the bulb has been replaced,

check that it is properly secured.

Dipped beam headlight

To change the bulb:

– remove cover A;

– disconnect the wiring 5 (black lead);

– unclip the spring 2 and remove the

bulb.

Bulb type: H1.

FRONT HEADLIGHTS: changing bulbs (1/3)

The engine may be hot

when carrying out opera-

tions in close proximity. In

addition, the engine cooling

fan can come on at any moment.

Risk of injury.

B

Main beam headlight

To change the bulb:

– remove cover B;

– disconnect the wiring 4 (black lead);

– unclip the spring 3 and remove the

bulb.

Bulb type: H1.

It is essential to use anti-U.V. 55W

bulbs so as not to damage the plastic

on the headlights.

Do not touch the bulb glass. Hold it

by its base.

When the bulb has been changed,

make sure you refit the cover correctly.

A

1

2

54

3

The bulbs are under pres-

sure and can break when

replaced.

Risk of injury.

Before performing any action in the engine compartment, the ignition

must be switched off by pressing the engine stop button (please see the

information on “Starting, stopping the engine” in Section 2).

Page 201 of 244

5.21

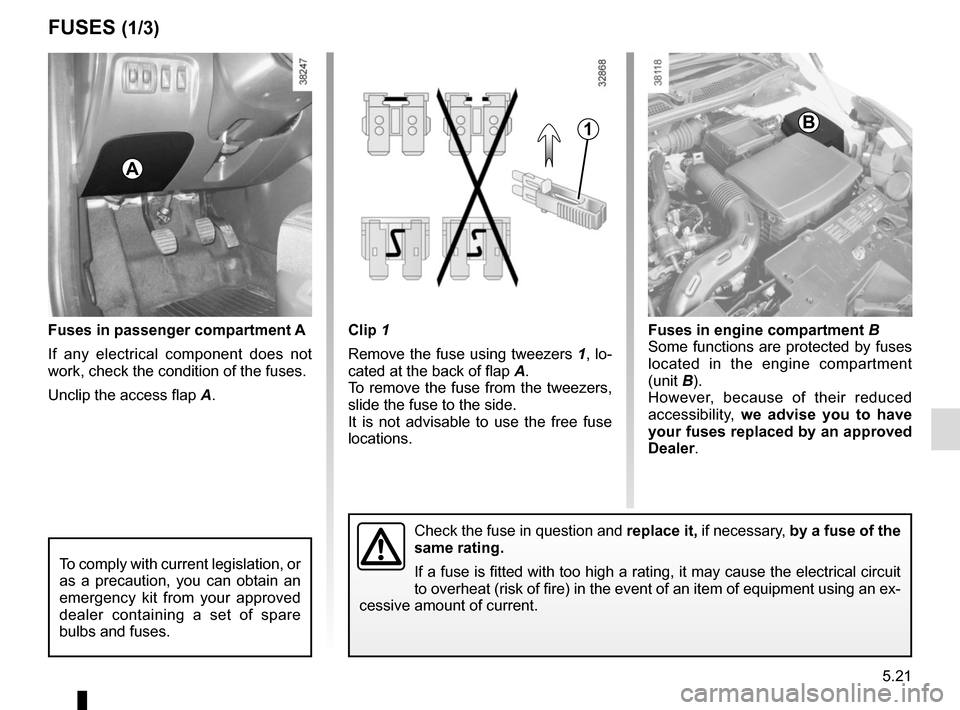

Clip 1

Remove the fuse using tweezers 1, lo-

cated at the back of flap A.

To remove the fuse from the tweezers,

slide the fuse to the side.

It is not advisable to use the free fuse

locations.Fuses in passenger compartment A

If any electrical component does not

work, check the condition of the fuses.

Unclip the access flap A.

FUSES (1/3)

Fuses in engine compartment B

Some functions are protected by fuses

located in the engine compartment

(unit B).

However, because of their reduced

accessibility, we advise you to have

your fuses replaced by an approved

Dealer .

1

A

B

To comply with current legislation, or

as a precaution, you can obtain an

emergency kit from your approved

dealer containing a set of spare

bulbs and fuses.

Check the fuse in question and replace it, if necessary, by a fuse of the

same rating.

If a fuse is fitted with too high a rating, it may cause the electrical \

circuit

to overheat (risk of fire) in the event of an item of equipment using \

an ex-

cessive amount of current.

