wheel RENAULT SCENIC 2000 J64 / 1.G Technical Note 3426A User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: SCENIC, Model: RENAULT SCENIC 2000 J64 / 1.GPages: 118, PDF Size: 1.5 MB

Page 29 of 118

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Timing belt

11

11 - 3

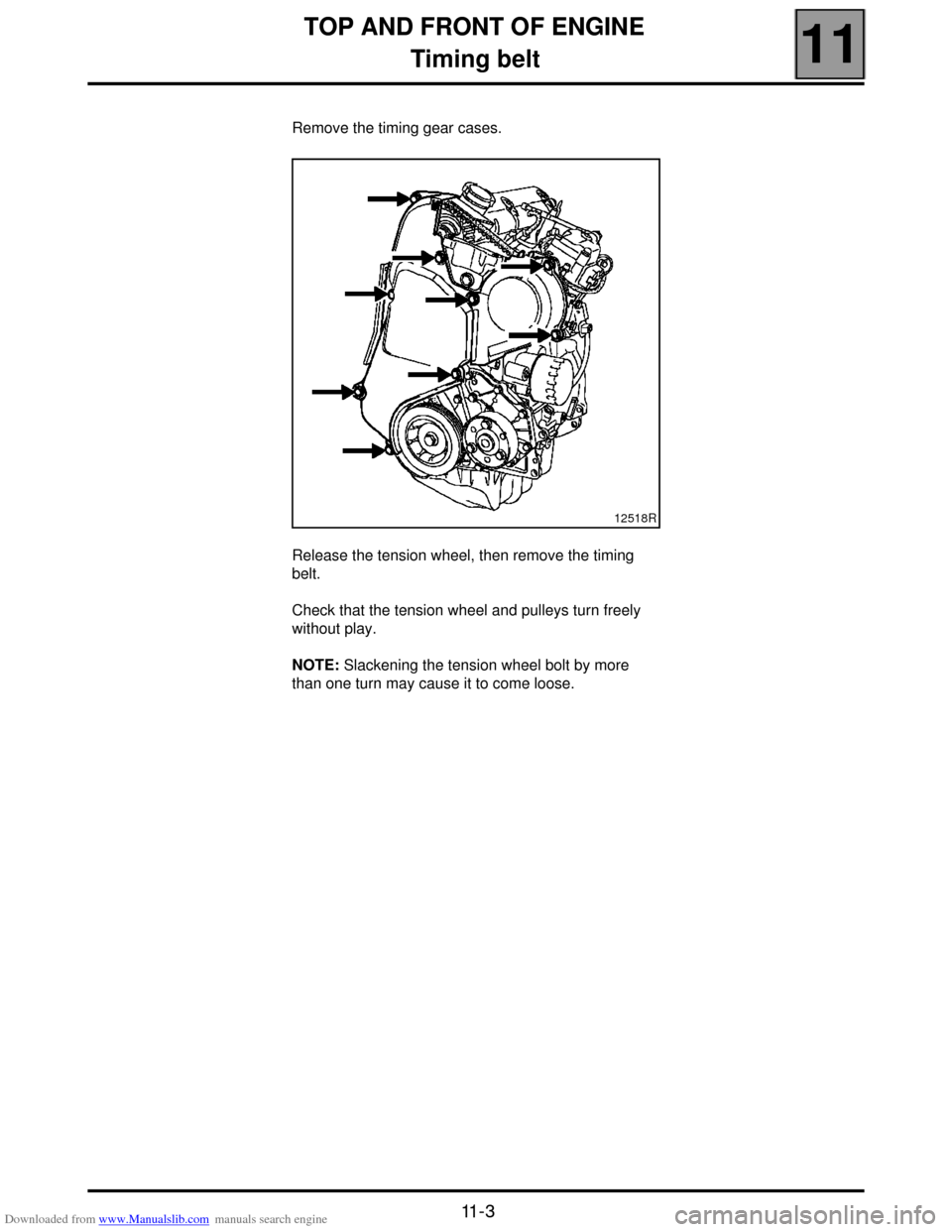

Remove the timing gear cases.

Release the tension wheel, then remove the timing

belt.

Check that the tension wheel and pulleys turn freely

without play.

NOTE: Slackening the tension wheel bolt by more

than one turn may cause it to come loose.

