heater RENAULT KANGOO 1998 KC / 1.G Heating And Ventilation Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1998, Model line: KANGOO, Model: RENAULT KANGOO 1998 KC / 1.GPages: 73

Page 5 of 73

Fit the complete control panel without screwing it

in place.

On the bottom right-hand side

Fit the cable on to the mark.

Place the air distribution control on position

, place the heater control on the maxi-

mum cold position (blue mark) and check that the

flaps are at their end stop.

HEATING

Control cables

61

98815R92224R1

REMOVAL

The control cables can be removed without remo-

ving the dashboard.

Remove :

- the ashtray,

- the control unit.

In the bottom right-hand side of the passenger

compartment

Remove the securing clip (E) (depending on which

cable is to be replaced) :

- from the hot/cold air flap control cable,

or

- from the air distribution cable.

REFITTING

Route the cable through the control panel loca-

tion.

Push back the flap control to prevent the cable

from coming out of its location.

Fit securing clips (E) and (M).

61-2

Page 8 of 73

HEATING

Radiator

61

13084S98816R

13085S

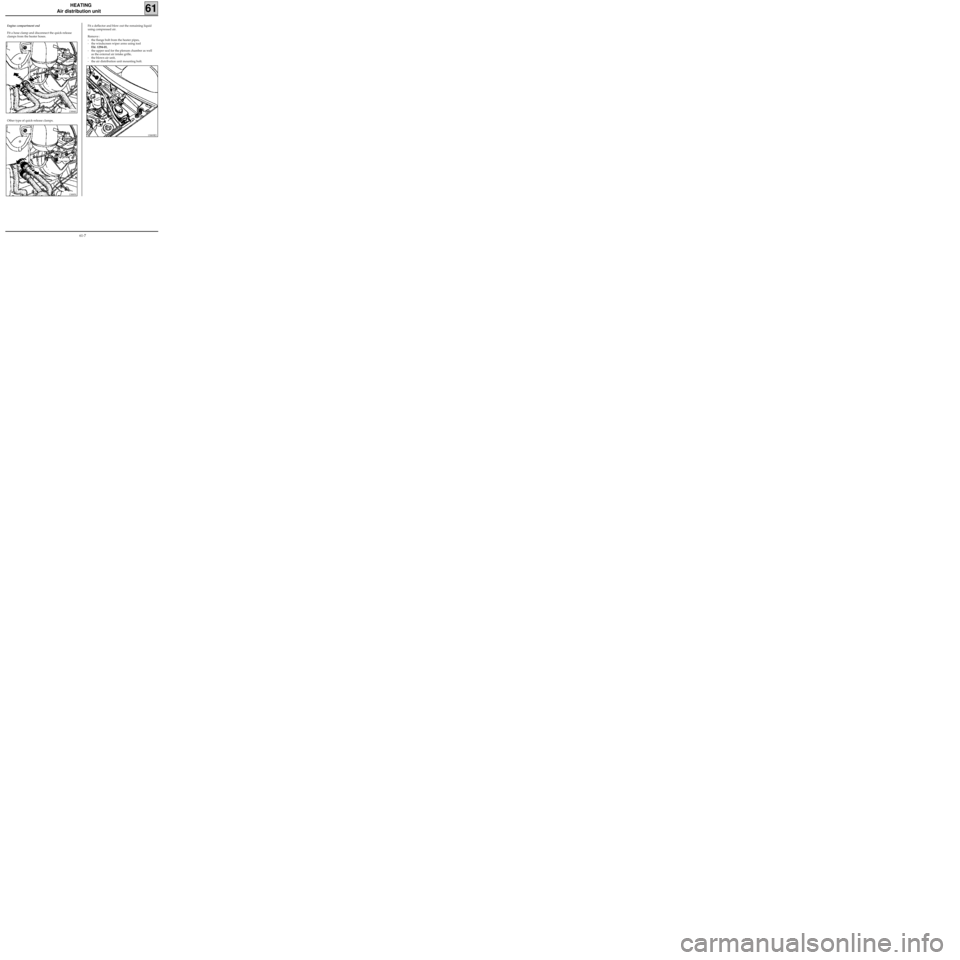

Other type of quick-release hose clamps.

