engine RENAULT SCENIC 2000 J64 / 1.G Technical Note 3426A Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: SCENIC, Model: RENAULT SCENIC 2000 J64 / 1.GPages: 118, PDF Size: 1.5 MB

Page 101 of 118

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Starter

16

16-4

Starter

IDENTIFICATION

Type Engine Starter motor

XA0 5 F9Q 732 MITSUBISHI M1T85781

Page 102 of 118

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Starter

16

16-5

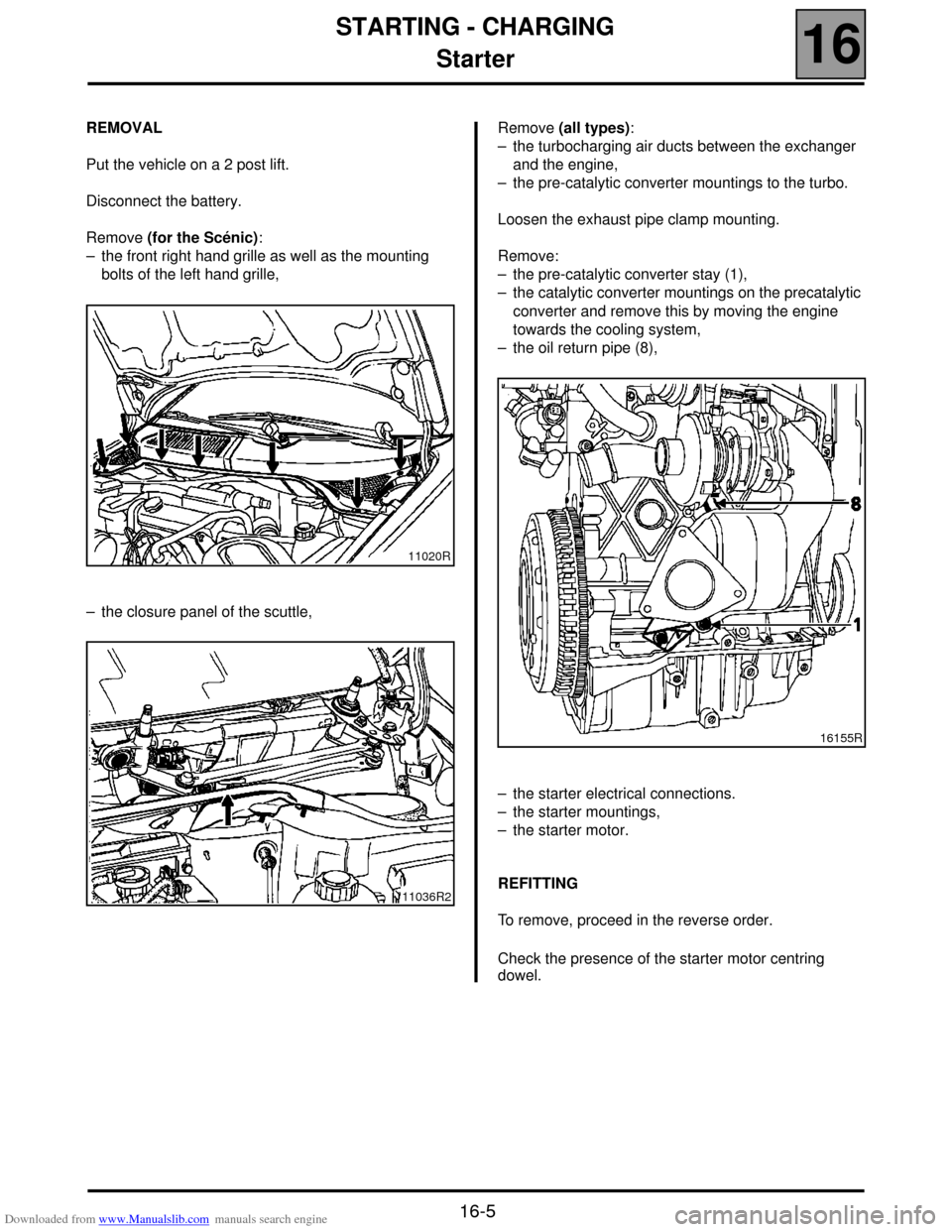

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Remove (for the Scénic):

– the front right hand grille as well as the mounting

bolts of the left hand grille,

– the closure panel of the scuttle,Remove (all types):

– the turbocharging air ducts between the exchanger

and the engine,

– the pre-catalytic converter mountings to the turbo.