12518R

Page 30 of 118

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Timing belt

11

11 - 4

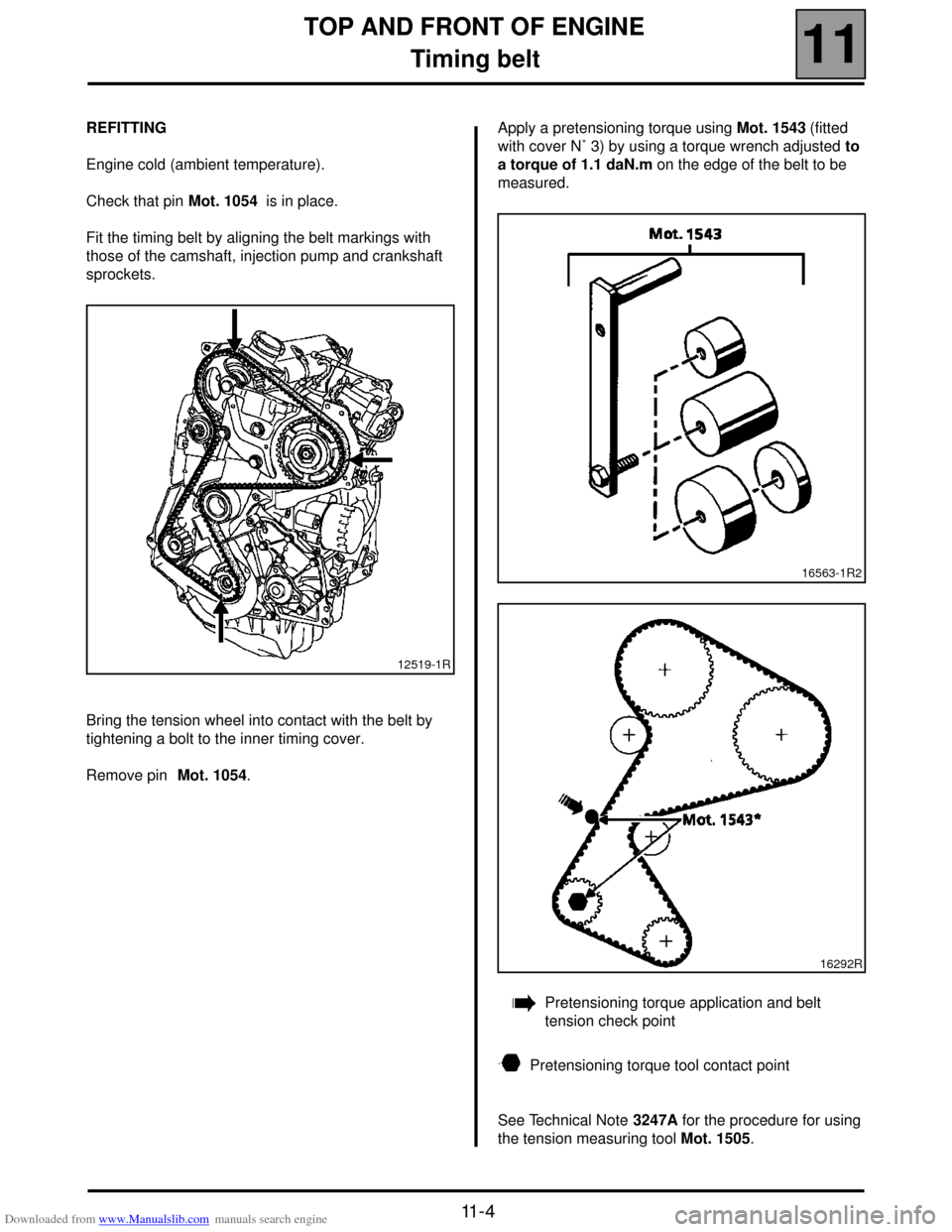

REFITTING

Engine cold (ambient temperature).

Check that pin Mot. 1054 is in place.

Fit the timing belt by aligning the belt markings with

those of the camshaft, injection pump and crankshaft

sprockets.

Bring the tension wheel into contact with the belt by

tightening a bolt to the inner timing cover.

Remove pin Mot. 1054.Apply a pretensioning torque using Mot. 1543 (fitted

with cover N˚ 3) by using a torque wrench adjusted to

a torque of 1.1 daN.m on the edge of the belt to be

measured.

