oil RENAULT KANGOO 1998 KC / 1.G Heating And Ventilation Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1998, Model line: KANGOO, Model: RENAULT KANGOO 1998 KC / 1.GPages: 73

Page 13 of 73

AIR CONDITIONING

General

62

A Passenger compartment

B Engine compartment

C Exterior air

D To air mixing unit

E Scuttle panel grille

F Exterior or recirculated air

1 Compressor with variable capacity

2 Condenser

3 Dehydration canister

4 Pressure sensor

5 High pressure valve

6 Pressure relief valve

7 Evaporator

8 Low pressure valve

9 Heating/ventilation fan

10 Cooling fan

11 Engine radiator

12 High pressure fluid

13 Low pressure vapour

14 High pressure vapour

Consumables:

- Compressor oil

SANDEN SP 10: 135 cm3 ± 15

- Coolant

R134a: 650 g ± 35

- Compressor

SANDEN SD 7V 16

62-2

Page 35 of 73

c11010.0

AIR CONDITIONING

Fault finding charts

62

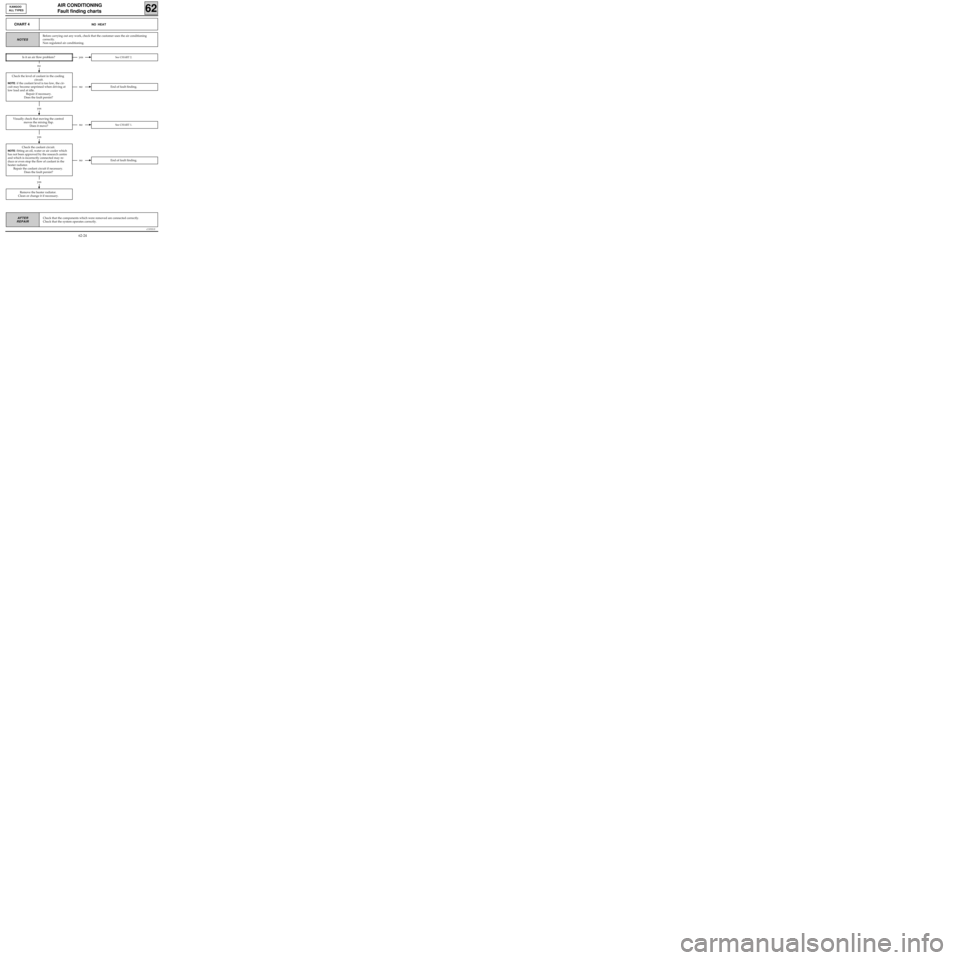

KANGOO

ALL TYPES

AFTER

REPAIR

no

CHART 4NO HEAT

NOTES

Is it an air flow problem?yesSee CHART 2.

yes

yes

noSee CHART 1.

noEnd of fault finding.

noEnd of fault finding.