Loosen the exhaust pipe clamp mounting.

Remove:

– the pre-catalytic converter stay (1),

– the catalytic converter mountings on the precatalytic

converter and remove this by moving the engine

towards the cooling system,

– the oil return pipe (8),

– the starter electrical connections.

– the starter mountings,

– the starter motor.

REFITTING

To remove, proceed in the reverse order.

Check the presence of the starter motor centring

dowel.

11020R

11036R2

16155R

Page 103 of 118

Downloaded from www.Manualslib.com manuals search engine COOLING SYSTEM

Filling and bleeding

19

119 COOLING SYSTEM

Filling and bleeding

There is no heater matrix water control valve.

Water flow is continuous in the heater matrix, which

contributes to the cooling of the engine.

FILLING

It is essential to open the bleed screw on the

cylinder head coolant pipe housing outlet.

Fill the circuit through the expansion bottle opening.

Close the bleed screw as soon as the fluid runs out in

a continuous jet.

Start the engine (2500 rpm).

Adjust the level by overflow for a period of about

4 minutes.

Tighten the expansion bottle cap.

BLEEDING

Let the engine run for 20 minutes at 2500 rpm, until

the engine cooling fan operates (time required for

automatic degassing).

Check the liquid level is at the "Maximum" marker.

DO NOT OPEN THE BLEED SCREW(S) WITH THE

ENGINE RUNNING.

REFIT THE EXPANSION BOTTLE CAP WHILE THE

ENGINE IS WARM.

