check engine RENAULT CLIO 2012 X85 / 3.G Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2012, Model line: CLIO, Model: RENAULT CLIO 2012 X85 / 3.GPages: 268, PDF Size: 8.73 MB

Page 184 of 268

Downloaded from www.Manualslib.com manuals search engine levels .................................................... (up to the end of the DU)

engine coolant ....................................................... (current page)

tanks and reservoirs coolant ............................................................. (current page)

levels: coolant ............................................................. (current page)

4.8

ENG_UD19908_3

Niveau / Filtres (X85 - B85 - C85 - S85 - K85 - Renault)

ENG_NU_853-7_BCSK85_Renault_4

Jaune NoirNoir texte

Frequency of checking coolant level

Check the coolant level regularly

(very severe damage is likely to be

caused to the engine if it runs out of

coolant).

If the level needs to be topped up, only

use products approved by our Technical

Department which ensure:

– protection against freezing;

– an anti-corrosion protection for the

cooling system.

Levels

engine coolant

Consult your approved dealer at

once if you notice an abnormal or

repeated drop in any of the fluid

levels.

No operations should be

carried out on the cooling

circuit when the engine is

hot.

Risk of burns.

Replacement interval

Refer to the Maintenance Service

Booklet for your vehicle.

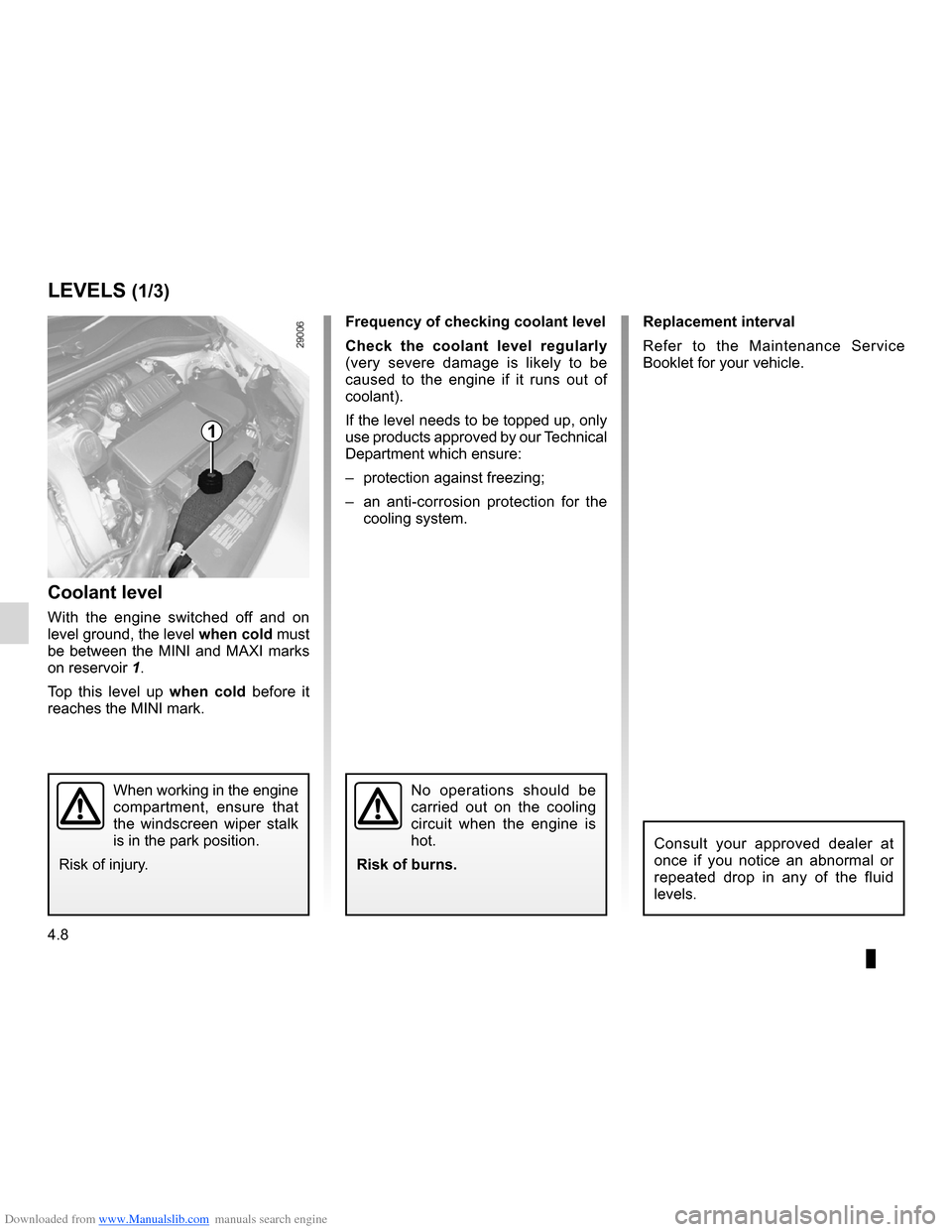

Coolant level

With the engine switched off and on

level ground, the level when cold must

be between the MINI and MAXI marks

on reservoir 1.

Top this level up when cold before it

reaches the MINI mark.

LEVELS (1/3)

1

When working in the engine

compartment, ensure that

the windscreen wiper stalk

is in the park position.

Risk of injury.

Page 185 of 268

Downloaded from www.Manualslib.com manuals search engine brake fluid .............................................................. (current page)

levels: brake fluid ........................................................ (current page)

tanks and reservoirs brake fluid ........................................................ (current page)

JauneNoirNoir texte

4.9

ENG_UD19908_3

Niveau / Filtres (X85 - B85 - C85 - S85 - K85 - Renault)

