air condition RENAULT ESPACE 2000 J66 / 3.G Technical Note 3426A Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: ESPACE, Model: RENAULT ESPACE 2000 J66 / 3.GPages: 52, PDF Size: 0.98 MB

Page 2 of 52

Downloaded from www.Manualslib.com manuals search engine Contents

Page

07

10

11

12

16

VALUES AND SETTINGS

Capacities - Grades 07-1

Tightening the cylinder head 07-2

ENGINE AND PERIPHERALS

Identification 10-1

Oil pressure 10-2

Engine and transmission assembly 10-3

TOP AND FRONT OF ENGINE

Accessories belt 11-1

Timing belt 11-2

Cylinder head gasket 11-8

TURBOCHARGING - FUEL

MIXTURE

Turbocharger 12-1

Air inlet 12-3

Exhaust manifold 12-7

Inlet manifold 12-8

STARTING - CHARGING

Alternator 16-1

Starter 16-4Page

19

21

61

62

COOLING SYSTEM

Filling - bleeding 19-1

Diagram 19-2

Coolant pump 19-3

Suspended mountings 19-4

Cooling system 19-5

MANUAL GEARBOX

Identification 21-1

Gears 21-2

Lubricants 21-3

Remove and refit 21-4

HEATING

Additional heating 61-1

AIR CONDITIONING

Air conditioning compressor 62-1

Page 9 of 52

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-5

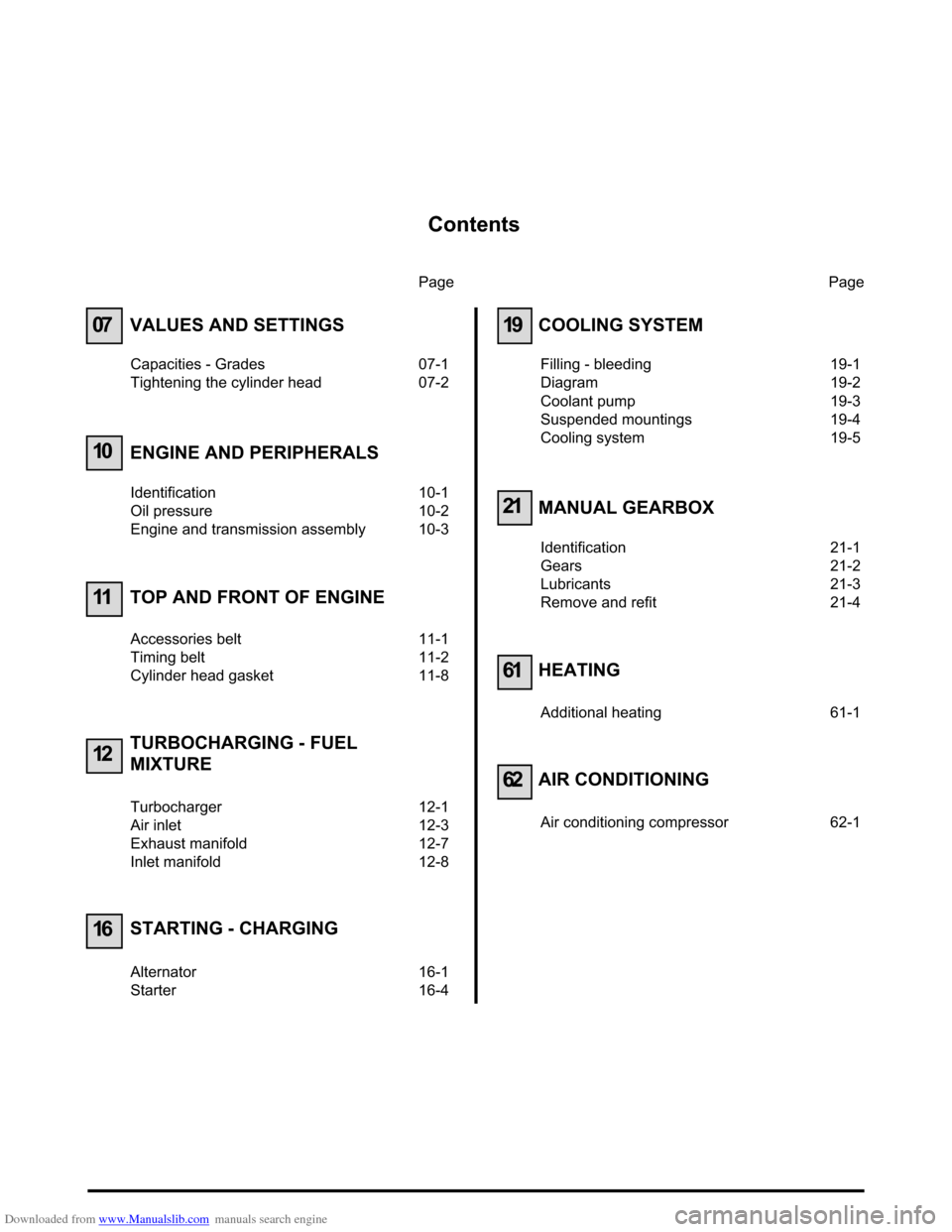

Disconnect the air conditioning compressor pipe

connections.

Remove the complete heater exhaust line (if fitted).Remove:

–the exhaust pre catalytic converter,

–the engine tie-bar.

Disconnect the olives on the gearbox control cable.