Before carrying out any work, check that the customer uses the air conditioning

correctly.

Non regulated air conditioning.

Check the level of coolant in the cooling

circuit.

NOTE: if the coolant level is too low, the cir-

cuit may become unprimed when driving at

low load and at idle.

Repair if necessary.

Does the fault persist?

Visually check that moving the control

moves the mixing flap.

Does it move?

yes

Check the coolant circuit.

NOTE: fitting an oil, water or air cooler which

has not been approved by the research centre

and which is incorrectly connected may re-

duce or even stop the flow of coolant in the

heater radiator.

Repair the coolant circuit if necessary.

Does the fault persist?

Remove the heater radiator.

Clean or change it if necessary.

Check that the components which were removed are connected correctly.

Check that the system operates correctly.

62-24

Page 60 of 73

AIR CONDITIONING

Evaporator

62

Move aside the dashboard by removing:

- the six steering column mounting bolts,

- the four dashboard side retaining nuts and the

two bolts behind the ashtray assembly.

NOTE: take care to protect the sections of the

dashboard which are susceptible to damage using

cloths.

Remove the two evaporator housing mountings

behind the dashboard on the passenger side.

Remove the evaporator housing.

Carefully remove the evaporator from its housing.

REFITTING

Check that the harness tubes are not in contact

(risk of noise).

Proceed in the reverse order to removal.

Tighten the retaining nut (connecting pipes to

pressure relief valve) to 0.8 daN.m (pay attention

to the condition of the seals).

NOTE: when refitting the dashboard, check:

- that the electrical wiring is positioned correctly,

- that the air flow pipes are positioned correctly

(glove box for example).

Create a vacuum, then fill the R134a coolant cir-

cuit using the filling equipment.

IMPORTANT

When an evaporator is changed, add 30 ml of

P.A.G. SP 10 oil to the circuit.

Use the same oil for refitting the seals taking care

to position them correctly.

62-49

Page 61 of 73

AIR CONDITIONING

Air blower unit

62

REMOVAL

An air blower unit can only be changed following

removal of the evaporator (refer to the

"Evaporator" section).

Remove the two heater fan assembly mounting

bolts.

Remove the heater fan assembly.

REFITTING

Refitting does not present any special points.

After refitting the heater fan assembly and the

evaporator, create a vacuum and then fill the

R134a coolant circuit using the filling equipment.

IMPORTANT

Ensure that all of the seals are positioned correct-

ly. Lubricate them with

P.A.G. SP 10 oil.

