heating RENAULT ESPACE 2000 J66 / 3.G Technical Note 3426A Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: ESPACE, Model: RENAULT ESPACE 2000 J66 / 3.GPages: 52, PDF Size: 0.98 MB

Page 2 of 52

Downloaded from www.Manualslib.com manuals search engine Contents

Page

07

10

11

12

16

VALUES AND SETTINGS

Capacities - Grades 07-1

Tightening the cylinder head 07-2

ENGINE AND PERIPHERALS

Identification 10-1

Oil pressure 10-2

Engine and transmission assembly 10-3

TOP AND FRONT OF ENGINE

Accessories belt 11-1

Timing belt 11-2

Cylinder head gasket 11-8

TURBOCHARGING - FUEL

MIXTURE

Turbocharger 12-1

Air inlet 12-3

Exhaust manifold 12-7

Inlet manifold 12-8

STARTING - CHARGING

Alternator 16-1

Starter 16-4Page

19

21

61

62

COOLING SYSTEM

Filling - bleeding 19-1

Diagram 19-2

Coolant pump 19-3

Suspended mountings 19-4

Cooling system 19-5

MANUAL GEARBOX

Identification 21-1

Gears 21-2

Lubricants 21-3

Remove and refit 21-4

HEATING

Additional heating 61-1

AIR CONDITIONING

Air conditioning compressor 62-1

Page 46 of 52

Downloaded from www.Manualslib.com manuals search engine HEATING

Additional heating

61

161HEATING

Additional heating

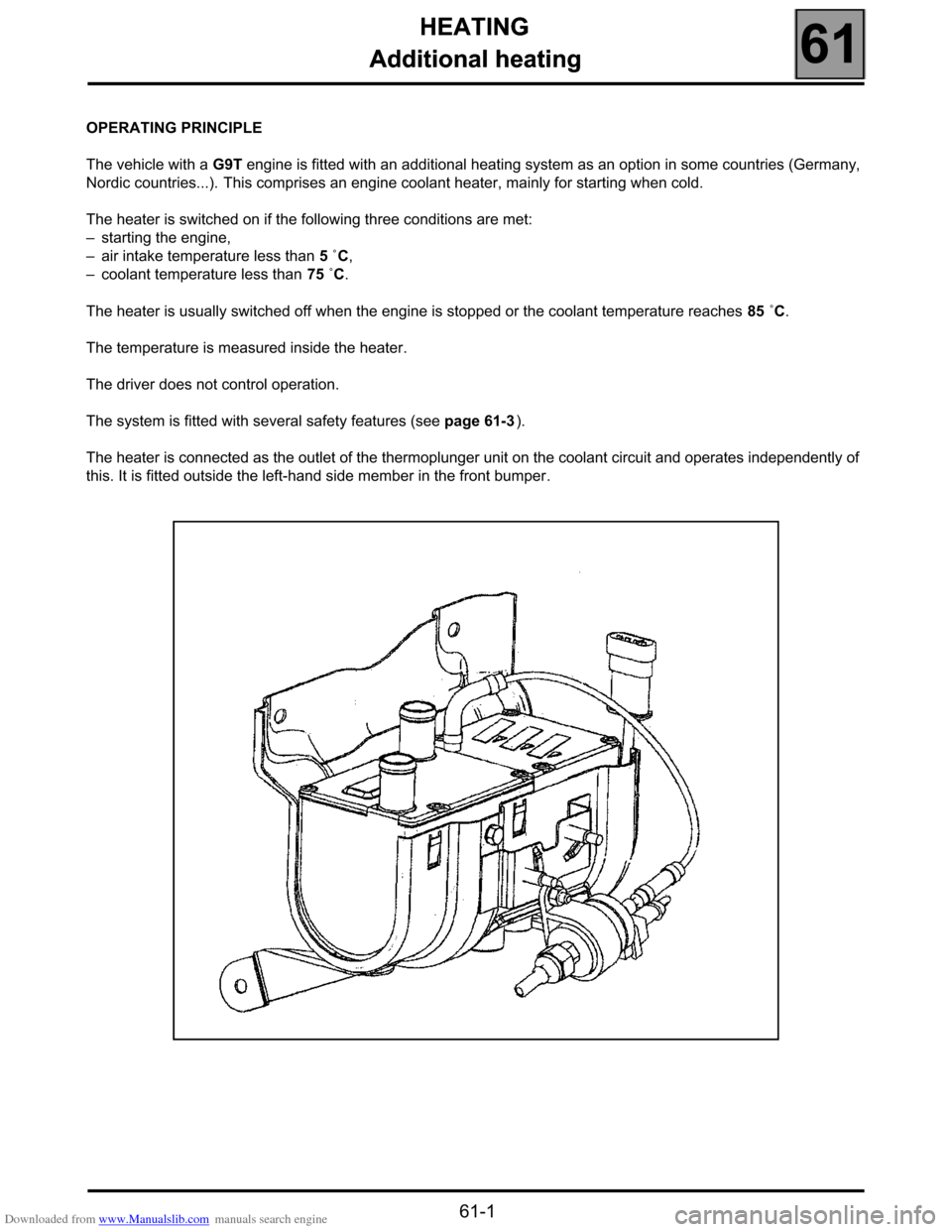

OPERATING PRINCIPLE

The vehicle with a G9T engine is fitted with an additional heating system as an option in some countries (Germany,

Nordic countries...). This comprises an engine coolant heater, mainly for starting when cold.

The heater is switched on if the following three conditions are met:

–starting the engine,

–air intake temperature less than 5 ˚C,

–coolant temperature less than 75 ˚C.

The heater is usually switched off when the engine is stopped or the coolant temperature reaches 85 ˚C.

The temperature is measured inside the heater.

The driver does not control operation.

The system is fitted with several safety features (see page 61-3).

The heater is connected as the outlet of the thermoplunger unit on the coolant circuit and operates independently of

this. It is fitted outside the left-hand side member in the front bumper.

