lock RENAULT CLIO 1997 X57 / 1.G Petrol Engines User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: CLIO, Model: RENAULT CLIO 1997 X57 / 1.GPages: 55, PDF Size: 4.15 MB

Page 38 of 55

ENGINE AND PERIPHERALS

En

gine repair10

- the water pump,

92312R

- the three bolts mounting the oil pump sprocket

on the hub, and remove the sprocket and chain

assembly,

- the oil pump.

Carry out the marking of the big end shells with

reference to their bodies.

WARNING: Do not use a scriber tool for the mar-

kin

g, in order to avoid starting any cracks in the

connectin

g rods .

Use an indelible

pencil instead.

Remove:

- the big end shells and the bearings,

- the liner clamps

(Mot. 588),

- the "liners - pistons - connecting rods" assem-

blies,

- the bearing shells with their bearings (mar

k

them),

- the crankshaft (recover the side clearance

shims),

- the crankshaft bearings in the cylinder block.

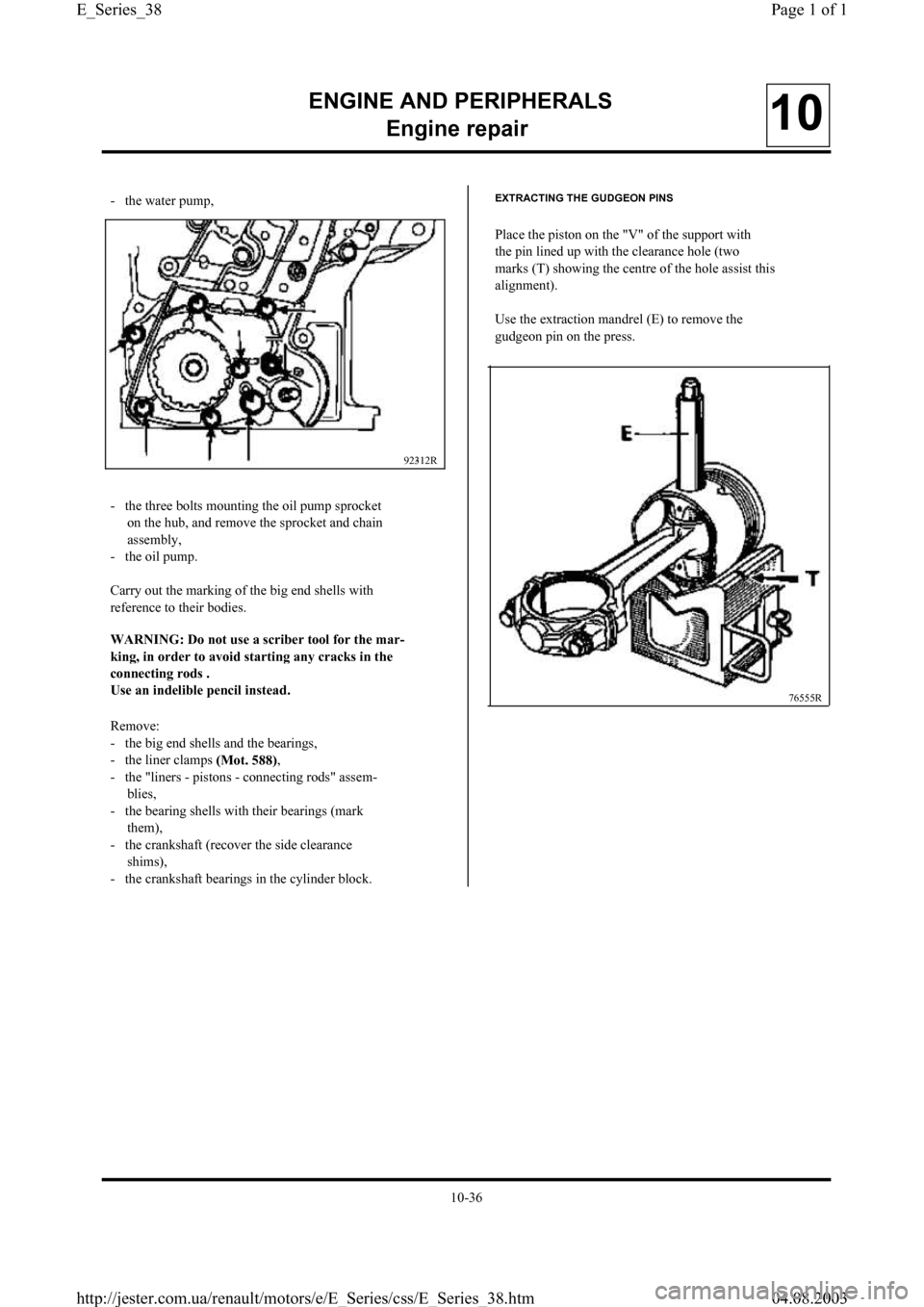

EXTRACTING THE GUDGEON PINS

Place the piston on the "V" of the support with

the pin lined up with the clearance hole (two

marks (T) showing the centre of the hole assist this

alignment).

Use the extraction mandrel (E) to remove the

gudgeon pin on the press.

