torque RENAULT CLIO 1997 X57 / 1.G Petrol Engines User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: CLIO, Model: RENAULT CLIO 1997 X57 / 1.GPages: 55, PDF Size: 4.15 MB

Page 45 of 55

ENGINE AND PERIPHERALS

En

gine repair10

Fit:

- the oil pump, checking that the centring dowls

are present, and tighten to a torque value of

2.5 daN.m,

- the two sprockets and chain of the oil pump,

and tighten the three bolts mounting the

sprocket to the hub to

1 daN.m,

- the crankshaft end cover, sealing it with

Loctite

518.

The bead (H) should be

0.6 to 1 mm wide and

should be applied as shown in the diagram be-

low. - the crankshaft seal (bearing No.1), using tool

Mot. 1129-01; this tool is designed to ensure an

offset seal bearing surface. Lubricate the lip

and the outside of the seal.

92319R

92067R

-the crankshaft end seal, using tool

Mot. 1128-

01; lubricate the lip and the outside diamete

r

of the seal.

Turn over the s

pacer if the old seal has marked

the bearin

g surface.

92318R

10-43

Page 1 of 1 E_Series_45

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_45.htm

Page 46 of 55

ENGINE AND PERIPHERALS

En

gine repair10

99179R1

Refit the sump and tighten to a torque value of

1 daN.m.

NOTE : A tight seal for the sump can only be ob-

tained using the special seal supplied by the afte

r-

sales service, except for engine

E7J 764 in which a

tight seal is achieved by using

RHODOR-SEAL

5661. Bead (D) should be

3 mm wide.

Do not forget to replace the two "half-moon"

seals at (A) with new ones.

Coat the flywheel bearing surface on the cranks-

haft with

AUTOFORM Loctite.

Fit the flywheel or the converter plate and immo-

bilise it with the toothed segment

Mot. 582-01.

Apply a drop of

FRENETANCH Loctite to the

bolts and tighten them to

5 - 5.5 daN.m.

Centre the clutch disc and secure the mechanism.

