check engine RENAULT CLIO 1997 X57 / 1.G Petrol Engines Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: CLIO, Model: RENAULT CLIO 1997 X57 / 1.GPages: 55, PDF Size: 4.15 MB

Page 13 of 55

ENGINE AND PERIPHERALS

S

pecifications10

VALVE CLEARANCES (in mm)

- Inlet0.10

- Exhaus

t0.25

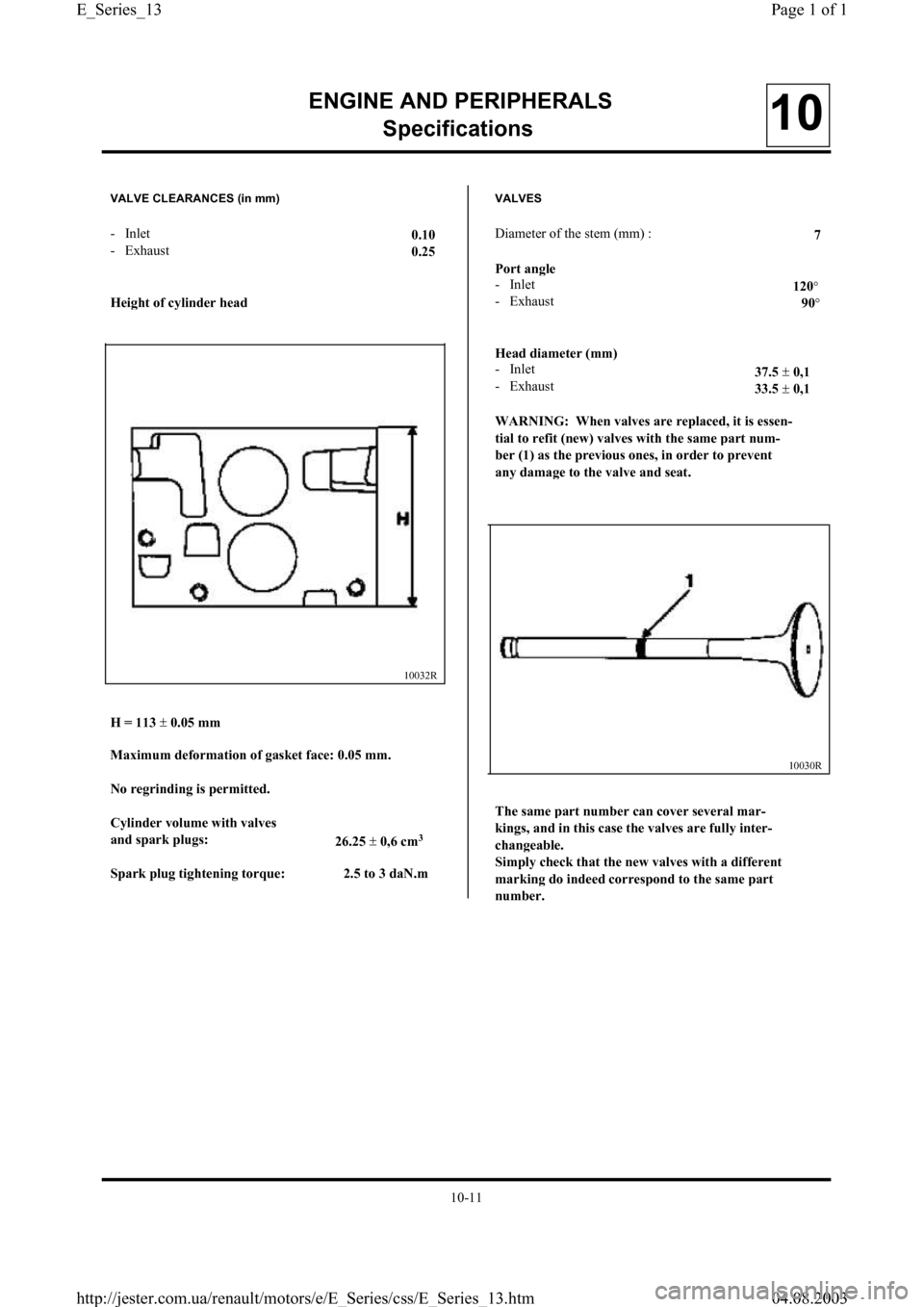

Hei

ght of cylinder head

10032R

H = 113 ±

0.05 mm

Maximum deformation of

gasket face: 0.05 mm.

No re

grinding is permitted.

C

ylinder volume with valves

and s

park plugs:

26.25 ±

0,6 cm3

Spark plug tightening torque: 2.5 to 3 daN.m

VALVES

Diameter of the stem (mm) :

7

Port an

gle

- Inle

t120°- Exhaust90°

Head diameter (mm)

- Inlet37.5 ±

0,1

- Exhaust33.5 ±

0,1

WARNING: When valves are re

placed, it is essen-

tial to refit

(new) valves with the same part num-

ber

(1) as the previous ones, in order to prevent

an

y damage to the valve and seat.

10030R

The same part number can cover several mar-

kin

gs, and in this case the valves are fully inter-

chan

geable.

Sim

ply check that the new valves with a different

markin

g do indeed correspond to the same part

number.

