coolant temperature RENAULT KANGOO 2013 X61 / 2.G Diesel DCM 1.2 Injection Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 204, PDF Size: 0.99 MB

Page 141 of 204

13B-141V1 MR-376-X76-13B000$110.mif

13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

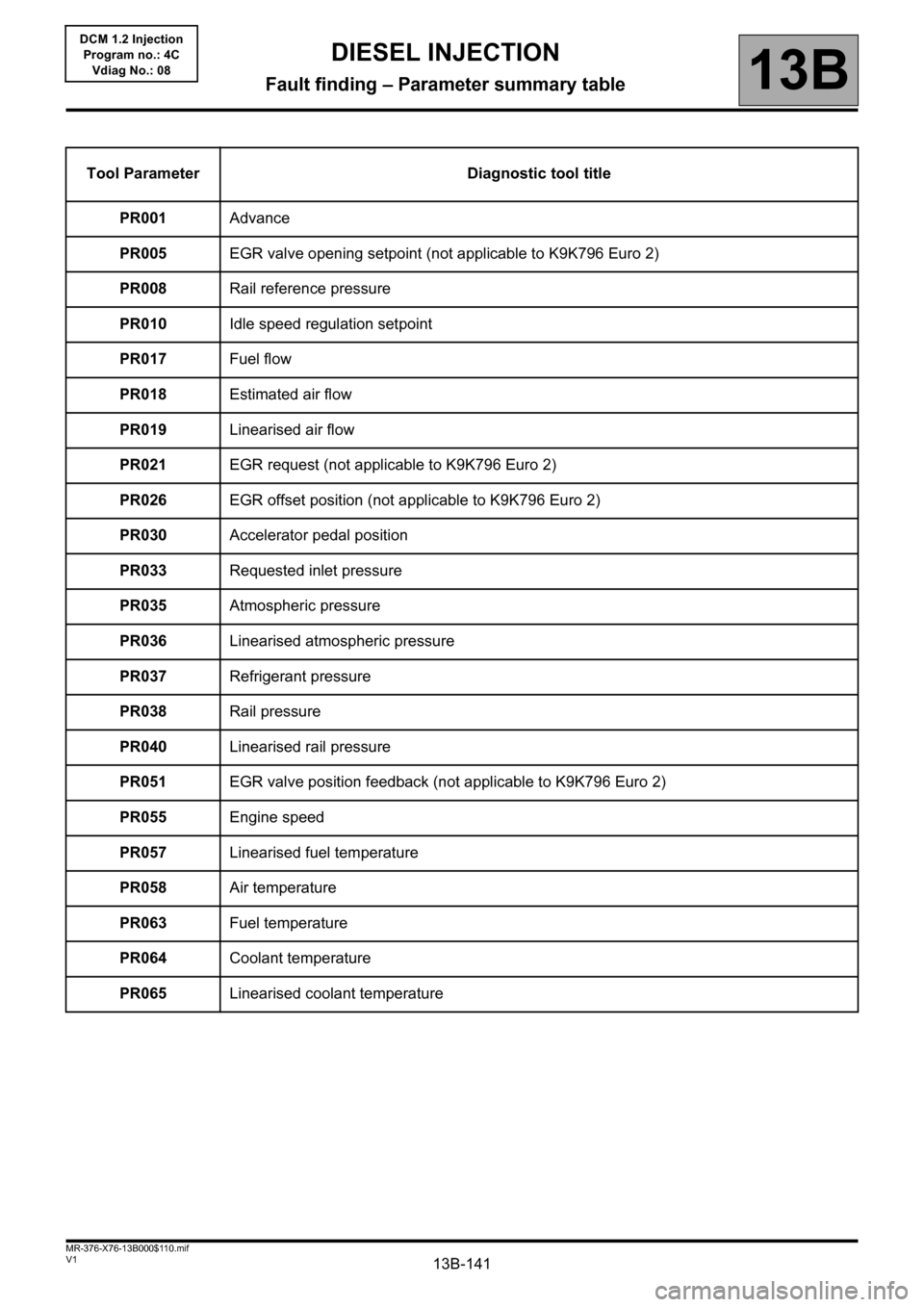

Tool Parameter Diagnostic tool title

PR001Advance

PR005EGR valve opening setpoint (not applicable to K9K796 Euro 2)

