engine oil RENAULT ESPACE 2000 J66 / 3.G Technical Note 3426A Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: ESPACE, Model: RENAULT ESPACE 2000 J66 / 3.GPages: 52, PDF Size: 0.98 MB

Page 2 of 52

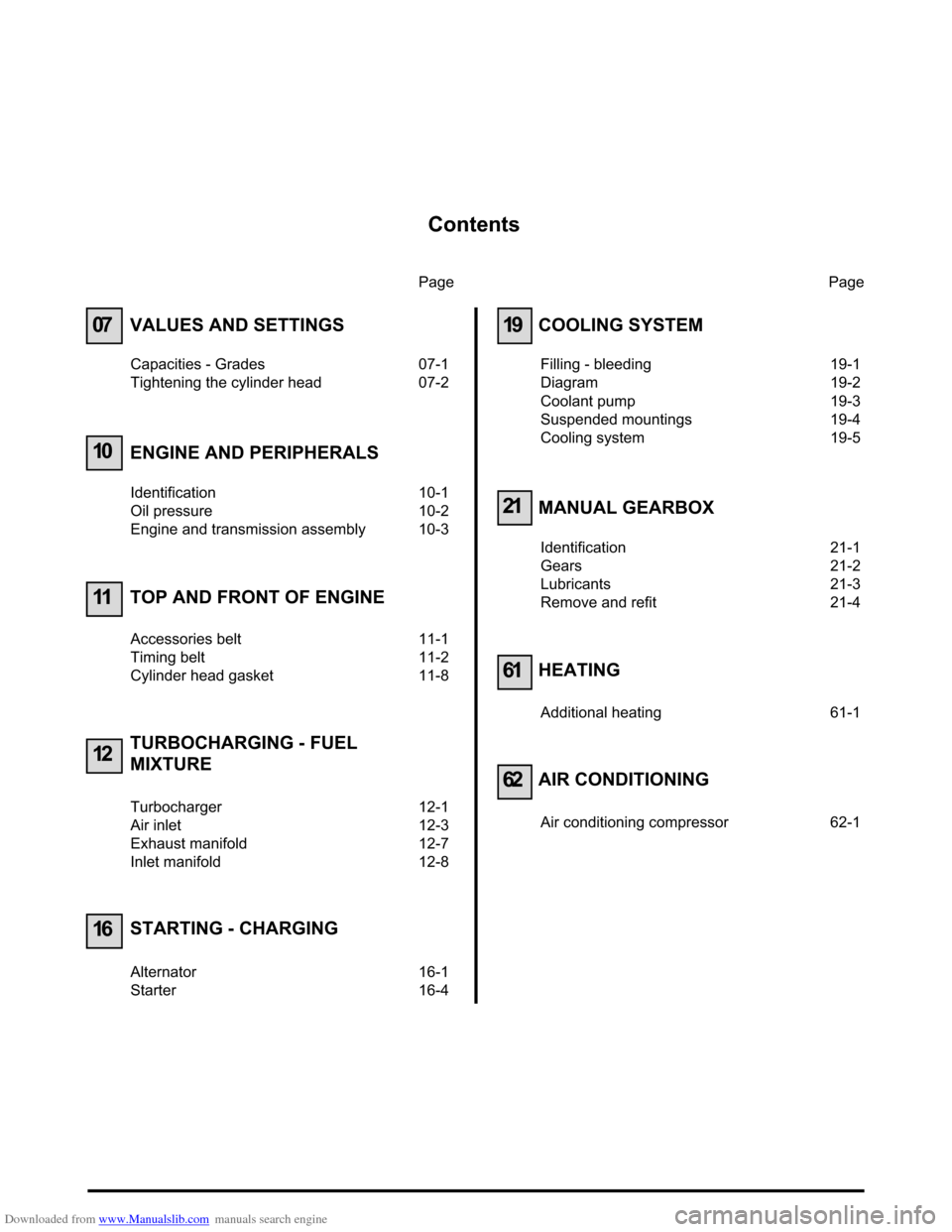

Downloaded from www.Manualslib.com manuals search engine Contents

Page

07

10

11

12

16

VALUES AND SETTINGS

Capacities - Grades 07-1

Tightening the cylinder head 07-2

ENGINE AND PERIPHERALS

Identification 10-1

Oil pressure 10-2

Engine and transmission assembly 10-3

TOP AND FRONT OF ENGINE

Accessories belt 11-1

Timing belt 11-2

Cylinder head gasket 11-8

TURBOCHARGING - FUEL

MIXTURE

Turbocharger 12-1

Air inlet 12-3

Exhaust manifold 12-7

Inlet manifold 12-8

STARTING - CHARGING

Alternator 16-1

Starter 16-4Page

19

21

61

62

COOLING SYSTEM

Filling - bleeding 19-1

Diagram 19-2

Coolant pump 19-3

Suspended mountings 19-4

Cooling system 19-5

MANUAL GEARBOX

Identification 21-1

Gears 21-2

Lubricants 21-3

Remove and refit 21-4