19-1

Page 104 of 118

Downloaded from www.Manualslib.com manuals search engine COOLING SYSTEM

Diagram

19

19-2

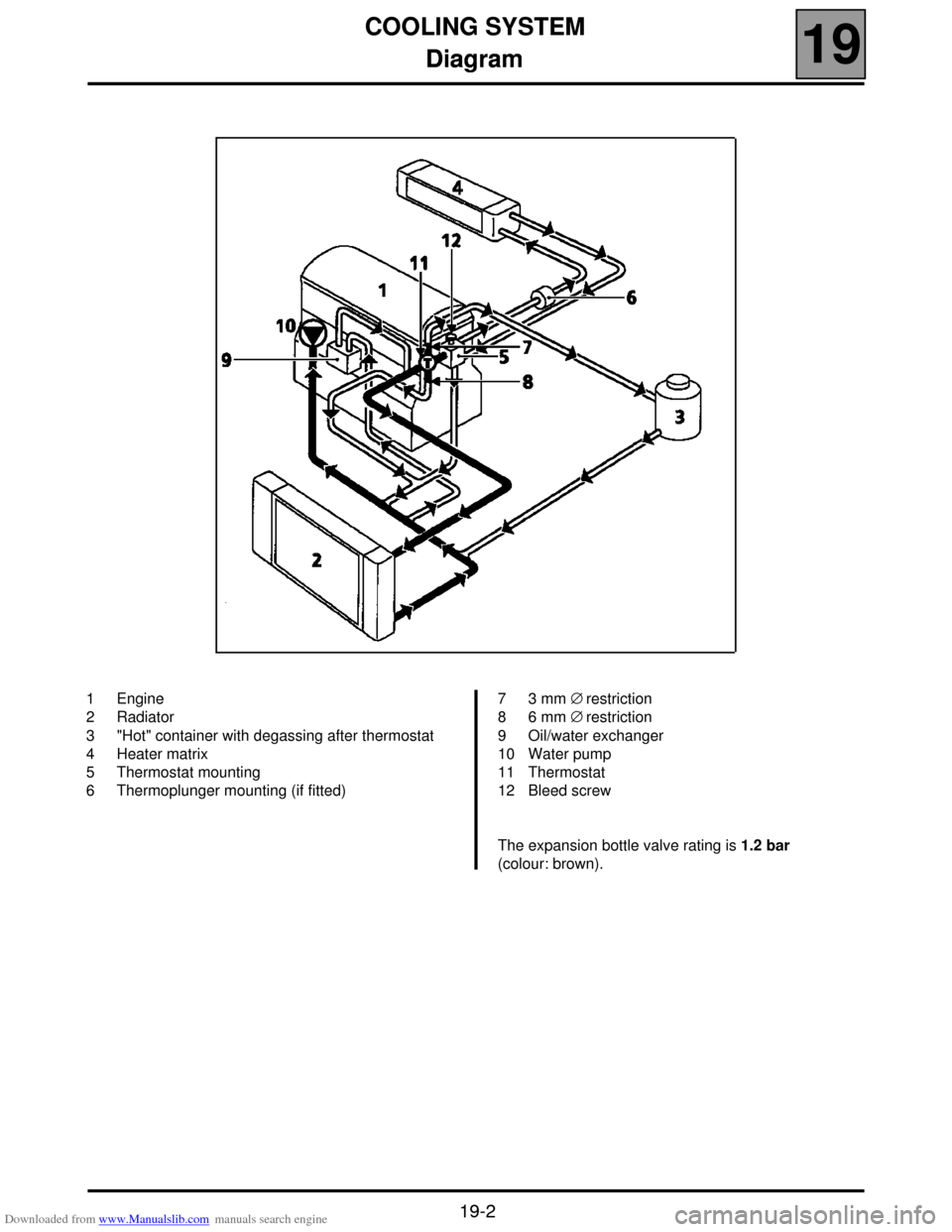

Diagram

1 Engine

2 Radiator

3 "Hot" container with degassing after thermostat

4 Heater matrix

5 Thermostat mounting

6 Thermoplunger mounting (if fitted)7 3 mm ∅ restriction

8 6 mm ∅ restriction

9 Oil/water exchanger

10 Water pump

11 Thermostat

12 Bleed screw

The expansion bottle valve rating is 1.2 bar

(colour: brown).

Page 105 of 118

Downloaded from www.Manualslib.com manuals search engine COOLING SYSTEM

Thermal plunger unit

19

19-3

Thermal plunger unit

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Remove the engine undertray.

Position the hose clips at the inlet and outlet of the

thermal plunger mounting unit (plugs).

Disconnect the hoses on this unit.

Remove the mounting bolt for the thermal plunger

support unit as well as the supply wires and remove

the unit.

REFITTING

The plugs are tightened in the usual fashion.

Refitting is the reverse of removal.

Top up the coolant and bleed the cooling circuit (see

section 19 "Filling - bleeding"). SPECIAL TOOLING REQUIRED

Mot. 453 -01

Mot. 1202

Mot. 1448Hose clamp pliers set

Hose clip pliers

Long nose pliers for hose clips

TIGHTENING TORQUES (in daN.m)

Thermal plungers 2

Page 106 of 118

Downloaded from www.Manualslib.com manuals search engine COOLING SYSTEM

Radiator

19

19-4

Radiator

REMOVAL

Put the vehicle on a two post lift.

Disconnect the battery.

Remove the engine undertray.

Drain the cooling circuit through the lower radiator

hose.

Disconnect the wiring of the fan unit.

Unclip the power steering reservoir and remove it.

