Diagram RENAULT KANGOO 2013 X61 / 2.G Petrol V42 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 279, PDF Size: 1.29 MB

Page 1 of 279

1Engine and peripherals

V2 MR-376-X76-17B050$TOC.mif

V2

17B

"The repair procedures given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The procedures may be modified as a result of changes introduced by the

manufacturer in the production of the various component units and accessories from

which his vehicles are constructed."

V2

All rights reserved by Renault s.a.s.

Edition Anglaise

Copying or translating, in part or in full, of this document or use of the service part

reference numbering system is forbidden without the prior written authority of

Renault s.a.s.

© Renault s.a.s. 2014

PETROL INJECTION

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06, 14, 16, 18

Fault finding – Introduction 17B - 2

Fault finding – List and location of components 17B - 4

Fault finding – Role of components 17B - 5

Fault finding – Operating diagram 17B - 7

Fault finding – Features 17B - 9

Fault finding – Replacement of components 17B - 12

Fault finding – Fault summary table 17B - 16

Fault finding – Interpretation of faults 17B - 21

Fault finding – Conformity check 17B - 160

Fault finding – Status summary table 17B - 161

Fault finding – Interpretation of statuses 17B - 163

Fault finding – Parameter summary table 17B - 180

Fault finding – Interpretation of parameters 17B - 183