REMOVAL

The radiator is removed after first removing the

air blower unit, the dashboard and the air distri-

bution unit.

Engine compartment end

Fit a hose clamp and disconnect the quick-release

clamps from the heater hoses.Fit a deflector and blow out the remaining liquid

using compressed air.

Remove the heater pipe flange bolt on the bul-

khead.

Passenger compartment end

Unclip the four securing clips (E) and take out the

radiator.

REFITTING

Refitting is carried out in reverse order to remo-

val.

Fit two mounting bolts (F) onto the body of the

unit if the clips have broken.

61-5

Page 9 of 73

HEATING

Air distribution unit

61

12969-1R

12965-1R

- the visor and the instrument panel,

- the switch stalk block assembly.

REMOVAL

Disconnect the battery.

Remove :

- the steering wheel bolt,

- the steering wheel after first placing the wheels

in a straight line.

ATTENTION: Follow the recommendations contai-

ned in section 88 relating to the AIR BAG system.

Remove :

- the steering wheel half-shell cowlings,Using adhesive tape, immobilise the rotor for the

air bag switch.

Remove :

- the ashtray,

- the two screws securing the heater control pa-

nel,

- the fuse holder plate securing screws (five

screws),

- the dashboard mounting nuts.

Unclip the wiring from the dashboard.

Remove the dashboard.

12971R

61-6

Page 10 of 73

HEATING

Air distribution unit

61

13084S

13069R3

13085S

Other type of quick-release clamps. Engine compartment end

Fit a hose clamp and disconnect the quick-release

clamps from the heater hoses.Fit a deflector and blow out the remaining liquid

using compressed air.

Remove :

- the flange bolt from the heater pipes,

- the windscreen wiper arms using tool

Elé. 1294-01,

- the upper seal for the plenum chamber as well

as the external air intake grille,

- the blown air unit,

- the air distribution unit mounting bolt.

61-7

Page 11 of 73

HEATING

Air distribution unit

61

PRO61.3

In the passenger compartment

Remove :

- the air distribution unit,

- the heater unit radiator.REFITTING

Check :

- that the wiring is correctly routed behind the

dashboard,

- that the air ducts are correctly secured to pre-

vent noises developing.

Change the steering wheel bolt (pre-bonded bolt,

tightening torque : 4.5 daN.m).

IMPORTANT : Before reconnecting the AIR BAG

cushion it is necessary to apply the air bag system

operational check procedure :

• Check that the AIR BAG warning light on the

instrument panel is illuminated when the igni-

tion is switched on.

• Connect an inert ignition unit to the AIR BAG

cushion connector and check that the warning

light extinguishes.

• Switch off the ignition, connect the AIR BAG

cushion in place of the inert ignition unit and

secure the cushion on to the steering wheel.

• Switch on the ignition, check that the air bag

warning light illuminates for three seconds

when the ignition is switched on and then ex-

tinguishes and remains extinguished.

If the warning light does not operate as indicated

above, please consult section 88 of the workshop

repair manual.