Remove:

– the upper cross member,

– the upper radiator mountings,

– the upper hoses on the radiator,

– the inlet manifold-air exchanger duct,

– the fan unit mountings on the radiator and remove

the fan,

– the radiator mountings on the condenser and remove

the radiator.REFITTING

Refitting is the reverse of removal.

Fill and bleed the cooling circuit (see section 19

"Filling and bleeding").

NOTE: ensure that the fins of the radiator or of the

condenser (if fitted) are not damaged when

removing-refitting, and protect them if necessary. SPECIAL TOOLING REQUIRED

Mot. 1202 -01

Hose clip pliers

Mot. 1202 -02

Mot. 1448 Long nose pliers for hose clips

Page 107 of 118

Downloaded from www.Manualslib.com manuals search engine COOLING SYSTEM

Water pump

19

19-5

Water pump

REMOVAL

Put the vehicle on a two post lift.

Disconnect the battery.

Remove the engine undertray.

Drain the cooling circuit through the lower radiator

hose.

Unclip the diesel filter and remove it.

Remove:

– the front right wheel along with the mudguard,

– the style cover,

– the accessories belt (see Section 07 "Accessories

belt tension"),

– the coolant pump and power assisted steering pump

pulleys,

– the water pump.Cleaning

It is very important not to scratch the gasket faces.

Use the Décapjoint product to dissolve any part of the

gasket which remains attached.

Wear gloves whilst carrying out the following

operation.

– Apply the product to the parts to be cleaned; wait

about ten minutes, then remove it using a wooden

spatula.

Do not allow this agent to drip on to the paintwork.

REFITTING

Refit:

– the water pump (fitted with a new gasket), tightening

the bolts to a torque of 1.7 daN.m,

– the accessories belt and tension it (see section 07

"Accessories belt tension").

Fill and bleed the cooling circuit, (see section 19

"Filling and Bleeding"). SPECIAL TOOLING REQUIRED

Mot. 1202 -01

Hose clip pliers

Mot. 1202 -02

Mot. 1448 Long nose pliers for hose clips

TIGHTENING TORQUES (in daN.m)