PR008Rail reference pressure

PR010Idle speed regulation setpoint

PR017Fuel flow

PR018Estimated air flow

PR019Linearised air flow

PR021EGR request (not applicable to K9K796 Euro 2)

PR026EGR offset position (not applicable to K9K796 Euro 2)

PR030Accelerator pedal position

PR033Requested inlet pressure

PR035Atmospheric pressure

PR036Linearised atmospheric pressure

PR037Refrigerant pressure

PR038Rail pressure

PR040Linearised rail pressure

PR051EGR valve position feedback (not applicable to K9K796 Euro 2)

PR055Engine speed

PR057Linearised fuel temperature

PR058Air temperature

PR063Fuel temperature

PR064Coolant temperature

PR065Linearised coolant temperature

DIESEL INJECTION

Fault finding – Parameter summary table

Page 144 of 204

13B-144

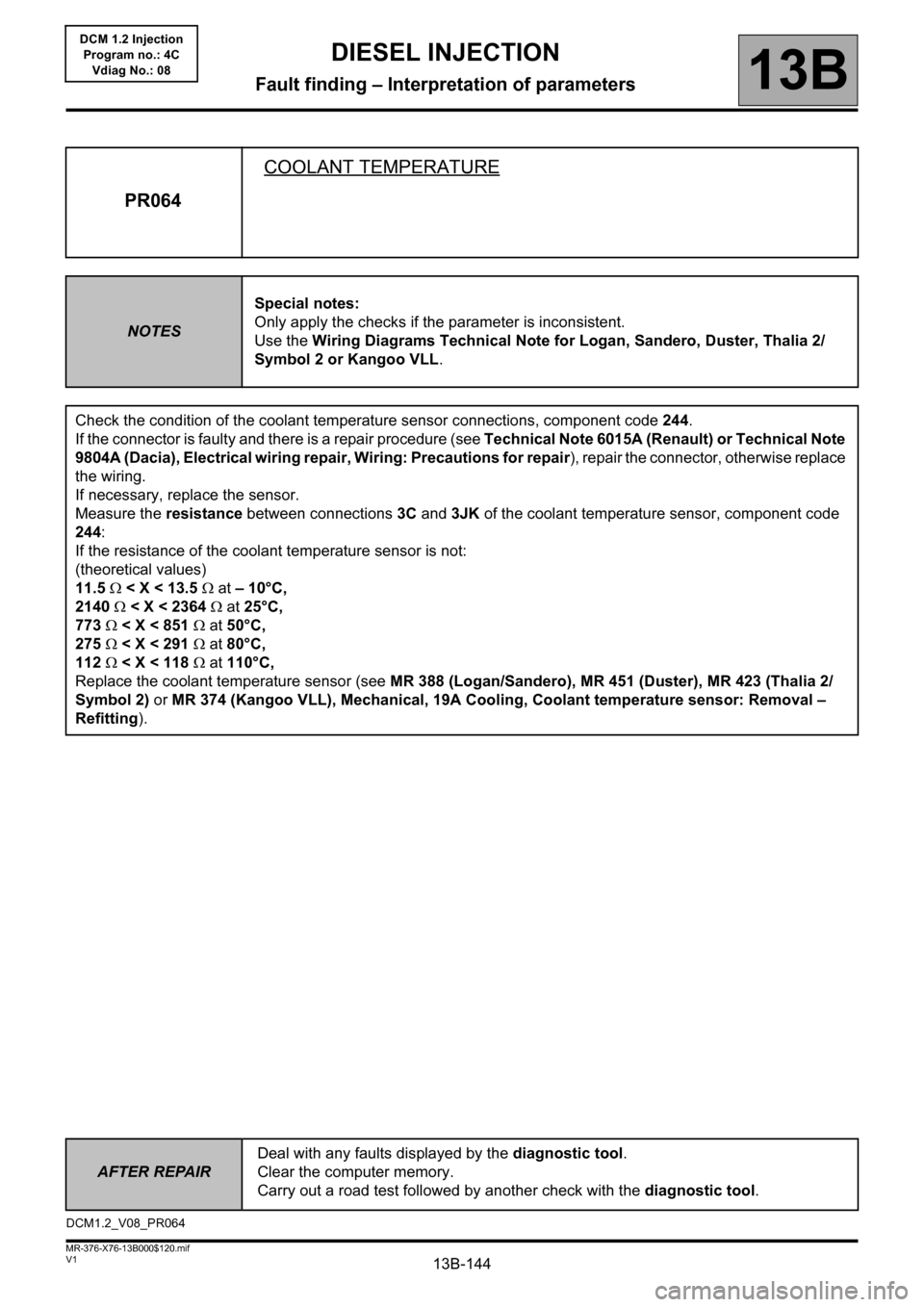

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-13B000$120.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

PR064COOLANT TEMPERATURE

NOTESSpecial notes:

Only apply the checks if the parameter is inconsistent.

Use the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2 or Kangoo VLL.

Check the condition of the coolant temperature sensor connections, component code 244.

If the connector is faulty and there is a repair procedure (see Technical Note 6015A (Renault) or Technical Note

9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the connector, otherwise replace

the wiring.

If necessary, replace the sensor.

Measure the resistance between connections 3C and 3JK of the coolant temperature sensor, component code

244:

If the resistance of the coolant temperature sensor is not:

(theoretical values)

11.5 < X < 13.5 at – 10°C,

2140 < X < 2364 at 25°C,

773 < X < 851 at 50°C,

275 < X < 291 at 80°C,

112 < X < 118 at 110°C,

Replace the coolant temperature sensor (see MR 388 (Logan/Sandero), MR 451 (Duster), MR 423 (Thalia 2/

Symbol 2) or MR 374 (Kangoo VLL), Mechanical, 19A Cooling, Coolant temperature sensor: Removal –

Refitting).