61-8

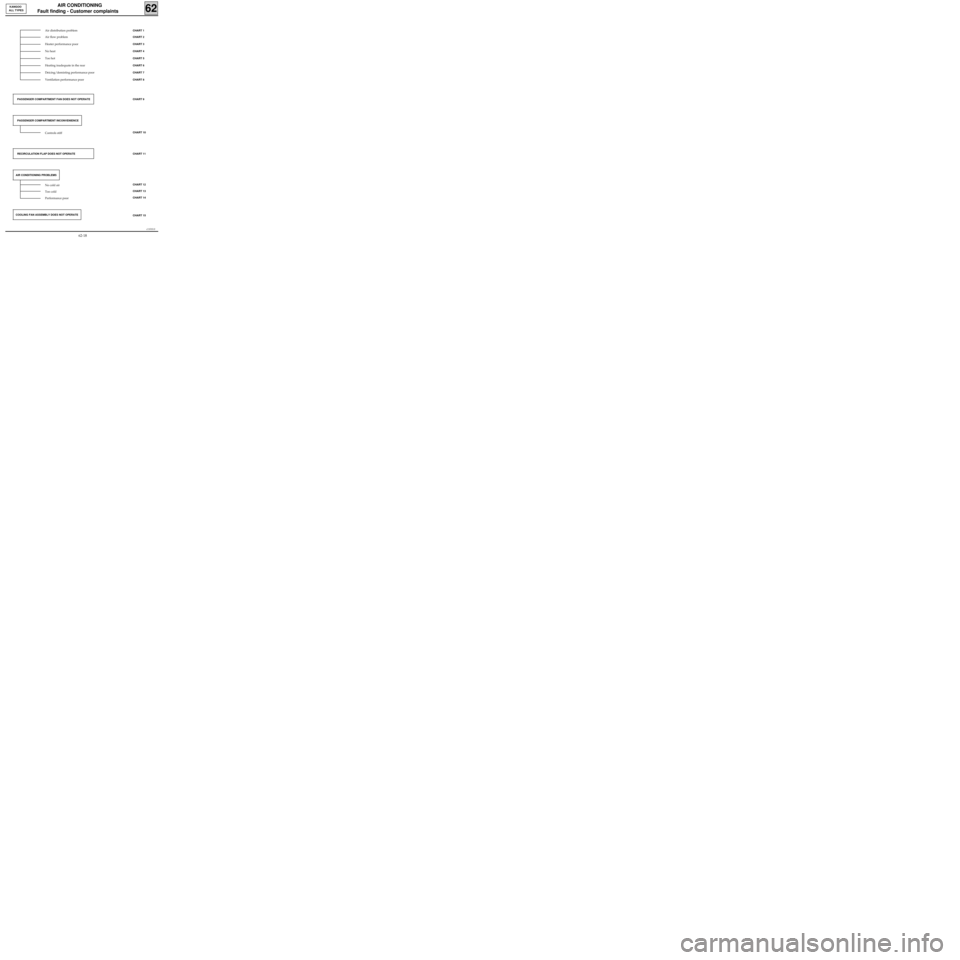

Page 29 of 73

c11010.0

AIR CONDITIONING

Fault finding - Customer complaints

62

KANGOO

ALL TYPES

CHART 1

CHART 2

CHART 3

CHART 4

CHART 5

CHART 6

CHART 7

CHART 8

PASSENGER COMPARTMENT FAN DOES NOT OPERATECHART 9

PASSENGER COMPARTMENT INCONVENIENCE

Controls stiffCHART 10

RECIRCULATION FLAP DOES NOT OPERATECHART 11

No cold air

Too cold

Performance poorCHART 12

CHART 13

CHART 14

AIR CONDITIONING PROBLEMS

CHART 15 COOLING FAN ASSEMBLY DOES NOT OPERATE

Air distribution problem

Air flow problem

Heater performance poor

No heat

Too hot

Heating inadequate in the rear

Deicing/demisting performance poor

Ventilation performance poor

62-18

Page 32 of 73

c11010.0

AIR CONDITIONING

Fault finding charts

62

KANGOO

ALL TYPES