HEATING

Additional heating 61-1

AIR CONDITIONING

Air conditioning compressor 62-1

Page 3 of 52

Downloaded from www.Manualslib.com manuals search engine VALUES AND SETTINGS

Capacities - Grades

07

107VALUES AND SETTINGS

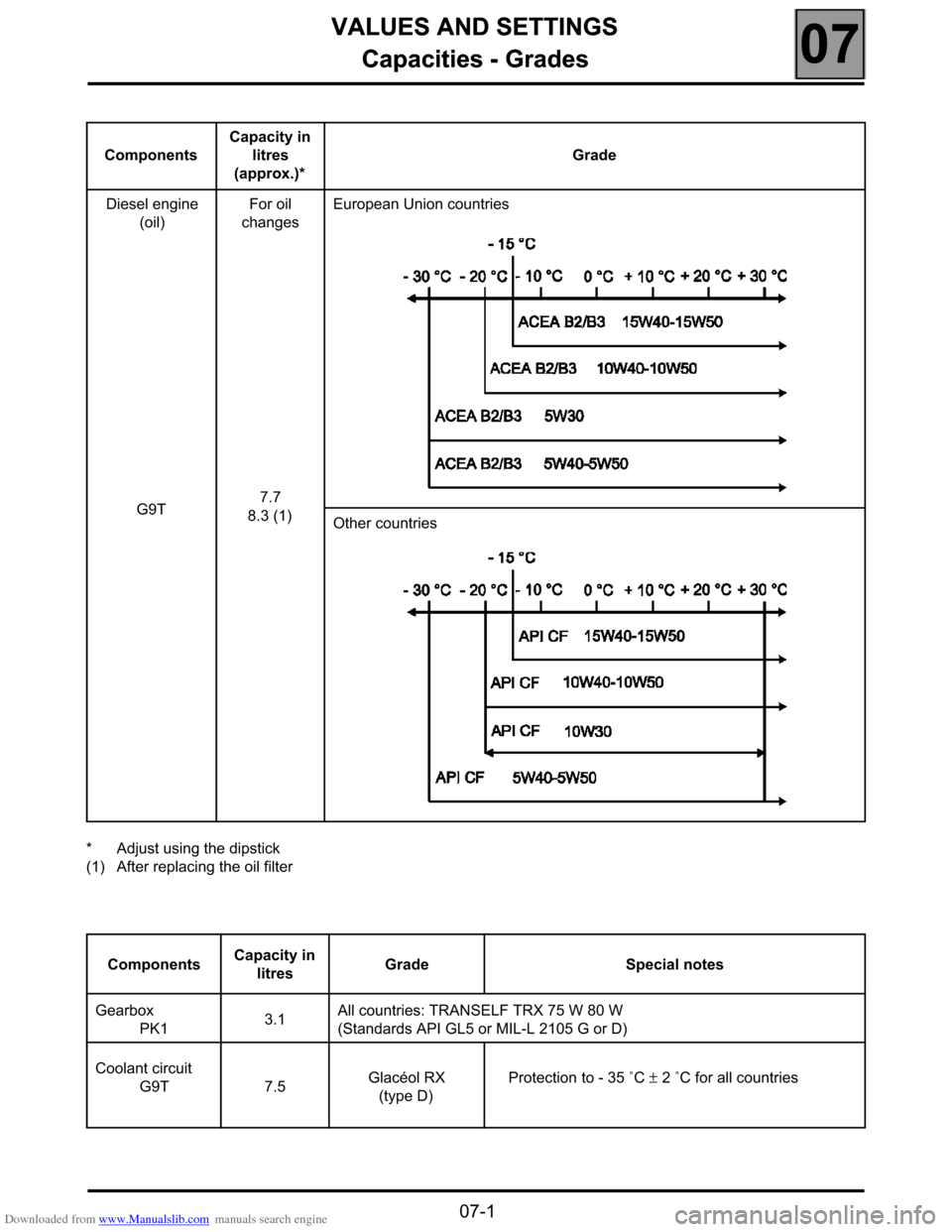

Capacities - Grades

* Adjust using the dipstick

(1) After replacing the oil filterComponentsCapacity in

litres

(approx.)*Grade

Diesel engine

(oil)

G9TFor oil

changes

7.7

8.3 (1)European Union countries

Other countries

ComponentsCapacity in

litresGrade Special notes

Gearbox

PK13.1All countries: TRANSELF TRX 75 W 80 W

(Standards API GL5 or MIL-L 2105 G or D)

Coolant circuit

G9T 7.5Glacéol RX

(type D)Protection to - 35 ˚C ± 2 ˚C for all countries

07-1

Page 6 of 52

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Oil pressure

10

10-2

Oil pressure

CHECKING

The oil pressure should be checked when the engine

is warm (approximately 80°C).

USE

Connect the pressure gauge in place of the oil

pressure switch.