10442M

Page 11 of 52

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-7

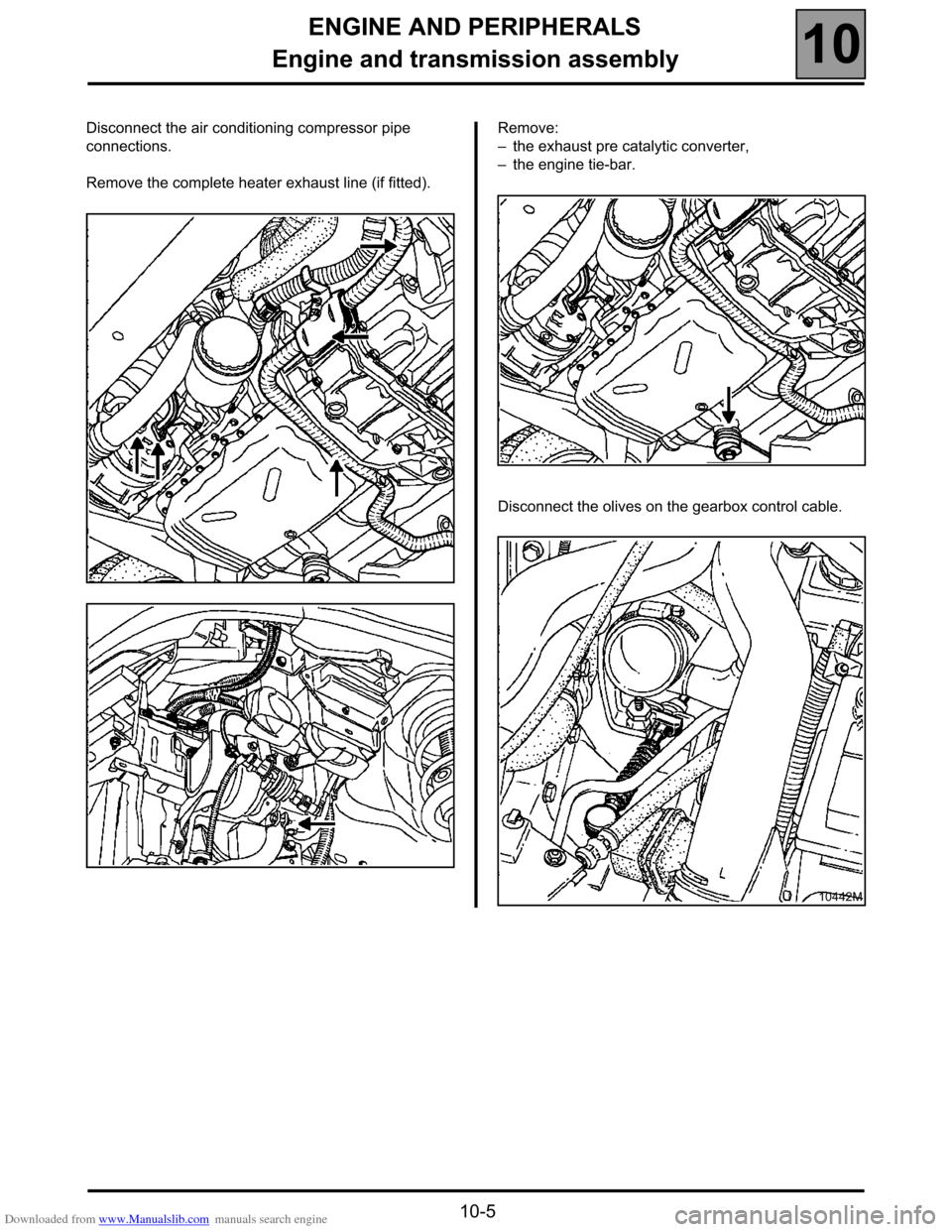

Disconnect the lead from the engine compartment

connection unit; be sure to mark the location of the

various connections correctly.

Separate:

–a connector from the battery tray,

–the control solenoid valve from the turbocharger

regulation valve.

Fit hose pliers on the clutch master cylinder supply

pipe (on the brake fluid tank side).

Open the clutch slave cylinder bleed screw

(WARNING: you must use a counter-spanner at (C)

to compensate the effort of loosening/retightening

the bleed screw (A); see Technical Note 3345A).Disconnect:

Left side:

–the clutch slave cylinder high pressure union and

release the pipe from its clips,

–the water hoses connecting the engine to the tank

and the heater matrix element.

Right side:

–the diesel supply (1) and return (2) element from the

injection pump to the filter. It is essential that you plug

the openings with the appropriate plugs from kit

Part No.: 77 01 206 381,

–the inertia switch connector (3),

–the air conditioning circuit low pressure pipe on the

mounting bracket on the throttle body.

Under the vehicle:

–the booster pump connector; refit the electric wiring

harness to the engine.