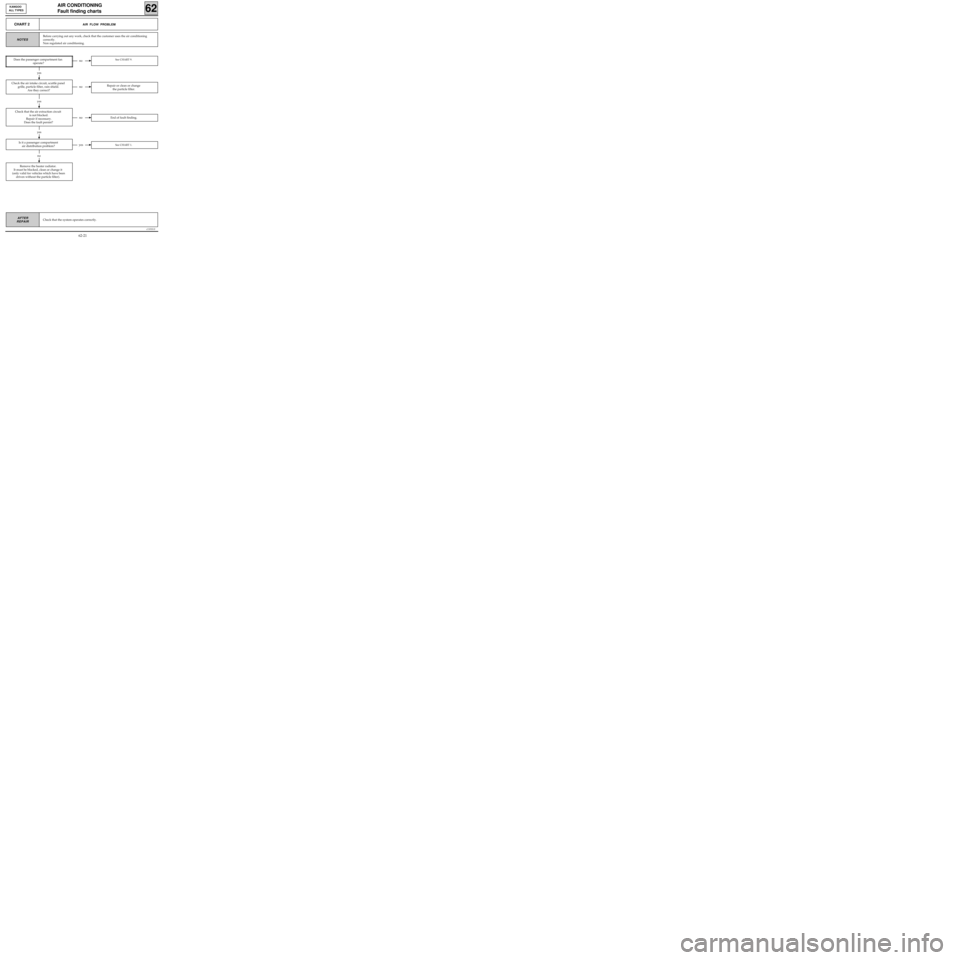

Check that the system operates correctly.AFTER

REPAIR

yes

CHART 2AIR FLOW PROBLEM

Before carrying out any work, check that the customer uses the air conditioning

correctly.

Non regulated air conditioning.

NOTES

no

yes

yes

yesSee CHART 1.

no

noEnd of fault finding.

Does the passenger compartment fan

operate?noSee CHART 9.

Repair or clean or change

the particle filter.Check the air intake circuit, scuttle panel

grille, particle filter, rain shield.

Are they correct?

Check that the air extraction circuit

is not blocked.

Repair if necessary.

Does the fault persist?

Is it a passenger compartment

air distribution problem?

Remove the heater radiator.

It must be blocked, clean or change it

(only valid for vehicles which have been

driven without the particle filter).