62-50

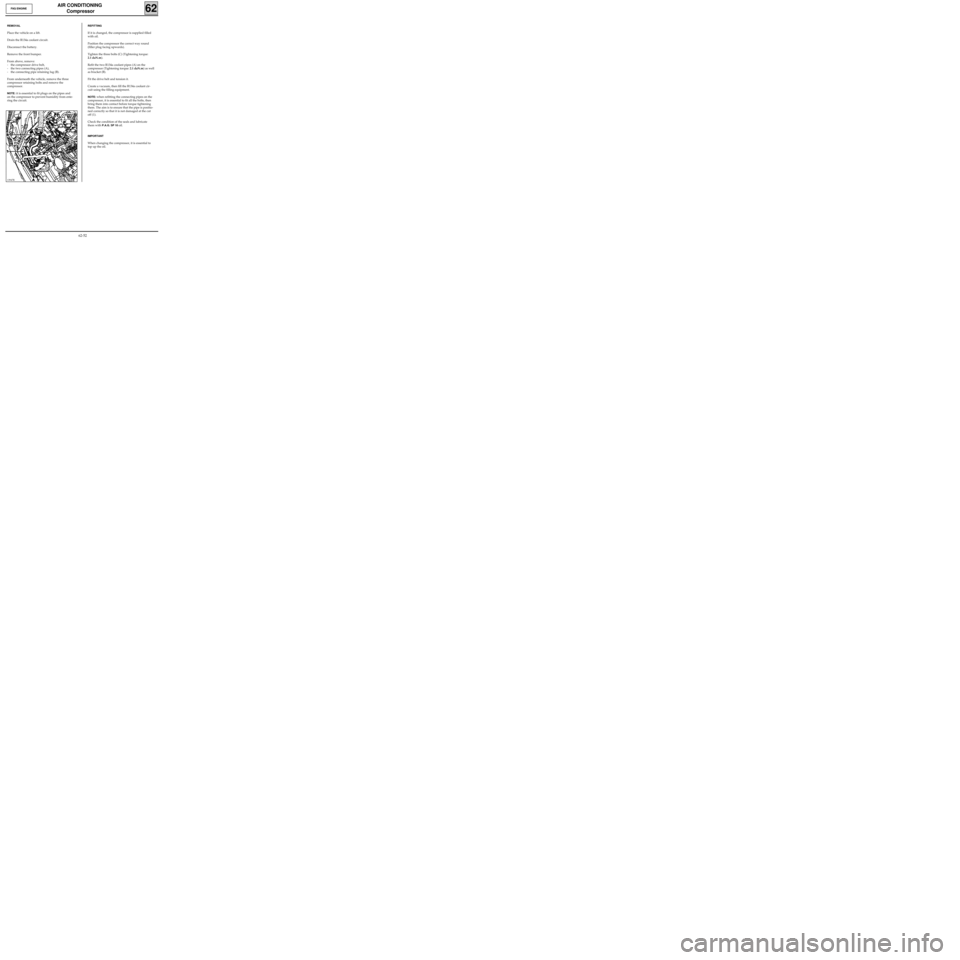

Page 62 of 73

AIR CONDITIONING

Compressor

62D7F ENGINE

13829R1

REMOVAL

Drain the R134a coolant circuit.

Disconnect the battery.

Remove:

- the compressor drive belt,

- the two connecting pipes (A),

- the retaining strut bolt (B),

- the three compressor retaining bolts (C).

Remove the compressor.

NOTE: it is essential to place plugs on the pipes

and on the compressor to prevent the entry of hu-

midity into the circuit.

REFITTING

If it is changed, the compressor is supplied filled

with oil.

Position the compressor the correct way round

(filler plug facing upwards).

Tighten the three bolts (C) (Tightening torque:

2.1 daN.m).

Fit the strut retaining bolts (B).

Refit the two R134a coolant pipes (A) on the

compressor (Tightening torque:

2.1 daN.m).

Fit the drive belt and tension it.

Create a vacuum, then fill the R134a coolant cir-

cuit using the filling equipment.

NOTE: when refitting the connecting pipes on the

compressor, it is essential to fit all the bolts, then

bring them into contact before torque tightening

them. The aim is to ensure that the pipe is positio-

ned correctly so that it is not damaged at the cut

off (1).

Check the condition of the seals and lubricate

them with

P.A.G. SP 10 oil.

IMPORTANT

When changing the compressor, it is essential to

top up the oil.

62-51

Page 63 of 73

AIR CONDITIONING

Compressor

62F8Q ENGINE

REMOVAL

Place the vehicle on a lift.

Drain the R134a coolant circuit.

Disconnect the battery.

Remove the front bumper.

From above, remove:

- the compressor drive belt,

- the two connecting pipes (A),

- the connecting pipe retaining lug (B).

From underneath the vehicle, remove the three

compressor retaining bolts and remove the

compressor.

NOTE: it is essential to fit plugs on the pipes and

on the compressor to prevent humidity from ente-

ring the circuit.

13947R

REFITTING

If it is changed, the compressor is supplied filled

with oil.

Position the compressor the correct way round

(filler plug facing upwards).

Tighten the three bolts (C) (Tightening torque:

2.1 daN.m).

Refit the two R134a coolant pipes (A) on the

compressor (Tightening torque:

2.1 daN.m) as well

as bracket (B).

Fit the drive belt and tension it.

Create a vacuum, then fill the R134a coolant cir-

cuit using the filling equipment.

NOTE: when refitting the connecting pipes on the

compressor, it is essential to fit all the bolts, then

bring them into contact before torque tightening

them. The aim is to ensure that the pipe is positio-

ned correctly so that it is not damaged at the cut

off (1).

Check the condition of the seals and lubricate

them with

P.A.G. SP 10 oil.

IMPORTANT

When changing the compressor, it is essential to

top up the oil.

62-52

Page 64 of 73

AIR CONDITIONING

Compressor

62E7J ENGINE

REMOVAL

Place the vehicle on a lift.