10-11

Page 1 of 1 E_Series_13

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_13.htm

Page 16 of 55

ENGINE AND PERIPHERALS

S

pecifications10

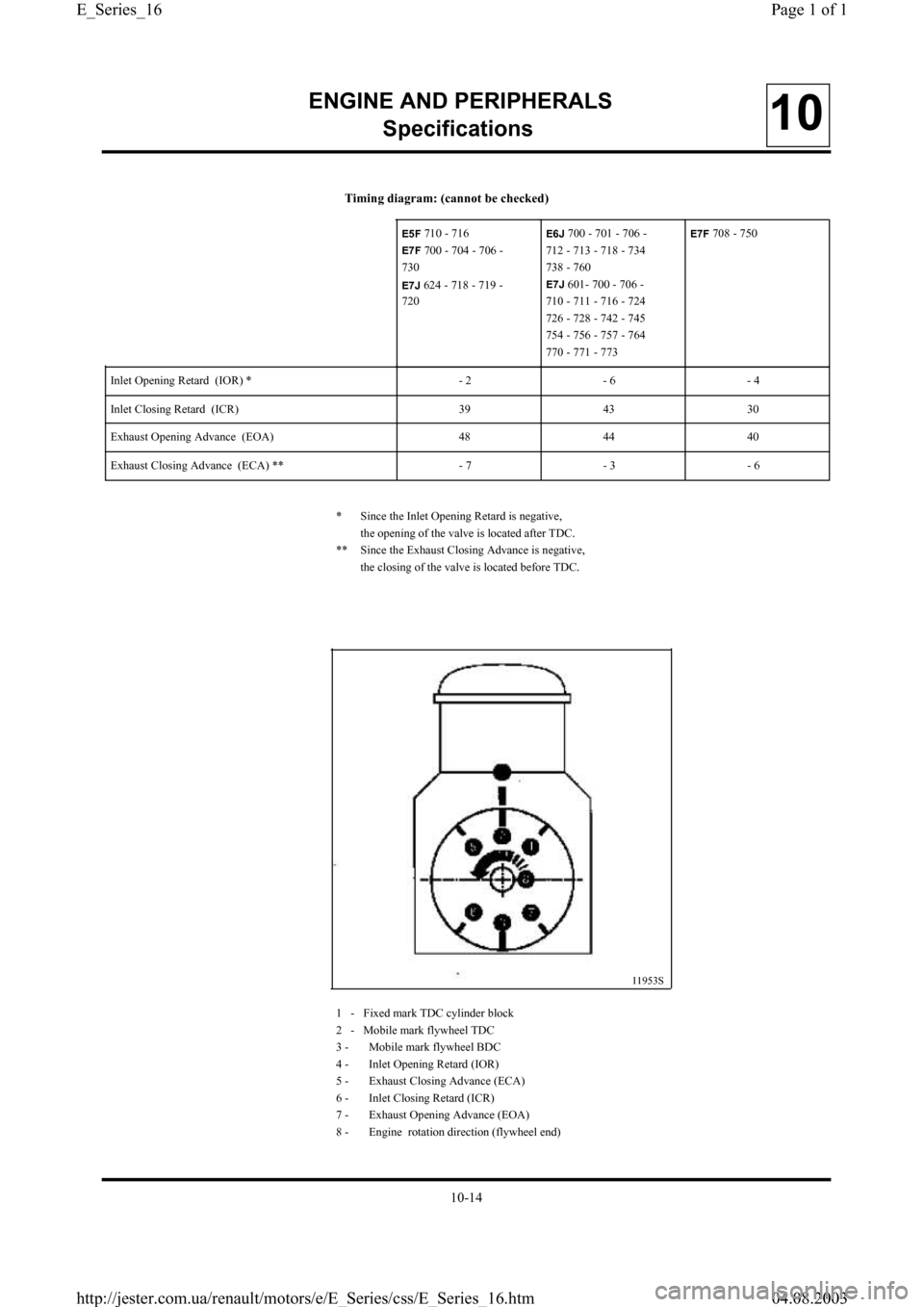

* Since the Inlet Opening Retard is negative,

the opening of the valve is located after TDC.

** Since the Exhaust Closing Advance is negative,

the closing of the valve is located before TDC.

11953S

Timing diagram: (cannot be checked)

1 - Fixed mark TDC cylinder block

2 - Mobile mark flywheel TDC

3 - Mobile mark flywheel BDC

4 - Inlet Opening Retard (IOR)

5 - Exhaust Closing Advance (ECA)

6 - Inlet Closing Retard (ICR)

7 - Exhaust Opening Advance (EOA)

8 - Engine rotation direction (flywheel end) Inlet Opening Retard (IOR) * - 2 - 6 - 4