Water pump bolts 1.7

Page 108 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE MOUNTING

Suspended engine mountings

19

19-6

Manual

gearbox1319 ENGINE MOUNTING

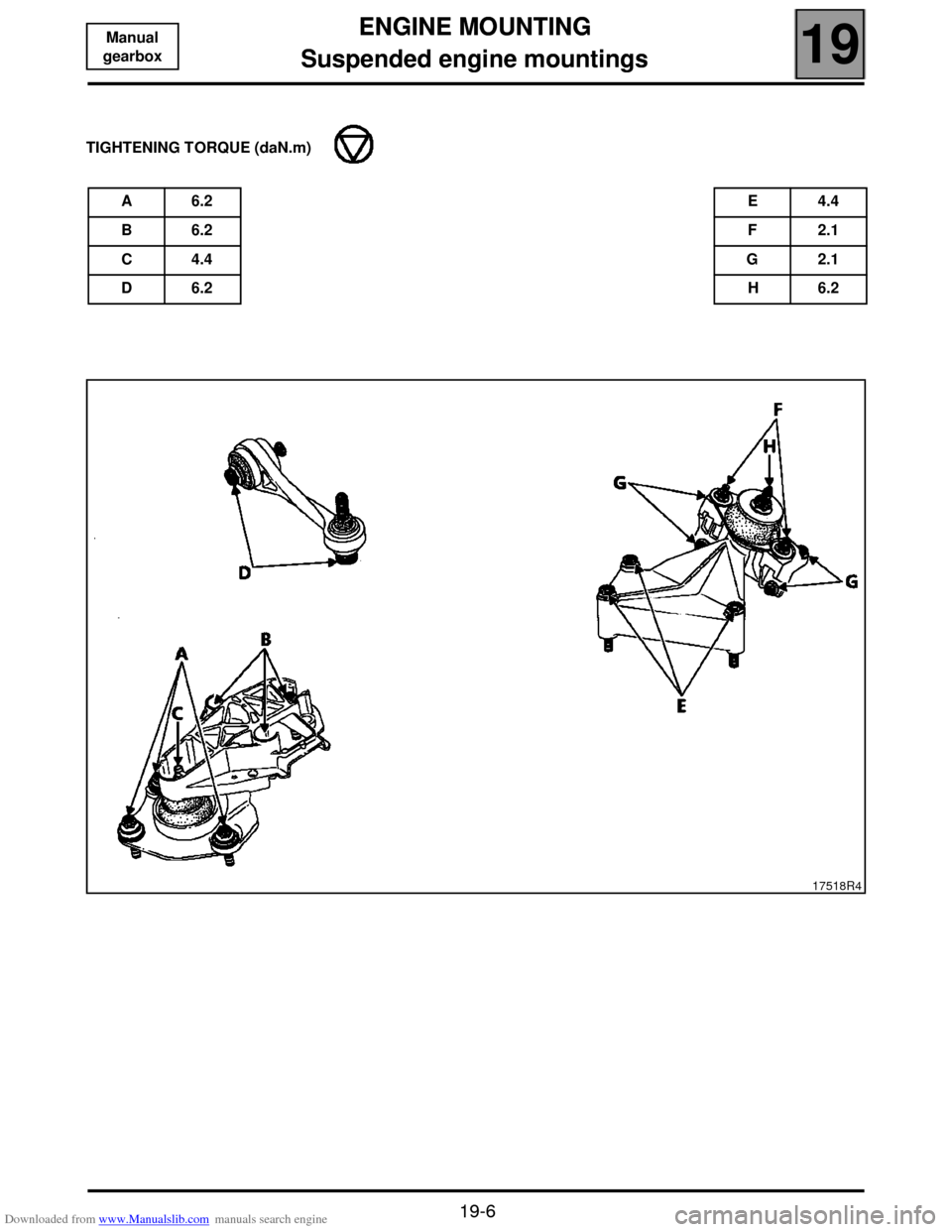

Suspended engine mountings

TIGHTENING TORQUE (daN.m)

A 6.2E 4.4

B 6.2F 2.1

C 4.4G 2.1

D 6.2H 6.2

17518R4

Page 109 of 118

Downloaded from www.Manualslib.com manuals search engine EXHAUST

Catalytic converter

19

19-7

1419 EXHAUST

Catalytic converter

Disconnect the battery and put the vehicle on a two

post lift.

Fit a flywheel immobiliser.

Loosen the catalytic converter/precatalytic converter

mountings.