Pretensioning torque application and belt

tension check point

Pretensioning torque tool contact point

See Technical Note 3247A for the procedure for using

the tension measuring tool Mot. 1505.

12519-1R

16563-1R2

16292R

Page 31 of 118

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Timing belt

11

11 - 5

Fit the reading head of Mot. 1505 and carry out the

measurement, then adjust the tension using the bolt

in contact with the belt until pretension value

T1 = 68 ± 3 Hertz is reached.

Tighten the tensioner.

Turn the crankshaft four times and reposition the

timing at top dead centre using the pin.

Remove pin Mot. 1054.

Apply a pretensioning torque using Mot. 1543 (fitted

with cover N˚ 3) by using a torque wrench adjusted to

a torque of 1.1 daN.m on the edge of the belt to be

measured.

Fit the reading head of Mot. 1505 and carry out the

measurement, then adjust the tension using the bolt

in contact with the belt until pretension value

T2 = 61 ± 5 Hertz is reached.

Tighten the tension wheel nut to a torque of 5 daN.m.

NOTE: it is vital that you tighten the tension wheel

nut to torque to avoid any slackening which may

cause damage to the engine.

Never refit a belt once removed, but replace it.

Replace the crankshaft pulley bolt and tighten it to a

torque of 2 daN.m plus an angle of 115˚ ± 15˚.