76555R

10-36

Page 1 of 1 E_Series_38

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_38.htm

Page 39 of 55

ENGINE AND PERIPHERALS

En

gine repair10

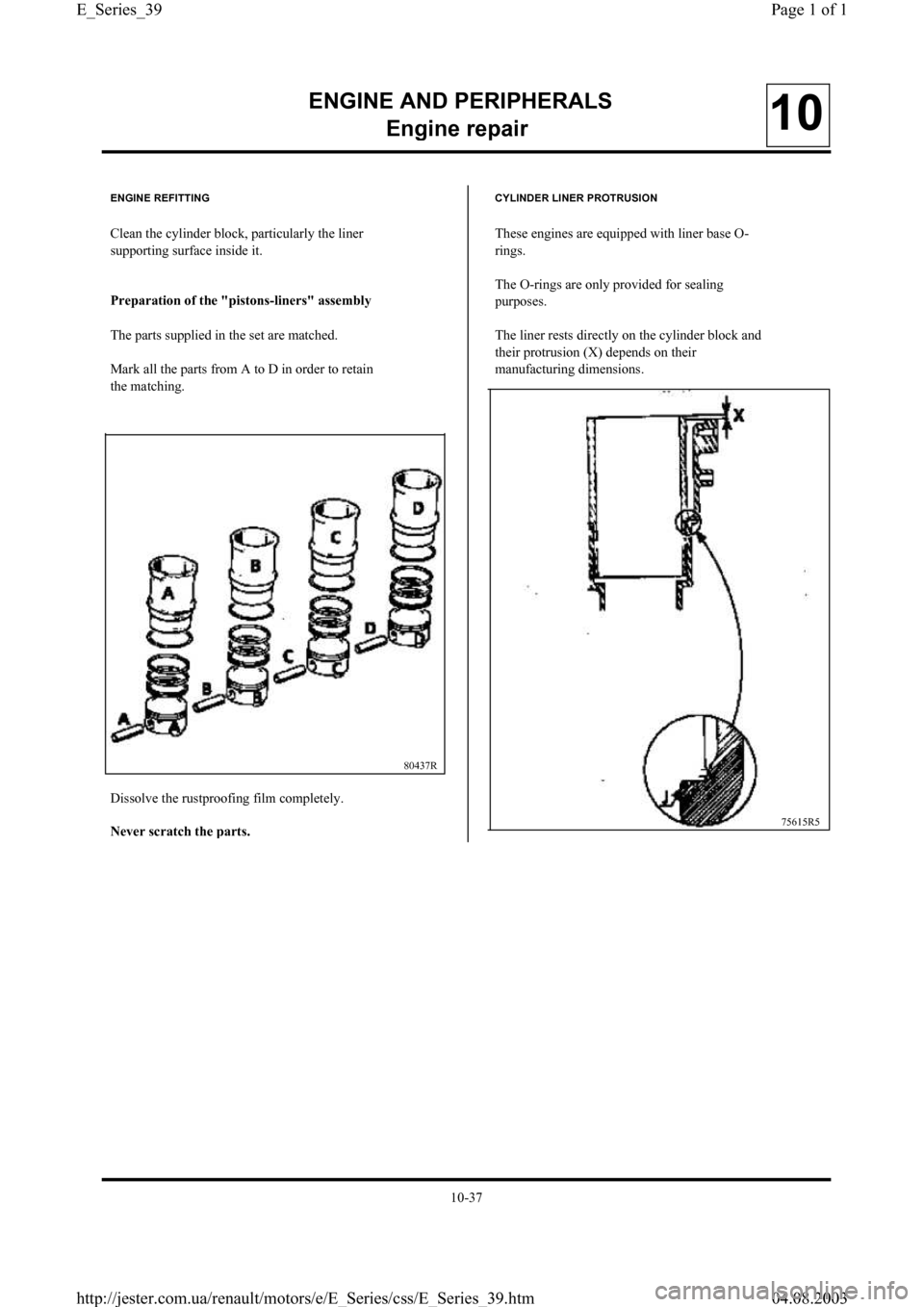

80437R ENGINE REFITTING

Clean the cylinder block, particularly the liner

supporting surface inside it.

Pre

paration of the "pistons-liners" assembly

The parts supplied in the set are matched.

Mark all the parts from A to D in order to retain

the matching.

Dissolve the rustproofing film completely.

Never scratch the

parts.

CYLINDER LINER PROTRUSION

These engines are equipped with liner base O-

rings.

The O-rings are only provided for sealing

purposes.

The liner rests directly on the cylinder block and

their protrusion (X) depends on thei

r

manufacturing dimensions.