15583R

18240-1M2

17527M1

Page 13 of 52

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-9

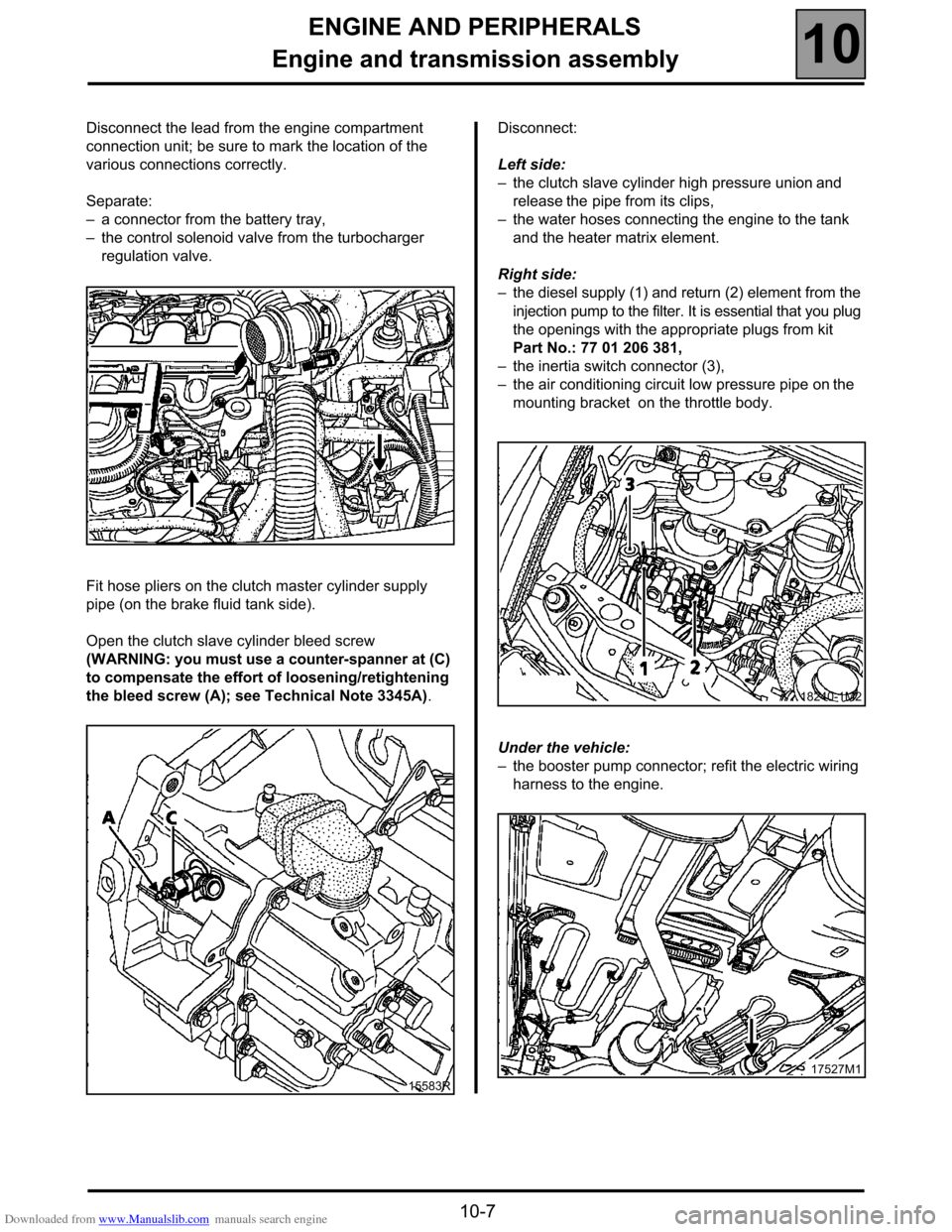

REFITTING - Special points

Pre-position the gearbox control cables.

Position the engine/gearbox assembly in its

compartment. Check the rear of the gearbox in relation

to the sub-frame.

Fitting suspended mountings: see section 19

"Suspended mountings".

Tighten all the bolts, nuts and studs to the

recommended torques.

Refitting is the reverse of removal.

Press the brake pedal several times to bring the

pistons into contact with the brake pads.

Reprogram all the components deprogrammed by

disconnecting the battery.

Fill the refrigerant circuit using the filling station (see

section 62 "Air conditioning").

Refrigerant fluid R134a: 800 ± 20 g.

Carry out:

–filling and bleeding of the cooling circuit (see

section 19),

–filling and bleeding of the power assisted steering

circuit,–bleed the hydraulic clutch circuit.

Damage to the union leads to replacement of the

master cylinder, and thus removal/refitting of the

gearbox.IT IS ESSENTIAL THAT YOU FOLLOW THE

BLEEDING METHOD GIVEN BELOW

VERY IMPORTANT:

When bleeding use a 19 mm ring spanner to

immobilise the rotating union (C) while tightening

and loosening the bleed screw (A) so as not to

damage the slave cylinder and the union.