62-21

Page 33 of 73

c11010.0

AIR CONDITIONING

Fault finding charts

62

KANGOO

ALL TYPES

Check that the system operates correctly.AFTER

REPAIR

no

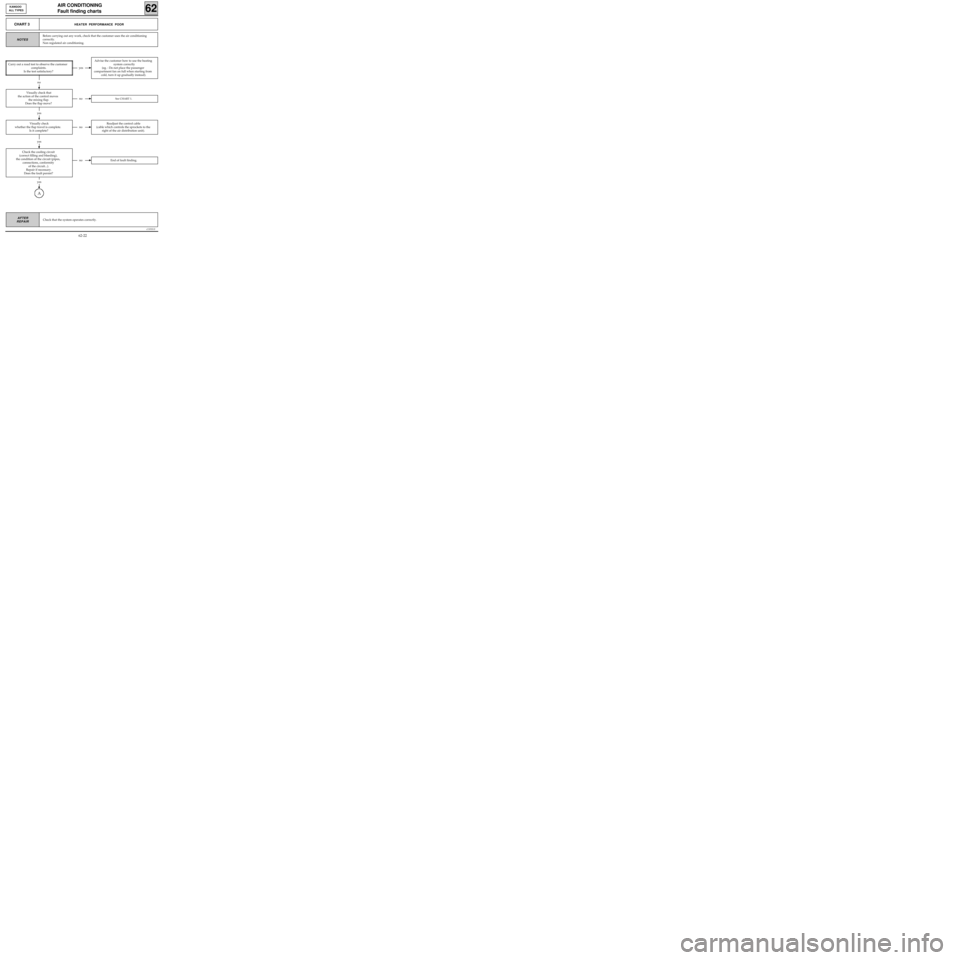

CHART 3HEATER PERFORMANCE POOR

NOTES

yes

Advise the customer how to use the heating

system correctly

(eg. : Do not place the passenger

compartment fan on full when starting from

cold, turn it up gradually instead).

Carry out a road test to observe the customer

complaints.

Is the test satisfactory?

yes

A

yes

yes

noSee CHART 1.

no

noEnd of fault finding.

Before carrying out any work, check that the customer uses the air conditioning

correctly.

Non regulated air conditioning.

Visually check that

the action of the control moves

the mixing flap.

Does the flap move?

Visually check

whether the flap travel is complete.

Is it complete?

Check the cooling circuit

(correct filling and bleeding),

the condition of the circuit (pipes,

connections, conformity

of the circuit...).

Repair if necessary.

Does the fault persist?

Readjust the control cable

(cable which controls the sprockets to the

right of the air distribution unit).

62-22

Page 34 of 73

c11010.0

AIR CONDITIONING

Fault finding charts

62

KANGOO

ALL TYPES

Check that the components which were removed are connected correctly.

