torque RENAULT CLIO 1997 X57 / 1.G Petrol Engines Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: CLIO, Model: RENAULT CLIO 1997 X57 / 1.GPages: 55, PDF Size: 4.15 MB

Page 2 of 55

Contents

Pages

ENGINE AND PERIPHERALS

- Foreword

- Section view

- En

gine identification

- Section and ti

ghtening torques

- Lubrication circuit dia

gram

-

S

pecifications

Standard exchan

ge

- S

pecial tooling required

- Essential e

quipment

- Engine repair

Ex

ploded view of cylinder head

Ex

ploded view of cylinder block

10-1

10-2

10-3

10-5

10-8

10-10

10-20

10-21

10-24

10-25

10-25

10-34

10

Page 1 of 1 E_Series_2

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_2.htm

Page 3 of 55

ENGINE AND PERIPHERALS

Foreword

10

USE OF THE MANUAL

In this manual you will find three major chapters:

- specifications,

- removal of en

gine,

- reassembl

y of engine.

To repair a component on the vehicle refer to the

Workshop Repair Manual and Technical Notes.

UNITS OF MEASUREMENT

- All the dimensions are expressed in millimetres,

mm (unless otherwise indicated).

The tightening torques:

- in decaNewton metres daN.m

(reminder:

1 daN.m = 1.02 m.kg).

The tightening torques without tolerances

must be kept within

±10°.

- in degrees, the tightening torques without to-

lerances must be kept within

±3 %.

The pressures are in

bars.