15583R

Page 28 of 52

Downloaded from www.Manualslib.com manuals search engine FUEL MIXTURE

Air intake

12

12-6

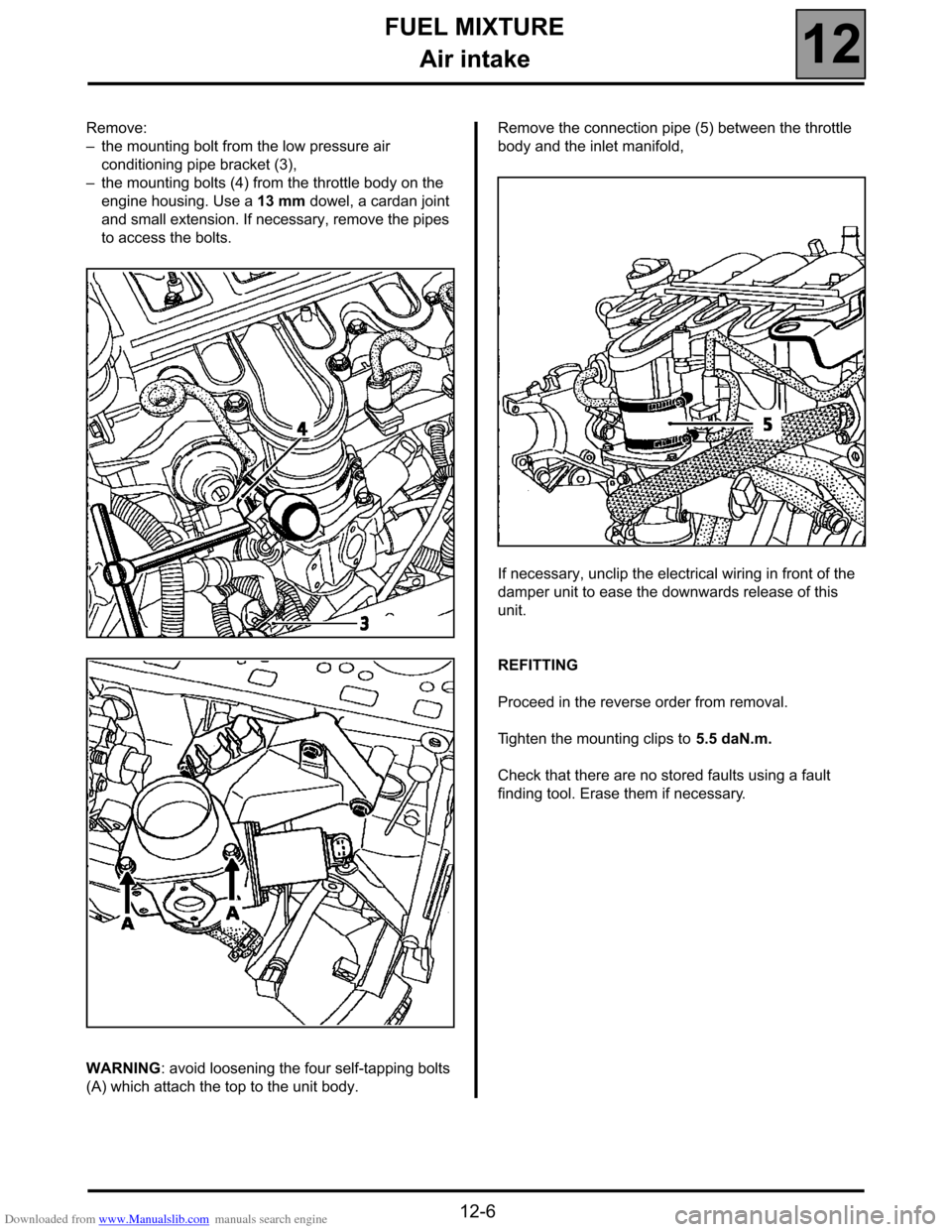

Remove:

–the mounting bolt from the low pressure air

conditioning pipe bracket (3),

–the mounting bolts (4) from the throttle body on the

engine housing. Use a 13 mm dowel, a cardan joint

and small extension. If necessary, remove the pipes

to access the bolts.

WARNING: avoid loosening the four self-tapping bolts

(A) which attach the top to the unit body.Remove the connection pipe (5) between the throttle

body and the inlet manifold,

If necessary, unclip the electrical wiring in front of the

damper unit to ease the downwards release of this

unit.

REFITTING

Proceed in the reverse order from removal.

Tighten the mounting clips to 5.5 daN.m.

Check that there are no stored faults using a fault

finding tool. Erase them if necessary.