See section 07 "Accessories belt tension" for the

tension value for fitting the power assisted steering

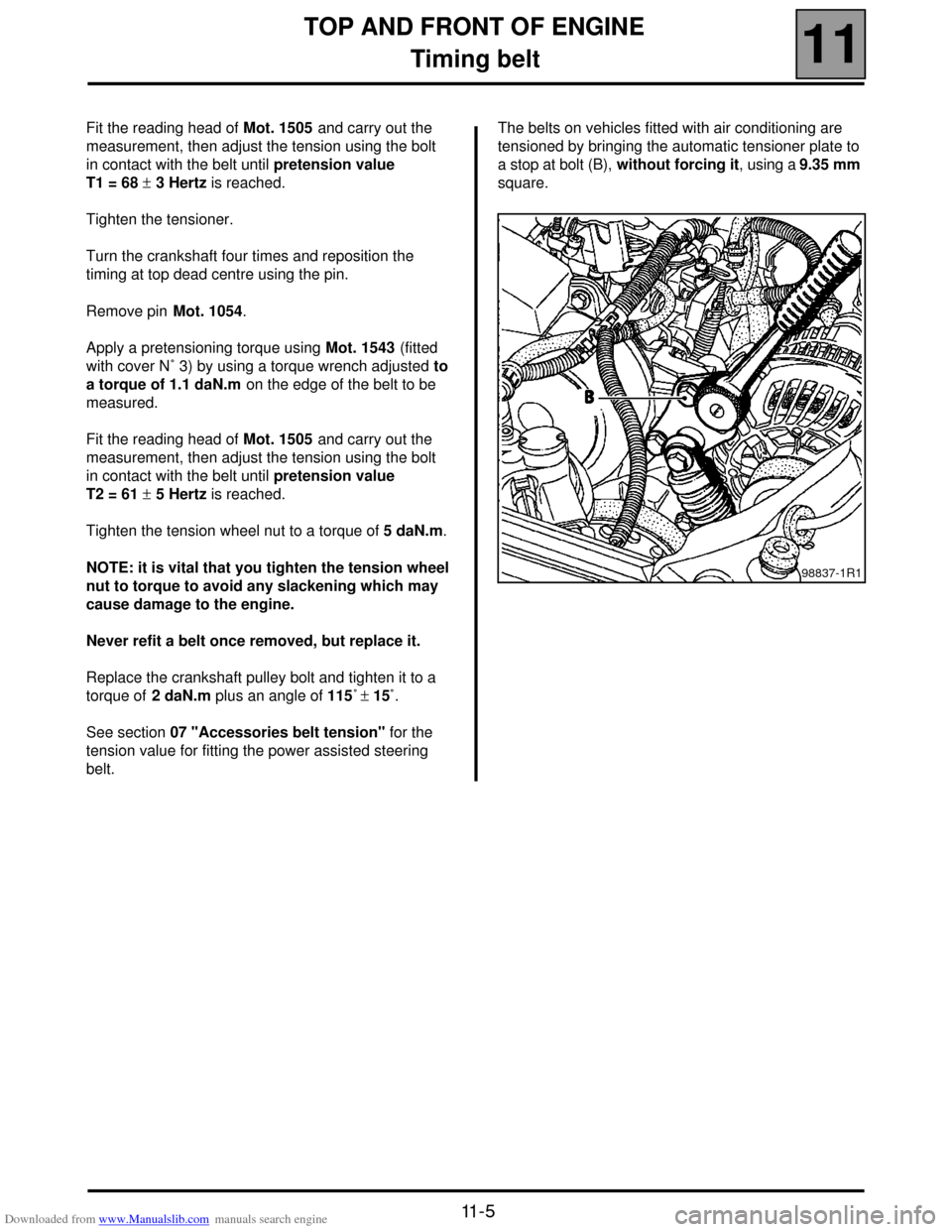

belt.The belts on vehicles fitted with air conditioning are

tensioned by bringing the automatic tensioner plate to

a stop at bolt (B), without forcing it, using a 9.35 mm

square.