Fit tool Tav. 1233-01 replacing the bolts of the sub-

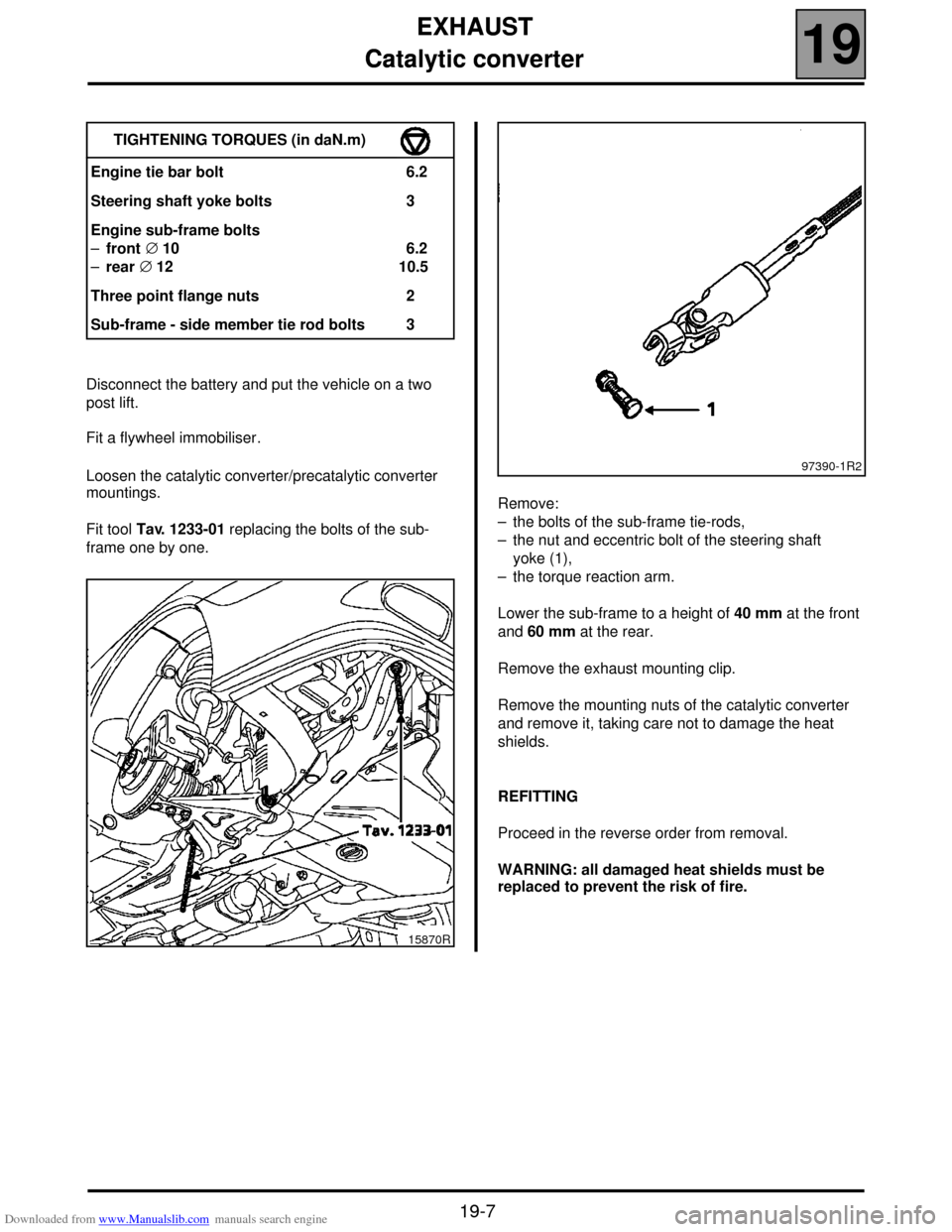

frame one by one.Remove:

– the bolts of the sub-frame tie-rods,

– the nut and eccentric bolt of the steering shaft

yoke (1),

– the torque reaction arm.

Lower the sub-frame to a height of 40 mm at the front

and 60 mm at the rear.

Remove the exhaust mounting clip.

Remove the mounting nuts of the catalytic converter

and remove it, taking care not to damage the heat

shields.

REFITTING

Proceed in the reverse order from removal.

WARNING: all damaged heat shields must be

replaced to prevent the risk of fire. TIGHTENING TORQUES (in daN.m)