Check that the system operates correctly.AFTER

REPAIR

yes

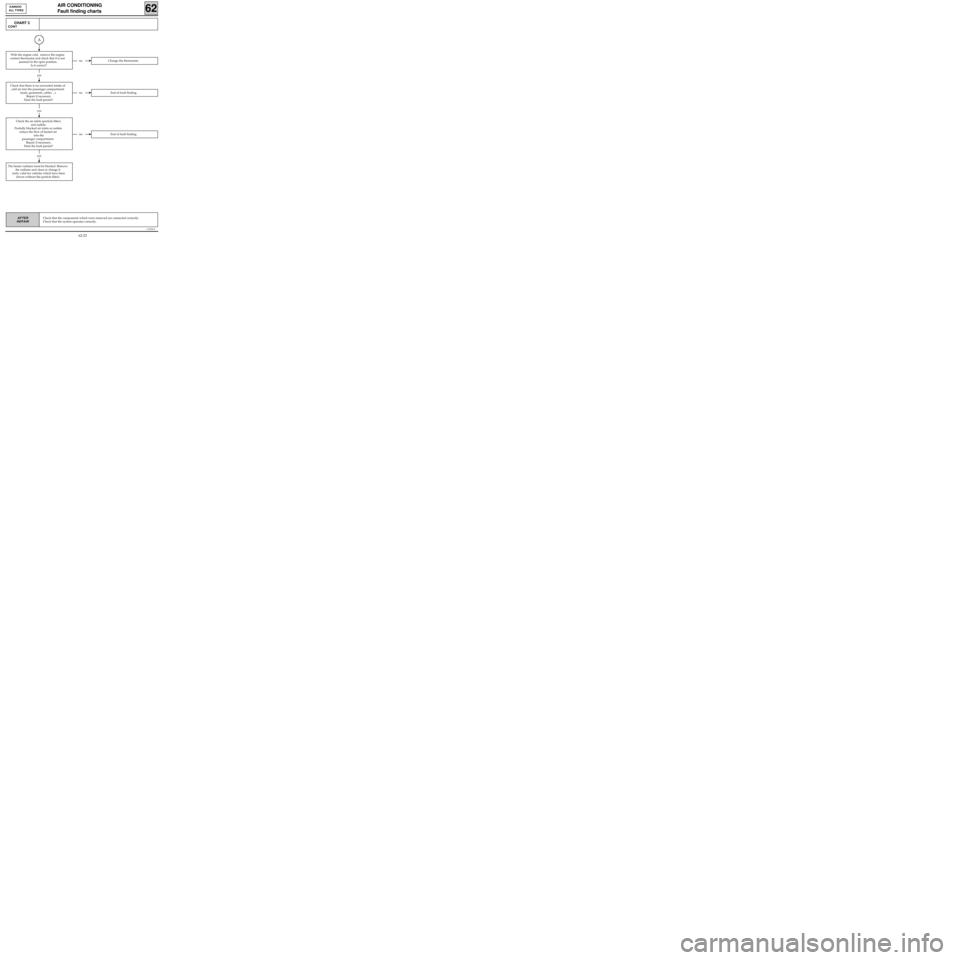

CHART 3

CONT

A

noChange the thermostat.

yes

yes

noEnd of fault finding.

noEnd of fault finding.

With the engine cold, remove the engine

coolant thermostat and check that it is not

jammed in the open position.

Is it correct?

Check that there is no unwanted intake of

cold air into the passenger compartment

(seals, grommets, cables ...).

Repair if necessary

Does the fault persist?

Check the air inlets (particle filter)

and outlets.

Partially blocked air inlets or outlets

reduce the flow of heated air

into the

passenger compartment.

Repair if necessary.

Does the fault persist?

The heater radiator must be blocked. Remove

the radiator and clean or change it

(only valid for vehicles which have been

driven without the particle filter).