DCM1.2_V08_PR064

Page 175 of 204

13B-175

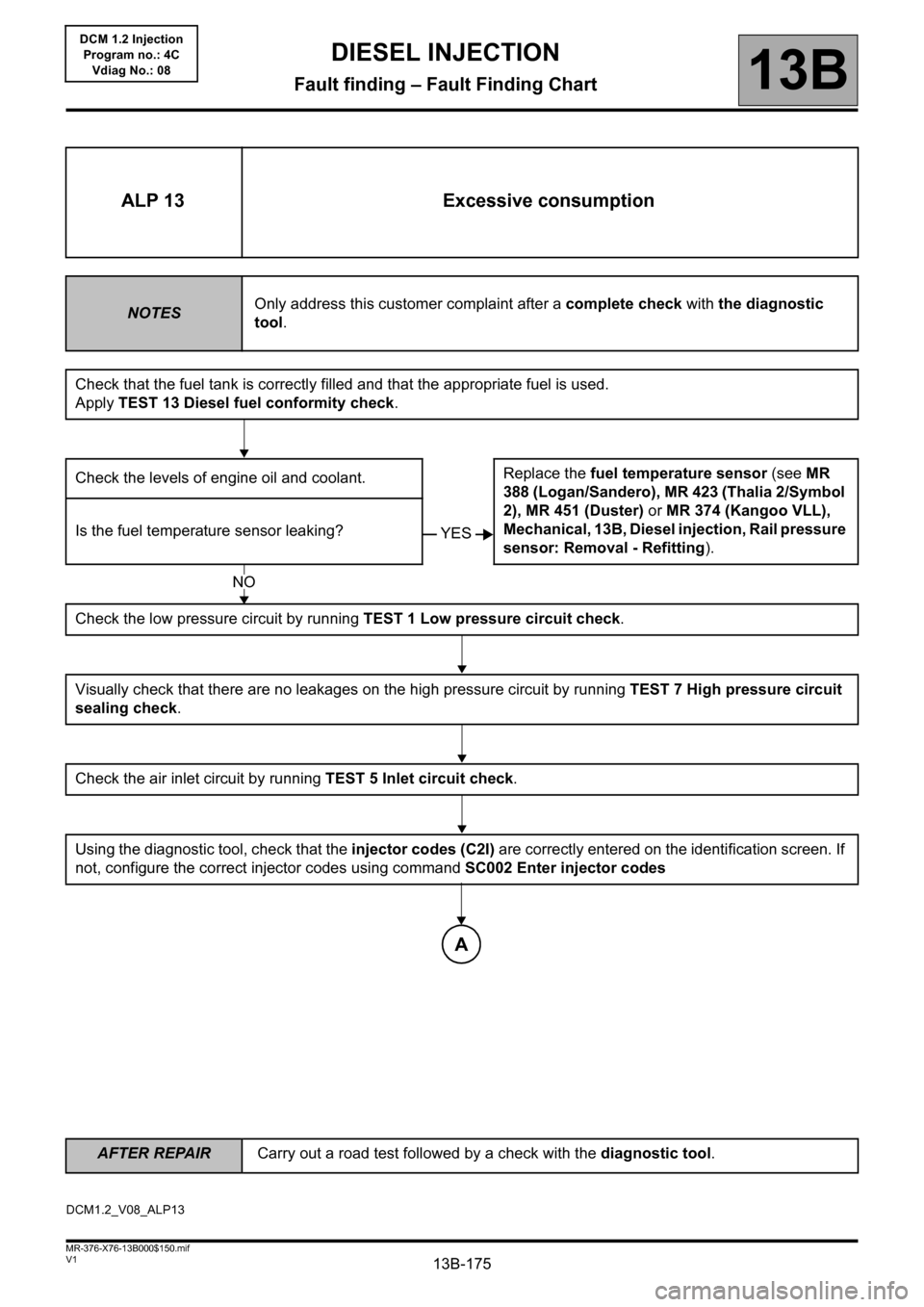

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

ALP 13 Excessive consumption

NOTESOnly address this customer complaint after a complete check with the diagnostic

tool.

Check that the fuel tank is correctly filled and that the appropriate fuel is used.

Apply TEST 13 Diesel fuel conformity check.

Check the levels of engine oil and coolant.Replace the fuel temperature sensor (see MR

388 (Logan/Sandero), MR 423 (Thalia 2/Symbol

2), MR 451 (Duster) or MR 374 (Kangoo VLL),

Mechanical, 13B, Diesel injection, Rail pressure

sensor: Removal - Refitting). Is the fuel temperature sensor leaking?

Check the low pressure circuit by running TEST 1 Low pressure circuit check.

Visually check that there are no leakages on the high pressure circuit by running TEST 7 High pressure circuit

sealing check.

Check the air inlet circuit by running TEST 5 Inlet circuit check.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes

YES

NO

A

DCM1.2_V08_ALP13

Page 191 of 204

13B-191V1 MR-376-X76-13B000$160.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