Oil pressure

1 000 rpm 1.2 bar

3 000 rpm 3.5 bars SPECIAL TOOLING REQUIRED

Mot. 836-05 Boxed kit for measuring oil

pressure

ESSENTIAL SPECIAL TOOLING

22 mm long socket

Page 23 of 52

Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Turbocharger

12

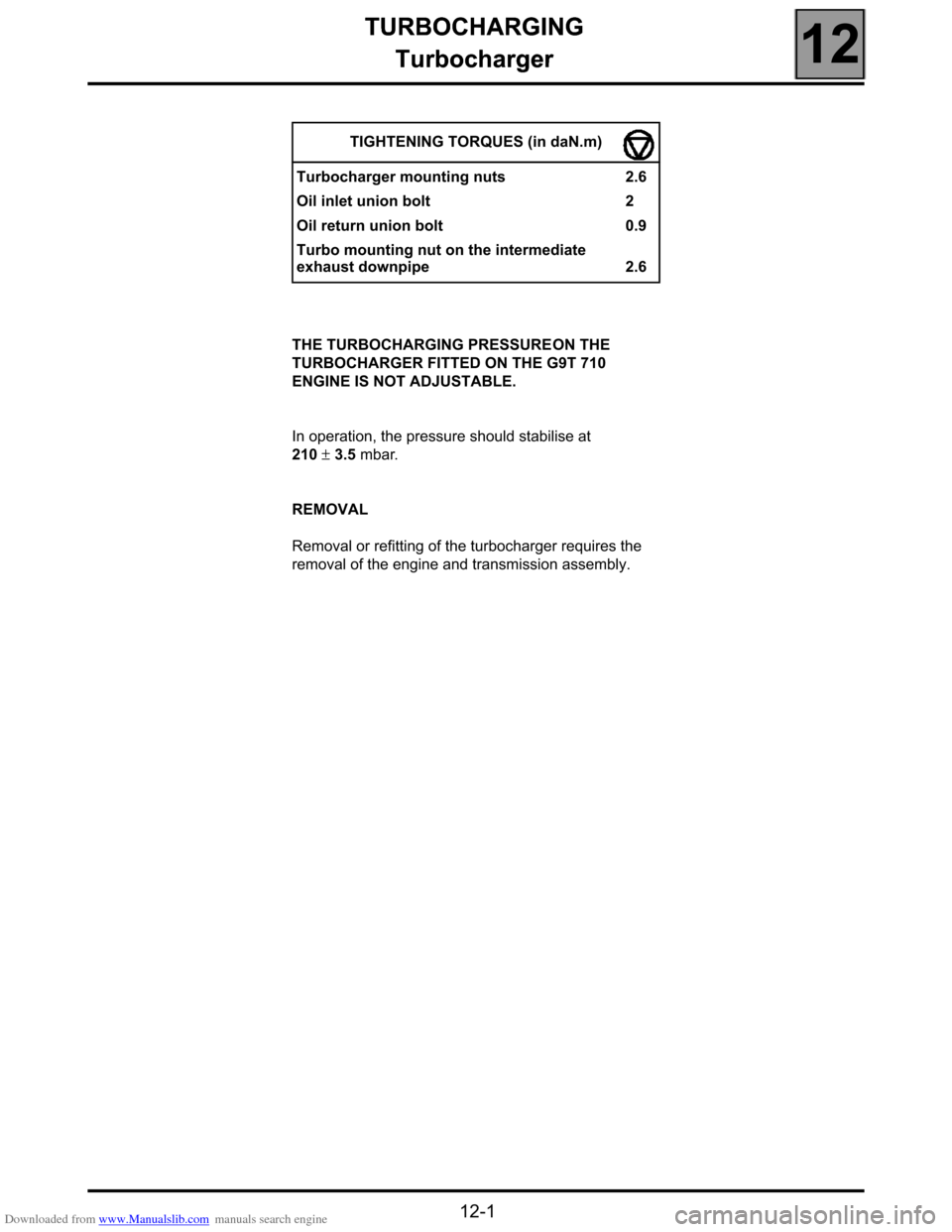

112TURBOCHARGING

Turbocharger

THE TURBOCHARGING PRESSURE ON THE

TURBOCHARGER FITTED ON THE G9T 710

ENGINE IS NOT ADJUSTABLE.

In operation, the pressure should stabilise at

210 ± 3.5 mbar.

REMOVAL

Removal or refitting of the turbocharger requires the

removal of the engine and transmission assembly.TIGHTENING TORQUES (in daN.m)