Inlet Closing Retard (ICR) 39 43 30

Exhaust Opening Advance (EOA) 48 44 40

Exhaust Closing Advance (ECA) ** - 7 - 3 - 6

E5F 710 - 716

E7F 700 - 704 - 706 -

730

E7J 624 -718 - 719 -

720

E6J 700 - 701 - 706 -

712 - 713 - 718 - 734

738 - 760

E7J 601- 700 - 706 -

710 - 711 - 716 - 724

726 - 728 - 742 - 745

754 - 756 - 757 - 764

770 - 771 - 773

E7F 708 - 750

10-14

Page 1 of 1 E_Series_16

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_16.htm

Page 19 of 55

ENGINE AND PERIPHERALS

S

pecifications10

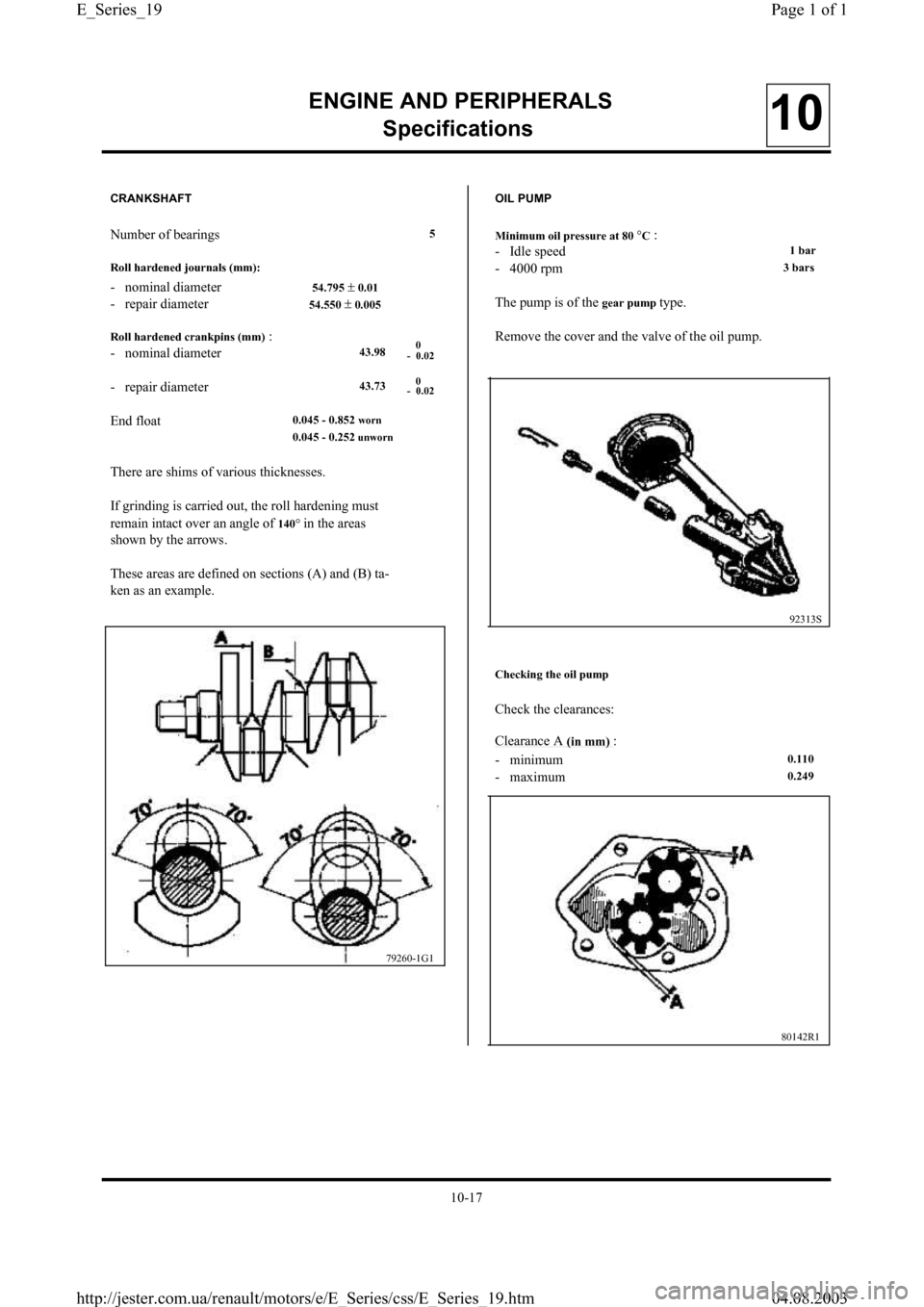

CRANKSHAFT

Number of bearings5

Roll hardened

journals (mm):

- nominal diameter 54.795 ± 0.01

- repair diameter 54.550 ± 0.005

Roll hardened crankpins (mm)

:

- nominal diamete

r43.98

- repair diameter43.73

End float 0.045 - 0.852 worn

0.045 - 0.252 unworn

There are shims of various thicknesses.

If grinding is carried out, the roll hardening mus

t

remain intact over an angle of 140° in the areas

shown by the arrows.

These areas are defined on sections (A) and (B) ta-

ken as an example.

0

- 0.02

0

- 0.02

79260-1G1

OIL PUMP

Minimum oil pressure at 80

°C:

- Idle spee

d1 bar

- 4000 rpm3 bars

The pump is of the gear pump type.

Remove the cover and the valve of the oil pump.

92313S

Checking the oil pump

Check the clearances:

Clearance

A(in mm) :