ENG_NU_853-7_BCSK85_Renault_4

brake fluid

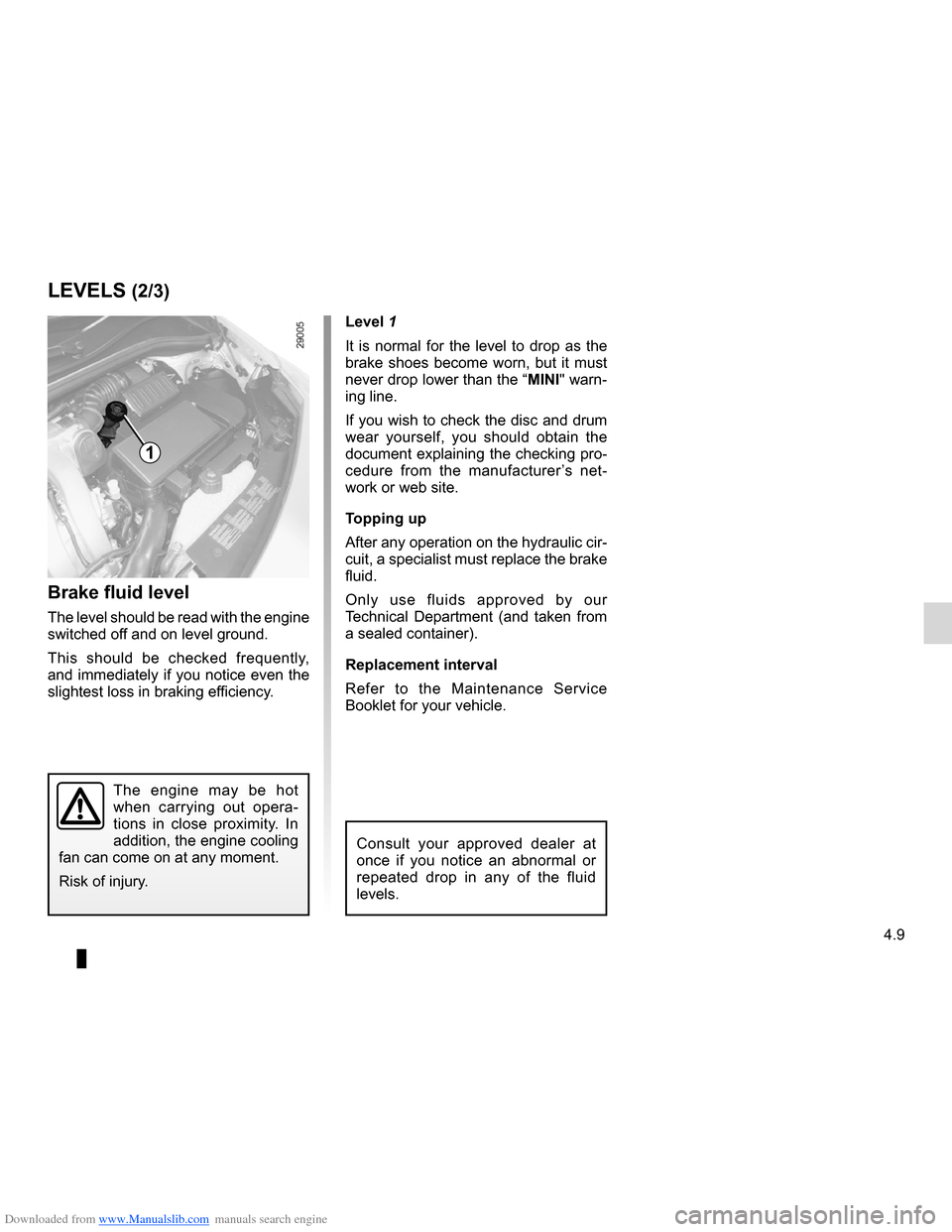

Level 1

It is normal for the level to drop as the

brake shoes become worn, but it must

never drop lower than the “MINI" warn-

ing line.

If you wish to check the disc and drum

wear yourself, you should obtain the

document explaining the checking pro-

cedure from the manufacturer ’s net -

work or web site.

Topping up

After any operation on the hydraulic cir-

cuit, a specialist must replace the brake

fluid.

Only use fluids approved by our

Technical Department (and taken from

a sealed container).

Replacement interval

Refer to the Maintenance Service

Booklet for your vehicle.

Brake fluid level

The level should be read with the engine

switched off and on level ground.

This should be checked frequently,

and immediately if you notice even the

slightest loss in braking efficiency.

LEVELS (2/3)

1

The engine may be hot

when carrying out opera -

tions in close proximity. In

addition, the engine cooling

fan can come on at any moment.

Risk of injury.

Consult your approved dealer at

once if you notice an abnormal or

repeated drop in any of the fluid

levels.

Page 190 of 268

Downloaded from www.Manualslib.com manuals search engine 4.14

ENG_UD25392_1

Entretien de la carrosserie (X95 - J95 - R95 - Renault)

ENG_NU_853-7_BCSK85_Renault_4

– bird droppings , which cause a

chemical reaction with the paint that

rapidly discolours paintwork and

may even cause the paint to peel

off;

Wash the vehicle immediately to

remove these marks since it is im -

possible to remove them by polish -

ing;

– salt, particularly in the wheel arches

and underneath the body after driv -

ing in areas where the roads have

been gritted.

Using a roller type car wash

Return the windscreen wiper stalk to

the Park position (refer to the informa-

tion on the “Windscreen washer, wiper”

in Section 1). Check the mounting of

external accessories, additional lights

and mirrors, and ensure that the wiper

blades are secured with adhesive tape.

Remove the radio aerial mast if your