61-1

Page 47 of 52

Downloaded from www.Manualslib.com manuals search engine HEATING

Additional heating

61

61-2

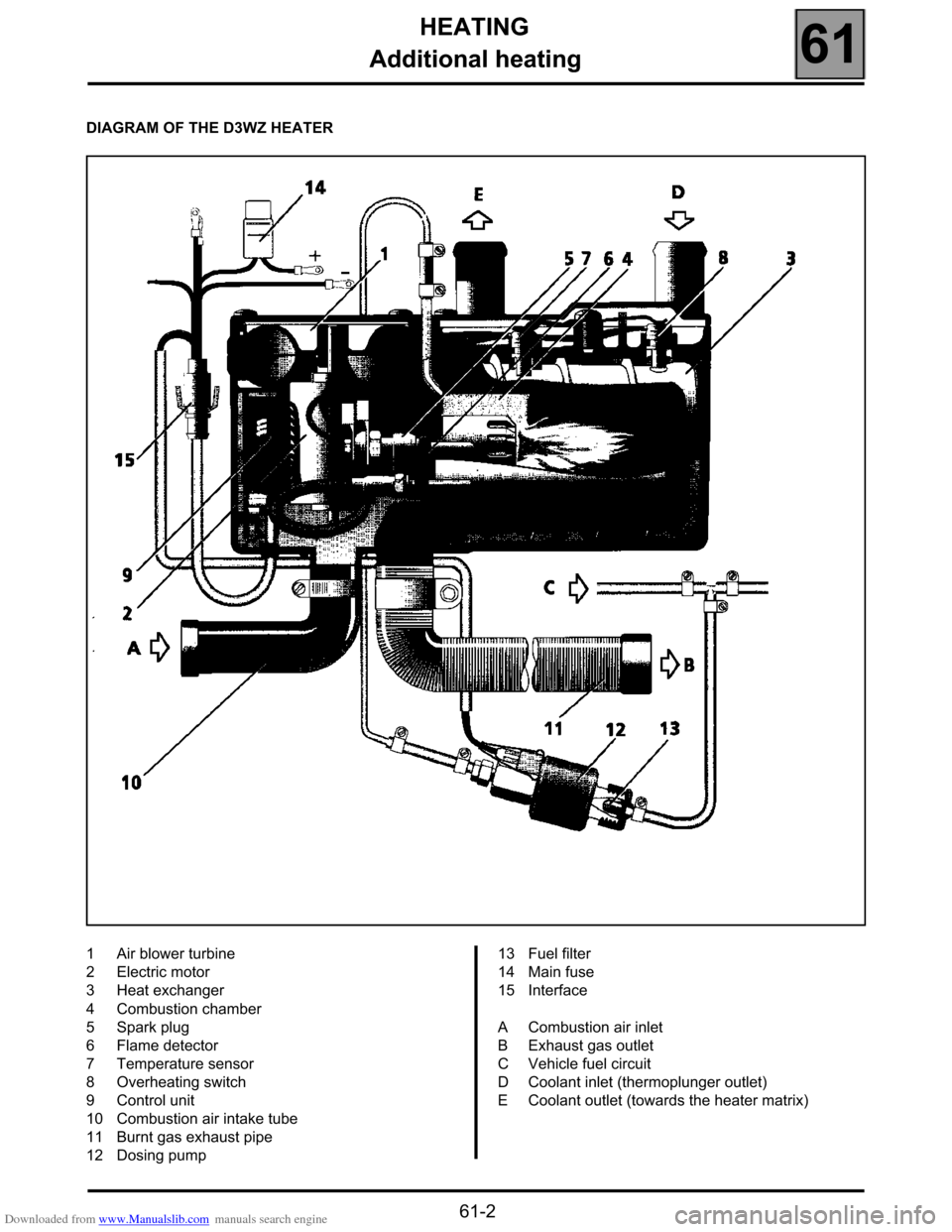

DIAGRAM OF THE D3WZ HEATER

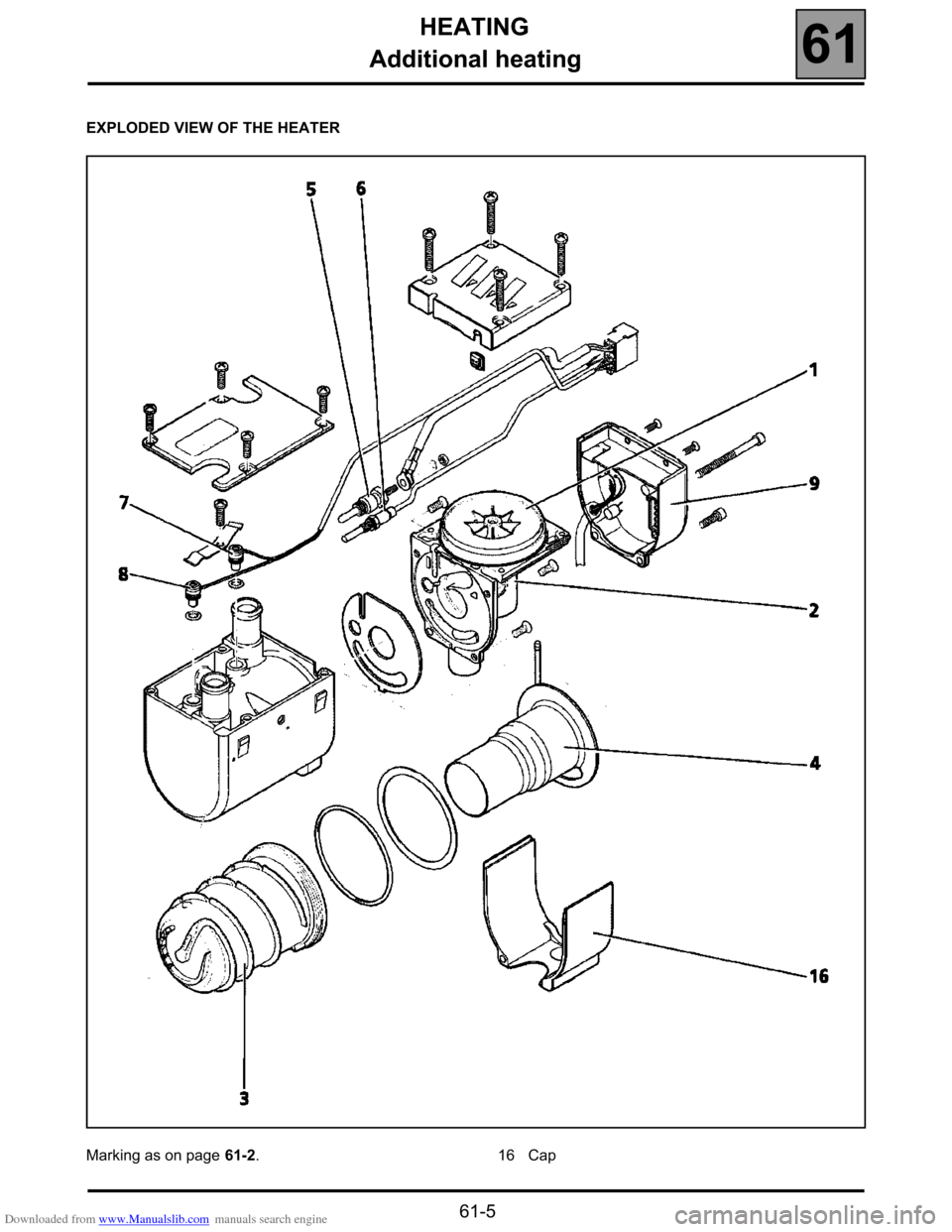

1Air blower turbine

2Electric motor

3Heat exchanger

4Combustion chamber

5Spark plug

6Flame detector

7Temperature sensor

8Overheating switch

9Control unit

10 Combustion air intake tube

11 Burnt gas exhaust pipe

12 Dosing pump 13 Fuel filter

14 Main fuse

15 Interface

ACombustion air inlet

BExhaust gas outlet

CVehicle fuel circuit

DCoolant inlet (thermoplunger outlet)

ECoolant outlet (towards the heater matrix)