- minimum

0.110

- maximum0.249

80142R1

10-17

Page 1 of 1 E_Series_19

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_19.htm

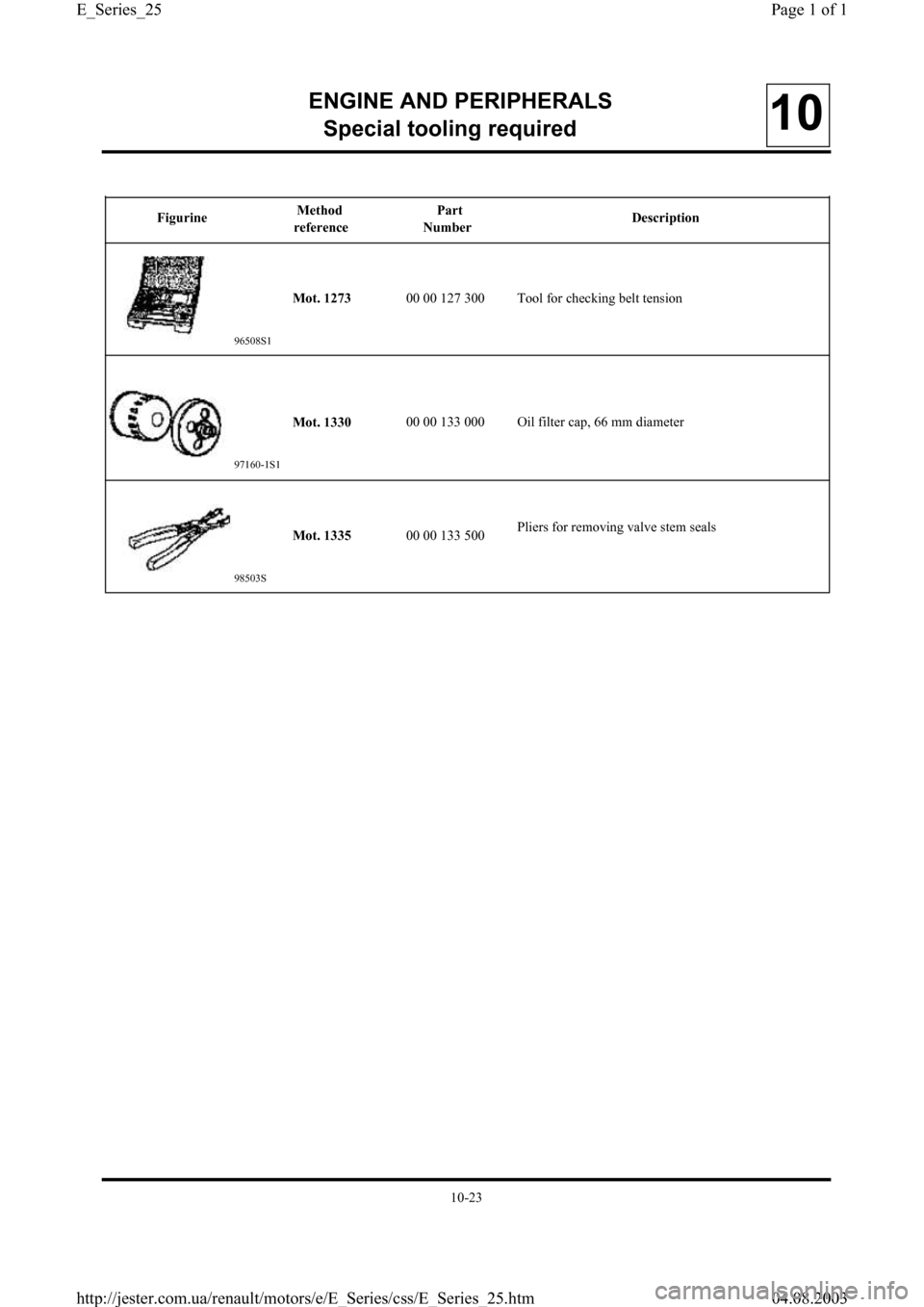

Page 25 of 55

97160-1S1

FigurineMethod

referencePart

NumberDescription

ENGINE AND PERIPHERALS

S

pecial tooling required10

96508S1

Mot. 133000 00 133 000 Oil filter cap, 66 mm diameter

Mot. 127300 00 127 300 Tool for checking belt tension

Mot. 133500 00 133 500Pliers for removing valve stem seals

98503S

10-23

Page 1 of 1 E_Series_25

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_25.htm

Page 32 of 55

ENGINE AND PERIPHERALS

En