75615R5

10-37

Page 1 of 1 E_Series_39

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_39.htm

Page 40 of 55

ENGINE AND PERIPHERALS

En

gine repair10

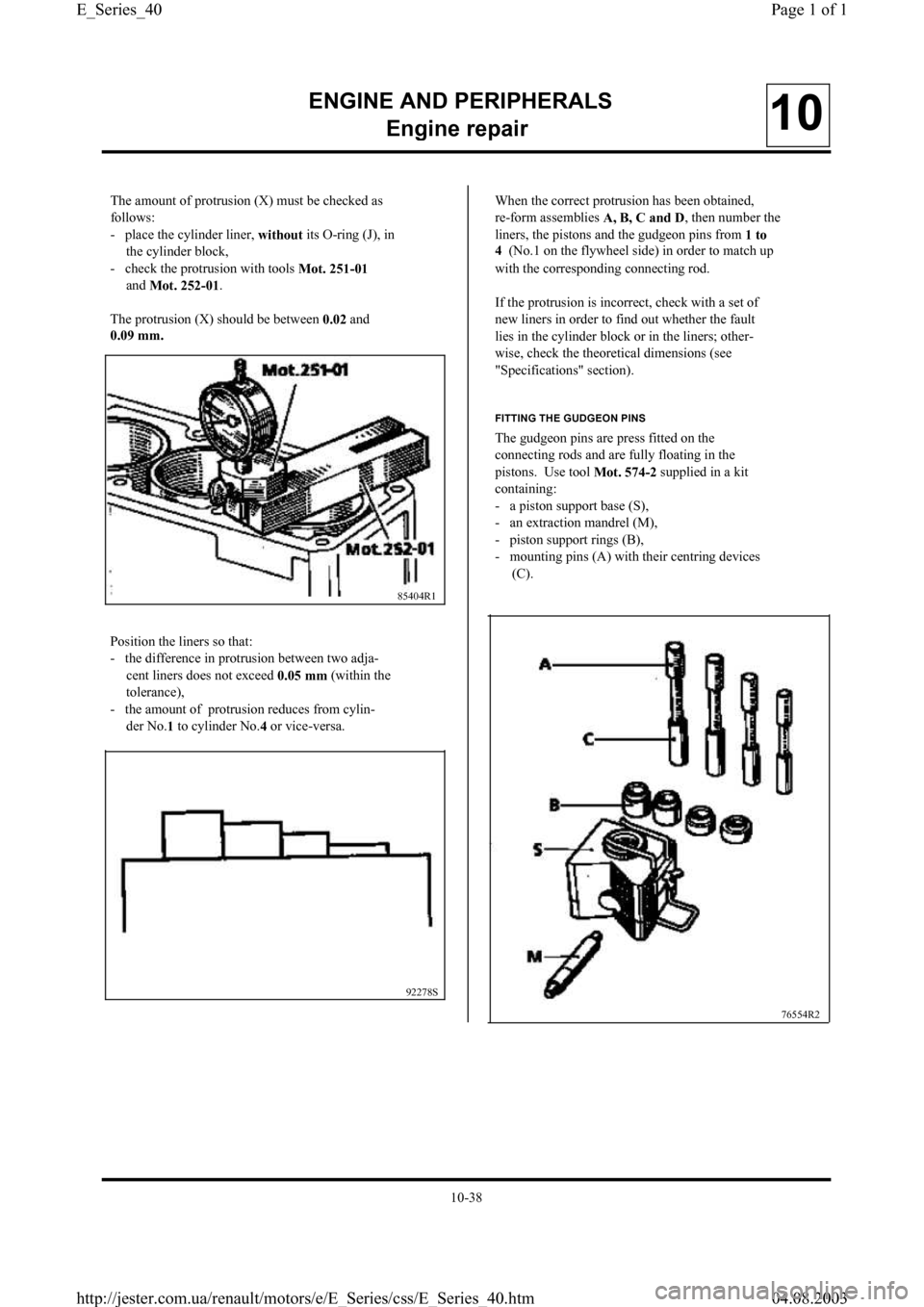

The amount of protrusion (X) must be checked as

follows:

- place the cylinder liner,

without its O-ring (J), in

the cylinder block,

- check the protrusion with tools

Mot. 251-01

and

Mot. 252-01.

The protrusion (X) should be between

0.02 and

0.09 mm.

Position the liners so that:

- the difference in protrusion between two adja-

cent liners does not exceed

0.05 mm (within the

tolerance),

- the amount of protrusion reduces from cylin-

der No.

1 to cylinder No.

4 or vice-versa.

85404R1

92278S

When the correct protrusion has been obtained,

re-form assemblies

A, B, C and D, then number the

liners, the pistons and the gudgeon pins from

1 to

4 (No.1 on the flywheel side) in order to match up

with the corresponding connecting rod.

If the protrusion is incorrect, check with a set of

new liners in order to find out whether the faul

t

lies in the cylinder block or in the liners; other-

wise, check the theoretical dimensions (see

"Specifications" section).

FITTING THE GUDGEON PINS

The gudgeon pins are press fitted on the

connecting rods and are fully floating in the

pistons. Use tool

Mot. 574-2 supplied in a kit

containing:

- a piston support base (S),

- an extraction mandrel (M),

- piston support rings (B),

- mounting pins (A) with their centring devices

(C).