Fault finding – Command summary table 17B - 213

Fault finding – Customer complaints 17B - 215

Fault finding – Fault Finding Chart 17B - 220

Fault finding – Test summary table 17B - 248

Fault finding – Tests 17B - 250

Page 2 of 279

17B-2V2 MR-376-X76-17B050$010.mif

17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

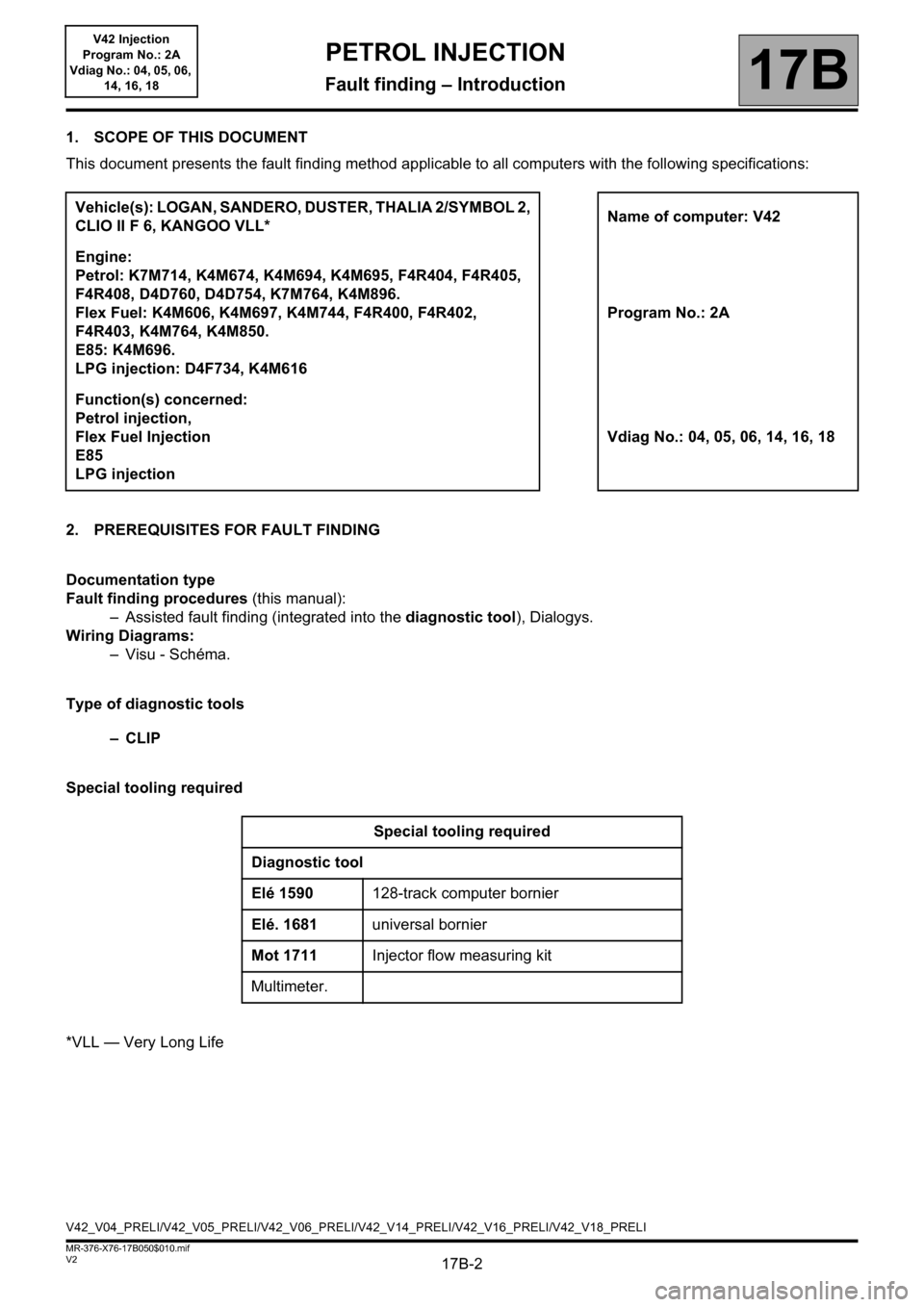

1. SCOPE OF THIS DOCUMENT

This document presents the fault finding method applicable to all computers with the following specifications:

2. PREREQUISITES FOR FAULT FINDING

Documentation type

Fault finding procedures (this manual):

– Assisted fault finding (integrated into the diagnostic tool), Dialogys.

Wiring Diagrams:

–Visu - Schéma.

Type of diagnostic tools

–CLIP

Special tooling required

*VLL — Very Long LifeVehicle(s): LOGAN, SANDERO, DUSTER, THALIA 2/SYMBOL 2,

CLIO II F 6, KANGOO VLL*Name of computer: V42

Engine:

Petrol: K7M714, K4M674, K4M694, K4M695, F4R404, F4R405,

F4R408, D4D760, D4D754, K7M764, K4M896.

Flex Fuel: K4M606, K4M697, K4M744, F4R400, F4R402,

F4R403, K4M764, K4M850.

E85: K4M696.

LPG injection: D4F734, K4M616Program No.: 2A

Function(s) concerned:

Petrol injection,

Flex Fuel Injection

E85

LPG injectionVdiag No.: 04, 05, 06, 14, 16, 18

Special tooling required

Diagnostic tool

Elé 1590128-track computer bornier

Elé. 1681universal bornier

Mot 1711Injector flow measuring kit

Multimeter.