Page 205 of 244

5.25

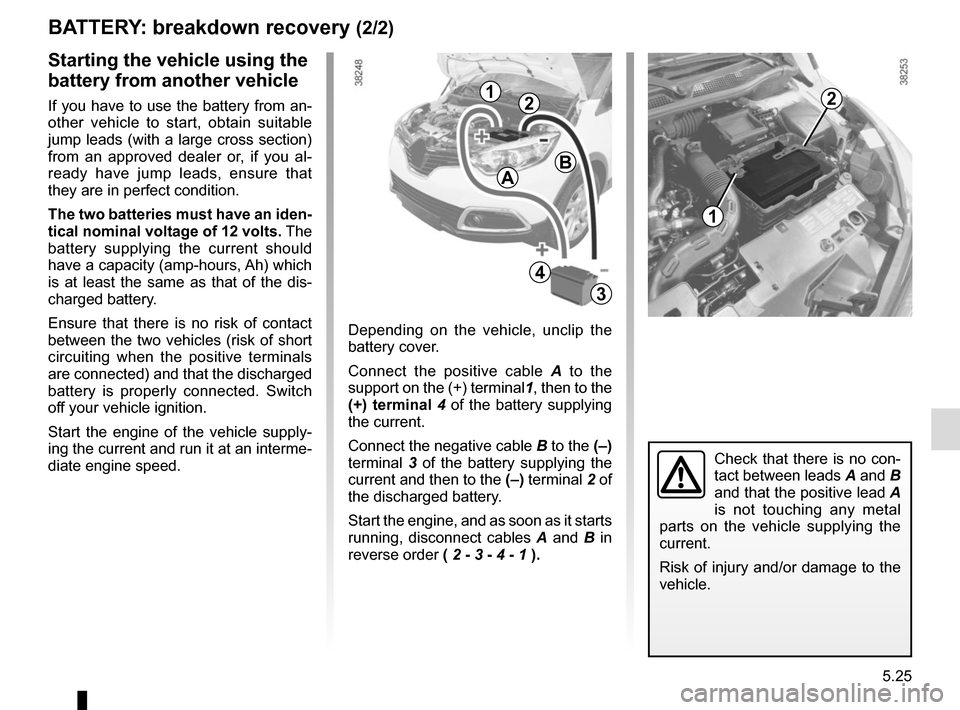

BATTERY: breakdown recovery (2/2)

Depending on the vehicle, unclip the

battery cover.

Connect the positive cable A to the

support on the (+) terminal 1, then to the

(+) terminal 4 of the battery supplying

the current.

Connect the negative cable B to the (–)

terminal 3 of the battery supplying the

current and then to the (–) terminal 2 of

the discharged battery.

Start the engine, and as soon as it starts

running, disconnect cables A and B in

reverse order ( 2 - 3 - 4 - 1 ).

Starting the vehicle using the

battery from another vehicle

If you have to use the battery from an-

other vehicle to start, obtain suitable

jump leads (with a large cross section)

from an approved dealer or, if you al-

ready have jump leads, ensure that

they are in perfect condition.

The two batteries must have an iden-

tical nominal voltage of 12 volts. The

battery supplying the current should

have a capacity (amp-hours, Ah) which

is at least the same as that of the dis-

charged battery.

Ensure that there is no risk of contact

between the two vehicles (risk of short

circuiting when the positive terminals

are connected) and that the discharged

battery is properly connected. Switch

off your vehicle ignition.

Start the engine of the vehicle supply-

ing the current and run it at an interme-

diate engine speed.

Check that there is no con-

tact between leads A and B

and that the positive lead A

is not touching any metal

parts on the vehicle supplying the

current.

Risk of injury and/or damage to the

vehicle.