Drain the R134a coolant circuit.

Disconnect the battery.

Remove:

- the engine undertray,

- the bumper.

From above, remove:

- the accessories drive belt,

- the two R134a connecting pipes (A).

From underneath the vehicle, remove:

- the compressor drive belt,

- the compressor retaining bolts and remove the

the compressor.

NOTE: it is essential to fit plugs on the pipes and

on the compressor to prevent humidity from ente-

ring the circuit.

REFITTING

If it is changed, the compressor is supplied filled

with oil.

Position the compressor the correct way round

(filler plug facing upwards).

Tighten the retaining bolts (C) (Tightening tor-

que: 2.1 daN.m).

Refit the two R134a coolant pipes (A) on the

compressor (Tightening torque:

2.1 daN.m).

Fit the drive belts and tension them.

Create a vacuum, then fill the R134a coolant cir-

cuit using the filling equipment.

NOTE: when refitting the connecting pipes on the

compressor, it is essential to fit all the bolts, then

bring them into contact before torque tightening

them. The aim is to ensure that the pipe is positio-

ned correctly so that it is not damaged at the cut

off (1).

Check the condition of the seals and lubricate

them with

P.A.G. SP 10 oil.

IMPORTANT

When changing the compressor, it is essential to

top up the oil.

14229R

62-53

Page 65 of 73

AIR CONDITIONING

Condenser

62

13828R

REMOVAL

It is not necessary to use a lift.

Drain the R134a coolant circuit.

Disconnect the battery.

Remove:

- the plastic air deflector on the upper crossmem-

ber,

- the seal (1),

- the upper crossmember (2),

- the retaining bolt (3),

- the two R134a coolant pipes (4) (fit plugs to

prevent the entry of humidity),

- the two radiator upper retaining bolts.Move the radiator-condenser assembly as far back

as possible towards the engine.

Remove the four condenser to radiator retaining

bolts (6).

Carefully remove the condenser.

REFITTING

Proceed in the reverse order to removal.

Check the condition of the seals.

Create a vacuum, then fill the circuit with R134a

using the filling equipment.

IMPORTANT

When changing the condenser, add 30 ml of

P.A.G. SP 10 oil to the circuit.

NOTE: tightening torque of bolts (6) : 0.8 daN.m.

13830R

62-54

Page 67 of 73

AIR CONDITIONING

Dehydration canister

62

13828R1

Remove the dehydration canister from under-

neath the vehicle.

Fit plugs on each hole to prevent any entry of hu-

midity into the components.

REFITTING

Proceed in the reverse order to removal.

Check that the seals are in good condition and lu-

bricate them with

P.A.G. SP 10 oil.

Create a vacuum, then fill the R134a coolant cir-

cuit using the filling equipment.

When changing the dehydration canister, add 15

ml of

P.A.G. SP 10 oil to the circuit.

NOTE: tightening torque of bolt (2) : 1.2 daN.m

REMOVAL

Drain the R134a coolant circuit using the filling

equipment.

Remove:

- the two radiator upper mounting bolts,

- the two mounting bolts which secure the pipes

to the dehydration canister.

Move back the radiator-condenser assembly

slightly.

Through the bumper, remove the two dehydra-

tion canister to condenser retaining bolts (1).

62-56

Page 68 of 73

AIR CONDITIONING

Connecting pipes

62

PRO62.4

Disconnect the battery.

Drain the R134a coolant circuit using the filling

equipment.

LOW PRESSURE PIPE

REMOVAL

Remove the mounting bolt on the pressure relief

valve.

Fit plugs to the pressure relief valve and the pipe.

Remove the mounting bolt on the compressor.

Fit plugs to the compressor and the pipe.

Unscrew the pipe retaining lug.

Remove the low pressure pipe.

REFITTING

Proceed in the reverse order to removal.

Check the condition of the seals and lubricate

them with

P.A.G. SP 10 oil.

When changing a pipe, add 10 ml of SP 10 oil or

when a pipe bursts (rapid leak), add 100 ml.

Create a vacuum, then fill the R134a coolant cir-

cuit using the filling equipment.

NOTE:

- Pipes to compressor

retaining bolt:2.1 daN.m

- Pipes to pressure relief valve

retaining nut:0.8 daN.m

- Pipes to condenser

retaining bolt:0.8 daN.m

62-57