76554R2

10-38

Page 1 of 1 E_Series_40

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_40.htm

Page 43 of 55

ENGINE AND PERIPHERALS

En

gine repair10

92317S

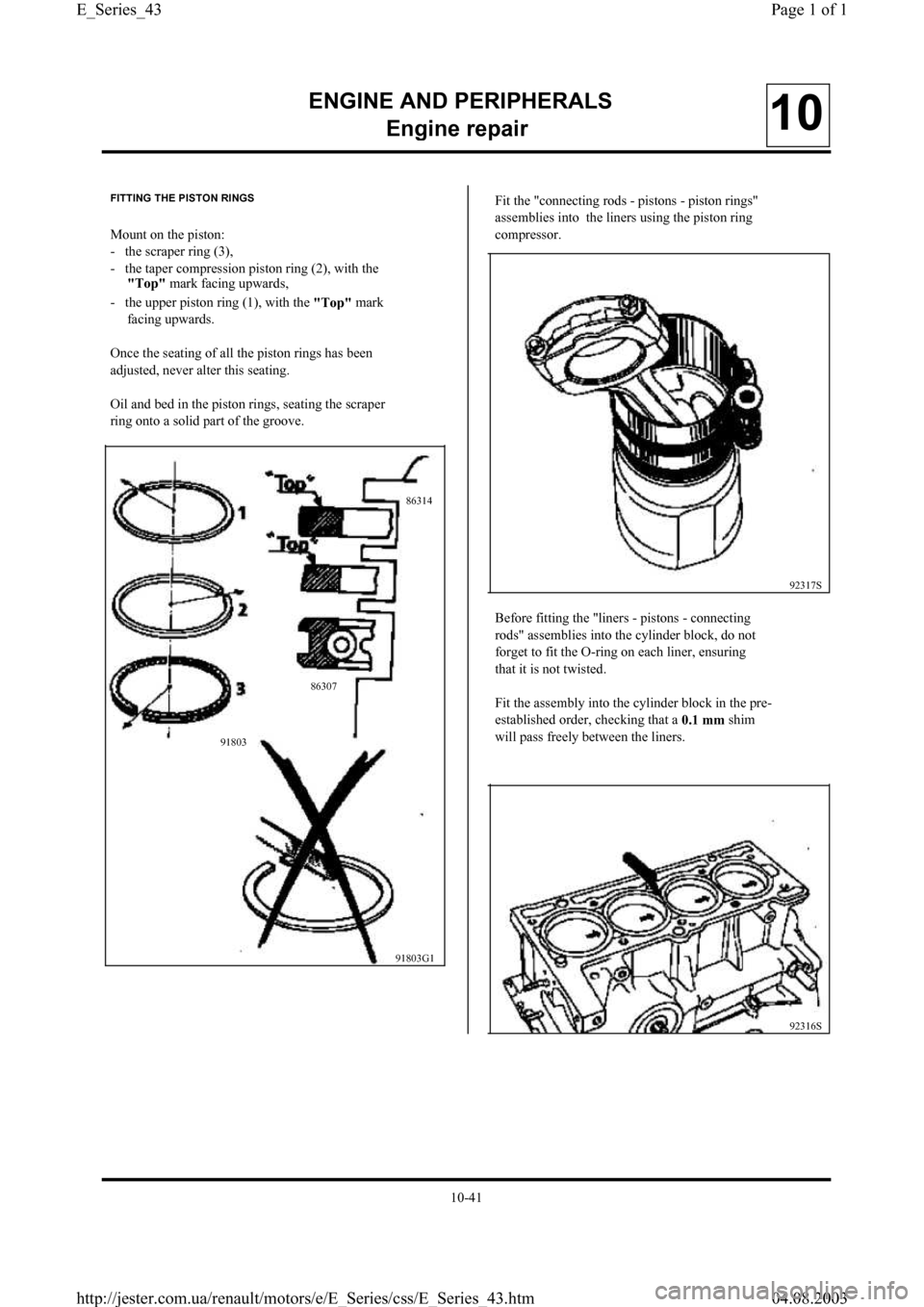

91803G1 FITTING THE PISTON RINGS

Mount on the piston:

- the scraper ring (3),

- the taper compression piston ring (2), with the

"To

p" mark facing upwards,

- the upper piston ring (1), with the

"To

p" mark

facing upwards.

Once the seating of all the piston rings has been

adjusted, never alter this seating.

Oil and bed in the piston rings, seating the scrape

r

ring onto a solid part of the groove.Fit the "connecting rods - pistons - piston rings"

assemblies into the liners using the piston ring

compressor.

Before fitting the "liners - pistons - connecting

rods" assemblies into the cylinder block, do no

t

forget to fit the O-ring on each liner, ensuring

that it is not twisted.

Fit the assembly into the cylinder block in the pre-

established order, checking that a

0.1 mm shim

will pass freely between the liners.

92316S 918038630786314

10-41

Page 1 of 1 E_Series_43

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_43.htm

Page 44 of 55

ENGINE AND PERIPHERALS

En

gine repair10

Immobilise the liners using tool

Mot. 588.