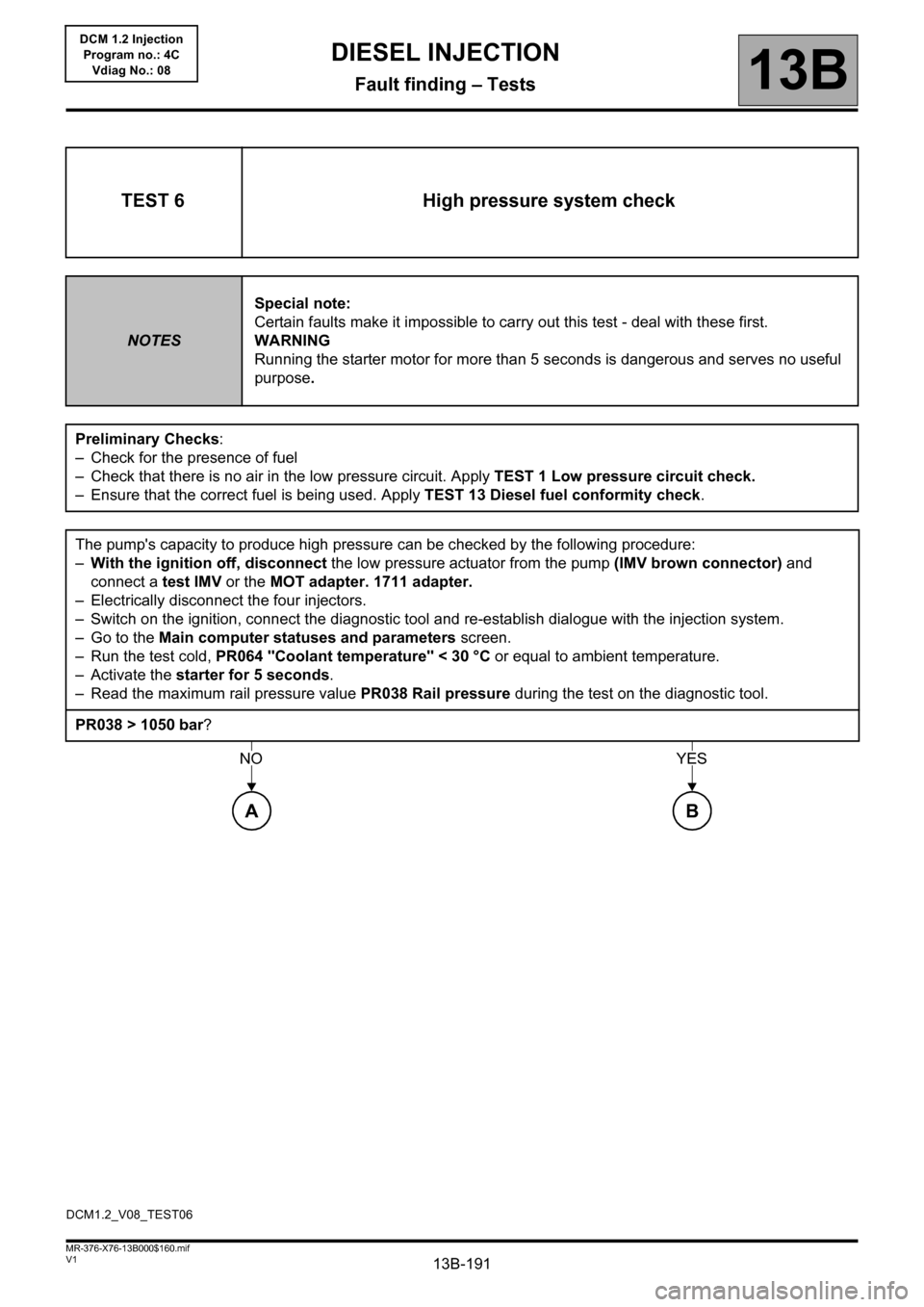

TEST 6 High pressure system check

NOTESSpecial note:

Certain faults make it impossible to carry out this test - deal with these first.

WARNING

Running the starter motor for more than 5 seconds is dangerous and serves no useful

purpose.

Preliminary Checks:

– Check for the presence of fuel

– Check that there is no air in the low pressure circuit. Apply TEST 1 Low pressure circuit check.

– Ensure that the correct fuel is being used. Apply TEST 13 Diesel fuel conformity check.

The pump's capacity to produce high pressure can be checked by the following procedure:

–With the ignition off, disconnect the low pressure actuator from the pump (IMV brown connector) and

connect a test IMV or the MOT adapter. 1711 adapter.

– Electrically disconnect the four injectors.

– Switch on the ignition, connect the diagnostic tool and re-establish dialogue with the injection system.

– Go to the Main computer statuses and parameters screen.

– Run the test cold, PR064 "Coolant temperature" < 30 °C or equal to ambient temperature.

–Activate the starter for 5 seconds.

– Read the maximum rail pressure value PR038 Rail pressure during the test on the diagnostic tool.

PR038 > 1050 bar?

A

NO

B

YES

DCM1.2_V08_TEST06

Page 194 of 204

13B-194V1 MR-376-X76-13B000$160.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