98837-1R1

Page 32 of 118

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Cylinder head gasket

11

11 - 6

Cylinder head gasket

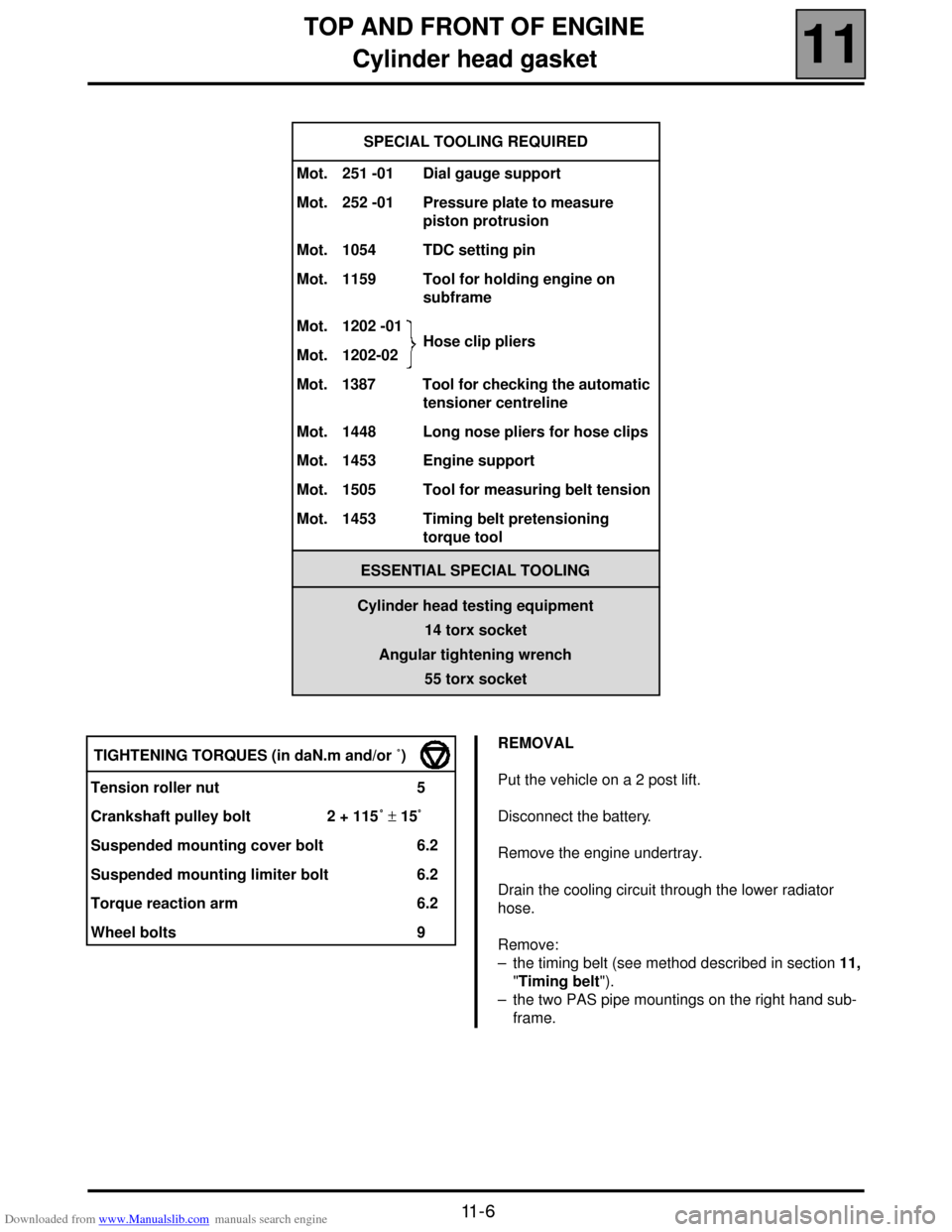

SPECIAL TOOLING REQUIRED

Mot. 251 -01 Dial gauge support

Mot. 252 -01 Pressure plate to measure

piston protrusion

Mot. 1054 TDC setting pin

Mot. 1159 Tool for holding engine on

subframe

Mot. 1202 -01

Hose clip pliers

Mot. 1202-02

Mot. 1387 Tool for checking the automatic

tensioner centreline

Mot. 1448 Long nose pliers for hose clips

Mot. 1453 Engine support

Mot. 1505 Tool for measuring belt tension

Mot. 1453 Timing belt pretensioning

torque tool

ESSENTIAL SPECIAL TOOLING

Cylinder head testing equipment

14 torx socket

Angular tightening wrench

55 torx socket

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Remove the engine undertray.

Drain the cooling circuit through the lower radiator

hose.

Remove:

– the timing belt (see method described in section 11,

"Timing belt").

– the two PAS pipe mountings on the right hand sub-

frame. TIGHTENING TORQUES (in daN.m and/or ˚)