Turbocharger mounting nuts 2.6

Oil inlet union bolt 2

Oil return union bolt 0.9

Turbo mounting nut on the intermediate

exhaust downpipe 2.6

12-1

Page 24 of 52

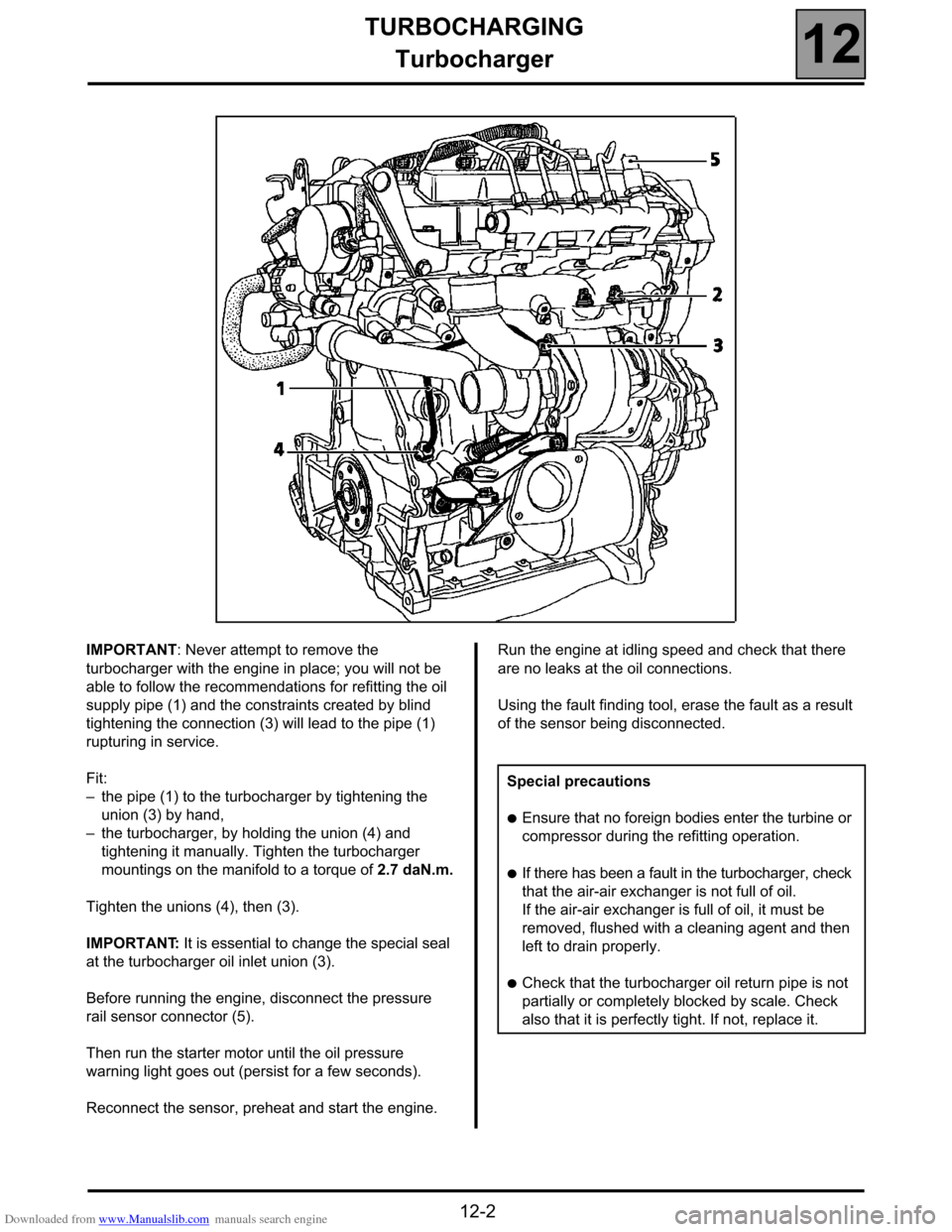

Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Turbocharger

12

12-2

IMPORTANT: Never attempt to remove the

turbocharger with the engine in place; you will not be

able to follow the recommendations for refitting the oil

supply pipe (1) and the constraints created by blind

tightening the connection (3) will lead to the pipe (1)

rupturing in service.

Fit:

–the pipe (1) to the turbocharger by tightening the

union (3) by hand,

–the turbocharger, by holding the union (4) and

tightening it manually. Tighten the turbocharger

mountings on the manifold to a torque of 2.7 daN.m.

Tighten the unions (4), then (3).

IMPORTANT: It is essential to change the special seal

at the turbocharger oil inlet union (3).

Before running the engine, disconnect the pressure

rail sensor connector (5).

Then run the starter motor until the oil pressure

warning light goes out (persist for a few seconds).

Reconnect the sensor, preheat and start the engine.Run the engine at idling speed and check that there

are no leaks at the oil connections.

Using the fault finding tool, erase the fault as a result

of the sensor being disconnected.

Special precautions

●Ensure that no foreign bodies enter the turbine or

compressor during the refitting operation.

●If there has been a fault in the turbocharger, check

that the air-air exchanger is not full of oil.

If the air-air exchanger is full of oil, it must be

removed, flushed with a cleaning agent and then

left to drain properly.

●Check that the turbocharger oil return pipe is not

partially or completely blocked by scale. Check

also that it is perfectly tight. If not, replace it.