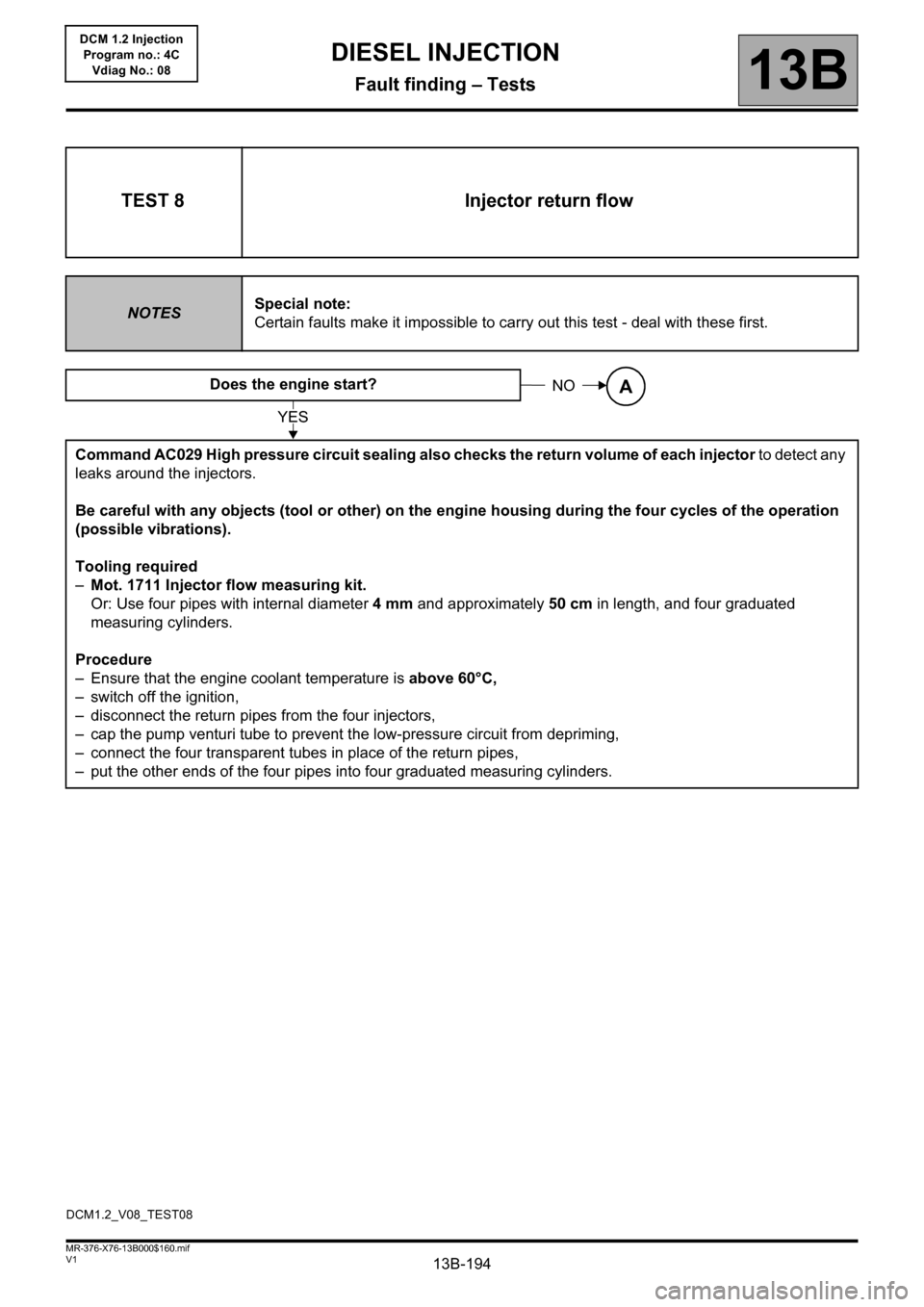

TEST 8 Injector return flow

NOTESSpecial note:

Certain faults make it impossible to carry out this test - deal with these first.

Does the engine start?

Command AC029 High pressure circuit sealing also checks the return volume of each injector to detect any

leaks around the injectors.

Be careful with any objects (tool or other) on the engine housing during the four cycles of the operation

(possible vibrations).

Tooling required

–Mot. 1711 Injector flow measuring kit.

Or: Use four pipes with internal diameter 4mm and approximately 50 cm in length, and four graduated

measuring cylinders.

Procedure

– Ensure that the engine coolant temperature is above 60°C,

– switch off the ignition,

– disconnect the return pipes from the four injectors,

– cap the pump venturi tube to prevent the low-pressure circuit from depriming,

– connect the four transparent tubes in place of the return pipes,

– put the other ends of the four pipes into four graduated measuring cylinders.

NOA

YES

DCM1.2_V08_TEST08