vehicle is fitted with this equipment.

Remember to remove the tape and refit

the antenna after washing.y ou should

Observe the vehicle stopping distances

when driving on gravelled surfaces to

prevent paint damage.

Repair, or have repaired quickly, areas

where the paint has been damaged, to

prevent corrosion spreading.

Remember to visit the body shop pe -

riodically in order to maintain your

anti-corrosion warranty. Refer to the

Maintenance Service Booklet.

Respect local regulations about wash -

ing vehicles (e.g. do not wash your ve-

hicle on a public highway).

Wash your car frequently, with the

engine off, with cleaning products rec-

ommended by the manufacturer (never

use abrasive products). Rinse thor -

oughly beforehand with a jet:

– spots of tree resin and industrial

grime;

– mud in the wheel arches and under -

neath the body which forms damp

patches;

BODyWORK MAINTENANCE (2/2)

If it is necessary to clean mechani -

cal components, hinges, etc., spray

them with products approved by our

Technical Department to protect them

after they have been cleaned.

Cleaning the headlights

As the headlights are made of plastic

“glass”, use a soft cloth or cotton wool

to clean them. If this does not clean

them properly, moisten the cloth with

soapy water, then wipe clean with a soft

damp cloth or cotton wool.

Finally, carefully dry off with a soft dry

cloth.

Cleaning products containing alco -

hol must not be used.

We have selected special products

to care for your vehicle and you can

obtain these from the manufactur -

er’s accessory outlets.

Page 194 of 268

Downloaded from www.Manualslib.com manuals search engine puncture................................................ (up to the end of the DU)

emergency spare wheel ....................... (up to the end of the DU)

5.2

ENG_UD24923_2

Roue de secours (X85 - B85 - C85 - S85 - K85 - Renault)

ENG_NU_853-7_BCSK85_Renault_5

Jaune NoirNoir texte

In case of puncture

Depending on the vehicle, a tyre infla-

tion kit or emergency spare wheel is

provided (refer to the following pages).