Page 27 of 52

Downloaded from www.Manualslib.com manuals search engine FUEL MIXTURE

Air intake

12

12-5

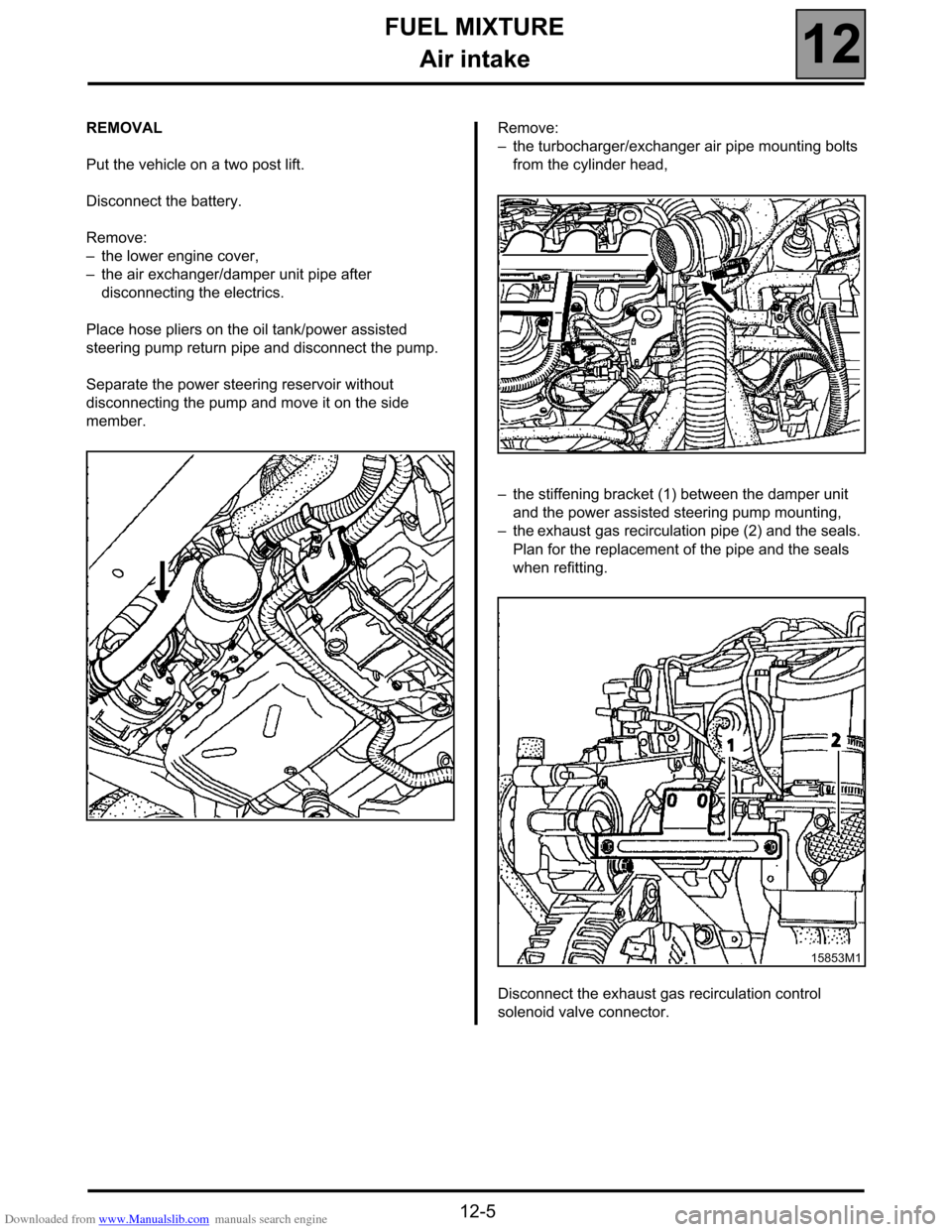

REMOVAL

Put the vehicle on a two post lift.

Disconnect the battery.

Remove:

–the lower engine cover,

–the air exchanger/damper unit pipe after

disconnecting the electrics.

Place hose pliers on the oil tank/power assisted

steering pump return pipe and disconnect the pump.

Separate the power steering reservoir without

disconnecting the pump and move it on the side

member.Remove:

–the turbocharger/exchanger air pipe mounting bolts

from the cylinder head,

–the stiffening bracket (1) between the damper unit

and the power assisted steering pump mounting,

–the exhaust gas recirculation pipe (2) and the seals.

Plan for the replacement of the pipe and the seals

when refitting.

Disconnect the exhaust gas recirculation control

solenoid valve connector.