Engine tie bar bolt 6.2

Steering shaft yoke bolts 3

Engine sub-frame bolts

–front ∅ 10

–rear ∅ 12 6.2

10.5

Three point flange nuts 2

Sub-frame - side member tie rod bolts 3

15870R

97390-1R2

Page 110 of 118

Downloaded from www.Manualslib.com manuals search engine MANUAL GEARBOX

Identification

21

21-1

121MANUAL GEARBOX

Identification

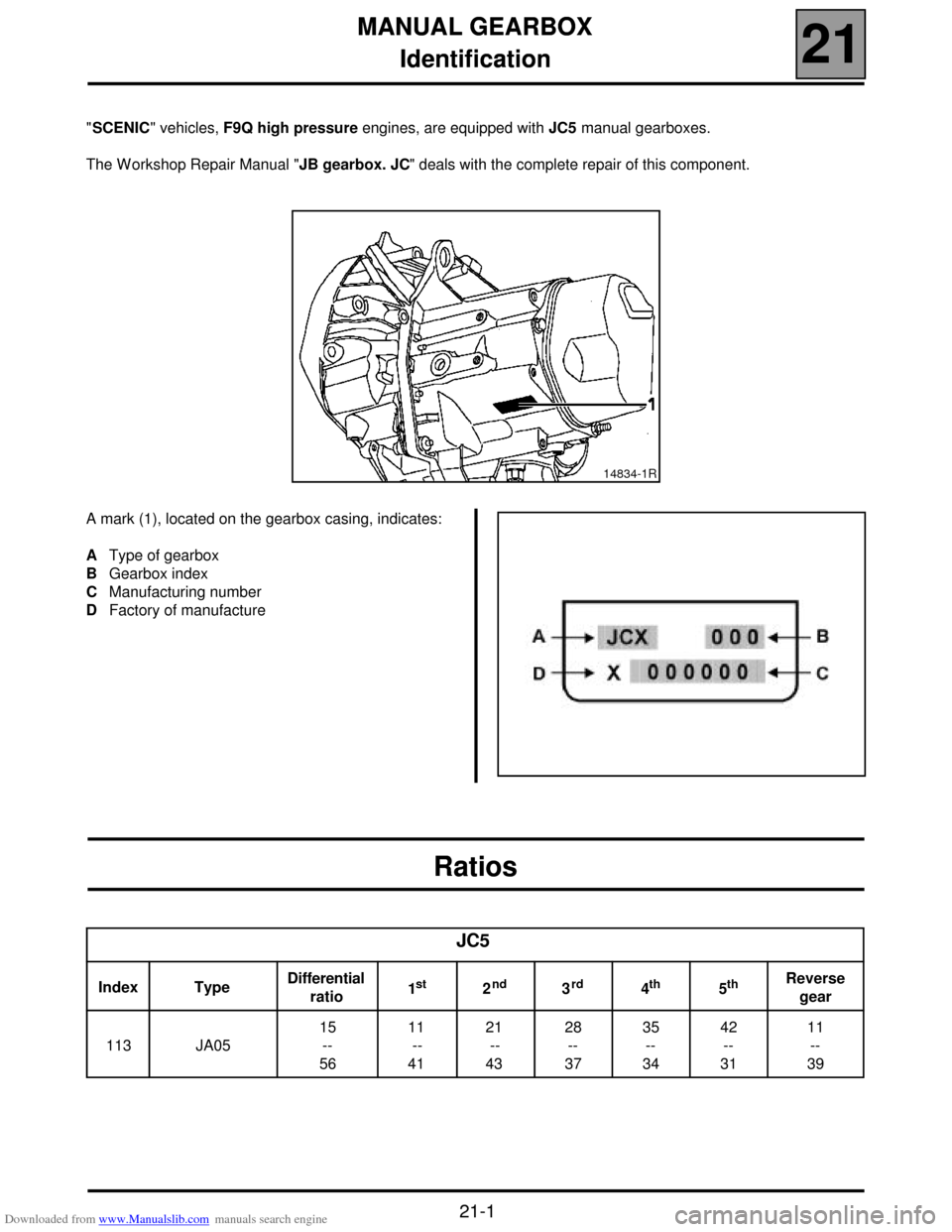

"SCENIC" vehicles, F9Q high pressure engines, are equipped with JC5 manual gearboxes.

The W orkshop Repair Manual "JB gearbox. JC" deals with the complete repair of this component.

A mark (1), located on the gearbox casing, indicates:

AType of gearbox

BGearbox index

CManufacturing number

DFactory of manufacture

Ratios

14834-1R

JC5

Index TypeDifferential

ratio1st2nd3rd4th5thReverse

gear

113 JA0515

--

56 11

--

41 21

--

4328

--

3735

--

34 42

--

3111

--

39