10-1

Page 1 of 1 E_Series_3

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_3.htm

Page 7 of 55

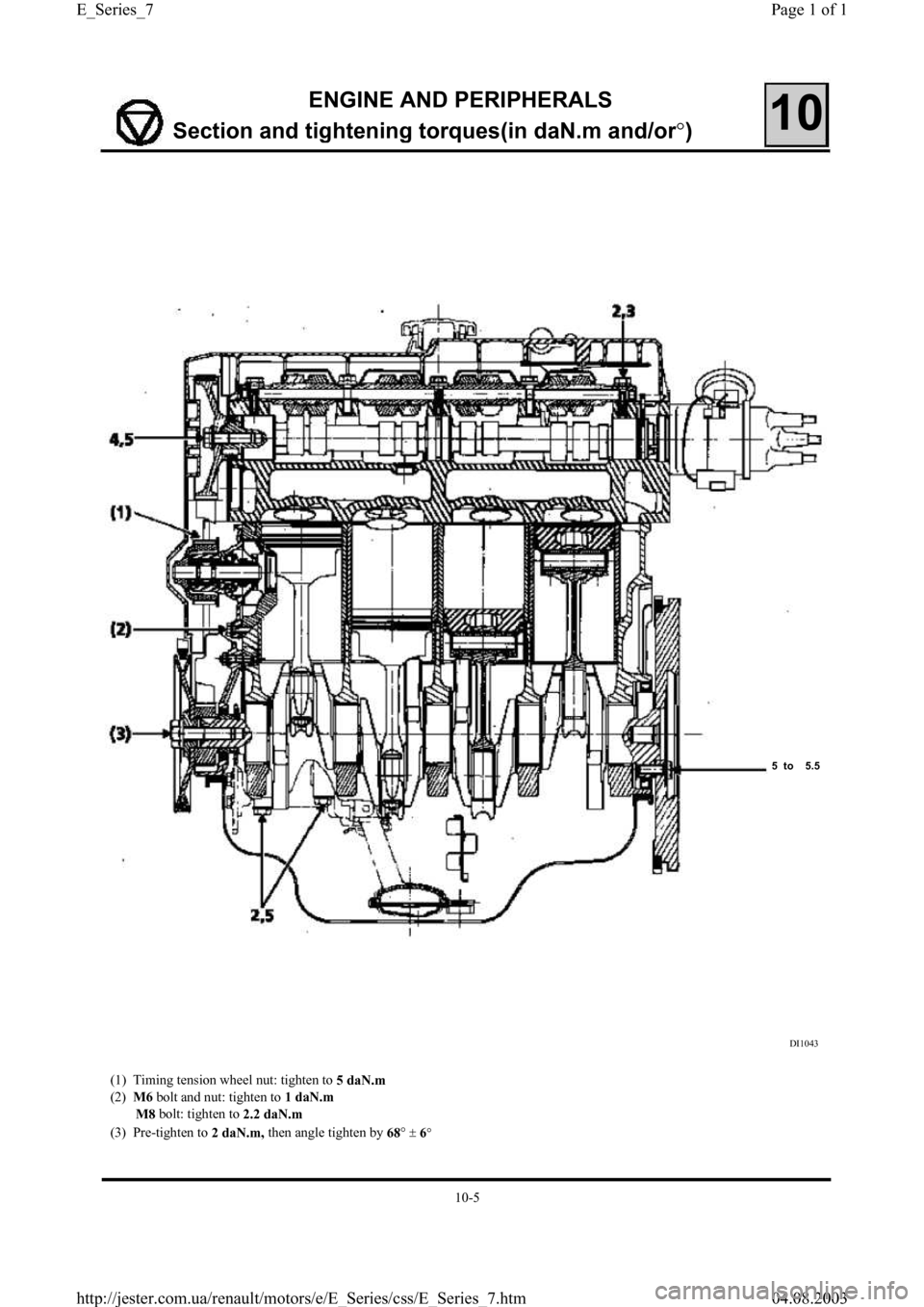

ENGINE AND PERIPHERALS

Section and ti

ghtening torques(in daN.m and/or°)10

(1) Timing tension wheel nut: tighten to

5 daN.m

(2)