62-23

Page 35 of 73

c11010.0

AIR CONDITIONING

Fault finding charts

62

KANGOO

ALL TYPES

AFTER

REPAIR

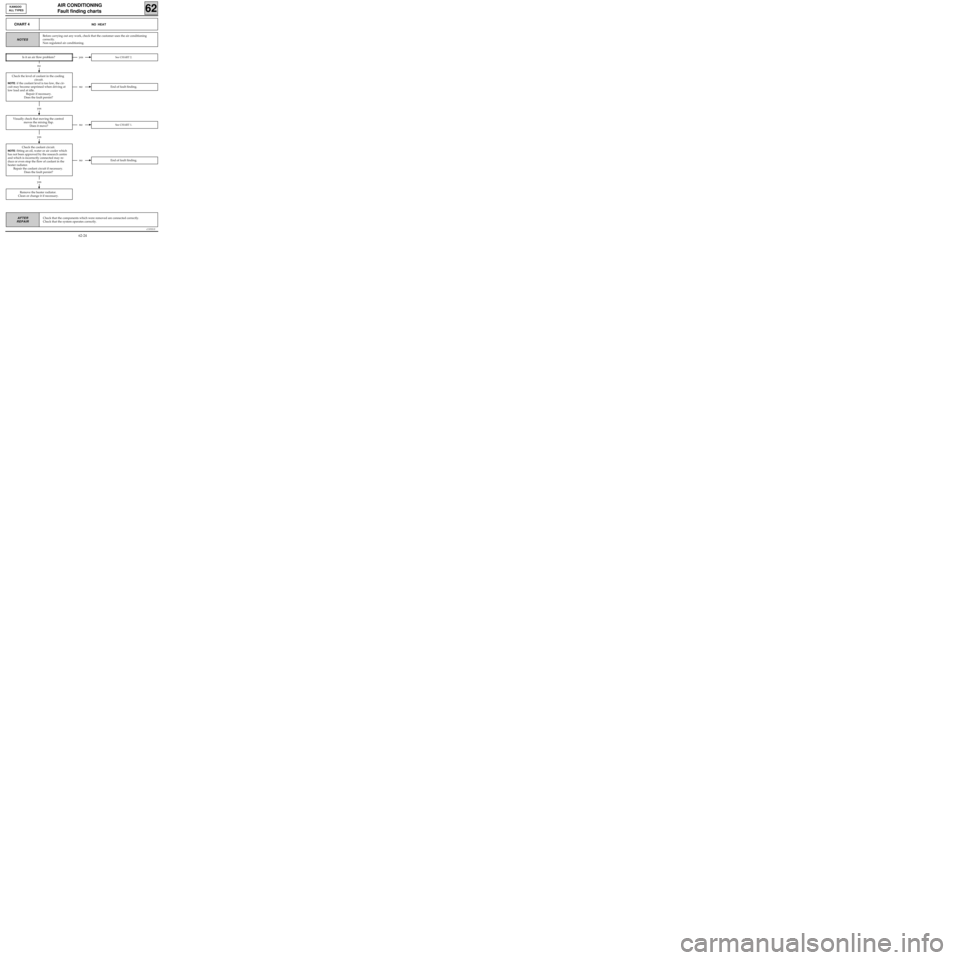

no

CHART 4NO HEAT

NOTES

Is it an air flow problem?yesSee CHART 2.

yes

yes

noSee CHART 1.

noEnd of fault finding.

noEnd of fault finding.

Before carrying out any work, check that the customer uses the air conditioning

correctly.

Non regulated air conditioning.

Check the level of coolant in the cooling

circuit.

NOTE: if the coolant level is too low, the cir-

cuit may become unprimed when driving at

low load and at idle.

Repair if necessary.

Does the fault persist?

Visually check that moving the control

moves the mixing flap.

Does it move?

yes

Check the coolant circuit.

NOTE: fitting an oil, water or air cooler which

has not been approved by the research centre

and which is incorrectly connected may re-

duce or even stop the flow of coolant in the

heater radiator.

Repair the coolant circuit if necessary.

Does the fault persist?

Remove the heater radiator.

Clean or change it if necessary.

Check that the components which were removed are connected correctly.

Check that the system operates correctly.

62-24