92062R

Shims of the following thicknesses (mm) are avai-

lable from the Parts Department:

2.80; 2.85; 2.90;

2.95.

Refit the connecting rod shells and tighten the

nuts to a torque value of

4.2 daN.m.

Check:

- the end float of the connecting rods,

- that the assembly is able to rotate properly. Fit the crankshaft and the end float shims.

Lubricate the crankpins and the main bearing

journals with engine oil.

Refit the crankshaft bearing shells.

Apply a thin layer of

RHODORSEAL 5661 on bea-

ring

N°

1 zone (K) and tighten the bolts to

2.5 daN.m , then angle tighten to

43°

± 6°.

Check the end floatof the crankshaft, which

should be between:

-

0.045 and 0.852 mmwith wear,

-

0.045 and 0.252 mmwithout wear.

92314S MOUNTING THE BEARING SHELLS

The connecting rod bearing shells are identical.

The crankshaft bearing shells are grooved on the

cylinder block side.

92315R

The upper shell of bearing

No. 5 is a special one

and is also grooved.

10-42

Page 1 of 1 E_Series_44

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_44.htm

Page 49 of 55

ENGINE AND PERIPHERALS

En

gine repair10

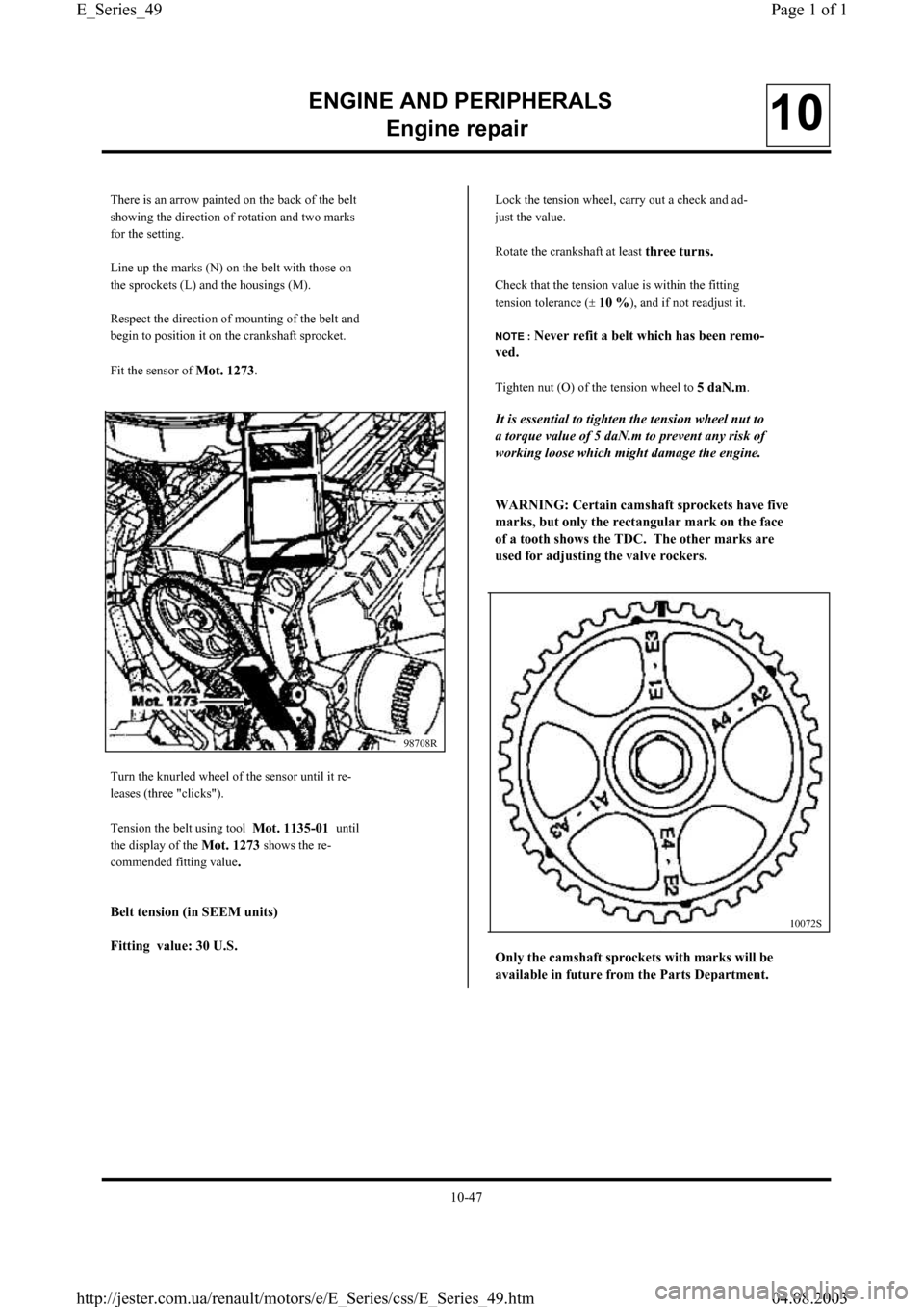

There is an arrow painted on the back of the belt

showing the direction of rotation and two marks

for the setting.

Line up the marks (N) on the belt with those on

the sprockets (L) and the housings (M).

Respect the direction of mounting of the belt and

begin to position it on the crankshaft sprocket.

Fit the sensor of

Mot. 1273.

98708R

Turn the knurled wheel of the sensor until it re-

leases (three "clicks").

Tension the belt using tool

Mot. 1135-01 until

the display of the

Mot. 1273 shows the re-

commended fitting value

.

Belt tension (in SEEM units)

Fitting value: 30 U.S.

Lock the tension wheel, carry out a check and ad-

just the value.

Rotate the crankshaft at least

three turns.

Check that the tension value is within the fitting

tension tolerance (

±10 %), and if not readjust it.

NOTE : Never refit a belt which has been remo-

ved.

Tighten nut (O) of the tension wheel to 5 daN.m.

It is essential to tighten the tension wheel nut to

a tor

que value of 5 daN.m to prevent any risk of

working loose which might damage the engine.

WARNING: Certain camshaft s

prockets have five

marks, but onl

y the rectangular mark on the face

of a tooth shows the TDC. The other marks are

used for ad

justing the valve rockers.

10072S

Only the camshaft sprockets with marks will be

available in future from the Parts De

partment.