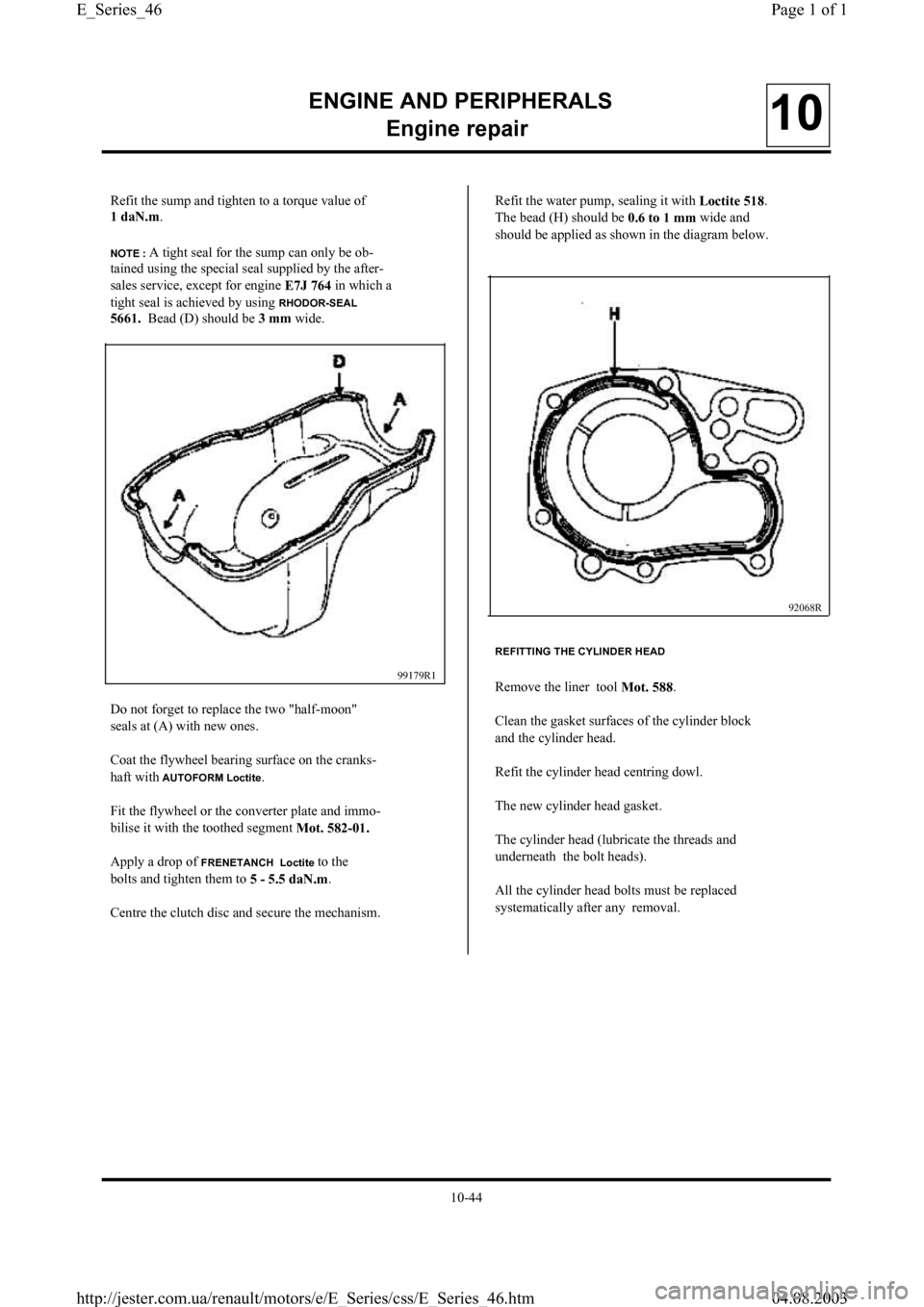

92068R

Refit the water pump, sealing it with

Loctite 518.

The bead (H) should be

0.6 to 1 mm wide and

should be applied as shown in the diagram below.

REFITTING THE CYLINDER HEAD

Remove the liner tool

Mot. 588.

Clean the gasket surfaces of the cylinder bloc

k

and the cylinder head.

Refit the cylinder head centring dowl.

The new cylinder head gasket.

The cylinder head (lubricate the threads and

underneath the bolt heads).

All the cylinder head bolts must be replaced

systematically after any removal.