V42_V04_PRELI/V42_V05_PRELI/V42_V06_PRELI/V42_V14_PRELI/V42_V16_PRELI/V42_V18_PRELI

PETROL INJECTION

Fault finding – Introduction

Page 7 of 279

17B-7V2 MR-376-X76-17B050$040.mif

17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

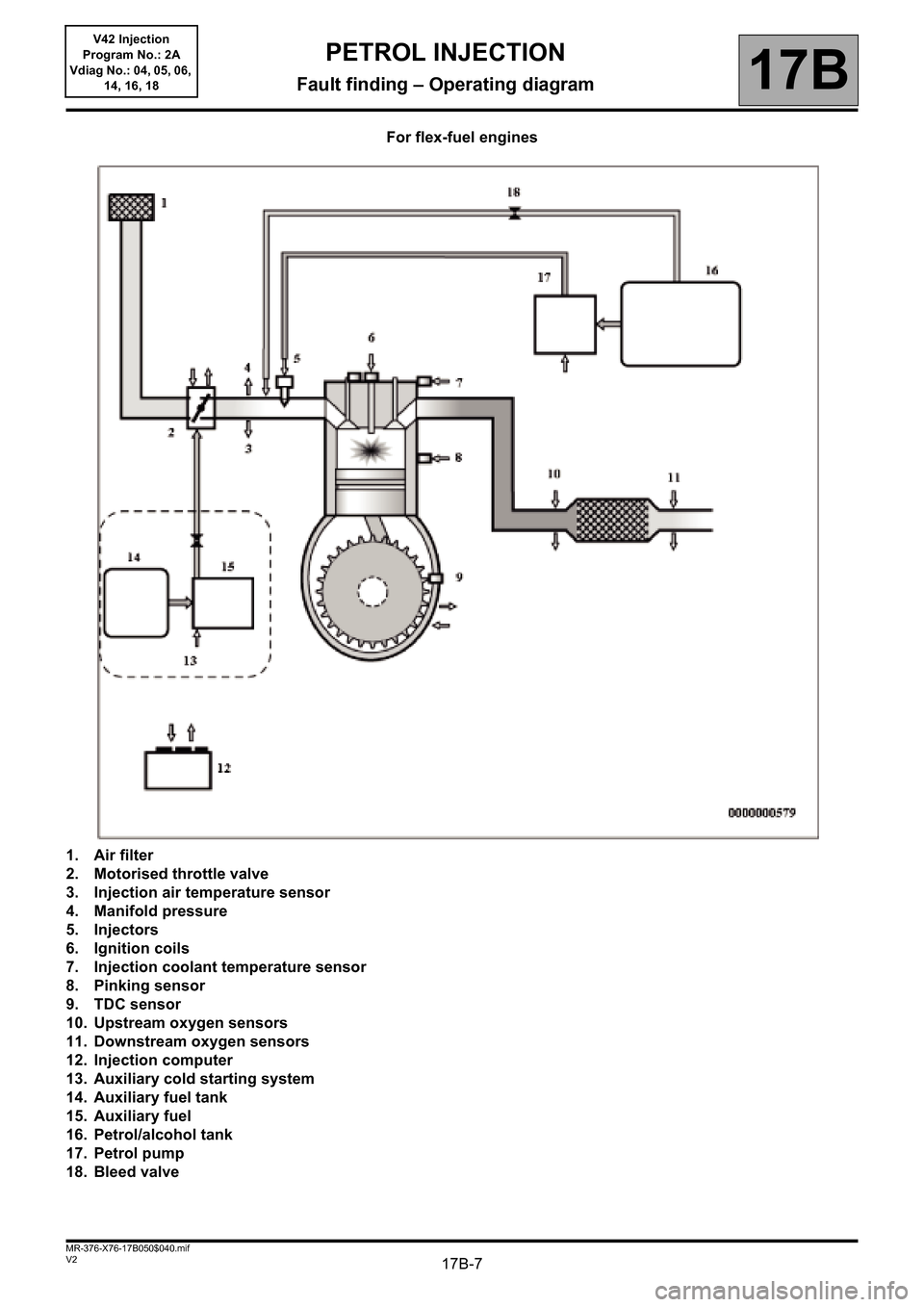

For flex-fuel engines

1. Air filter

2. Motorised throttle valve

3. Injection air temperature sensor

4. Manifold pressure

5. Injectors

6. Ignition coils

7. Injection coolant temperature sensor

8. Pinking sensor

9. TDC sensor

10. Upstream oxygen sensors

11. Downstream oxygen sensors

12. Injection computer

13. Auxiliary cold starting system

14. Auxiliary fuel tank

15. Auxiliary fuel

16. Petrol/alcohol tank

17. Petrol pump

18. Bleed valve

PETROL INJECTION

Fault finding – Operating diagram

Page 8 of 279

17B-8V2 MR-376-X76-17B050$040.mif

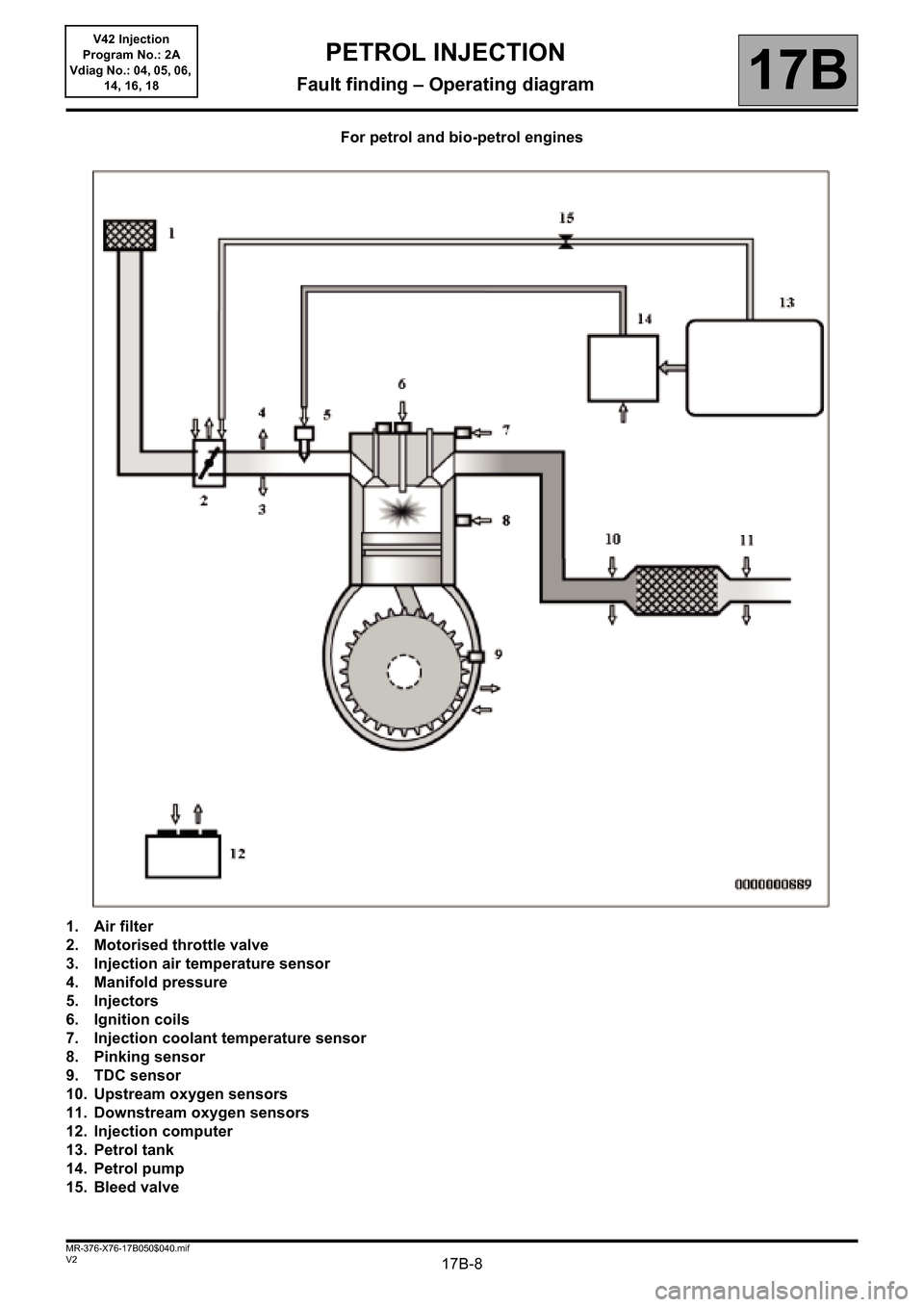

PETROL INJECTION

Fault finding – Operating diagram17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

For petrol and bio-petrol engines

1. Air filter

2. Motorised throttle valve

3. Injection air temperature sensor

4. Manifold pressure

5. Injectors

6. Ignition coils

7. Injection coolant temperature sensor

8. Pinking sensor

9. TDC sensor

10. Upstream oxygen sensors

11. Downstream oxygen sensors

12. Injection computer

13. Petrol tank

14. Petrol pump

15. Bleed valve

Page 21 of 279

17B-21

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V2 MR-376-X76-17B050$081.mif

17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