M6

bolt and nut: tighten to

1 daN.m

M8

bolt: tighten to

2.2 daN.m

(3) Pre-tighten to

2 daN.m, then angle tighten by

68°

±6°

DI1043

5 to 5.5

10-5

Page 1 of 1 E_Series_7

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_7.htm

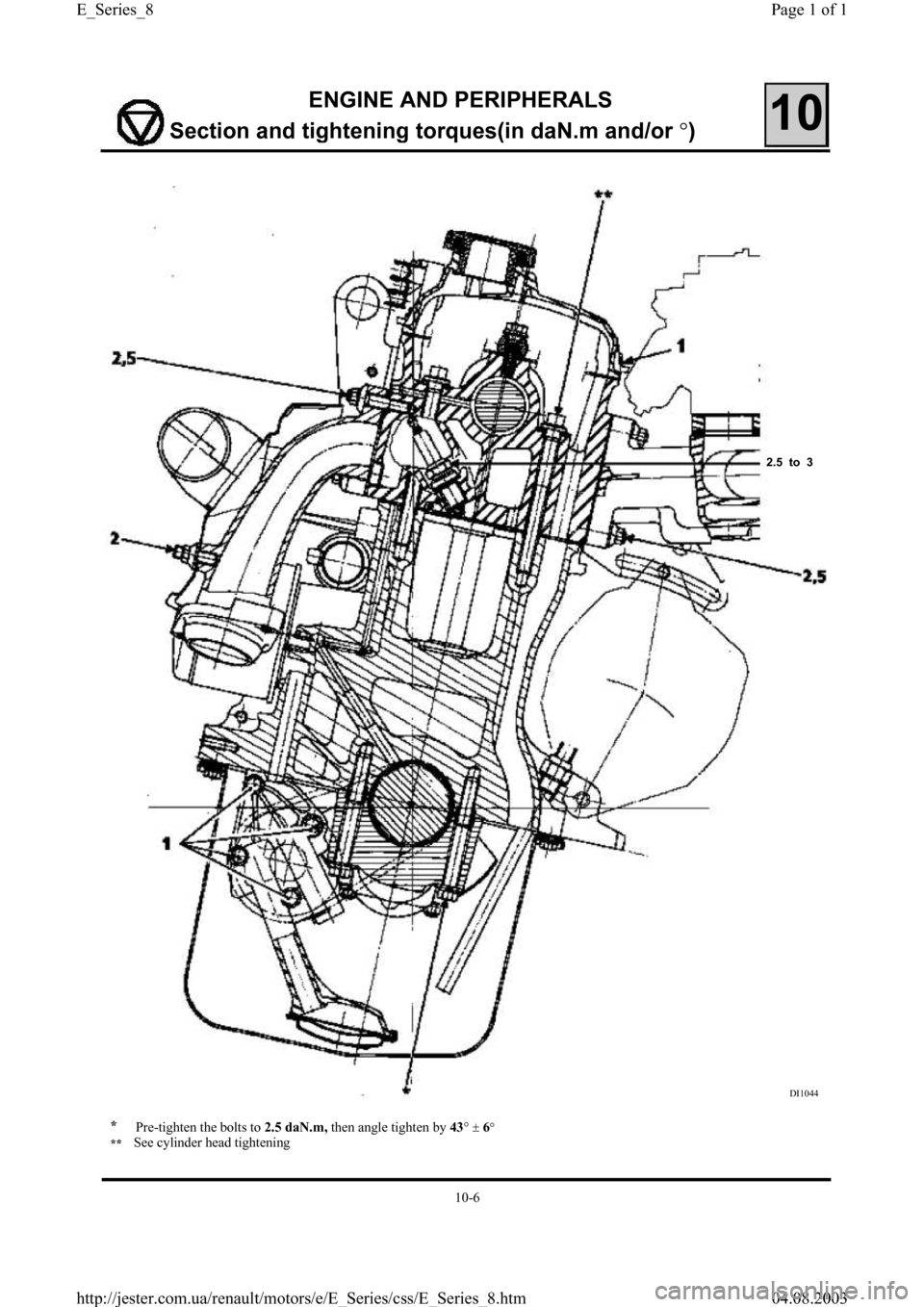

Page 8 of 55

ENGINE AND PERIPHERALS

Section and ti

ghtening torques(in daN.m and/or °)10