Page 33 of 52

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Alternator

16

16-2

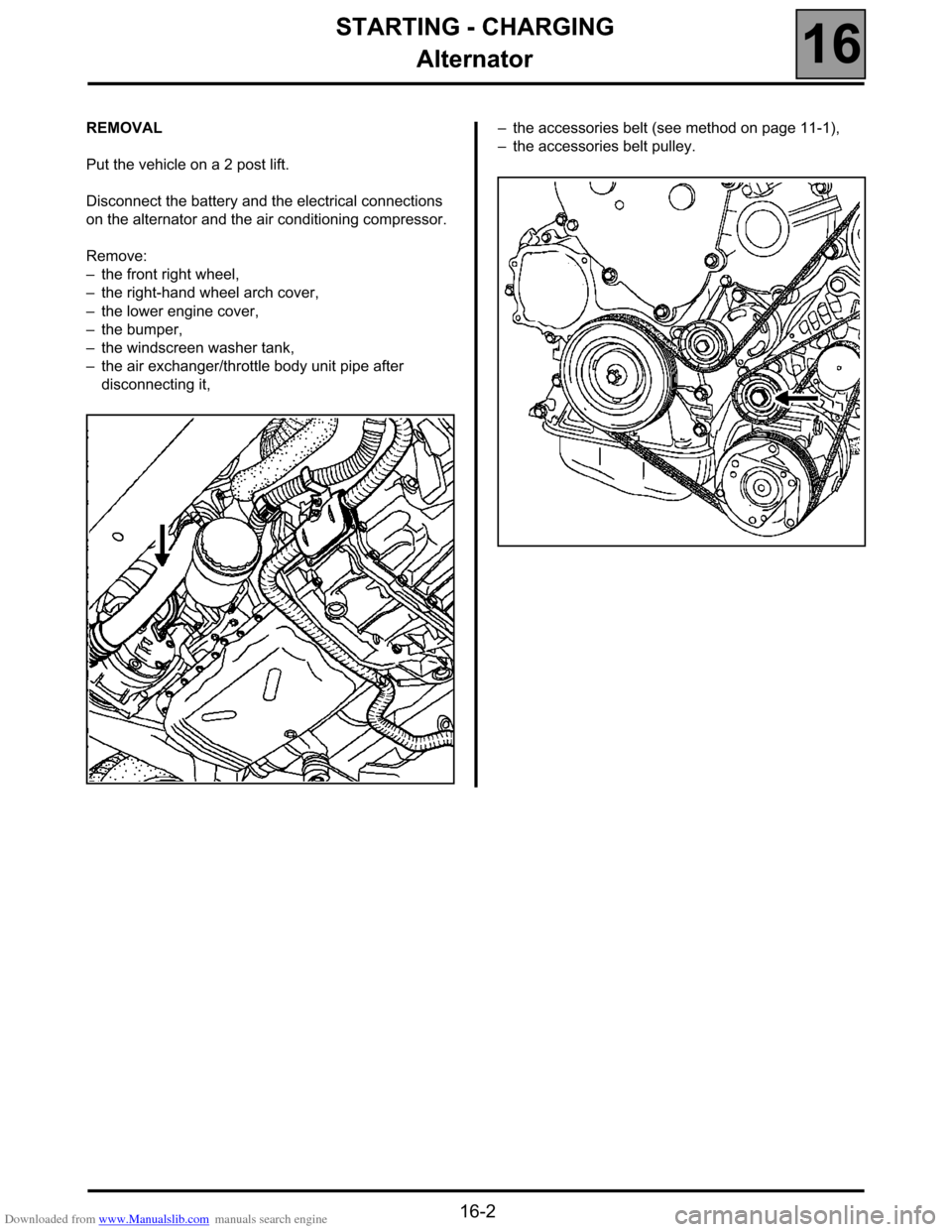

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery and the electrical connections

on the alternator and the air conditioning compressor.

Remove:

–the front right wheel,

–the right-hand wheel arch cover,

–the lower engine cover,

–the bumper,

–the windscreen washer tank,

–the air exchanger/throttle body unit pipe after

disconnecting it,–the accessories belt (see method on page 11-1),

–the accessories belt pulley.