gine repair10

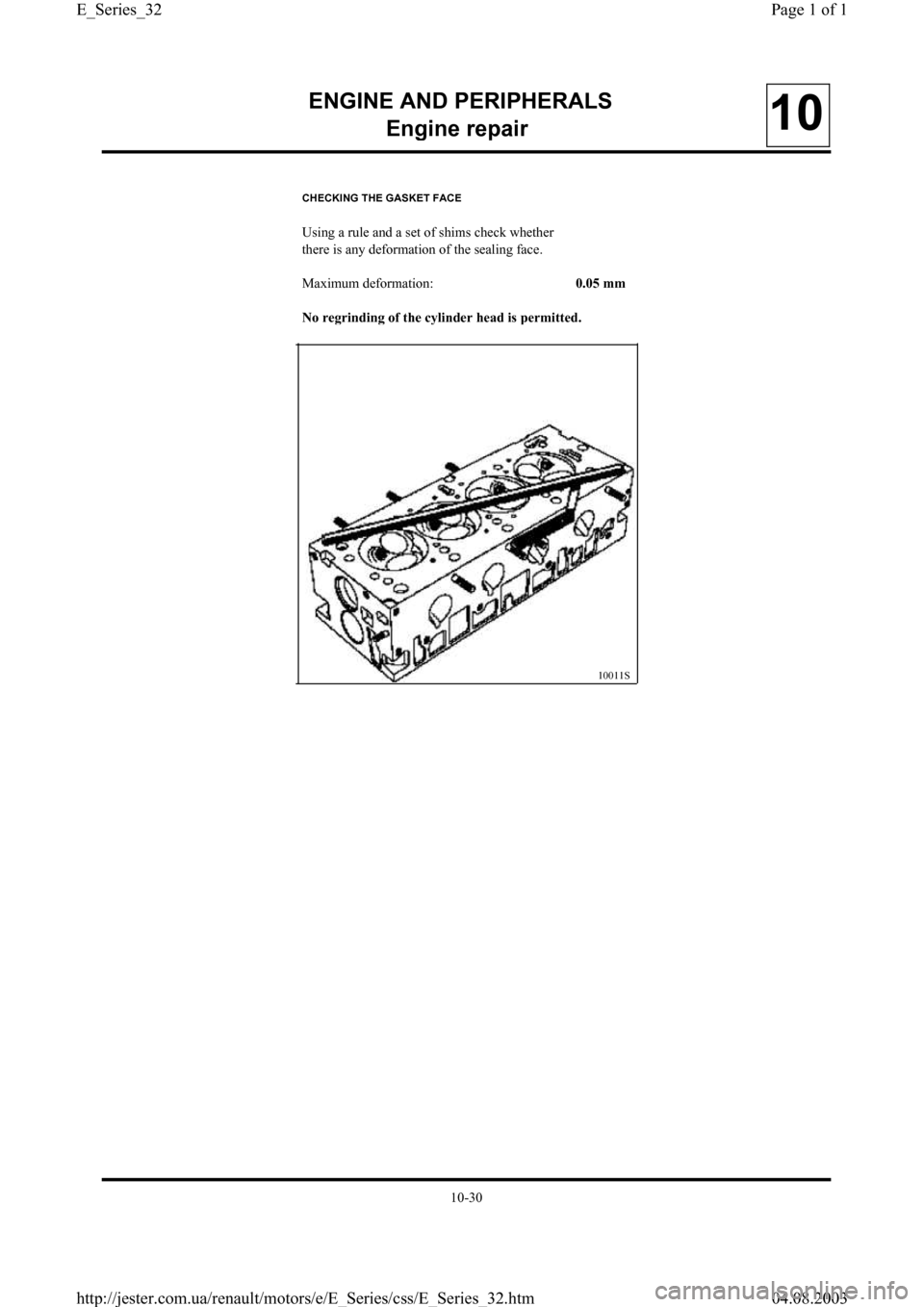

CHECKING THE GASKET FACE

Using a rule and a set of shims check whether

there is any deformation of the sealing face.

Maximum deformation:

0.05 mm

No re

grinding of the cylinder head is permitted.

10011S

10-30

Page 1 of 1 E_Series_32

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_32.htm

Page 34 of 55

ENGINE AND PERIPHERALS

En

gine repair10

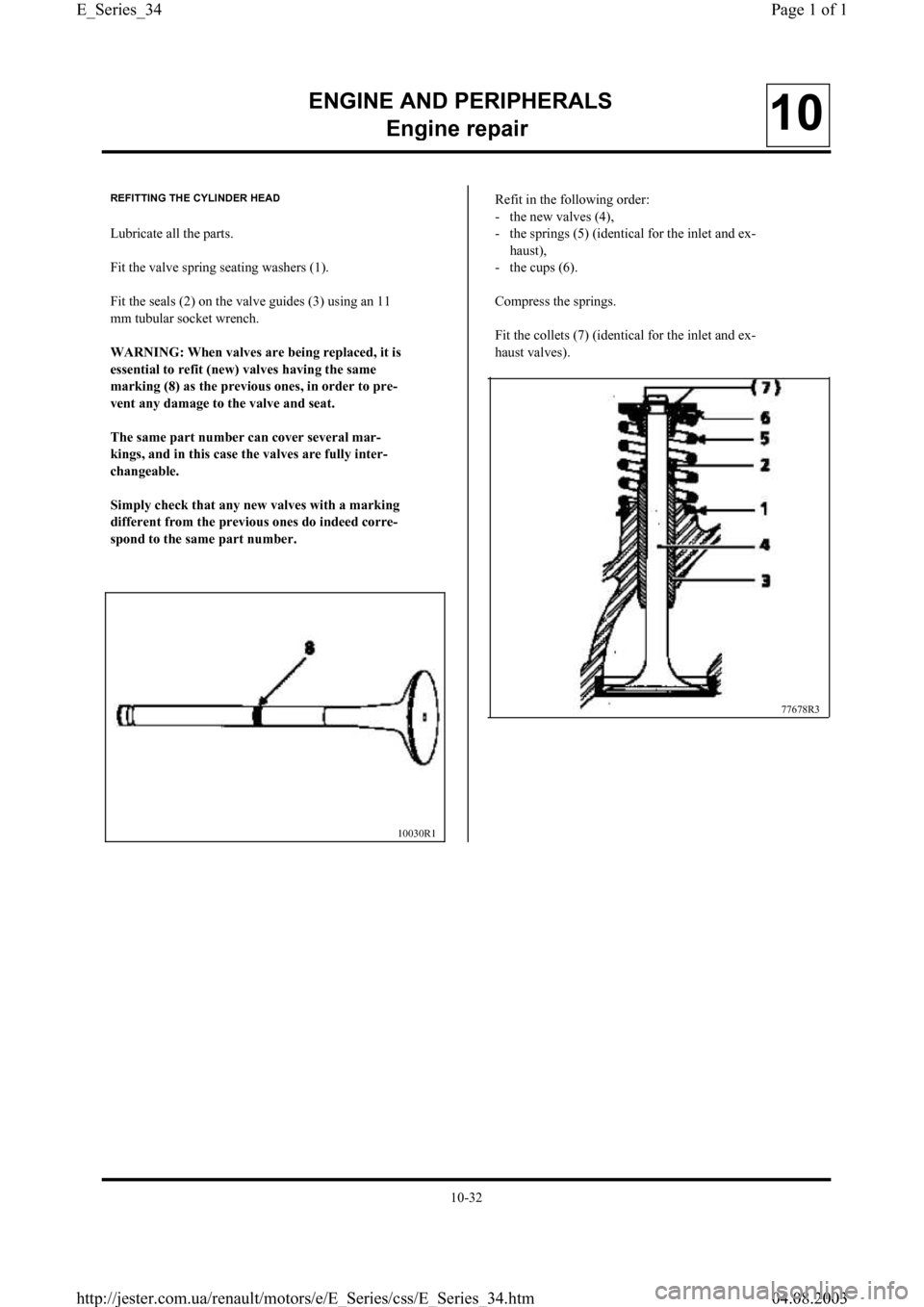

REFITTING THE CYLINDER HEAD

Lubricate all the parts.

Fit the valve spring seating washers (1).

Fit the seals (2) on the valve guides (3) using an 11

mm tubular socket wrench.