Tension roller nut 5

Crankshaft pulley bolt 2 + 115˚ ± 15˚

Suspended mounting cover bolt 6.2

Suspended mounting limiter bolt 6.2

Torque reaction arm 6.2

Wheel bolts 9

Page 45 of 118

Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Air-air exchanger

12

12-7

Air-air exchanger

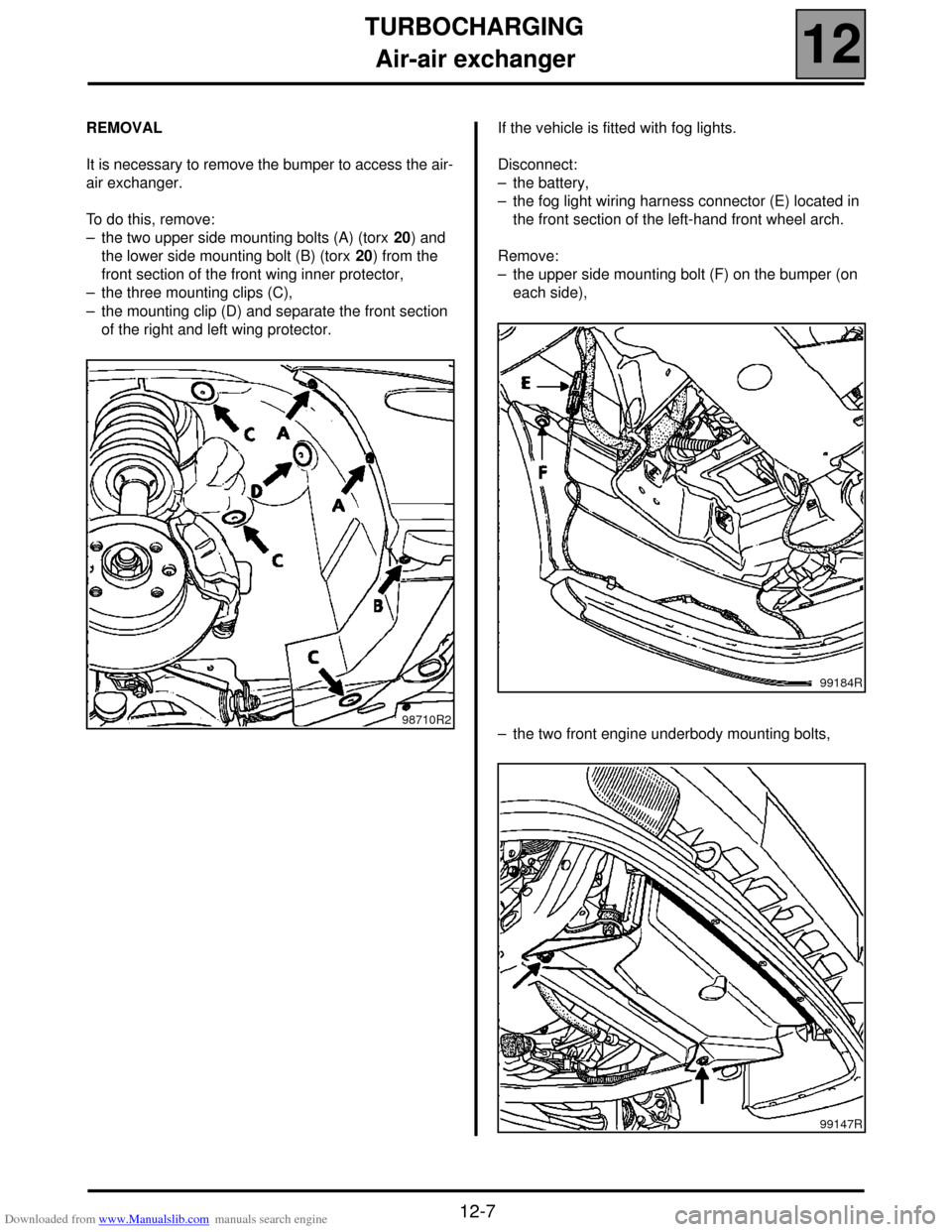

REMOVAL

It is necessary to remove the bumper to access the air-

air exchanger.

To do this, remove:

– the two upper side mounting bolts (A) (torx 20) and

the lower side mounting bolt (B) (torx 20) from the

front section of the front wing inner protector,

– the three mounting clips (C),

– the mounting clip (D) and separate the front section

of the right and left wing protector.If the vehicle is fitted with fog lights.

Disconnect:

– the battery,

– the fog light wiring harness connector (E) located in

the front section of the left-hand front wheel arch.

Remove:

– the upper side mounting bolt (F) on the bumper (on

each side),

– the two front engine underbody mounting bolts,

98710R2

99184R

99147R

Page 99 of 118

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Alternator

16

16-2

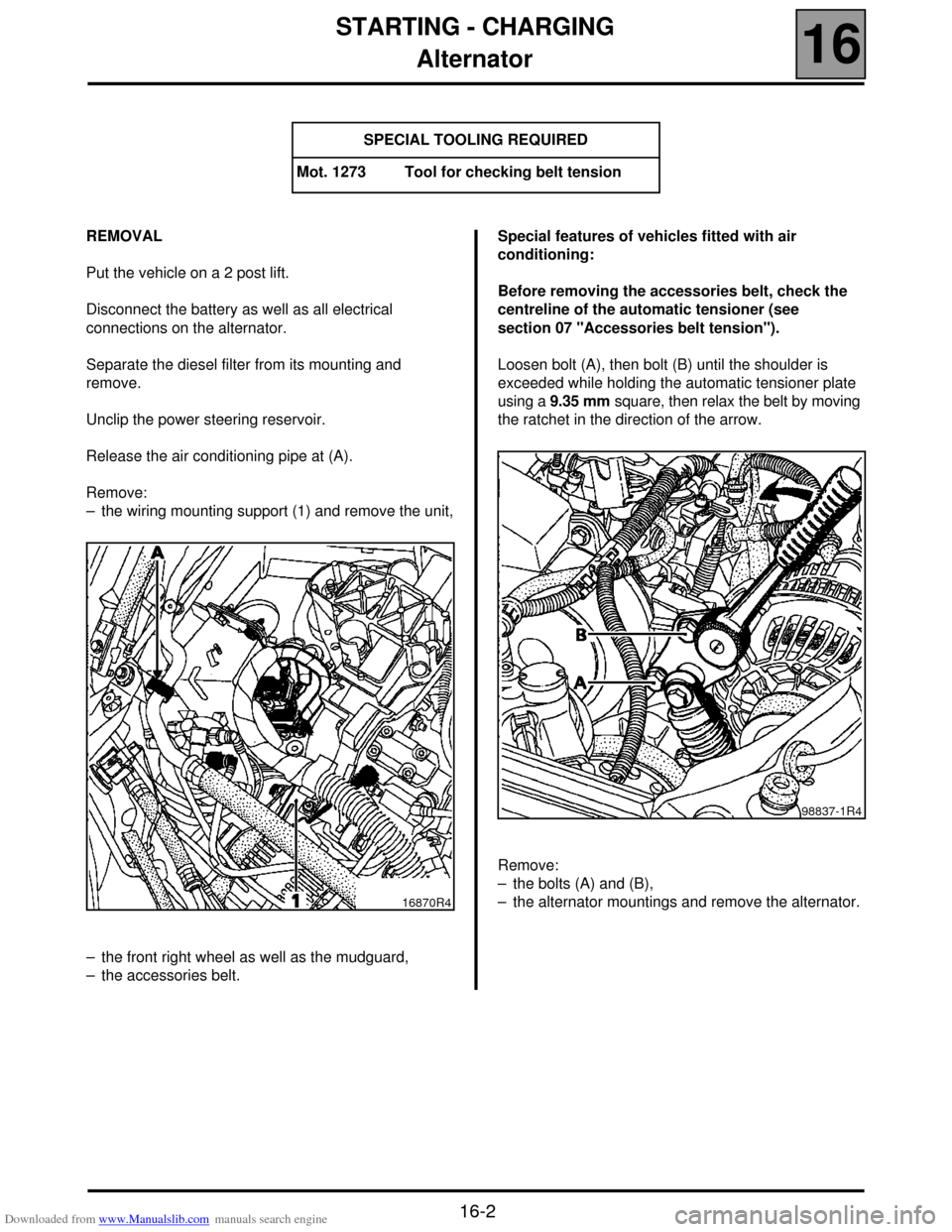

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery as well as all electrical

connections on the alternator.

Separate the diesel filter from its mounting and

remove.

Unclip the power steering reservoir.

Release the air conditioning pipe at (A).

Remove:

– the wiring mounting support (1) and remove the unit,

– the front right wheel as well as the mudguard,

– the accessories belt.Special features of vehicles fitted with air

conditioning:

Before removing the accessories belt, check the

centreline of the automatic tensioner (see

section 07 "Accessories belt tension").

Loosen bolt (A), then bolt (B) until the shoulder is

exceeded while holding the automatic tensioner plate

using a 9.35 mm square, then relax the belt by moving

the ratchet in the direction of the arrow.

Remove:

– the bolts (A) and (B),

– the alternator mountings and remove the alternator. SPECIAL TOOLING REQUIRED

Mot. 1273 Tool for checking belt tension

16870R4

98837-1R4

Page 107 of 118

Downloaded from www.Manualslib.com manuals search engine COOLING SYSTEM

Water pump

19

19-5

Water pump

REMOVAL

Put the vehicle on a two post lift.

Disconnect the battery.

Remove the engine undertray.

Drain the cooling circuit through the lower radiator

hose.

Unclip the diesel filter and remove it.

Remove:

– the front right wheel along with the mudguard,

– the style cover,

– the accessories belt (see Section 07 "Accessories

belt tension"),

– the coolant pump and power assisted steering pump

pulleys,

– the water pump.Cleaning

It is very important not to scratch the gasket faces.

Use the Décapjoint product to dissolve any part of the

gasket which remains attached.

Wear gloves whilst carrying out the following

operation.

– Apply the product to the parts to be cleaned; wait

about ten minutes, then remove it using a wooden

spatula.

Do not allow this agent to drip on to the paintwork.

REFITTING

Refit:

– the water pump (fitted with a new gasket), tightening

the bolts to a torque of 1.7 daN.m,

– the accessories belt and tension it (see section 07

"Accessories belt tension").

Fill and bleed the cooling circuit, (see section 19

"Filling and Bleeding"). SPECIAL TOOLING REQUIRED

Mot. 1202 -01

Hose clip pliers

Mot. 1202 -02

Mot. 1448 Long nose pliers for hose clips

TIGHTENING TORQUES (in daN.m)