*

Pre-tighten the bolts to

2.5 daN.m, then angle tighten by

43°±6°

** See cylinder head tightening

DI1044

2.5 to 3

10-6

Page 1 of 1 E_Series_8

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_8.htm

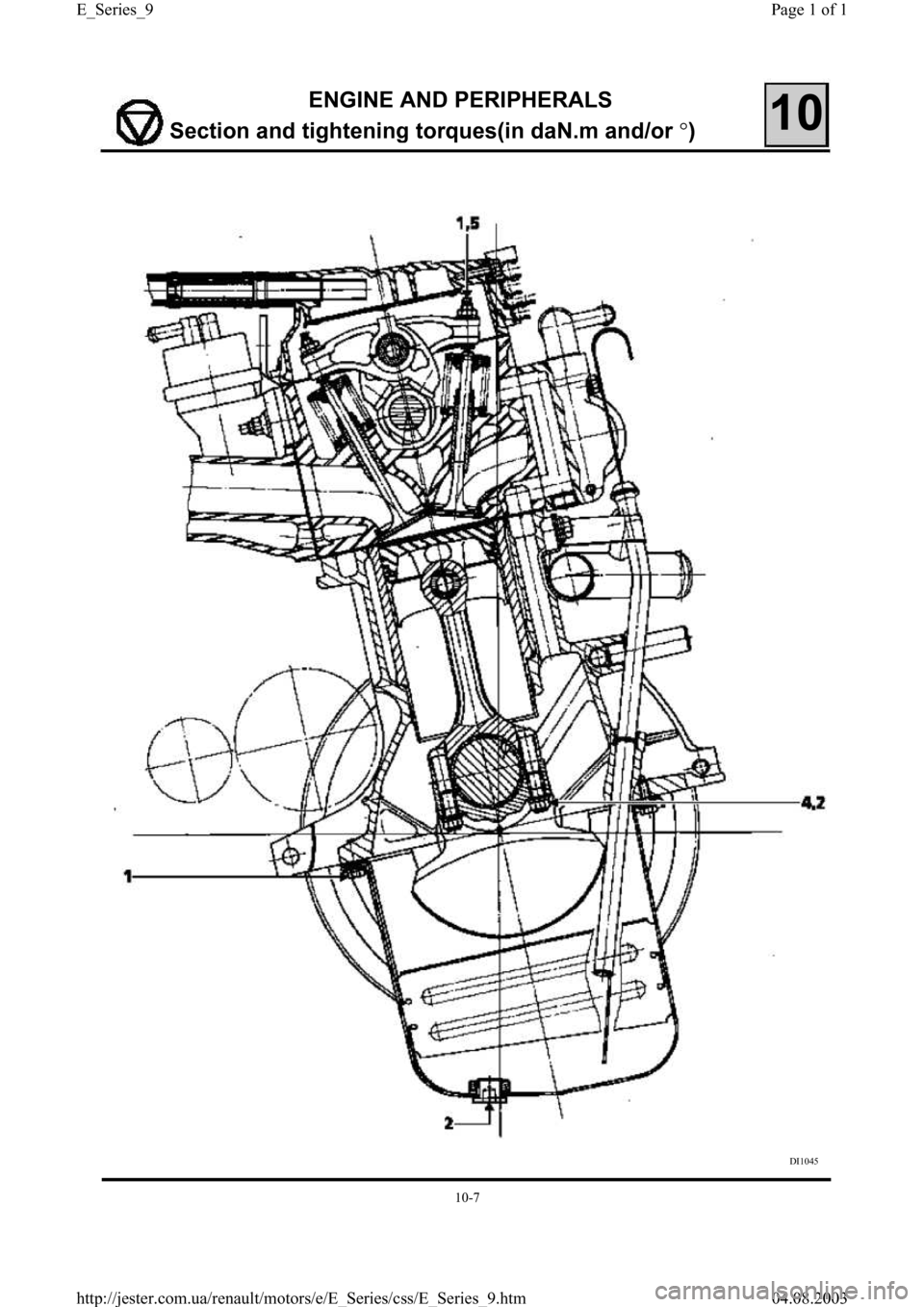

Page 9 of 55

ENGINE AND PERIPHERALS

Section and ti

ghtening torques(in daN.m and/or °)10