DF001

PRESENT OR

STOREDCOOLANT TEMPERATURE SENSOR CIRCUIT4.DEF: Voltage too low

5.DEF: Voltage too high

6.DEF: Micro-cut

NOTESSpecial notes:

– The OBD and Level 1 warning lights illuminate.

See the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2, Clio II F 6, Kangoo VLL.

Check the connection and condition of the connector of the coolant temperature sensor, component code 244

and of the connections of the injection computer, component code 120.

If the connector(s) are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Disconnect the connector of the injection computer, component code 120 (see MR 388 (Logan and Sandero), MR

451 (Duster), MR 423 (Thalia 2/Symbol 2), MR 430 (Clio II F 6) or MR 374 (Kangoo VLL), Mechanical, 17B,

Petrol injection, Petrol injection computer: Removal - Refitting).

Measure the resistance of component 244 by connections 3JK and 3C of the injection computer connector,

component code 120.

If the resistance of the coolant temperature sensor, component code 244 is not between 100 X 10 k (K7M,

K4M, D4D engines), 85 X 82 k (Duster F4R and K4M engine) at ambient temperature: replace the coolant

temperature sensor, component code 244 (see MR 388 (Logan and Sandero), MR 451 (Duster), MR 423 (Thalia

2/Symbol 2), MR 430 (Clio II F 6) or MR 374 (Kangoo VLL), Mechanical, 19A, Cooling, Coolant temperature

sensor: Removal - Refitting).

Check the insulation, continuity and absence of interference resistance on the following connections:

–3JK between components 120 and 244.