Page 48 of 52

Downloaded from www.Manualslib.com manuals search engine HEATING

Additional heating

61

61-3

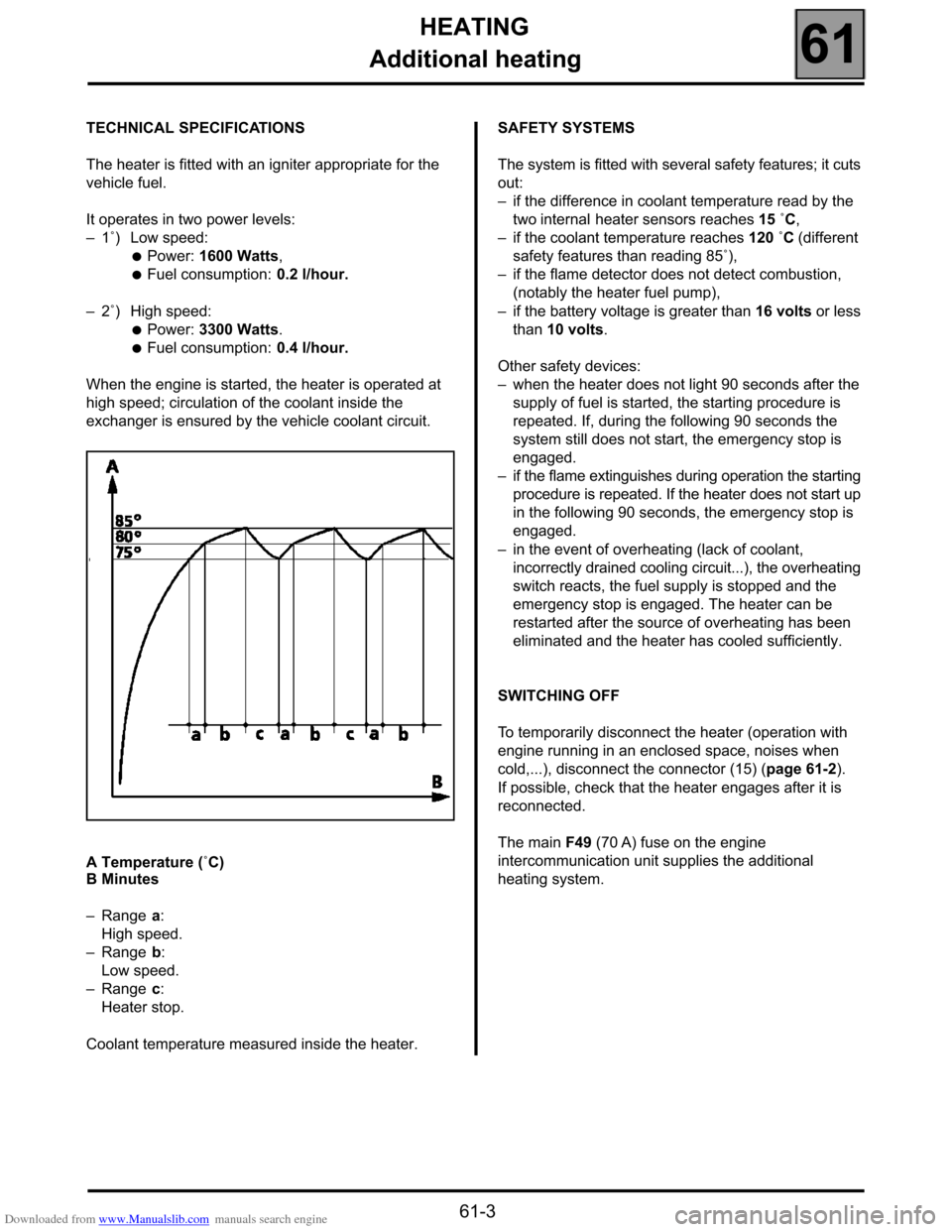

TECHNICAL SPECIFICATIONS

The heater is fitted with an igniter appropriate for the

vehicle fuel.

It operates in two power levels:

–1˚) Low speed:

●Power: 1600 Watts,

●Fuel consumption: 0.2 l/hour.

–2˚) High speed:

●Power: 3300 Watts.

●Fuel consumption: 0.4 l/hour.

When the engine is started, the heater is operated at

high speed; circulation of the coolant inside the

exchanger is ensured by the vehicle coolant circuit.

A Temperature (˚C)

B Minutes

–Range a:

High speed.

–Range b:

Low speed.

–Range c:

Heater stop.

Coolant temperature measured inside the heater.SAFETY SYSTEMS

The system is fitted with several safety features; it cuts

out:

–if the difference in coolant temperature read by the

two internal heater sensors reaches 15 ˚C,

–if the coolant temperature reaches 120 ˚C (different

safety features than reading 85˚),

–if the flame detector does not detect combustion,

(notably the heater fuel pump),

–if the battery voltage is greater than 16 volts or less

than 10 volts.

Other safety devices:

–when the heater does not light 90 seconds after the

supply of fuel is started, the starting procedure is

repeated. If, during the following 90 seconds the

system still does not start, the emergency stop is

engaged.

–if the flame extinguishes during operation the starting

procedure is repeated. If the heater does not start up

in the following 90 seconds, the emergency stop is

engaged.

–in the event of overheating (lack of coolant,

incorrectly drained cooling circuit...), the overheating

switch reacts, the fuel supply is stopped and the

emergency stop is engaged. The heater can be

restarted after the source of overheating has been

eliminated and the heater has cooled sufficiently.

SWITCHING OFF

To temporarily disconnect the heater (operation with

engine running in an enclosed space, noises when

cold,...), disconnect the connector (15) (page 61-2).

If possible, check that the heater engages after it is

reconnected.

The main F49 (70 A) fuse on the engine

intercommunication unit supplies the additional

heating system.