15853M1

Page 36 of 52

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Starter

16

16-5

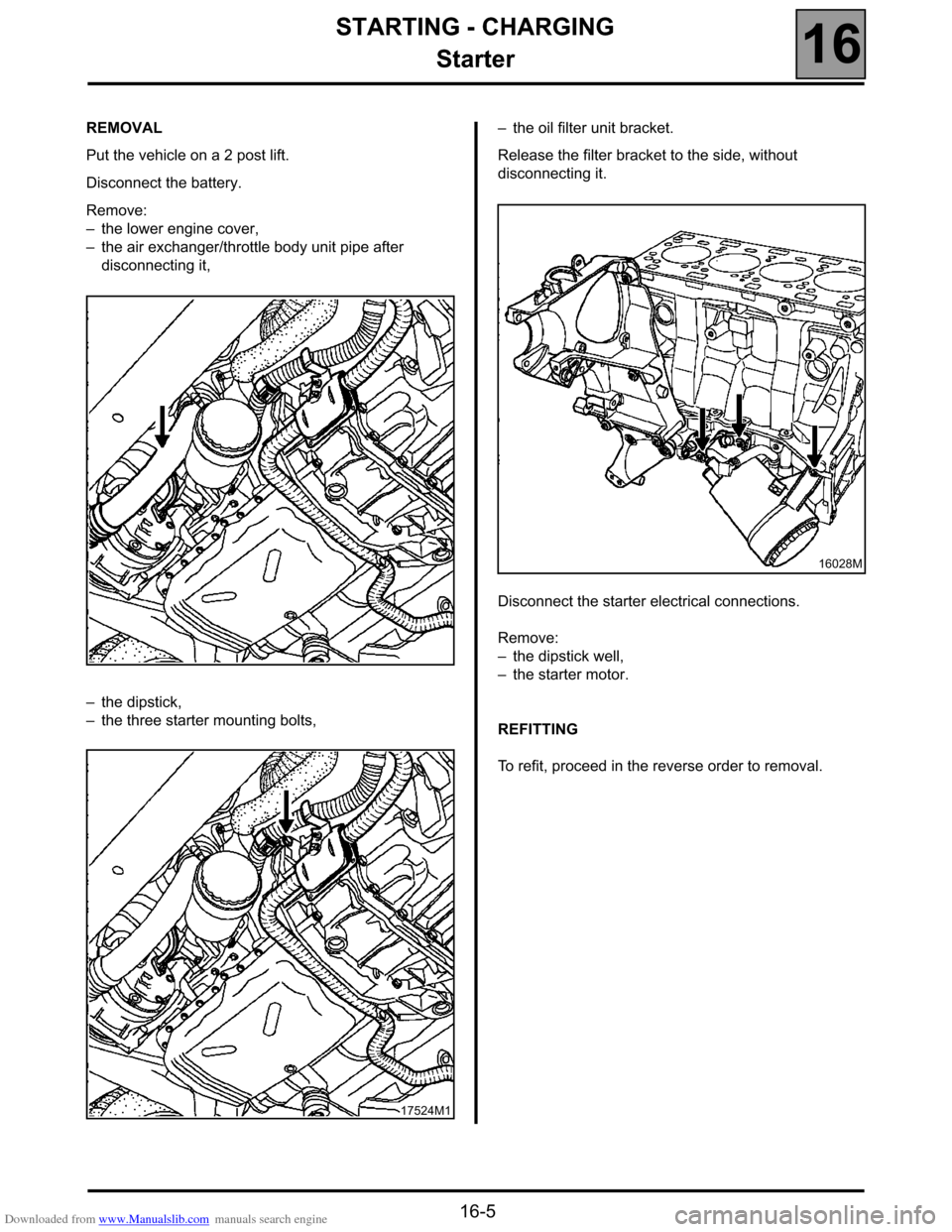

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Remove:

–the lower engine cover,

–the air exchanger/throttle body unit pipe after

disconnecting it,

–the dipstick,

–the three starter mounting bolts,–the oil filter unit bracket.

Release the filter bracket to the side, without

disconnecting it.

Disconnect the starter electrical connections.

Remove:

–the dipstick well,

–the starter motor.

REFITTING

To refit, proceed in the reverse order to removal.