Page 34 of 52

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Alternator

16

16-3

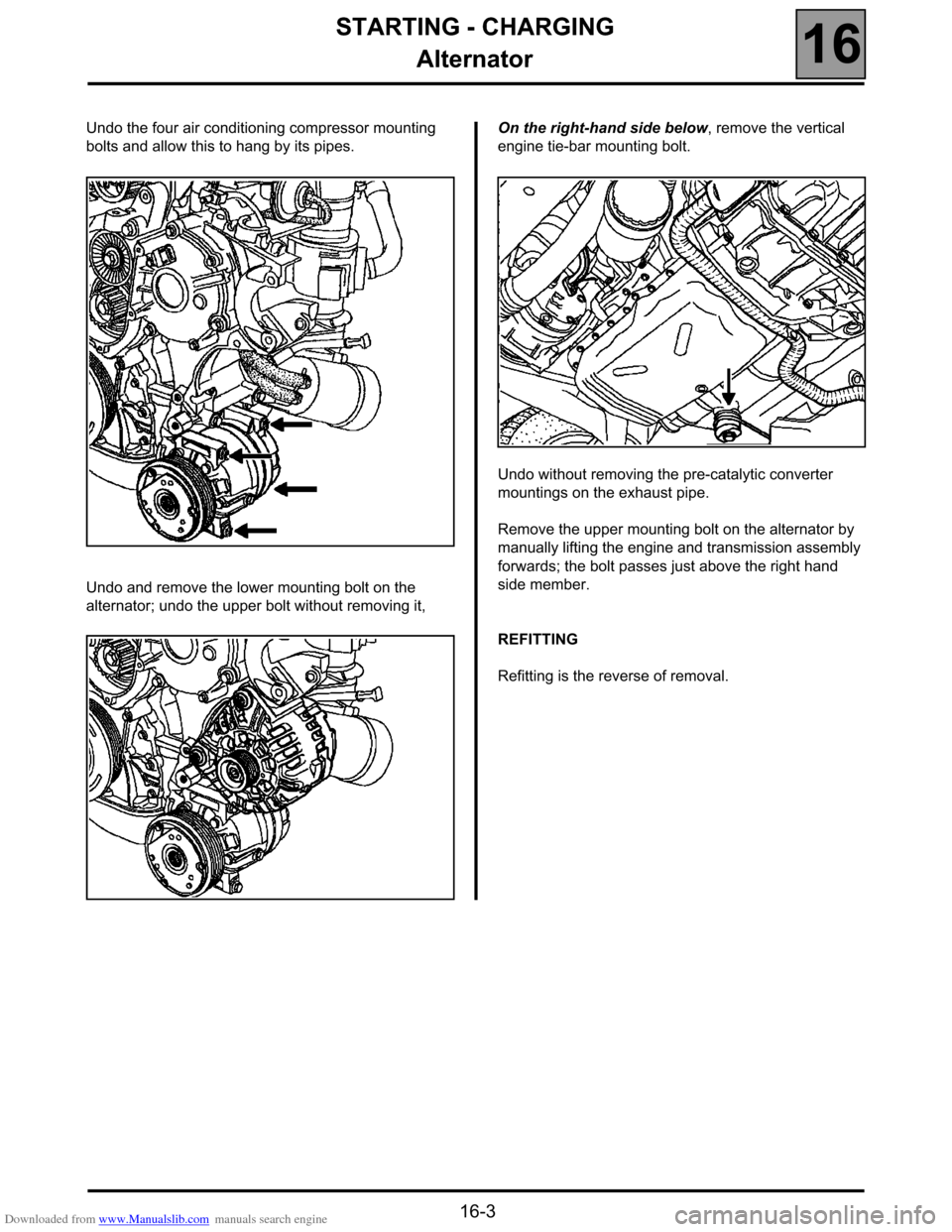

Undo the four air conditioning compressor mounting

bolts and allow this to hang by its pipes.

Undo and remove the lower mounting bolt on the

alternator; undo the upper bolt without removing it,On the right-hand side below, remove the vertical

engine tie-bar mounting bolt.

Undo without removing the pre-catalytic converter

mountings on the exhaust pipe.

Remove the upper mounting bolt on the alternator by

manually lifting the engine and transmission assembly

forwards; the bolt passes just above the right hand

side member.

REFITTING

Refitting is the reverse of removal.

Page 41 of 52

Downloaded from www.Manualslib.com manuals search engine COOLING SYSTEM

Cooling system

19

19-5

COOLING SYSTEM

Cooling system

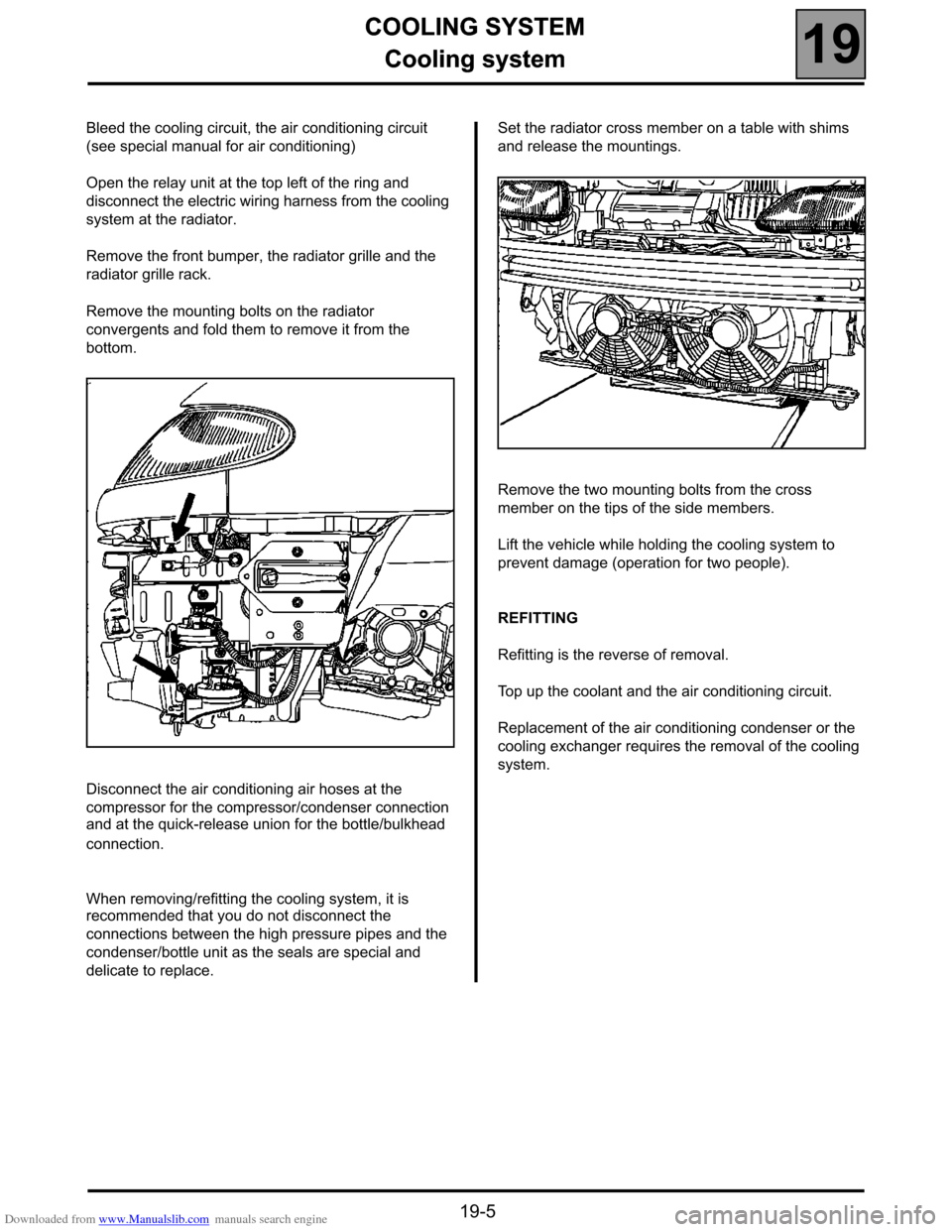

Bleed the cooling circuit, the air conditioning circuit

(see special manual for air conditioning)

Open the relay unit at the top left of the ring and

disconnect the electric wiring harness from the cooling

system at the radiator.