–3C between components 120 and 244.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the fault is still present, contact the Techline.

V42_V04_DF001/ V42_V05_DF001/V42_V06_DF001/V42_V14_DF001/V42_V16_DF001/V42_V18_DF001

PETROL INJECTION

Fault finding – Interpretation of faults

Page 22 of 279

17B-22

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V2 MR-376-X76-17B050$081.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

DF002

PRESENT OR

STOREDAIR TEMPERATURE SENSOR CIRCUIT2.DEF: Signal outside lower limit.

3.DEF: Signal outside upper limit.

NOTESSpecial notes:

– The OBD and Level 1 warning lights illuminate.

See the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2, Clio II F 6, Kangoo VLL.

Check the connection and condition of the connector of the air temperature sensor, component code 272 and of

the connections of the injection computer, component code 120.

If the connector or connectors are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Measure the resistance of the air temperature sensor, component code 272 between connections 3B and 3JQ.

If the resistance measured is not between 300 X 6 k or 100 X 50 k (Duster F4R engine) or 50

X 50 k (Duster K4M engine) at ambient temperature: replace the air temperature sensor, component code

272.

Check the insulation, continuity and absence of interference resistance on the following connections:

–3B between components 272 and 120.

–3JQ between components 272 and 120.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair

), repair the wiring, otherwise replace the wiring.

If the fault is still present, contact the Techline.

V42_V04_DF002/ V42_V05_DF002/V42_V06_DF002/V42_V14_DF002/V42_V16_DF002/V42_V18_DF002

Page 23 of 279

17B-23

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V2 MR-376-X76-17B050$081.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

DF011

PRESENT OR

STOREDSENSOR FEED VOLTAGE NO. 11.DEF: Above maximum threshold.

2.DEF: Below minimum threshold.

NOTESSpecial notes:

– The OBD and Level 2 warning lights illuminate.

See the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2, Clio II F 6, Kangoo VLL.

Disconnect the accelerator pedal sensor gang 1, component code 921 then switch on the ignition. Wait several

seconds so that the computer can update the fault status.

If the fault changes from present to stored: Replace the accelerator pedal sensor gang 1, component code 921

(see MR 388 (Logan and Sandero), MR 451 (Duster) MR 423 (Thalia 2/Symbol 2), MR 430 (Clio II F 6) or MR

374 (Kangoo VLL), Mechanical, 37A, Mechanical component controls, Accelerator pedal: Removal -

Refitting).

Disconnect the motorised throttle valve, component code 1076 then switch on the ignition (see MR 388 (Logan

and Sandero), MR 451 (Duster), MR 423 (Thalia 2/Symbol 2), MR 430 (Clio II F 6) or MR 374 (Kangoo VLL),

Mechanical, 12A, Fuel mixture, Throttle valve: Removal - Refitting).

Wait several seconds so that the computer can update the fault status.

If the fault changes from present to stored: Replace the damper valve position sensor, component code 1076, (see

MR 388 (Logan and Sandero), MR 451 (Duster) or MR 423 (Thalia 2/Symbol 2), MR 430 (Clio II F 6) or MR

374 (Kangoo VLL), Mechanical, 12A, Fuel mixture, Throttle valve: Removal - Refitting) referring to the

Replacement of components section.

Check the insulation, continuity and the absence of interference resistance on the following connections:

–3LR between components 921 and 120,

–3LT between components 921 and 120,

–3MN between components 1076 and 120,

–3MO between components 1076 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

V42_V04_DF011/ V42_V05_DF011/V42_V06_DF011/V42_V14_DF011/V42_V16_DF011/V42_V18_DF011

Page 24 of 279

17B-24

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V2 MR-376-X76-17B050$081.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

DF012

PRESENT OR

STOREDSENSOR SUPPLY VOLTAGE NO. 21.DEF: Above maximum threshold.

2.DEF: Below minimum threshold.

NOTESSpecial notes:

– The OBD and Level 2 warning lights illuminate.

See the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2, Clio II F 6, Kangoo VLL.

Disconnect the accelerator pedal sensor gang 2, component code 921 then switch on the ignition (see MR 388

(Logan and Sandero), MR 451 (Duster), MR 423 (Thalia 2/Symbol 2), MR 430 (Clio II F 6) or MR 374 (Kangoo

VLL), Mechanical, 37A, Mechanical component controls, Accelerator pedal: Removal - Refitting).

Wait several seconds so that the computer can update the fault status.