17524M1

16028M

Page 38 of 52

Downloaded from www.Manualslib.com manuals search engine COOLING SYSTEM

Diagram

19

19-2

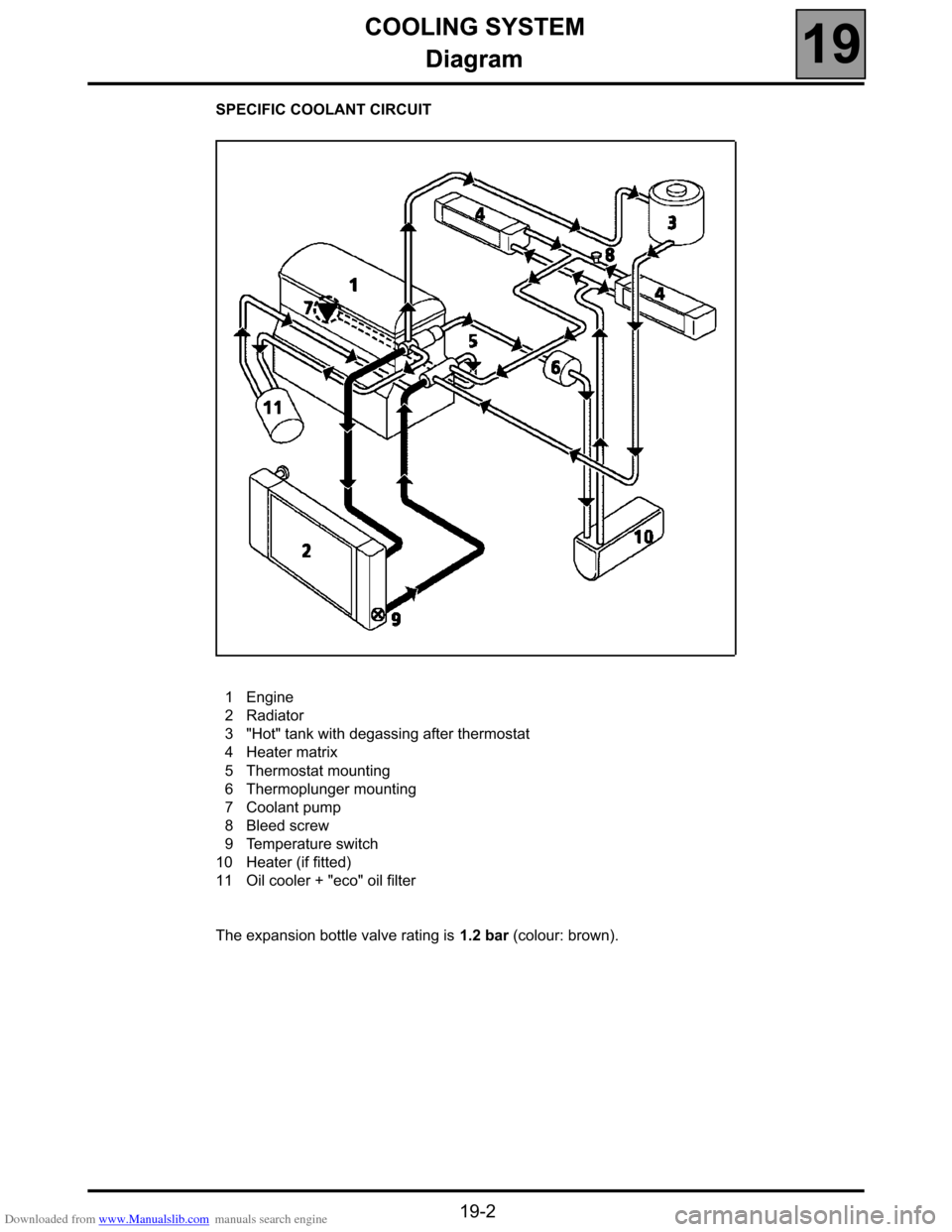

Diagram

SPECIFIC COOLANT CIRCUIT

1Engine

2Radiator

3"Hot" tank with degassing after thermostat

4Heater matrix

5Thermostat mounting

6Thermoplunger mounting

7Coolant pump

8Bleed screw

9Temperature switch

10 Heater (if fitted)

11 Oil cooler + "eco" oil filter

The expansion bottle valve rating is 1.2 bar (colour: brown).

Page 39 of 52

Downloaded from www.Manualslib.com manuals search engine COOLING SYSTEM

Coolant pump

19

19-3

Coolant pump

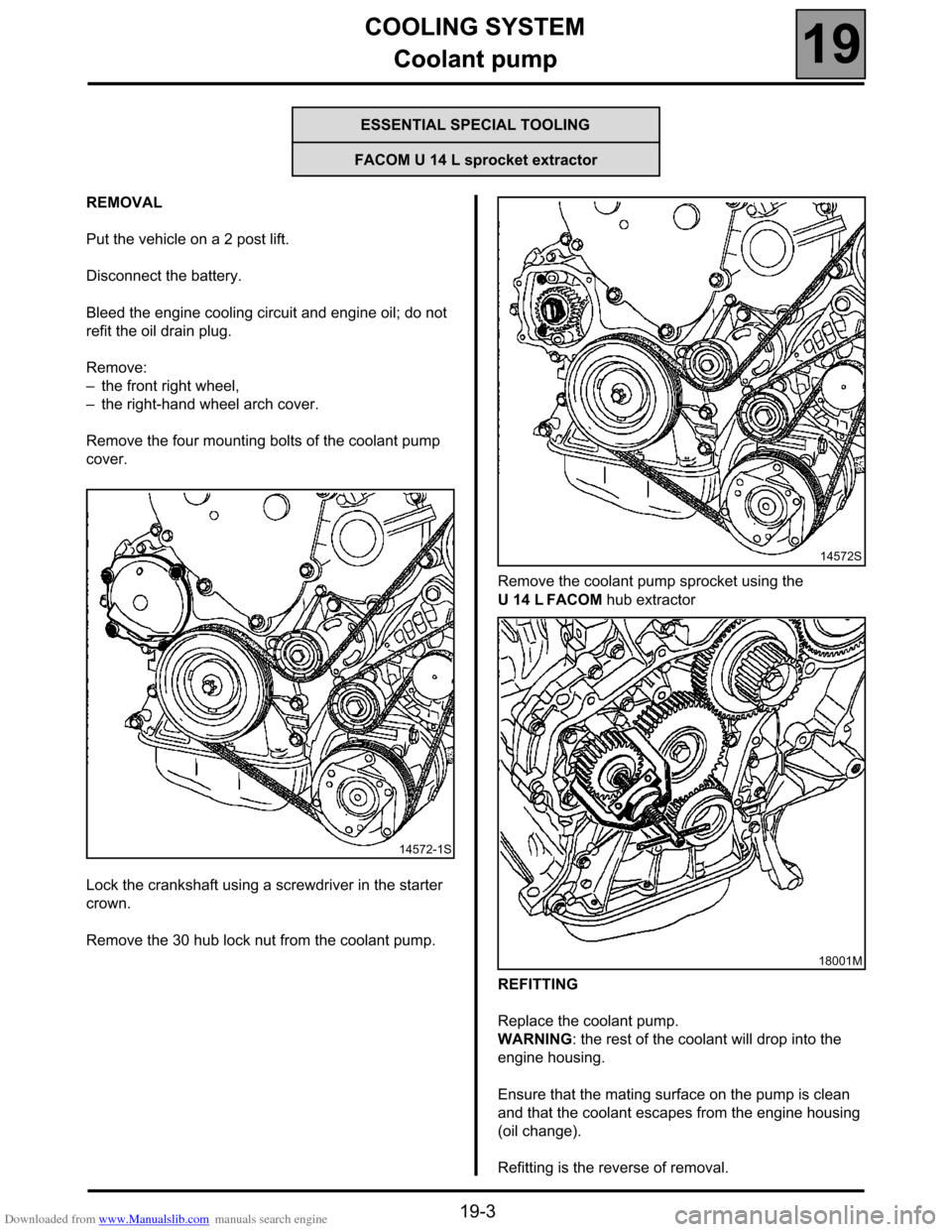

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Bleed the engine cooling circuit and engine oil; do not

refit the oil drain plug.