Water pump bolts 1.7

Page 109 of 118

Downloaded from www.Manualslib.com manuals search engine EXHAUST

Catalytic converter

19

19-7

1419 EXHAUST

Catalytic converter

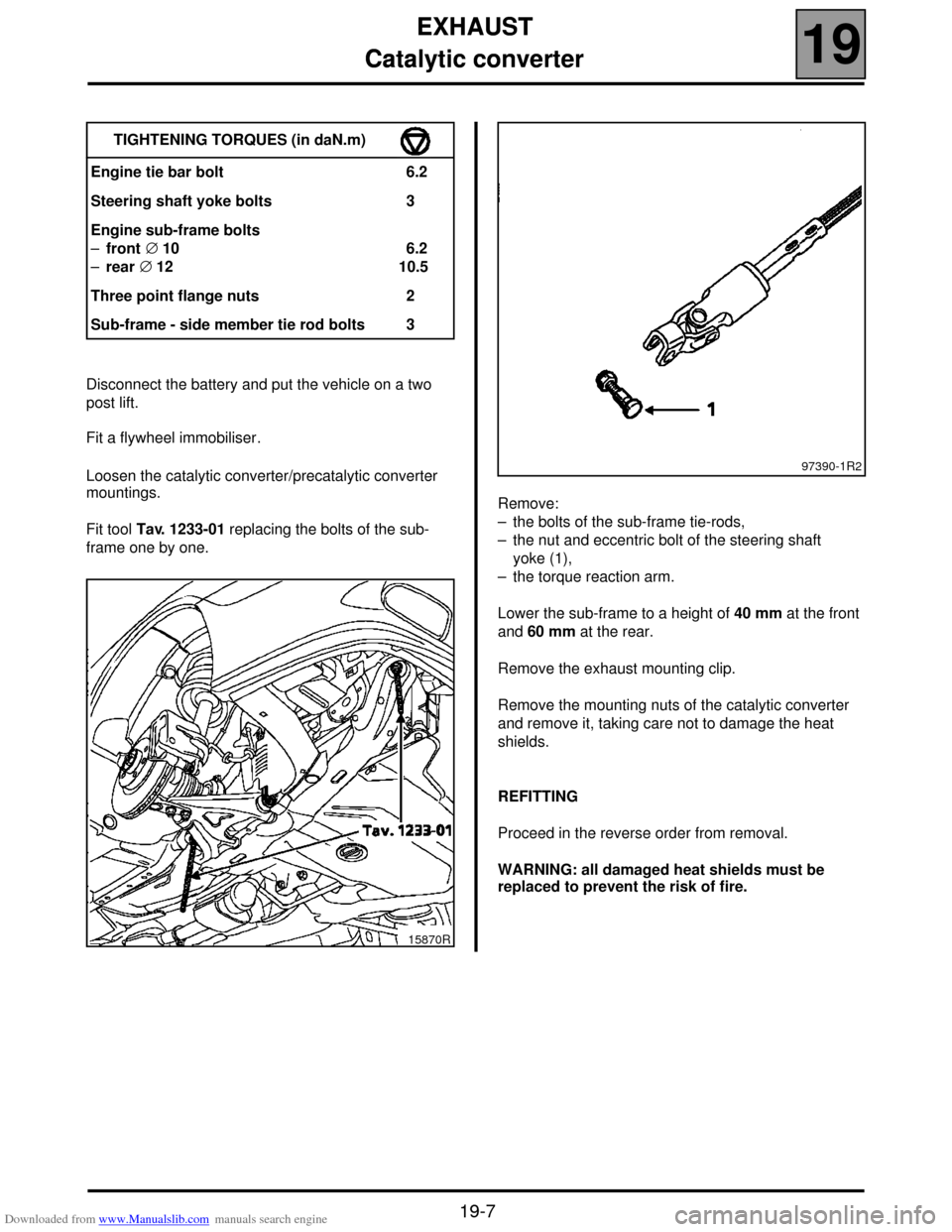

Disconnect the battery and put the vehicle on a two

post lift.

Fit a flywheel immobiliser.

Loosen the catalytic converter/precatalytic converter

mountings.

Fit tool Tav. 1233-01 replacing the bolts of the sub-

frame one by one.Remove:

– the bolts of the sub-frame tie-rods,

– the nut and eccentric bolt of the steering shaft

yoke (1),

– the torque reaction arm.

Lower the sub-frame to a height of 40 mm at the front

and 60 mm at the rear.

Remove the exhaust mounting clip.

Remove the mounting nuts of the catalytic converter

and remove it, taking care not to damage the heat

shields.

REFITTING

Proceed in the reverse order from removal.

WARNING: all damaged heat shields must be

replaced to prevent the risk of fire. TIGHTENING TORQUES (in daN.m)

Engine tie bar bolt 6.2

Steering shaft yoke bolts 3

Engine sub-frame bolts

–front ∅ 10

–rear ∅ 12 6.2

10.5

Three point flange nuts 2

Sub-frame - side member tie rod bolts 3

15870R

97390-1R2