If the emergency spare wheel has been stored for several years, have it

checked by your Dealer to ensure that it is safe to use.

Vehicle fitted with an emergency spare wheel that differs from the

other wheels:

– Never fit more than one emergency spare wheel to the same vehicle.

– When this is fitted to the vehicle, which must only be a temporary measure, the

driving speed must not exceed the speed indicated on the label on the wh\

eel.

– Replace the emergency spare wheel as soon as possible with a wheel identi -

cal to the original one.

– Fitting an emergency spare wheel may alter the way the vehicle usually runs.

Avoid sudden acceleration or deceleration and reduce your speed when cor-

nering.

– Fitting the damaged wheel into the emergency spare wheel housing will reduce

the vehicle’s ground clearance: avoid driving over any obstacles.

– If you need to use snow chains, fit the emergency spare wheel to the rear axle

and check the tyre pressure.

PUNCTURE, EMERGENCY SPARE WHEEL (1/4)

Page 197 of 268

Downloaded from www.Manualslib.com manuals search engine JauneNoirNoir texte

5.5

ENG_UD24923_2

Roue de secours (X85 - B85 - C85 - S85 - K85 - Renault)

ENG_NU_853-7_BCSK85_Renault_5

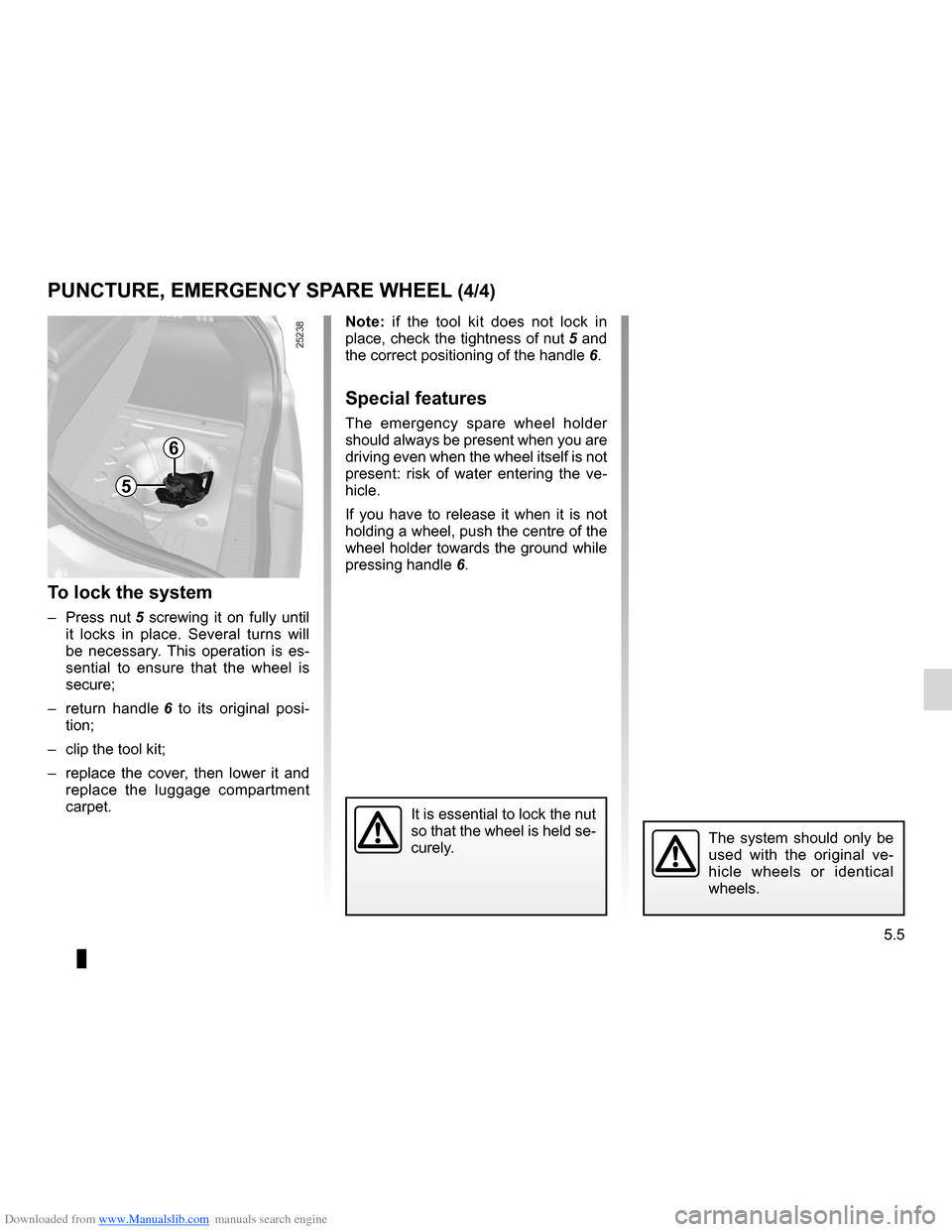

Note: if the tool kit does not lock in

place, check the tightness of nut 5 and

the correct positioning of the handle 6.

Special features

The emergency spare wheel holder

should always be present when you are

driving even when the wheel itself is not

present: risk of water entering the ve -

hicle.

If you have to release it when it is not

holding a wheel, push the centre of the

wheel holder towards the ground while

pressing handle 6.

To lock the system

– Press nut 5 screwing it on fully until

it locks in place. Several turns will

be necessary. This operation is es -

sential to ensure that the wheel is

secure;

– return handle 6 to its original posi -

tion;

– clip the tool kit;

– replace the cover, then lower it and

replace the luggage compartment

carpet.

PUNCTURE, EMERGENCY SPARE WHEEL (4/4)

The system should only be

used with the original ve -

hicle wheels or identical

wheels.

It is essential to lock the nut

so that the wheel is held se-

curely.

6

5

Page 198 of 268