Remove the front bumper, the radiator grille and the

radiator grille rack.

Remove the mounting bolts on the radiator

convergents and fold them to remove it from the

bottom.

Disconnect the air conditioning air hoses at the

compressor for the compressor/condenser connection

and at the quick-release union for the bottle/bulkhead

connection.

When removing/refitting the cooling system, it is

recommended that you do not disconnect the

connections between the high pressure pipes and the

condenser/bottle unit as the seals are special and

delicate to replace.Set the radiator cross member on a table with shims

and release the mountings.

Remove the two mounting bolts from the cross

member on the tips of the side members.

Lift the vehicle while holding the cooling system to

prevent damage (operation for two people).

REFITTING

Refitting is the reverse of removal.

Top up the coolant and the air conditioning circuit.

Replacement of the air conditioning condenser or the

cooling exchanger requires the removal of the cooling

system.

Page 46 of 52

Downloaded from www.Manualslib.com manuals search engine HEATING

Additional heating

61

161HEATING

Additional heating

OPERATING PRINCIPLE

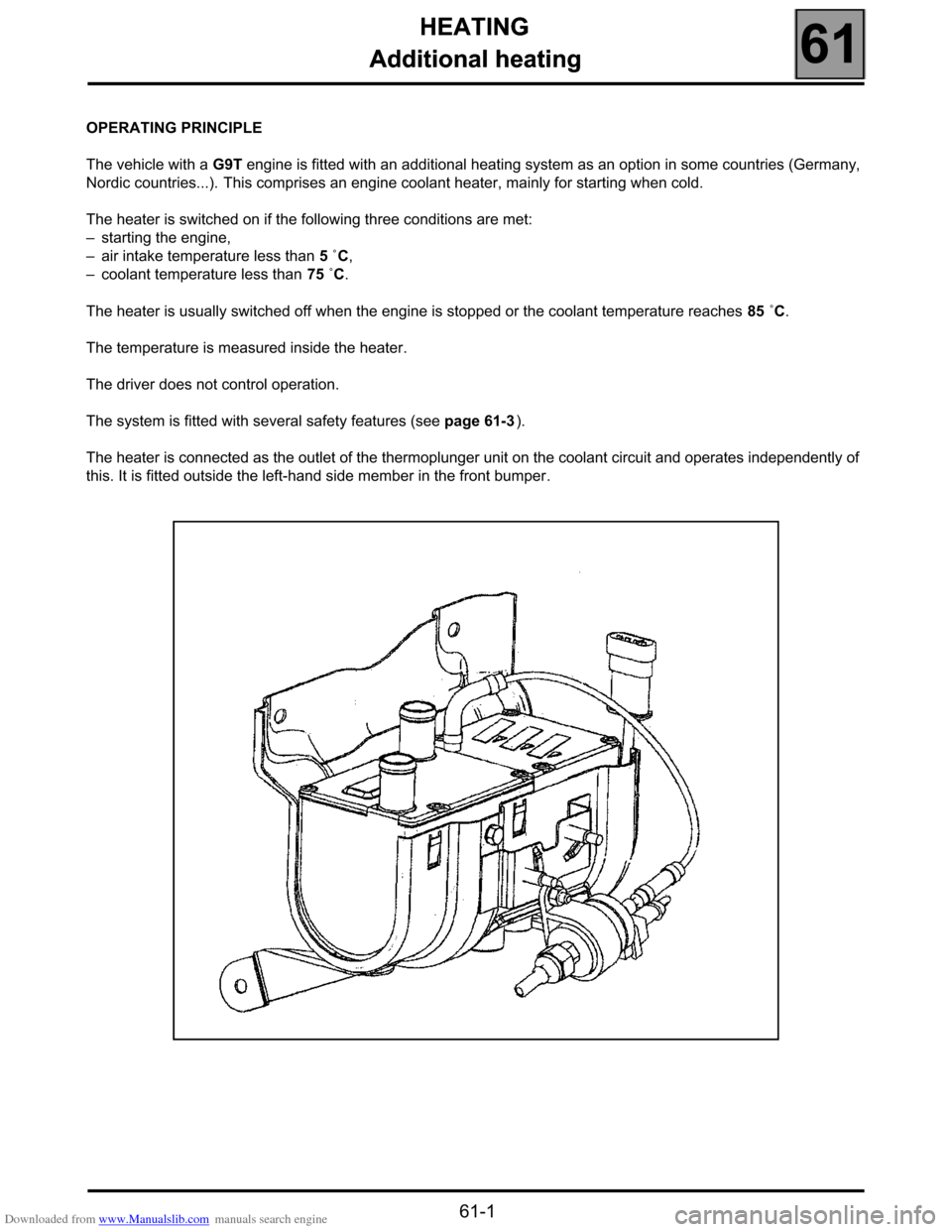

The vehicle with a G9T engine is fitted with an additional heating system as an option in some countries (Germany,

Nordic countries...). This comprises an engine coolant heater, mainly for starting when cold.