DI1045

10-7

Page 1 of 1 E_Series_9

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_9.htm

Page 13 of 55

ENGINE AND PERIPHERALS

S

pecifications10

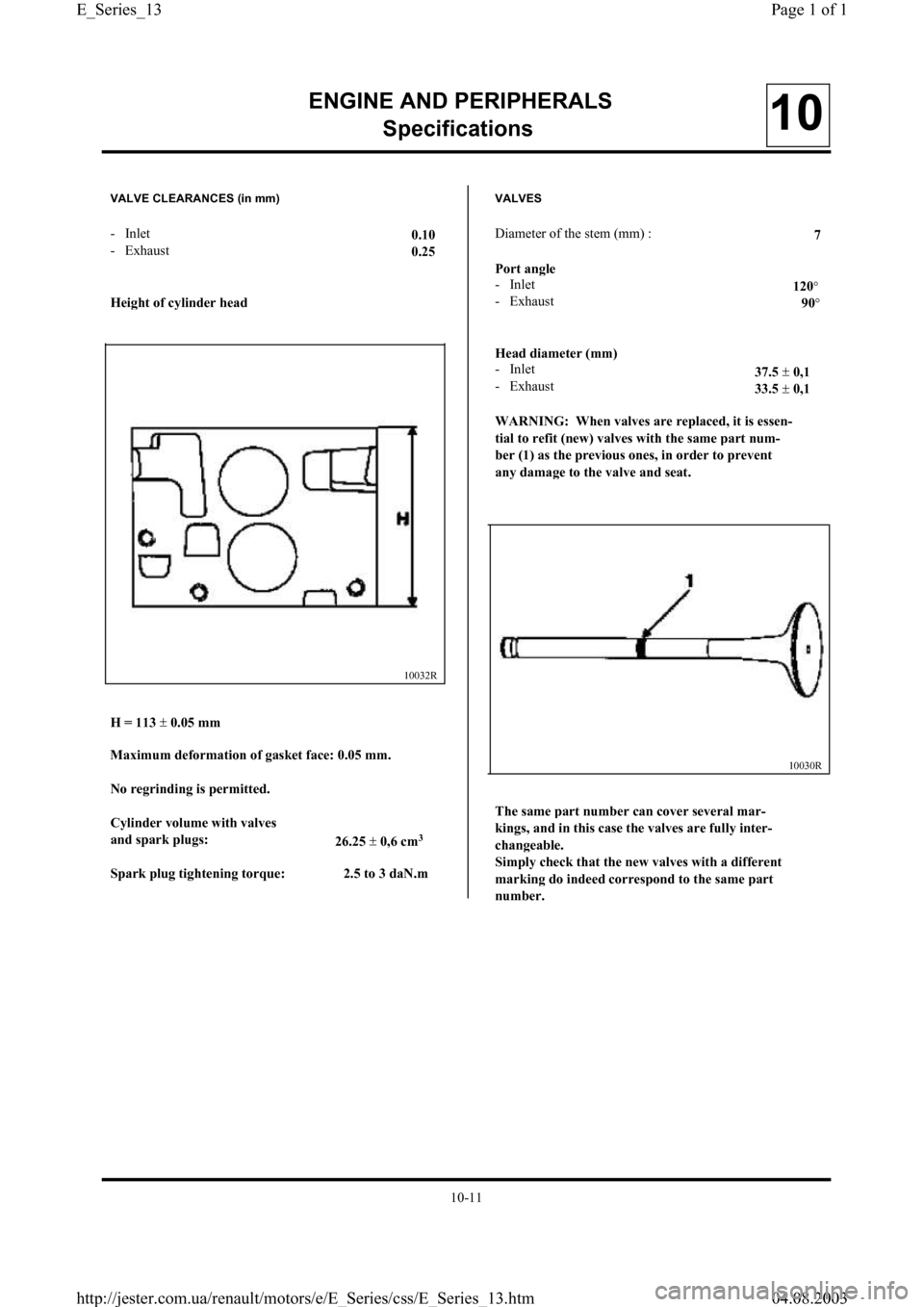

VALVE CLEARANCES (in mm)

- Inlet0.10

- Exhaus

t0.25

Hei

ght of cylinder head

10032R

H = 113 ±

0.05 mm

Maximum deformation of

gasket face: 0.05 mm.