Downloaded from www.Manualslib.com manuals search engine tyre inflation kit...................................... (up to the end of the DU)

5.6

ENG_UD22318_3

Kit de gonflage des pneumatiques (X85 - B85 - C85 - S85 - K85 - Renault\

)

ENG_NU_853-7_BCSK85_Renault_5

Jaune NoirNoir texte

Tyre pressure kit

TYRE PRESSURE KIT (1/3)

The kit is only approved for

inflating the tyres of the ve-

hicle originally equipped

with the kit.

It must never be used to inflate

the tyres of another vehicle, or any

other inflatable object (rubber ring,

rubber boat, etc.).

Avoid spillage on skin when han -

dling the repair liquid bottle. If drop-

lets do leak out, rinse them off with

plenty of water.

Keep the repair kit away from chil -

dren.

Do not dispose of the empty bottle

in the countryside. Return it to your

approved dealer or to a recycling or-

ganisation.

The bottle has a limited service

life which is indicated on its label.

Check the expiry date.

Contact an approved dealer to re -

place the inflation tube and repair

product bottle.

A

B

The kit repairs tyres when

tread A has been dam -

aged by objects smaller

than 4 mm. It cannot repair

all types of puncture, such as cuts

larger than 4 mm, or cuts in tyre

sidewall B.

Ensure also that the wheel rim is in

good condition.

Do not pull out the foreign body

causing the puncture if it is still in

the tyre.

Do not attempt to use the

inflation kit if the tyre has

been damaged as a result

of driving with a puncture.

You should therefore carefully check

the condition of the tyre sidewalls

before any operation.

Driving with underinflated, flat or

punctured tyres can be dangerous

and may make the tyre impossible

to repair.

This repair is temporary

A tyre which has been punctured

should always be inspected (and re-

paired, where possible) as soon as

possible by a specialist.

When taking a tyre which has been

repaired using this kit to be replaced,

you must inform the specialist.

When driving, vibration may be felt

due to the presence of the repair

product injected into the tyre.

Page 200 of 268

Downloaded from www.Manualslib.com manuals search engine 5.8

ENG_UD22318_3

Kit de gonflage des pneumatiques (X85 - B85 - C85 - S85 - K85 - Renault\

)

ENG_NU_853-7_BCSK85_Renault_5

TYRE PRESSURE KIT (3/3)