Page 49 of 52

Downloaded from www.Manualslib.com manuals search engine HEATING

Additional heating

61

61-4

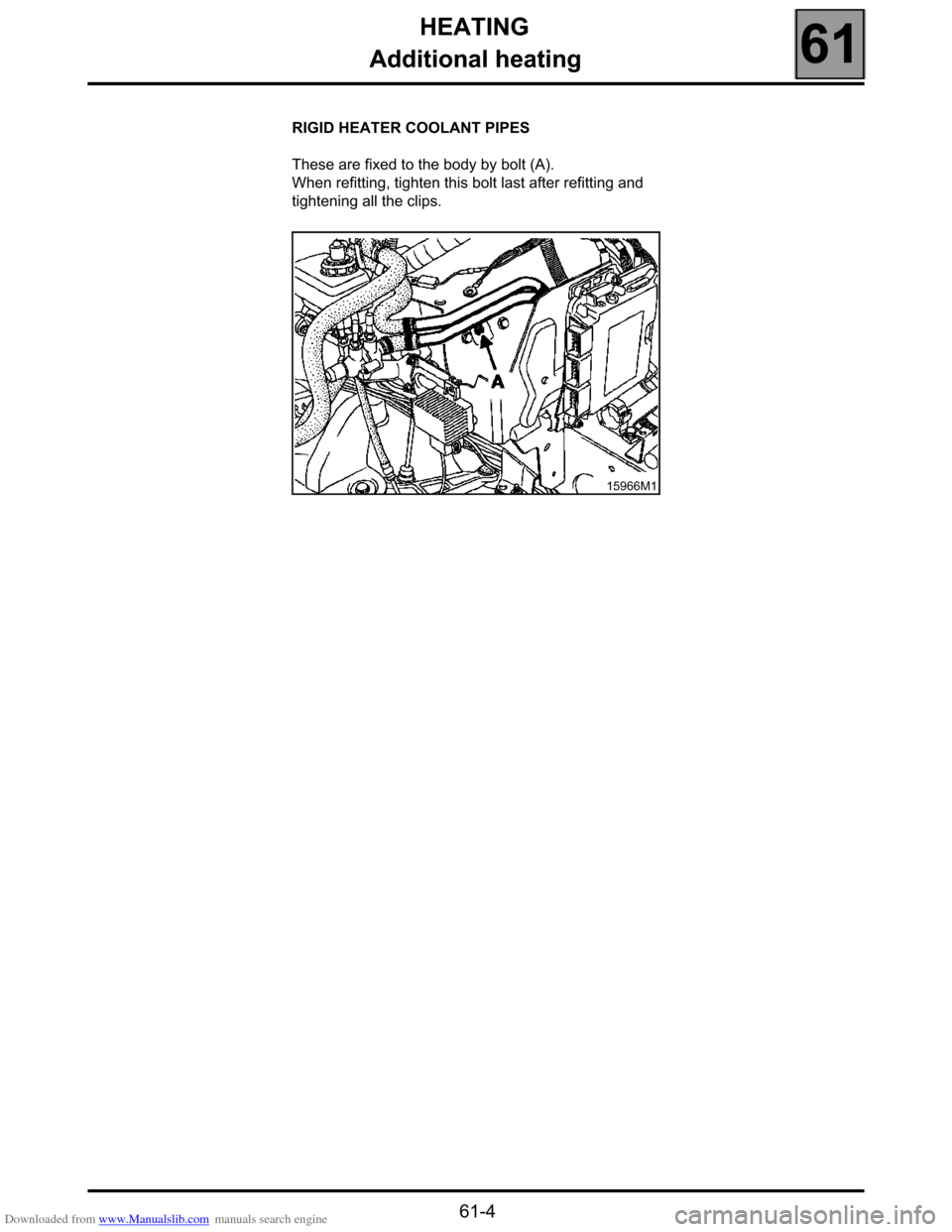

RIGID HEATER COOLANT PIPES

These are fixed to the body by bolt (A).

When refitting, tighten this bolt last after refitting and

tightening all the clips.