WARNING: When valves are bein

g replaced, it is

essential to refit

(new) valves having the same

markin

g (8) as the previous ones, in order to pre-

vent an

y damage to the valve and seat.

The same

part number can cover several mar-

kin

gs, and in this case the valves are fully inter-

chan

geable.

Sim

ply check that any new valves with a marking

different from the previous ones do indeed corre-

s

pond to the same part number.

10030R1

Refit in the following order:

- the new valves (4),

- the springs (5) (identical for the inlet and ex-

haust),

- the cups (6).

Compress the springs.

Fit the collets (7) (identical for the inlet and ex-

haust valves).

77678R3

10-32

Page 1 of 1 E_Series_34

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_34.htm

Page 35 of 55

ENGINE AND PERIPHERALS

En

gine repair10

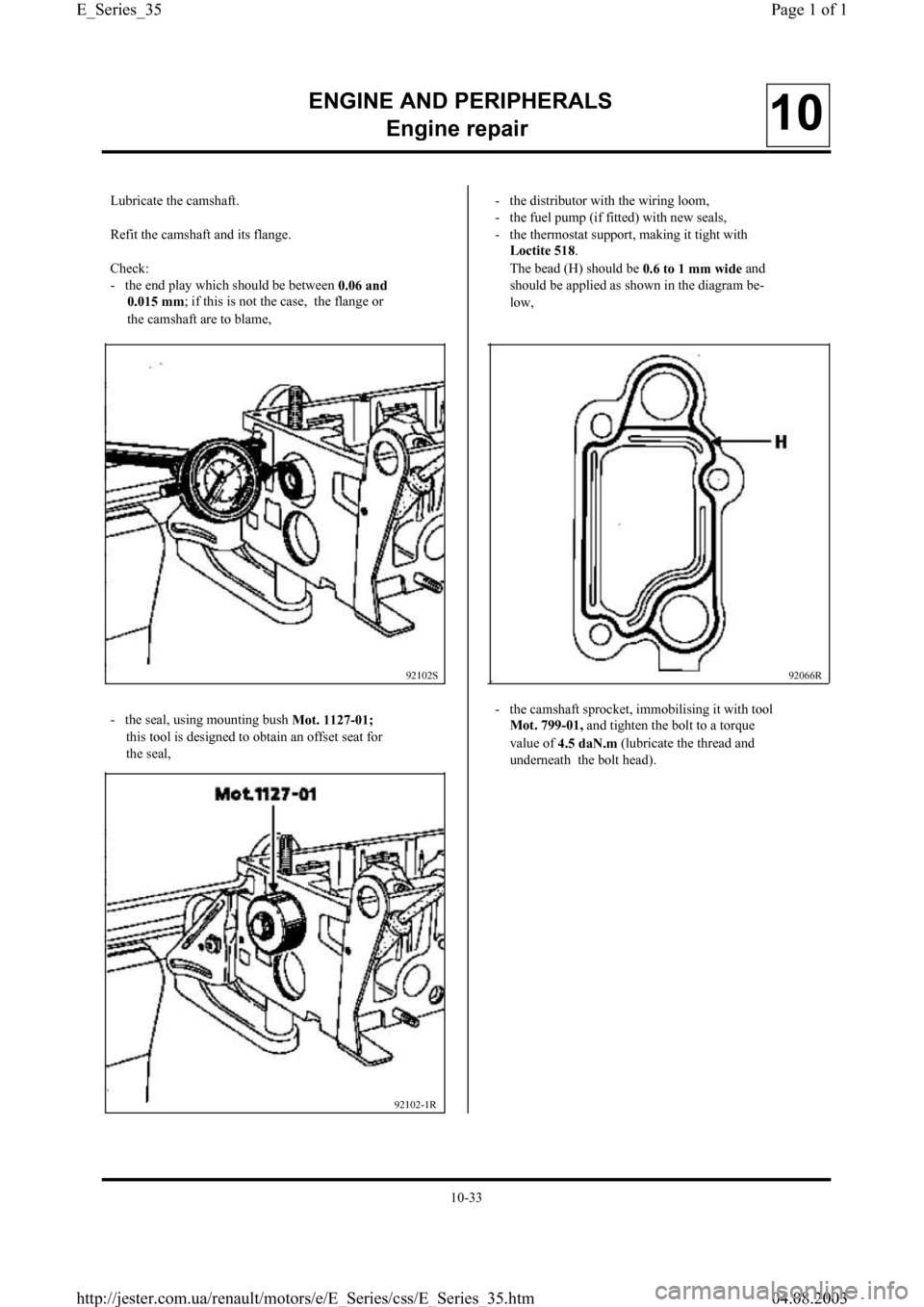

- the distributor with the wiring loom,

- the fuel pump (if fitted) with new seals,

- the thermostat support, making it tight with

Loctite 518.

The bead (H) should be

0.6 to 1 mm wide and

should be applied as shown in the diagram be-

low,

- the seal, using mounting bush

Mot. 1127-01;

this tool is designed to obtain an offset seat fo

r

the seal,

92102S92066R

Lubricate the camshaft.

Refit the camshaft and its flange.

Check:

- the end play which should be between

0.06 and

0.015 mm; if this is not the case, the flange o

r

the camshaft are to blame,

92102-1R

- the camshaft sprocket, immobilising it with tool

Mot. 799-01, and tighten the bolt to a torque

value of

4.5 daN.m (lubricate the thread an

d

underneath the bolt head).