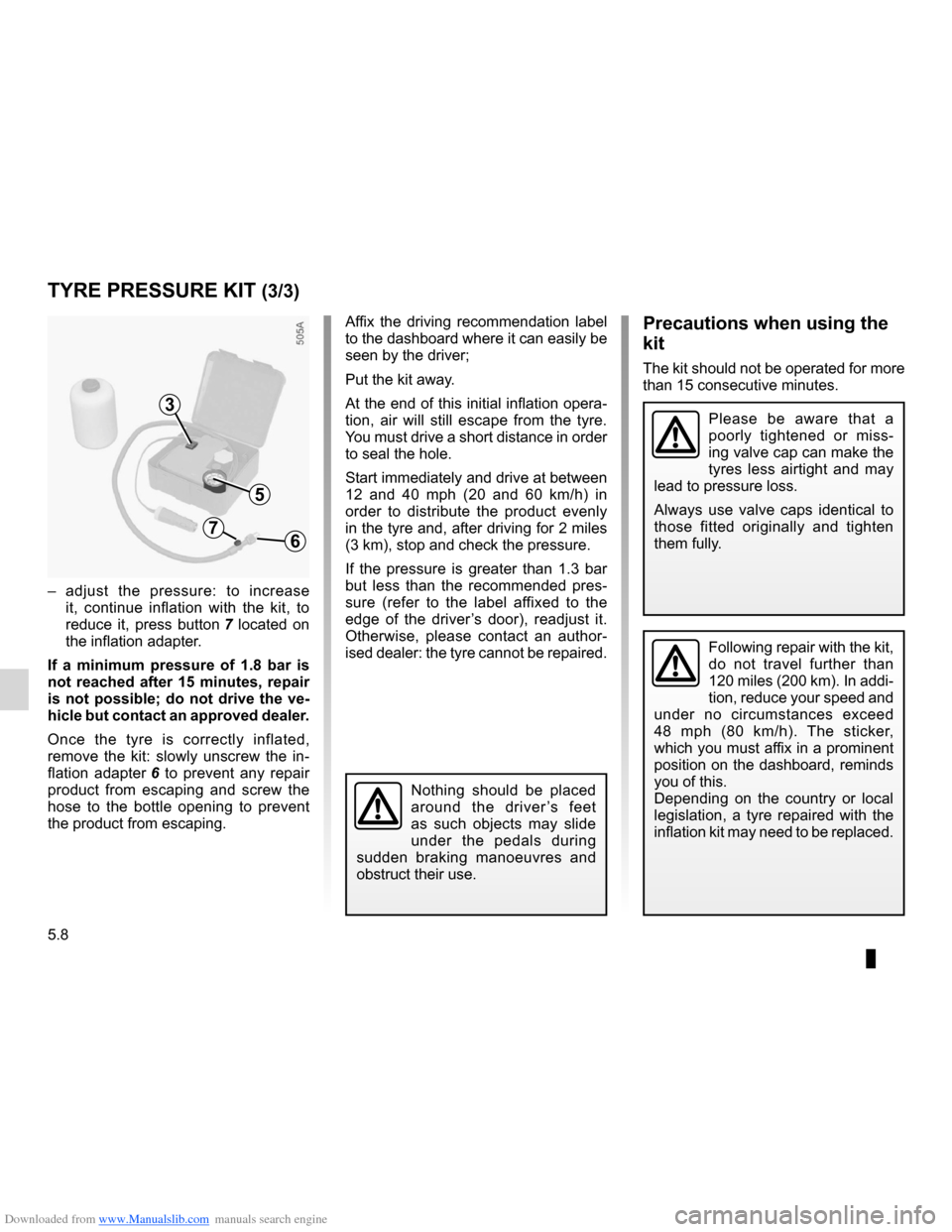

– adjust the pressure: to increase

it, continue inflation with the kit, to

reduce it, press button 7 located on

the inflation adapter.

If a minimum pressure of 1.8 bar is

not reached after 15 minutes, repair

is not possible; do not drive the ve-

hicle but contact an approved dealer.

Once the tyre is correctly inflated,

remove the kit: slowly unscrew the in -

flation adapter 6 to prevent any repair

product from escaping and screw the

hose to the bottle opening to prevent

the product from escaping.

Affix the driving recommendation label

to the dashboard where it can easily be

seen by the driver;

Put the kit away.

At the end of this initial inflation opera -

tion, air will still escape from the tyre.

You must drive a short distance in order

to seal the hole.

Start immediately and drive at between

12 and 40 mph (20 and 60 km/h) in

order to distribute the product evenly

in the tyre and, after driving for 2 miles

(3 km), stop and check the pressure.

If the pressure is greater than 1.3 bar

but less than the recommended pres -

sure (refer to the label affixed to the

edge of the driver’s door), readjust it.

Otherwise, please contact an author -

ised dealer: the tyre cannot be repaired.Precautions when using the

kit

The kit should not be operated for more

than 15 consecutive minutes.

3

5

7

Nothing should be placed

around the driver ’s feet

as such objects may slide

under the pedals during

sudden braking manoeuvres and

obstruct their use.