10-47

Page 1 of 1 E_Series_49

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_49.htm

Page 51 of 55

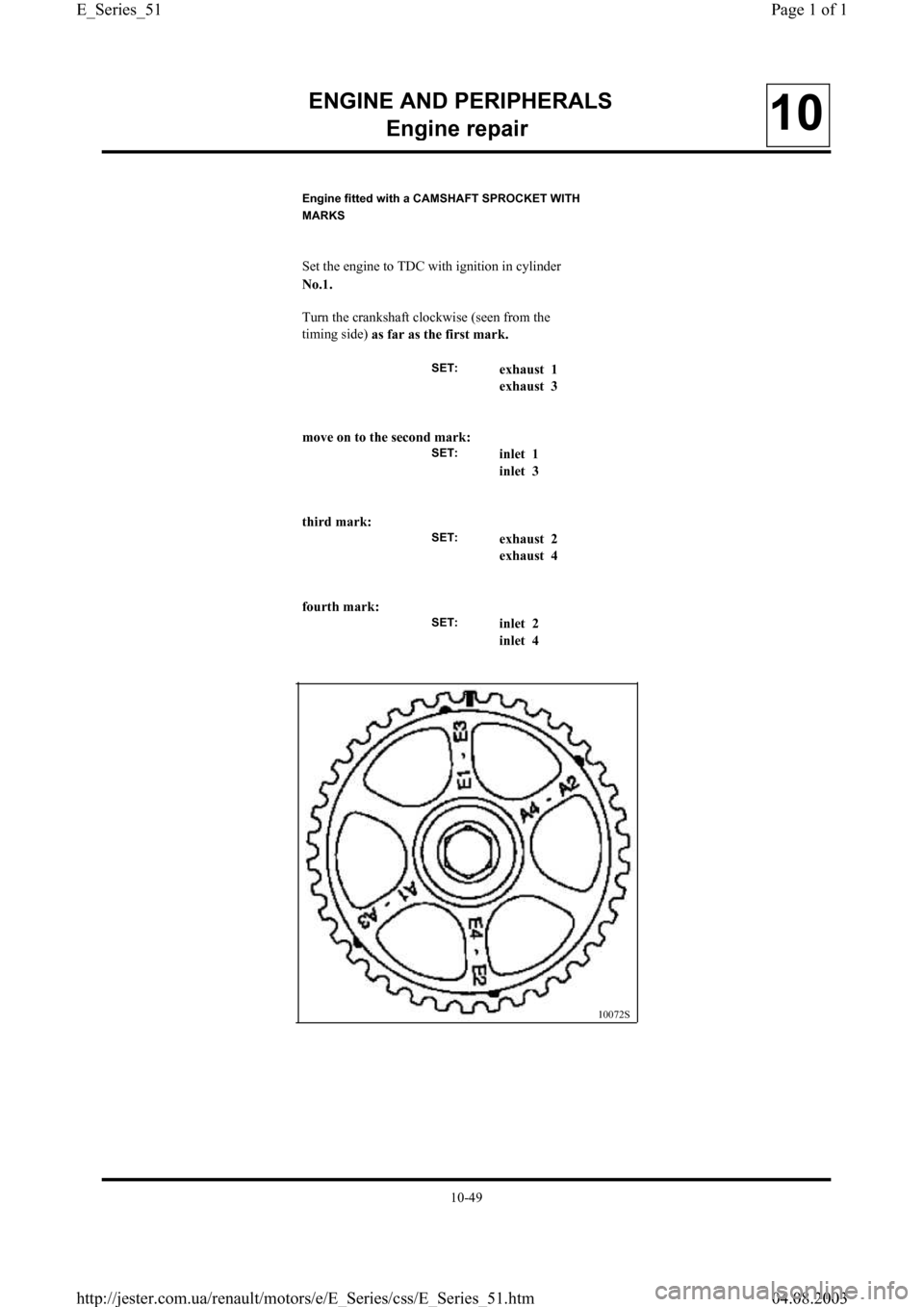

Engine fitted with a CAMSHAFT SPROCKET WITH

MARKS

Set the engine to TDC with ignition in cylinder

No.1.

Turn the crankshaft clockwise

(seen from the

timing side)

as far as the first mark.

SET:exhaust 1

exhaust 3

move on to the second mark:

SET:inlet 1

inlet 3

third mark:

SET:exhaust 2

exhaust 4

fourth mark:

SET:inlet 2

inlet 4

ENGINE AND PERIPHERALS

En

gine repair10

10072S

10-49

Page 1 of 1 E_Series_51

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_51.htm

Page 52 of 55

ENGINE AND PERIPHERALS

En

gine repair10

Refit:

- the cylinder head cover fitted with a new gas-

ket,

- the coolant pipe and the dipstick guide tube

with new seals,

- the timing cover,

- the crankshaft pulley tightening the bolt to

2 daN.m, then angle tighten to

68°

±6°,

- the inlet and exhaust manifolds, tightening the

nuts to

2.5 daN.m,

- the accessories belt or belts.

Tensionin

g process

Engine cold (ambient temperature).

Fit the new belt.

Position the sensor of the

Mot. 1273.

Turn the knurled wheel of the sensor until it re-

leases (three "clicks").

Tension the belt until the fitting value recommen-

ded on the next page is shown on the display of

the

Mot. 1273.

Lock the tension wheel, carry out a check and ad-

just the value.

Rotate the crankshaft

three turns.

Check that the tension value is within the fitting

tension tolerance, and if not readjust it.

NOTE : Never refit a belt which has been remo-

ved.

10-50

Page 1 of 1 E_Series_52

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_52.htm