1

212

4

AB

3

Page 208 of 244

5.28

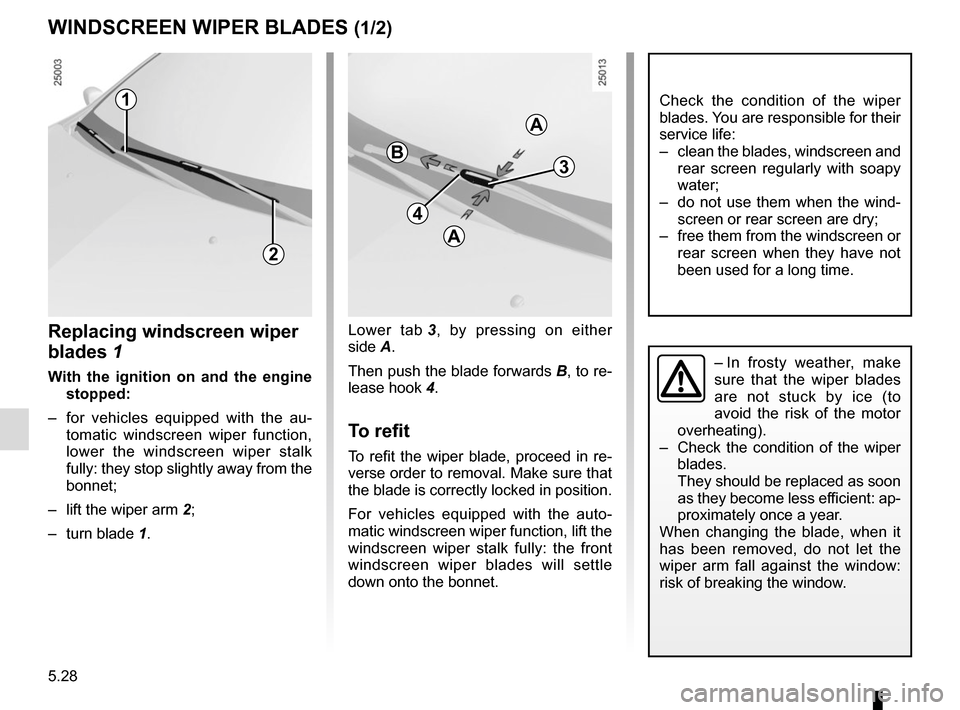

Lower tab 3, by pressing on either

side A.

Then push the blade forwards B, to re-

lease hook 4.

To refit

To refit the wiper blade, proceed in re-

verse order to removal. Make sure that

the blade is correctly locked in position.

For vehicles equipped with the auto-

matic windscreen wiper function, lift the

windscreen wiper stalk fully: the front

windscreen wiper blades will settle

down onto the bonnet.

Replacing windscreen wiper

blades 1

With the ignition on and the engine

stopped:

– for vehicles equipped with the au- tomatic windscreen wiper function,

lower the windscreen wiper stalk

fully: they stop slightly away from the

bonnet;

– lift the wiper arm 2;

– turn blade 1.

WINDSCREEN WIPER BLADES (1/2)

2

1

4

3B

A

A

Check the condition of the wiper

blades. You are responsible for their

service life:

– clean the blades, windscreen and

rear screen regularly with soapy

water;

– do not use them when the wind- screen or rear screen are dry;

– free them from the windscreen or rear screen when they have not

been used for a long time.

– In frosty weather, make

sure that the wiper blades

are not stuck by ice (to

avoid the risk of the motor

overheating).

– Check the condition of the wiper

blades.

They should be replaced as soon

as they become less efficient: ap-

proximately once a year.

When changing the blade, when it

has been removed, do not let the

wiper arm fall against the window:

risk of breaking the window.

Page 214 of 244

5.34

OPERATING FAULTS (3/6)

On the roadPOSSIBLE CAUSESWHAT TO DO

Vibrations. Tyres not inflated to correct pres-

sures, incorrectly balanced or dam-

aged. Check the tyre pressures: if this is not the

problem, have them checked by an ap-

proved Dealer.

White smoke from the exhaust. In the diesel version, this is necessar-

ily a fault. Smoke may be caused by

particle filter regeneration. Please refer to the information on “Special

features of diesel versions” in Section 2.

Smoke under the bonnet. Short-circuit or cooling system leak. Stop, switch off the ignition, stand away

from the vehicle and contact an approved

dealer.

The oil pressure warning light comes

on: while cornering or braking The level is too low. Top up the engine oil level (refer to the in-

formation on “Engine oil level: topping up,

filling” in Section 4).

is slow to go out or remains lit

under acceleration Loss of oil pressure.

Stop the vehicle and contact an approved

Dealer.

Page 215 of 244

5.35

OPERATING FAULTS (4/6)

On the roadPOSSIBLE CAUSESWHAT TO DO

Steering becomes heavy. Assistance overheating. Consult an approved dealer.

The engine is overheating. The cool-

ant temperature indicator is in the

warning zone and warning light

® comes on. Engine cooling fan not working. Stop the vehicle, switch off the engine and

contact an approved dealer.

Coolant leaks. Check the coolant reservoir: it should con- tain fluid. If there is no coolant, consult an

approved dealer as soon as possible.

Coolant boiling in the coolant reser-

voir. Mechanical fault: damaged cylinder

head gasket. Stop the engine.

Contact an approved dealer.

Radiator:

If there is a significant lack of coolant, remember that it must never b\

e topped up using cold coolant while

the engine is very warm. After any procedure on the vehicle which has involved even partial drain\

ing of the cooling

system, it must be refilled with a new mixture prepared in the correct p\

roportions. Reminder: only products approved

by our Technical Department may be used for this purpose.

Page 219 of 244

6.1

Section 6: Technical specifications

Vehicle identification plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . 6.2

Engine identification plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . 6.3

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.4

Engine specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . 6.5

Towing weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.6

Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.6

Replacement parts and repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . 6.7

Service sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.8

Anticorrosion check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . 6.14