6

Please be aware that a

poorly tightened or miss -

ing valve cap can make the

tyres less airtight and may

lead to pressure loss.

Always use valve caps identical to

those fitted originally and tighten

them fully.

Following repair with the kit,

do not travel further than

120 miles (200 km). In addi -

tion, reduce your speed and

under no circumstances exceed

48 mph (80 km/h). The sticker,

which you must affix in a prominent

position on the dashboard, reminds

you of this.

Depending on the country or local

legislation, a tyre repaired with the

inflation kit may need to be replaced.

Page 201 of 268

Downloaded from www.Manualslib.com manuals search engine tool kit ................................................... (up to the end of the DU)

hubcap tool ........................................... (up to the end of the DU)

jack ....................................................... (up to the end of the DU)

wheelbrace ........................................... (up to the end of the DU)

towing hitch ........................................... (up to the end of the DU)

wheelbrace ........................................... (up to the end of the DU)

puncture ................................................ (up to the end of the DU)

5.9

ENG_UD19792_3

Bloc-outils (X85 - B85 - C85 - S85 - K85 - Renault)

ENG_NU_853-7_BCSK85_Renault_5

End piece for special wheel

bolt 3

Towing hitch 4

Refer to the information on “Towing” in

Section 5.

Hubcap tool 5 or 6This tool is used to remove the wheel

trims.

Jack 7Remove jack 7.

To refit, lower the jack fully and unscrew

it by one turn and pivot the base so that

it can be stored.

Storage compartment 1(depending on vehicle)

This is for storing a lock nut.

Wheelbrace 2This is used to tighten or release the

wheel bolts.

The tools included in the tool kit depend

on the vehicle.

Tool kit

A is located in the tray under

the luggage compartment carpet.

Depending on the vehicle, lift the cover,

then remove it.

Take out the tool kit, lifting it at both

ends.

To return it, proceed in the reverse

order to removal.

TOOL KIT

Tool kit

1

A

7

2

3

4

56

Do not leave the tools unsecured inside the vehicle as they may come loose under braking. After use, check that all the

tools are correctly clipped into the tool kit, then position it correctl\

y in its housing: there is a risk of injury.

If wheel bolts are supplied in the tool kit, only use these bolts for the emergency spare wheel: refer to the label affixed

to the emergency spare wheel.

The jack is designed for wheel changing purposes only. Under no circumstances should it be used for carrying out repairs un-

derneath the vehicle or to gain access to the underside of the vehicle.

Page 202 of 268

Downloaded from www.Manualslib.com manuals search engine hubcap tool ........................................... (up to the end of the DU)

trims ...................................................... (up to the end of the DU)

5.10

ENG_UD25542_2

Enjoliveur - Roue (X85 - B85 - C85 - S85 - K85 - Renault)

ENG_NU_853-7_BCSK85_Renault_5

Wheel trims - wheel

We would advise you to note down

the number engraved on the tool so

that you can replace it if it is lost.