10-33

Page 1 of 1 E_Series_35

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_35.htm

Page 40 of 55

ENGINE AND PERIPHERALS

En

gine repair10

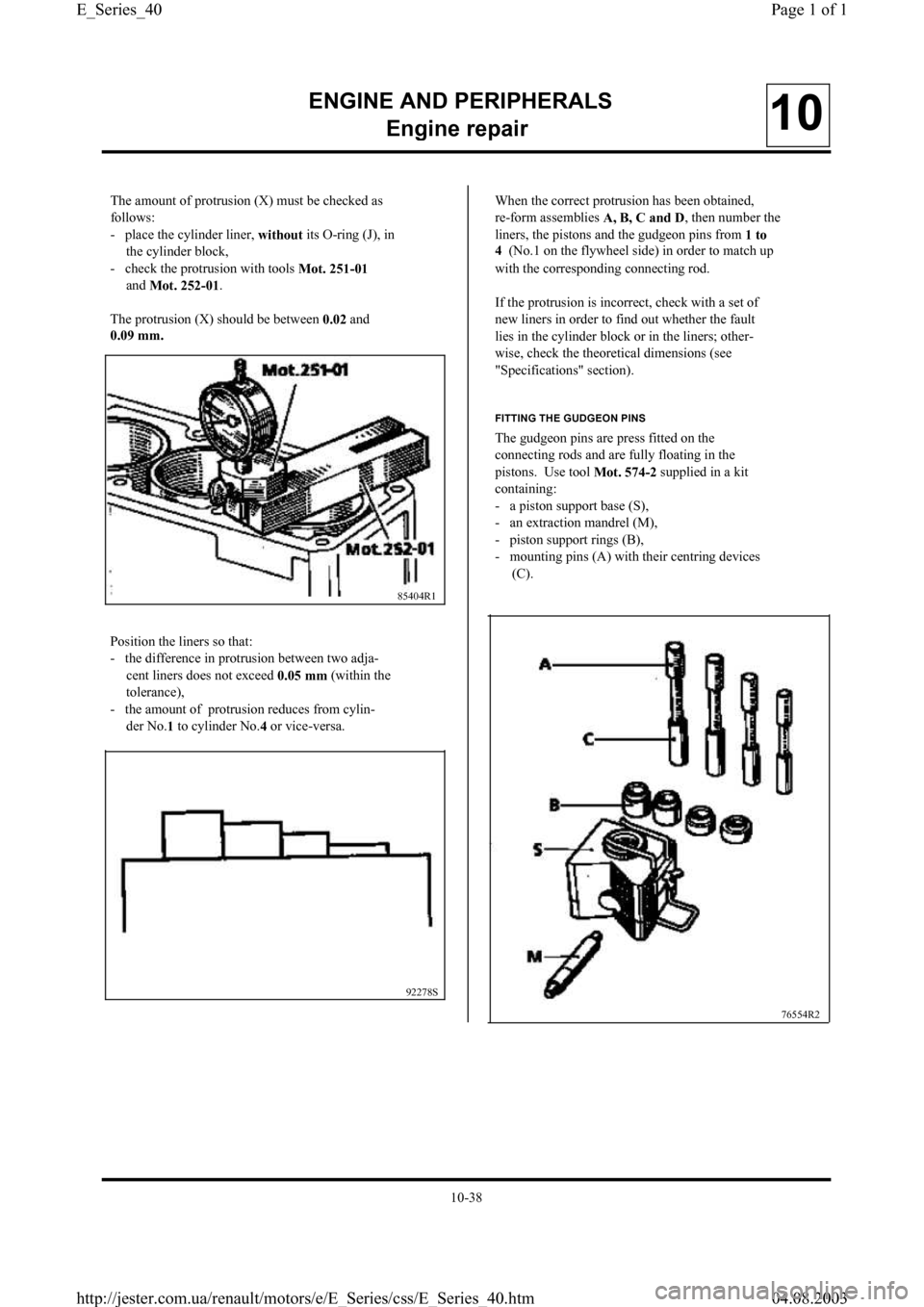

The amount of protrusion (X) must be checked as

follows:

- place the cylinder liner,

without its O-ring (J), in

the cylinder block,

- check the protrusion with tools

Mot. 251-01

and

Mot. 252-01.

The protrusion (X) should be between

0.02 and

0.09 mm.

Position the liners so that:

- the difference in protrusion between two adja-

cent liners does not exceed

0.05 mm (within the

tolerance),

- the amount of protrusion reduces from cylin-

der No.

1 to cylinder No.

4 or vice-versa.

85404R1

92278S

When the correct protrusion has been obtained,

re-form assemblies

A, B, C and D, then number the

liners, the pistons and the gudgeon pins from

1 to

4 (No.1 on the flywheel side) in order to match up

with the corresponding connecting rod.

If the protrusion is incorrect, check with a set of

new liners in order to find out whether the faul

t

lies in the cylinder block or in the liners; other-

wise, check the theoretical dimensions (see

"Specifications" section).

FITTING THE GUDGEON PINS

The gudgeon pins are press fitted on the

connecting rods and are fully floating in the

pistons. Use tool

Mot. 574-2 supplied in a kit

containing:

- a piston support base (S),

- an extraction mandrel (M),

- piston support rings (B),

- mounting pins (A) with their centring devices

(C).

76554R2

10-38

Page 1 of 1 E_Series_40

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_40.htm

Page 41 of 55

ENGINE AND PERIPHERALS

En

gine repair10

PREPARATION OF THE GUDGEON PINS

Check that the gudgeon pins are able to slide

freely in the corresponding new pistons.

Use centring device

C13 and mounting tools

A13

or

A13-01 for the shouldered gudgeon pins.

Mount the gudgeon pin (E) on the mounting tool

(A), tighten the centring device (C)

until contact is

made, then slacken b

y a quarter turn.