No re

grinding is permitted.

C

ylinder volume with valves

and s

park plugs:

26.25 ±

0,6 cm3

Spark plug tightening torque: 2.5 to 3 daN.m

VALVES

Diameter of the stem (mm) :

7

Port an

gle

- Inle

t120°- Exhaust90°

Head diameter (mm)

- Inlet37.5 ±

0,1

- Exhaust33.5 ±

0,1

WARNING: When valves are re

placed, it is essen-

tial to refit

(new) valves with the same part num-

ber

(1) as the previous ones, in order to prevent

an

y damage to the valve and seat.

10030R

The same part number can cover several mar-

kin

gs, and in this case the valves are fully inter-

chan

geable.

Sim

ply check that the new valves with a different

markin

g do indeed correspond to the same part

number.

10-11

Page 1 of 1 E_Series_13

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_13.htm

Page 21 of 55

ENGINE AND PERIPHERALS

S

pecifications10

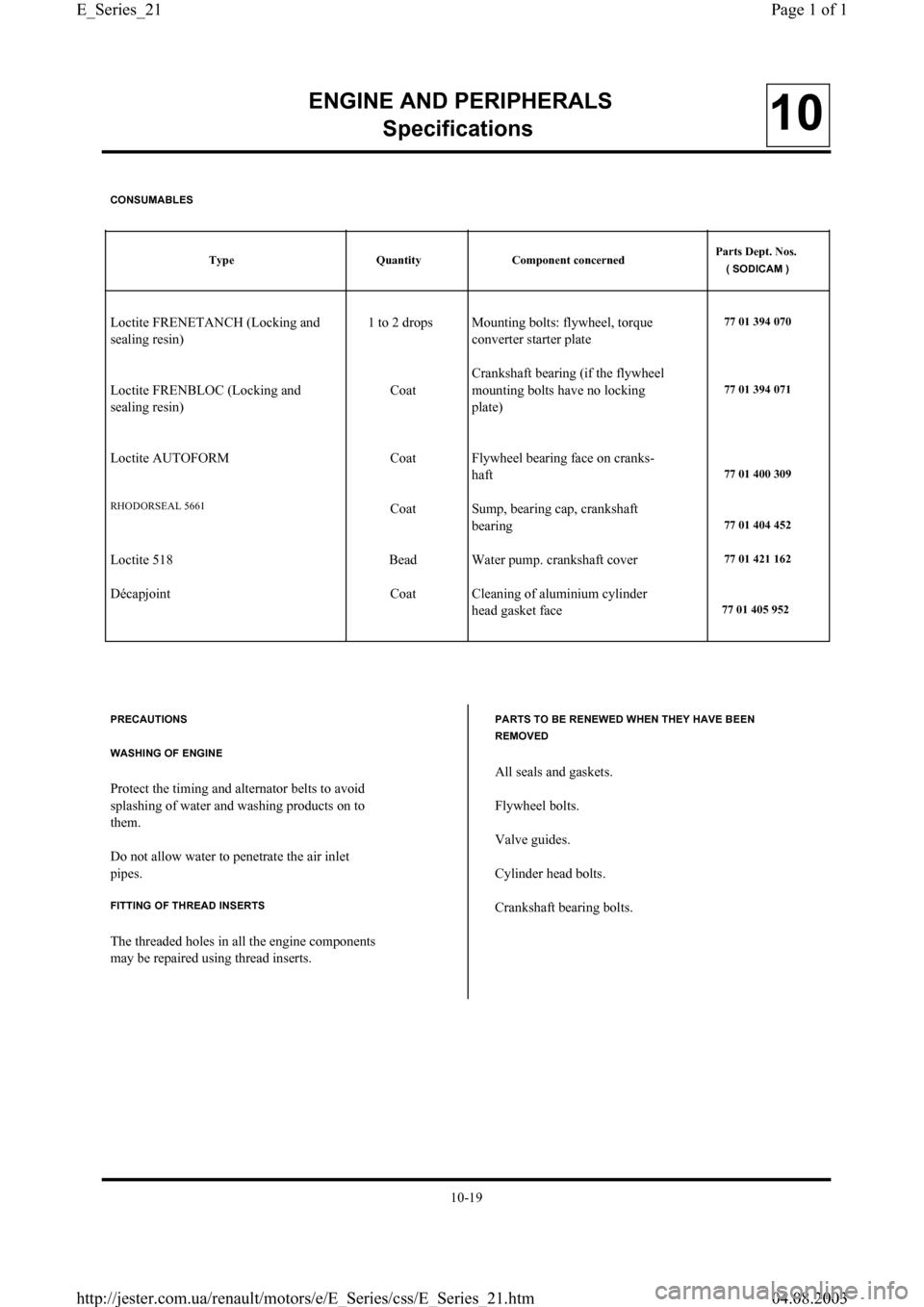

CONSUMABLES

PARTS TO BE RENEWED WHEN THEY HAVE BEEN

REMOVED

All seals and gaskets.

Flywheel bolts.

Valve guides.

Cylinder head bolts.

Crankshaft bearing bolts.

PRECAUTIONS

WASHING OF ENGINE

Protect the timing and alternator belts to avoid

splashing of water and washing products on to

them.

Do not allow water to penetrate the air inle

t

pipes.

FITTING OF THREAD INSERTS

The threaded holes in all the engine components

may be repaired using thread inserts.

Type QuantityComponent concernedParts Dept. Nos.

( SODICAM )

Loctite FRENETANCH (Locking and

sealing resin)

Loctite FRENBLOC (Locking and

sealing resin)

Loctite AUTOFORM

RHODORSEAL 5661

Loctite 518

Décapjoin

t

1 to 2 drops

Coa

t

Coat

Coat

Bead

Coa

t

Mounting bolts: flywheel, torque

converter starter plate

Crankshaft bearing (if the flywheel

mounting bolts have no locking

plate)