15966M1

Page 50 of 52

Downloaded from www.Manualslib.com manuals search engine HEATING

Additional heating

61

61-5

EXPLODED VIEW OF THE HEATER

Marking as on page 61-2.16 Cap

Page 51 of 52

Downloaded from www.Manualslib.com manuals search engine HEATING

Additional heating

61

61-6

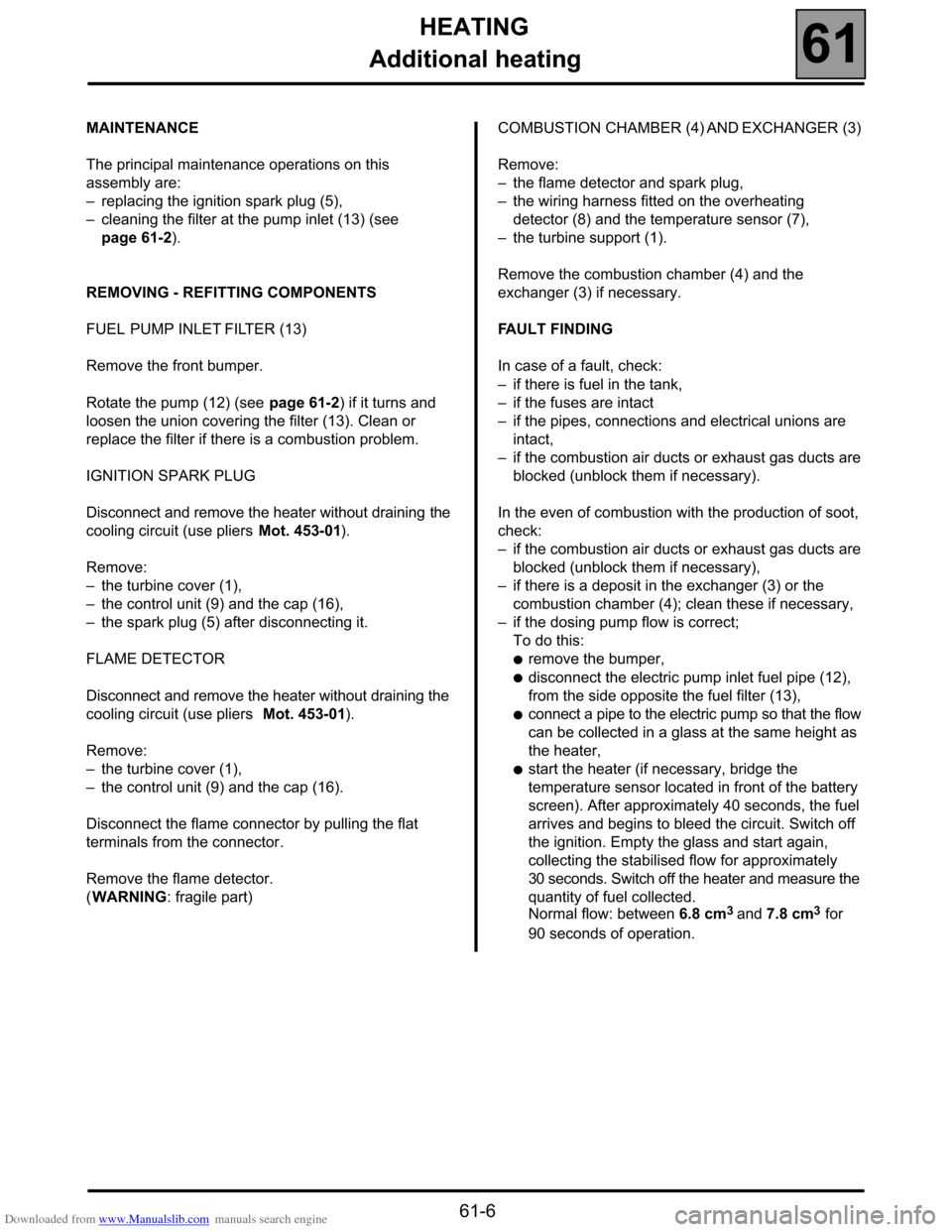

MAINTENANCE

The principal maintenance operations on this

assembly are:

–replacing the ignition spark plug (5),

–cleaning the filter at the pump inlet (13) (see

page 61-2).

REMOVING - REFITTING COMPONENTS

FUEL PUMP INLET FILTER (13)

Remove the front bumper.

Rotate the pump (12) (see page 61-2) if it turns and

loosen the union covering the filter (13). Clean or

replace the filter if there is a combustion problem.

IGNITION SPARK PLUG

Disconnect and remove the heater without draining the

cooling circuit (use pliers Mot. 453-01).

Remove:

–the turbine cover (1),

–the control unit (9) and the cap (16),

–the spark plug (5) after disconnecting it.

FLAME DETECTOR

Disconnect and remove the heater without draining the

cooling circuit (use pliers Mot. 453-01).

Remove:

–the turbine cover (1),

–the control unit (9) and the cap (16).

Disconnect the flame connector by pulling the flat

terminals from the connector.

Remove the flame detector.

(WARNING: fragile part)COMBUSTION CHAMBER (4) AND EXCHANGER (3)

Remove:

–the flame detector and spark plug,