76716R PREPARATION OF THE CONNECTING RODS

Visually check:

- the condition of the connecting rod (twisting -

straightness),

- the bearing surface between the shells and the

connecting rod bodies (if necessary, remove

any burrs with a grinding wheel to obtain a co

r-

rect bearing surface).

Use a

1500 W heating plate.

Put the little ends on the heating plate.

Ensure that the whole surface of the little end is in

contact with the plate.

Put a piece of self-pickling tin solder with a mel-

ting point of about

250

° onto each little end at (a)

to act as a temperature check.

Heat the little end until the piece of self-pickling

solder melts.

DI1038

12367R

10-39

Page 1 of 1 E_Series_41

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_41.htm

Page 42 of 55

ENGINE AND PERIPHERALS

En

gine repair10

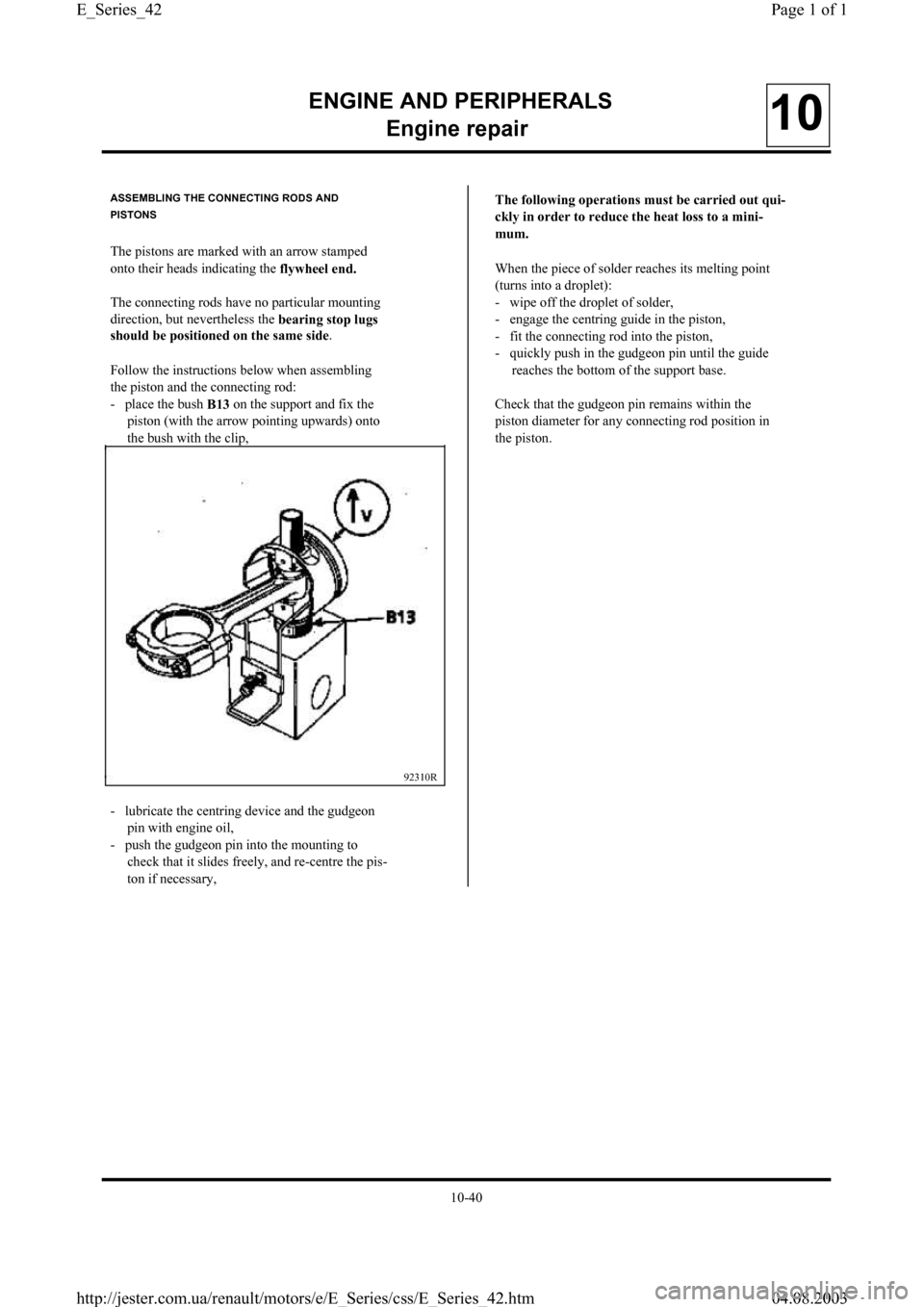

ASSEMBLING THE CONNECTING RODS AND

PISTONS

The pistons are marked with an arrow stamped

onto their heads indicating the

flywheel end.

The connecting rods have no particular mounting

direction, but nevertheless the

bearin

g stop lugs

should be

positioned on the same side.

Follow the instructions below when assembling

the piston and the connecting rod:

- place the bush

B13 on the support and fix the

piston (with the arrow pointing upwards) onto

the bush with the clip,

92310R

- lubricate the centring device and the gudgeon

pin with engine oil,

- push the gudgeon pin into the mounting to

check that it slides freely, and re-centre the pis-

ton if necessary,The followin

g operations must be carried out qui-

ckl

y in order to reduce the heat loss to a mini-

mum.

When the piece of solder reaches its melting poin

t

(turns into a droplet):

- wipe off the droplet of solder,

- engage the centring guide in the piston,

- fit the connecting rod into the piston,

- quickly push in the gudgeon pin until the guide

reaches the bottom of the support base.

Check that the gudgeon pin remains within the

piston diameter for any connecting rod position in

the piston.

10-40

Page 1 of 1 E_Series_42

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_42.htm