Flywheel bearing face on cranks-

haf

t

Sump, bearing cap, crankshaft

bearing

Water pump. crankshaft cove

r

Cleaning of aluminium cylinder

head gasket face

77 01 394 070

77 01 394 071

77 01 400 309

77 01 404 452

77 01 421 162

77 01 405 952

10-19

Page 1 of 1 E_Series_21

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_21.htm

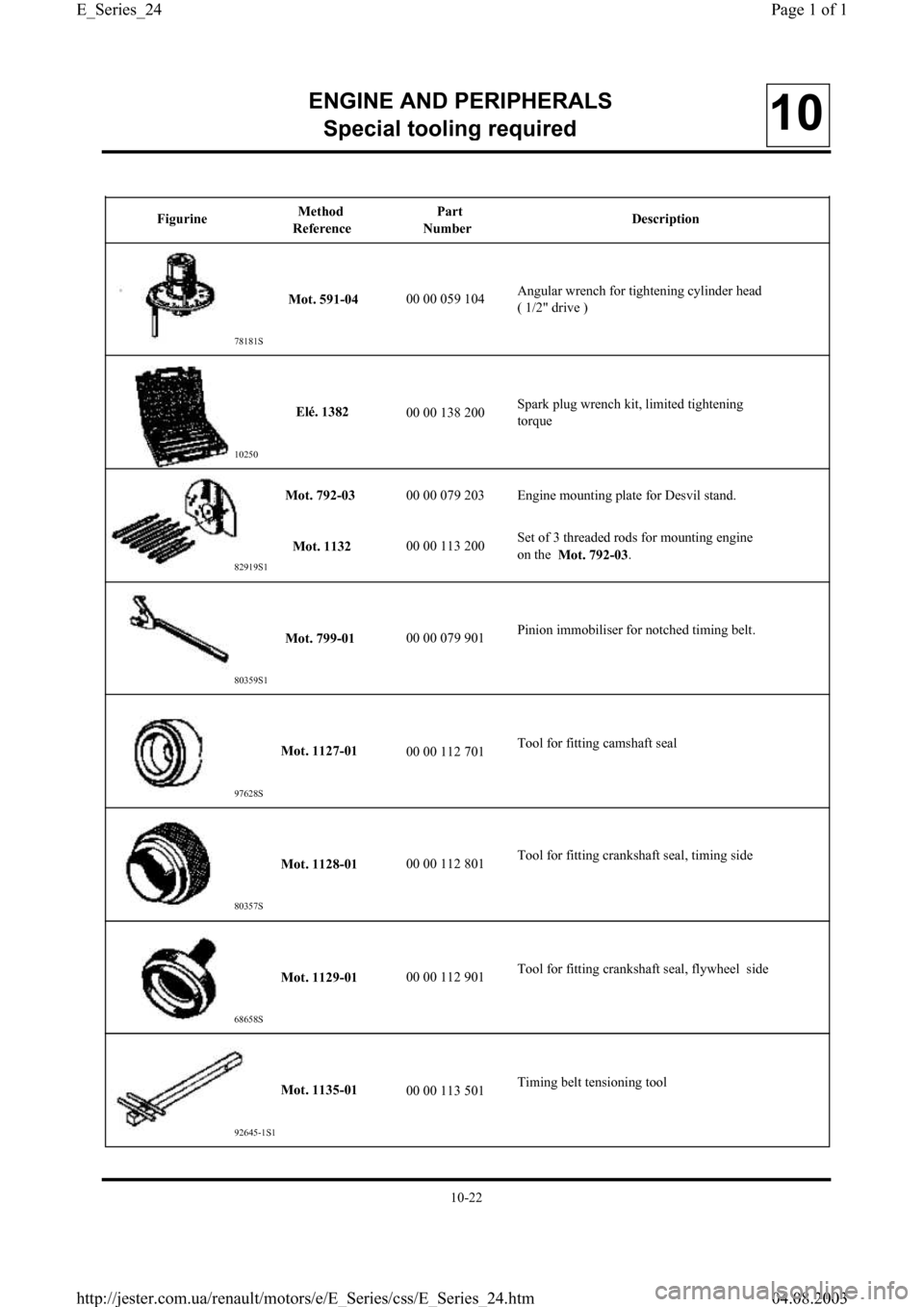

Page 24 of 55

Mot. 792-03

Mot. 1132 Fi

gurineMethod

ReferencePart

NumberDescription

ENGINE AND PERIPHERALS

S

pecial tooling required10

Mot. 591-0400 00 059 104

Elé. 1382

00 00 138 200

78181S

10250

82919S1

80359S1

97628S

Mot. 799-0100 00 079 901

80357S

Mot. 1128-0100 00 112 801Tool for fitting crankshaft seal, timing side Angular wrench for tightening cylinder head

( 1/2" drive )

Spark plug wrench kit, limited tightening

torque

Pinion immobiliser for notched timing belt.

68658S

Mot. 1129-0100 00 112 901Tool for fitting crankshaft seal, flywheel side

92645-1S1

Mot. 1135-01

00 00 113 501Timing belt tensioning tool En

gine mounting plate for Desvil stand.

Set of 3 threaded rods for mounting engine

on the

Mot. 792-03. 00 00 079 203

00 00 113 200

Mot. 1127-01

00 00 112 701Tool for fitting camshaft seal

10-22

Page 1 of 1 E_Series_24

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_24.htm

Page 35 of 55

ENGINE AND PERIPHERALS

En

gine repair10

- the distributor with the wiring loom,

- the fuel pump (if fitted) with new seals,

- the thermostat support, making it tight with

Loctite 518.