–the wiring harness fitted on the overheating

detector (8) and the temperature sensor (7),

–the turbine support (1).

Remove the combustion chamber (4) and the

exchanger (3) if necessary.

FAULT FINDING

In case of a fault, check:

–if there is fuel in the tank,

–if the fuses are intact

–if the pipes, connections and electrical unions are

intact,

–if the combustion air ducts or exhaust gas ducts are

blocked (unblock them if necessary).

In the even of combustion with the production of soot,

check:

–if the combustion air ducts or exhaust gas ducts are

blocked (unblock them if necessary),

–if there is a deposit in the exchanger (3) or the

combustion chamber (4); clean these if necessary,

–if the dosing pump flow is correct;

To do this:

●remove the bumper,

●disconnect the electric pump inlet fuel pipe (12),

from the side opposite the fuel filter (13),

●connect a pipe to the electric pump so that the flow

can be collected in a glass at the same height as

the heater,

●start the heater (if necessary, bridge the

temperature sensor located in front of the battery

screen). After approximately 40 seconds, the fuel

arrives and begins to bleed the circuit. Switch off

the ignition. Empty the glass and start again,

collecting the stabilised flow for approximately

30 seconds. Switch off the heater and measure the

quantity of fuel collected.

Normal flow: between 6.8 cm

3 and 7.8 cm3 for

90 seconds of operation.