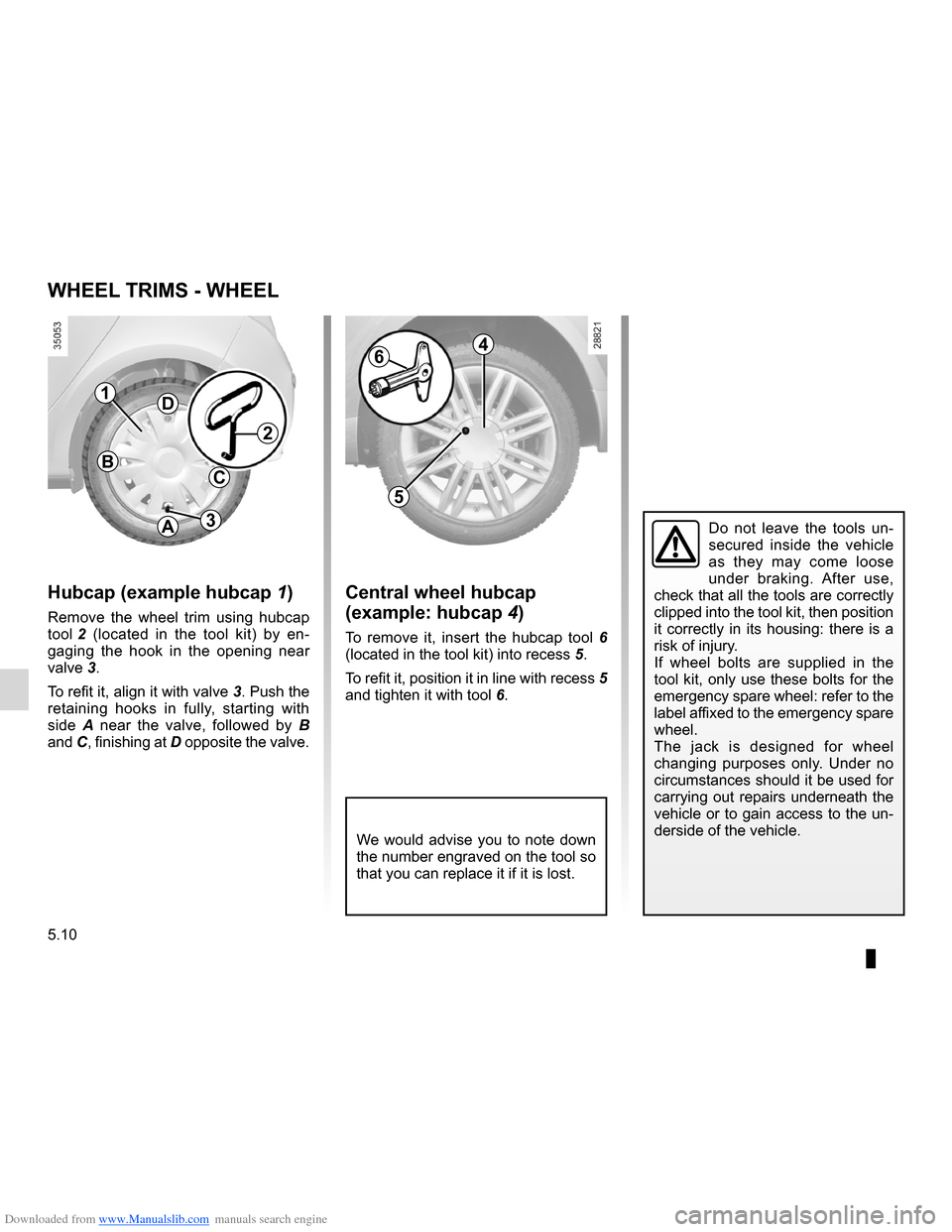

Central wheel hubcap

(example: hubcap 4)

To remove it, insert the hubcap tool 6

(located in the tool kit) into recess 5.

To refit it, position it in line with recess 5

and tighten it with tool 6.

Hubcap (example hubcap 1)

Remove the wheel trim using hubcap

tool 2 (located in the tool kit) by en -

gaging the hook in the opening near

valve 3.

To refit it, align it with valve 3. Push the

retaining hooks in fully, starting with

side A near the valve, followed by B

and C, finishing at D opposite the valve.

WHEEL TRIMS - WHEEL

4

5

6

Do not leave the tools un -

secured inside the vehicle

as they may come loose

under braking. After use,

check that all the tools are correctly

clipped into the tool kit, then position

it correctly in its housing: there is a

risk of injury.

If wheel bolts are supplied in the

tool kit, only use these bolts for the

emergency spare wheel: refer to the

label affixed to the emergency spare

wheel.

The jack is designed for wheel

changing purposes only. Under no

circumstances should it be used for

carrying out repairs underneath the

vehicle or to gain access to the un-

derside of the vehicle.

1

2

3A

B

D

C

Page 204 of 268

Downloaded from www.Manualslib.com manuals search engine 5.12

ENG_UD19793_3

Changement de roue (X85 - B85 - C85 - S85 - K85 - Renault)

ENG_NU_853-7_BCSK85_Renault_5

Anti-theft bolt

If you use anti-theft bolts, fit these

nearest the valve (otherwise it may

not be possible to fit the wheel trim).

If you have a puncture, re -

place the wheel as soon as

possible.

A tyre which has been punc-

tured should always be inspected

(and repaired, where possible) by a

specialist.

If the vehicle is parked on

the hard shoulder, you must

warn other road users of

your vehicle’s presence

with a warning triangle or with other

devices as per the legislation apply-

ing to the country you are in.

CHANGING A WHEEL (2/2)

Undo the bolts and take off the wheel.

Fit the emergency spare wheel on the

central hub and turn it to locate the

mounting holes in the wheel and the

hub.

Tighten the bolts and lower the jack.

With the wheel on the ground, tighten

the screws as fully as possible and

check the tightness as soon as possi -

ble (tightening torque 110 N.m).