The heater is switched on if the following three conditions are met:

–starting the engine,

–air intake temperature less than 5 ˚C,

–coolant temperature less than 75 ˚C.

The heater is usually switched off when the engine is stopped or the coolant temperature reaches 85 ˚C.

The temperature is measured inside the heater.

The driver does not control operation.

The system is fitted with several safety features (see page 61-3).

The heater is connected as the outlet of the thermoplunger unit on the coolant circuit and operates independently of

this. It is fitted outside the left-hand side member in the front bumper.

61-1

Page 52 of 52

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

Air conditioning compressor

62

62-1

662AIR CONDITIONING

Air conditioning compressor

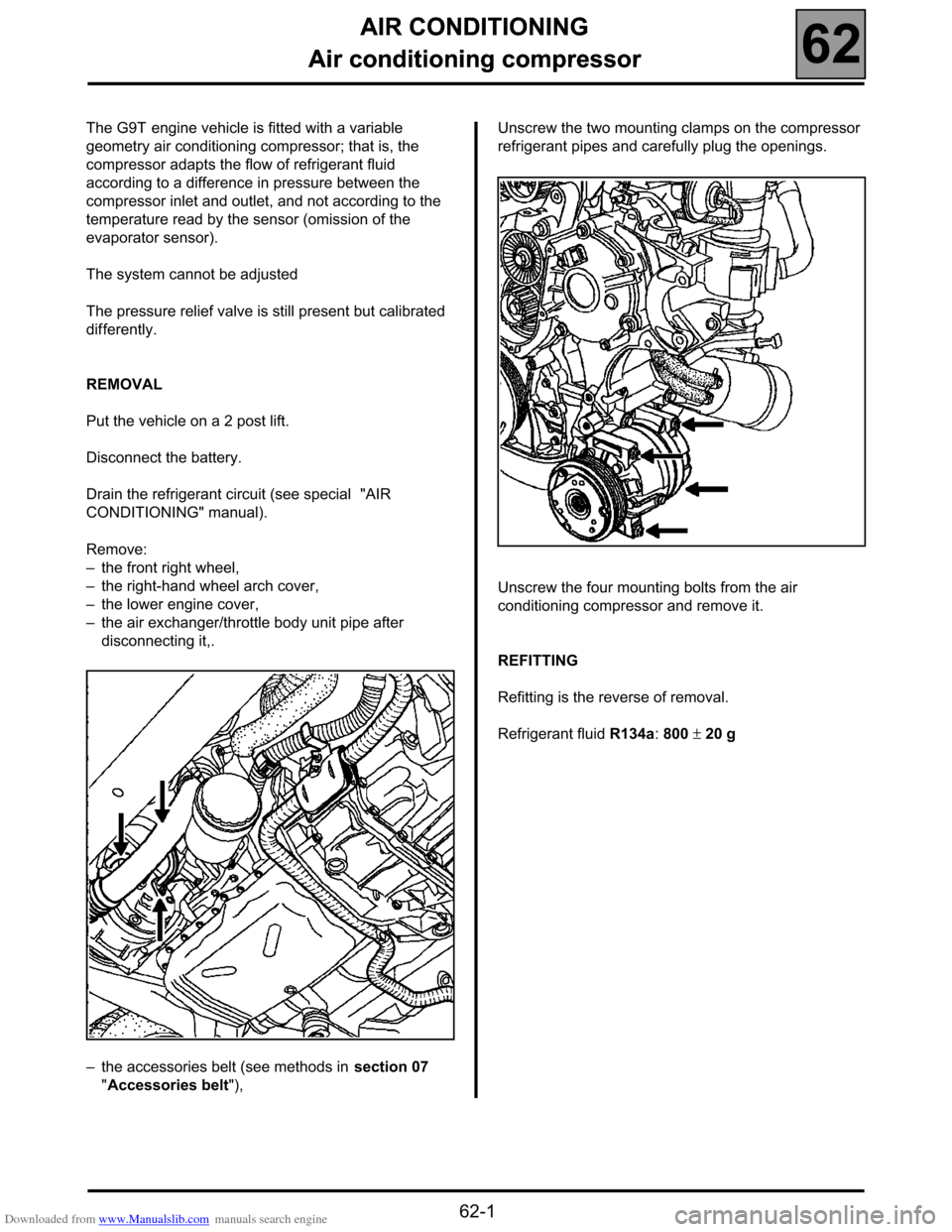

The G9T engine vehicle is fitted with a variable

geometry air conditioning compressor; that is, the

compressor adapts the flow of refrigerant fluid

according to a difference in pressure between the

compressor inlet and outlet, and not according to the

temperature read by the sensor (omission of the

evaporator sensor).

The system cannot be adjusted

The pressure relief valve is still present but calibrated

differently.

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Drain the refrigerant circuit (see special "AIR

CONDITIONING" manual).

Remove:

–the front right wheel,

–the right-hand wheel arch cover,

–the lower engine cover,

–the air exchanger/throttle body unit pipe after

disconnecting it,.

–the accessories belt (see methods in section 07

"Accessories belt"),Unscrew the two mounting clamps on the compressor

refrigerant pipes and carefully plug the openings.

Unscrew the four mounting bolts from the air

conditioning compressor and remove it.

REFITTING

Refitting is the reverse of removal.

Refrigerant fluid R134a: 800 ± 20 g