10-44

Page 1 of 1 E_Series_46

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_46.htm

Page 47 of 55

ENGINE AND PERIPHERALS

En

gine repair10

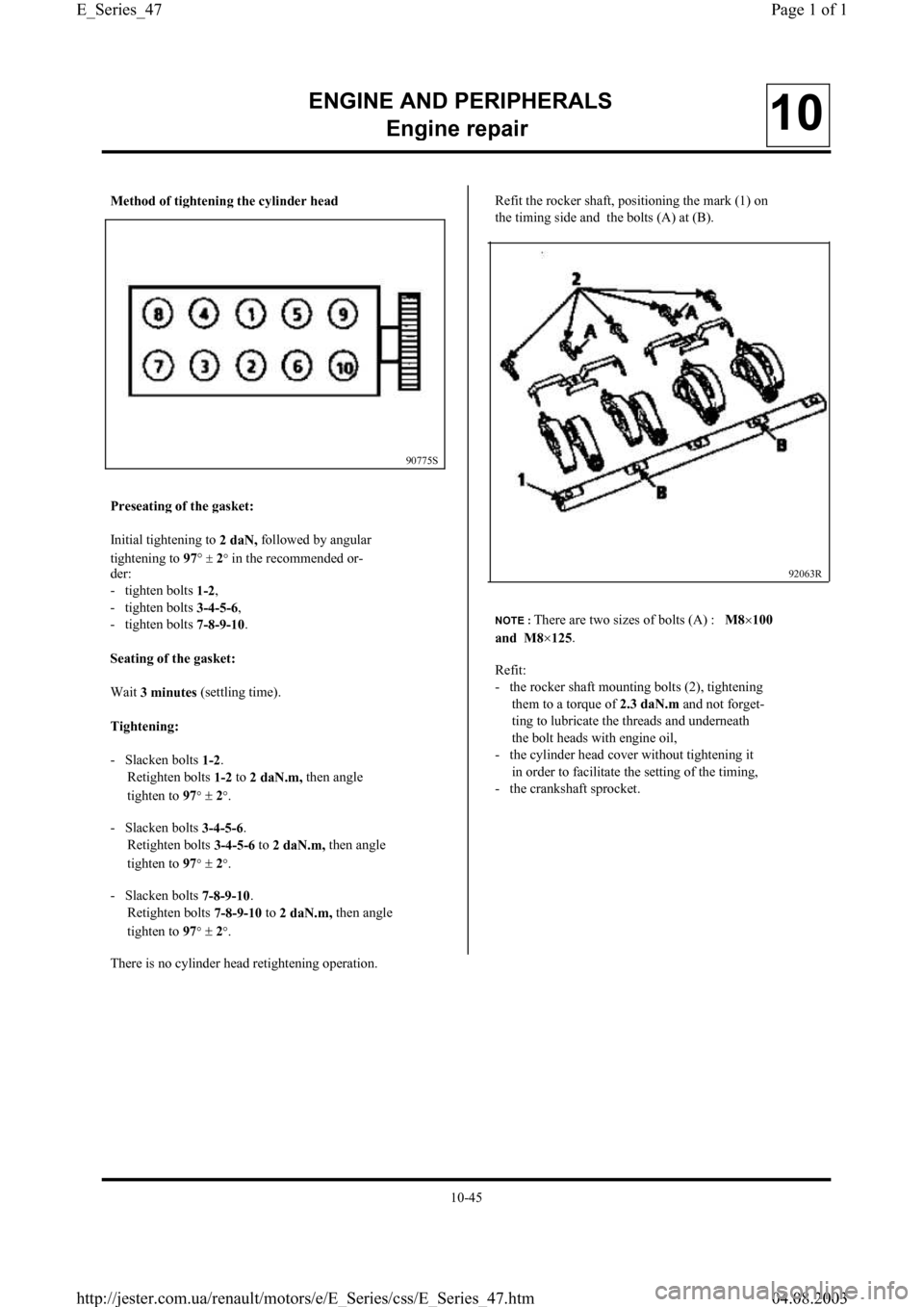

Method of tightening the cylinder head

90775S

Preseating of the gasket:

Initial tightening to

2 daN, followed by angula

r

tightening to

97°

± 2° in the recommended or-

der:

- tighten bolts

1-2,

- tighten bolts

3-4-5-6,

- tighten bolts

7-8-9-10.

Seatin

g of the gasket:

Wait

3 minutes (settling time).

Ti

ghtening:

- Slacken bolts

1-2.

Retighten bolts

1-2 to

2 daN.m, then angle

tighten to

97

° ±

2°.

- Slacken bolts

3-4-5-6.

Retighten bolts

3-4-5-6 to

2 daN.m, then angle

tighten to

97

° ±

2°.

- Slacken bolts

7-8-9-10.

Retighten bolts

7-8-9-10 to

2 daN.m, then angle

tighten to

97

° ±

2°.

There is no cylinder head retightening operation.Refit the rocker shaft, positioning the mark (1) on

the timing side and the bolts (A) at (B).

92063R

NOTE :

There are two sizes of bolts (A) :

M8×

100

and M8×

125.

Refit:

- the rocker shaft mounting bolts (2), tightening

them to a torque of

2.3 daN.m and not forge

t-

ting to lubricate the threads and underneath

the bolt heads with engine oil,

- the cylinder head cover without tightening i

t

in order to facilitate the setting of the timing,

- the crankshaft sprocket.

10-45

Page 1 of 1 E_Series_47

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_47.htm