The bead (H) should be

0.6 to 1 mm wide and

should be applied as shown in the diagram be-

low,

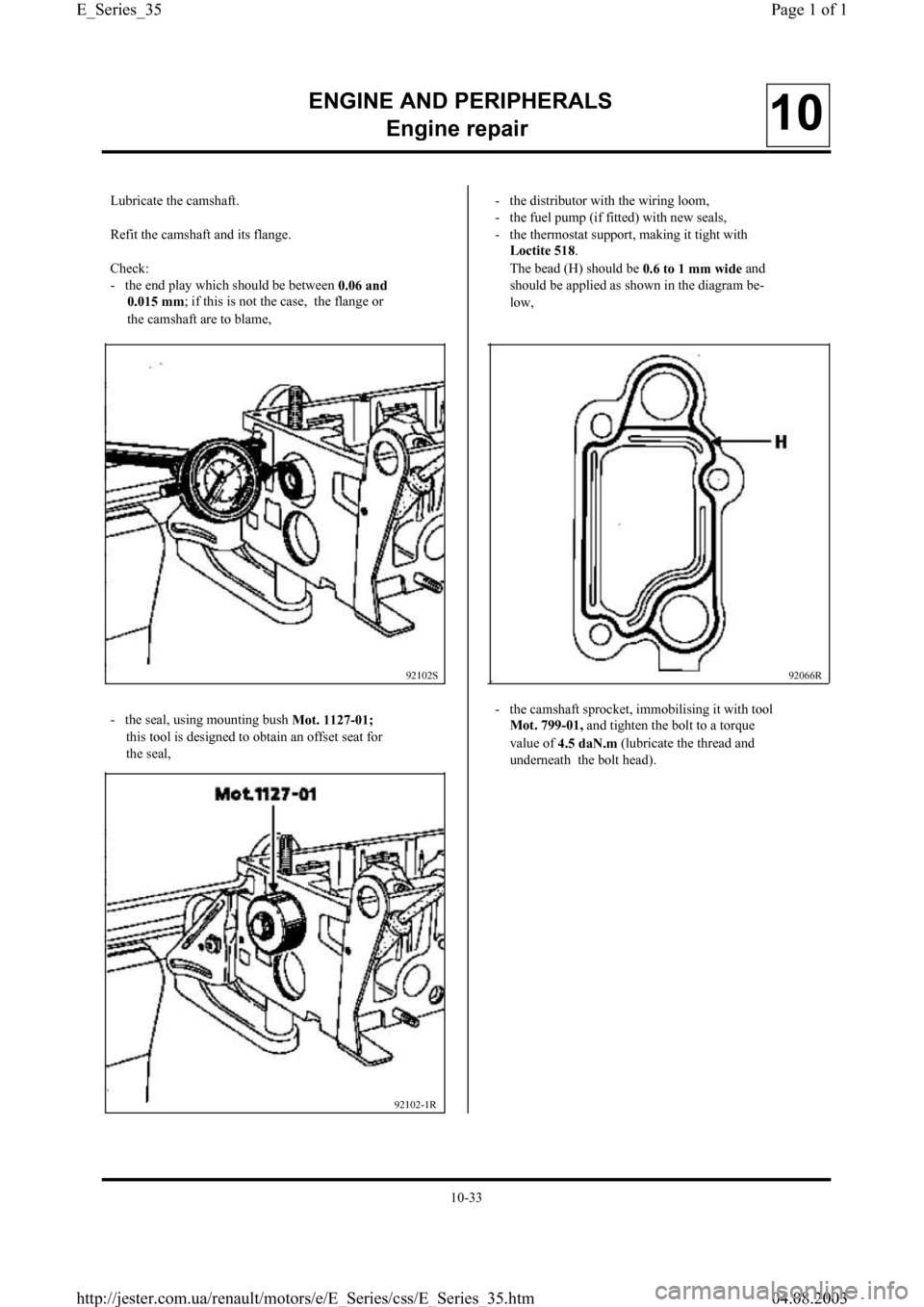

- the seal, using mounting bush

Mot. 1127-01;

this tool is designed to obtain an offset seat fo

r

the seal,

92102S92066R

Lubricate the camshaft.

Refit the camshaft and its flange.

Check:

- the end play which should be between

0.06 and

0.015 mm; if this is not the case, the flange o

r

the camshaft are to blame,

92102-1R

- the camshaft sprocket, immobilising it with tool

Mot. 799-01, and tighten the bolt to a torque

value of

4.5 daN.m (lubricate the thread an

d

underneath the bolt head).

10-33

Page 1 of 1 E_Series_35

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_35.htm

Page 44 of 55

ENGINE AND PERIPHERALS

En

gine repair10

Immobilise the liners using tool

Mot. 588.

92062R

Shims of the following thicknesses (mm) are avai-

lable from the Parts Department:

2.80; 2.85; 2.90;

2.95.

Refit the connecting rod shells and tighten the

nuts to a torque value of

4.2 daN.m.

Check:

- the end float of the connecting rods,

- that the assembly is able to rotate properly. Fit the crankshaft and the end float shims.

Lubricate the crankpins and the main bearing

journals with engine oil.

Refit the crankshaft bearing shells.

Apply a thin layer of

RHODORSEAL 5661 on bea-

ring

N°

1 zone (K) and tighten the bolts to

2.5 daN.m , then angle tighten to

43°

± 6°.

Check the end floatof the crankshaft, which

should be between:

-

0.045 and 0.852 mmwith wear,

-

0.045 and 0.252 mmwithout wear.

92314S MOUNTING THE BEARING SHELLS

The connecting rod bearing shells are identical.

The crankshaft bearing shells are grooved on the

cylinder block side.

92315R

The upper shell of bearing

No. 5 is a special one

and is also grooved.

10-42

Page 1 of 1 E_Series_44

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_44.htm