If the fault changes from present to stored: Replace the accelerator pedal sensor gang 2, component code 921

(see MR 388 (Logan and Sandero), MR 451 (Duster) or MR 423 (Thalia 2/Symbol 2), Mechanical, 37A,

Mechanical component controls, Accelerator pedal: Removal - Refitting).

Disconnect the manifold pressure sensor, component code 147, then switch on the ignition.

Wait several seconds so that the computer can update the fault status.

If the fault changes from present to stored: Replace the inlet pressure sensor, component code 147.

Disconnect the Freon pressure sensor, component code 1202, then switch on the ignition (see MR 388 (Logan

and Sandero), MR 451 (Duster), MR 423 (Thalia 2/Symbol 2), MR 430 (Clio II F 6) or MR 374 (Kangoo VLL),

Mechanical, 62A, Air conditioning, Pressure sensor: Removal - Refitting).

Wait several seconds so that the computer can update the fault status.

If the fault changes from present to stored: Replace the Freon pressure sensor, component code 1202 (see MR

388 (Logan and Sandero), MR 451 (Duster), MR 423 (Thalia 2/Symbol 2), MR 430 (Clio II F 6) or MR 374

(Kangoo VLL), Mechanical, 62A, Air conditioning, Pressure sensor: Removal - Refitting).

Check the insulation, continuity and the absence of interference resistance on the following connections:

–3LU between components 921 and 120,

–3LV between components 921 and 120,

–3AJP between components 147 and 120,

–3AJR between components 147 and 120,

–38Y between components 1202 and 120,

–38U between components 1202 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

V42_V04_DF012/ V42_V05_DF012/V42_V06_DF012/V42_V14_DF012/V42_V16_DF012/V42_V18_DF012

Page 25 of 279

17B-25

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V2 MR-376-X76-17B050$081.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

DF015

PRESENT OR

STOREDMAIN RELAY CONTROL CIRCUITCC.0: Short circuit to earth.

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present:

– switch on the powerlatch phase - switch off + after ignition feed and switch on the

+ after ignition feed again).

See the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2, Clio II F 6, Kangoo VLL.

Check the connection and condition of the connectors of the passenger compartment fuse box, component code

1016, of the engine fuse box, component code 597, of the injection computer, component code 120 and of the

injection relay, component code 1047 (for Logan, Sandero, Duster) of the injection locking relay, component

code 238 (for Thalia 2/Symbol 2, Kangoo VLL) or of the injection computer supply relay, component code 983

(for Clio II F 6).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the condition and operation of the injection relay, component code 1047 (for Logan, Sandero, Duster), of

the injection locking relay, component code 238 (for Thalia 2/Symbol 2, Kangoo VLL) or of the injection computer

supply relay, component code 983 (for Clio II F 6).

In the event of a fault, replace the injection relay or the injection locking relay (see MR 388 (Logan and Sandero),

MR 451 (Duster), MR 423 (Thalia 2/Symbol 2), MR 430 (Clio II F 6) or MR 374 (Kangoo VLL), Mechanical, 87G,

Engine compartment connection unit, Engine compartment connection unit: List and location of

components).

V42_V04_DF015/ V42_V05_DF015/V42_V06_DF015/V42_V14_DF015/V42_V16_DF015/V42_V18_DF015

Page 27 of 279

17B-27

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V2 MR-376-X76-17B050$081.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

DF018

PRESENT OR

STOREDLOW SPEED FAN ASSEMBLY CONTROL CIRCUITCC.0: Short circuit to earth.

CC.1: Short circuit to +12 volts.

NOTESConditions for application to a stored fault:

The fault is declared present after the ignition has been switched on or after running

command AC038 Low speed fan assembly relay

See the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2, Clio II F 6, Kangoo VLL.

Run command AC038 and check the supply of the low speed fan assembly relay control circuit, component code

784, using a test light on connection 3JN of component 120.

Check the connection and condition of the connector of the injection computer, component code 120 and of the

low speed fan assembly relay, component code 784.

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation, continuity and check for absence of interference resistance on the following

connection:

–3JN between components 784 and 120.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Run command AC038 and check the supply of the low speed fan assembly relay power circuit using a test light on

connection BP7 of component 784.

If the check is not correct, replace the fan assembly control relay, component code 784.

If the fault is still present, contact the Techline.

V42_V04_DF018/ V42_V05_DF018/V42_V06_DF018/V42_V14_DF018/V42_V16_DF018/V42_V18_DF018