Remove:

–the front right wheel,

–the right-hand wheel arch cover.

Remove the four mounting bolts of the coolant pump

cover.

Lock the crankshaft using a screwdriver in the starter

crown.

Remove the 30 hub lock nut from the coolant pump.Remove the coolant pump sprocket using the

U 14 L FACOM hub extractor

REFITTING

Replace the coolant pump.

WARNING: the rest of the coolant will drop into the

engine housing.

Ensure that the mating surface on the pump is clean

and that the coolant escapes from the engine housing

(oil change).

Refitting is the reverse of removal.

ESSENTIAL SPECIAL TOOLING

FACOM U 14 L sprocket extractor

14572-1S

14572S

18001M

Page 44 of 52

Downloaded from www.Manualslib.com manuals search engine MANUAL GEARBOX

Lubricants

21

21-3

Lubricants

OIL CAPACITY :

–Maximum: 2.8 l

–Minimum: 2.3 l

OIL LEVEL

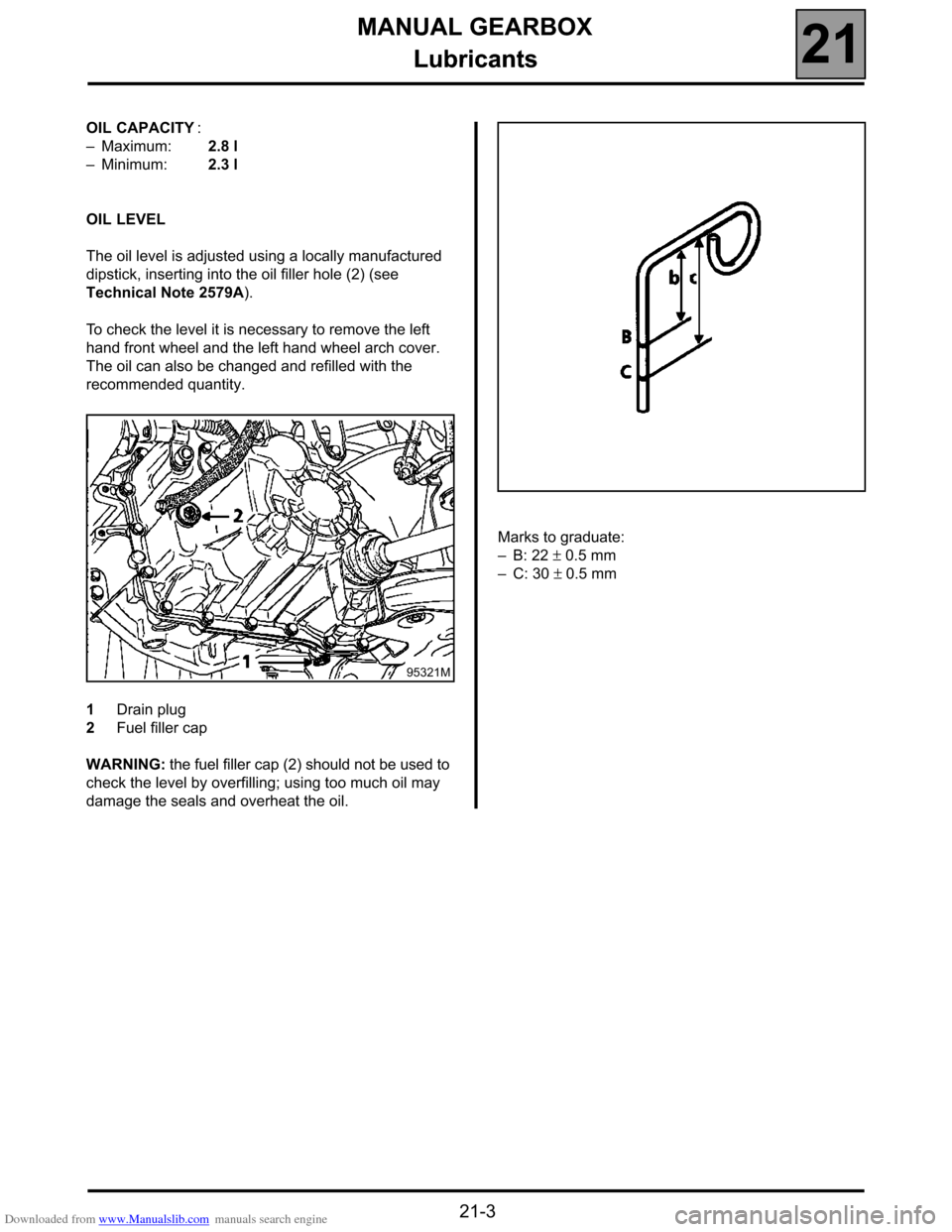

The oil level is adjusted using a locally manufactured

dipstick, inserting into the oil filler hole (2) (see

Technical Note 2579A).

To check the level it is necessary to remove the left

hand front wheel and the left hand wheel arch cover.

The oil can also be changed and refilled with the

recommended quantity.

1 Drain plug

2 Fuel filler cap

WARNING: the fuel filler cap (2) should not be used to

check the level by overfilling; using too much oil may

damage the seals and overheat the oil. Marks to graduate:

–B: 22 ± 0.5 mm

–C: 30 ± 0.5 mm

95321M