brake RENAULT SCENIC 2000 J64 / 1.G Technical Note 3426A Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: SCENIC, Model: RENAULT SCENIC 2000 J64 / 1.GPages: 118, PDF Size: 1.5 MB

Page 2 of 118

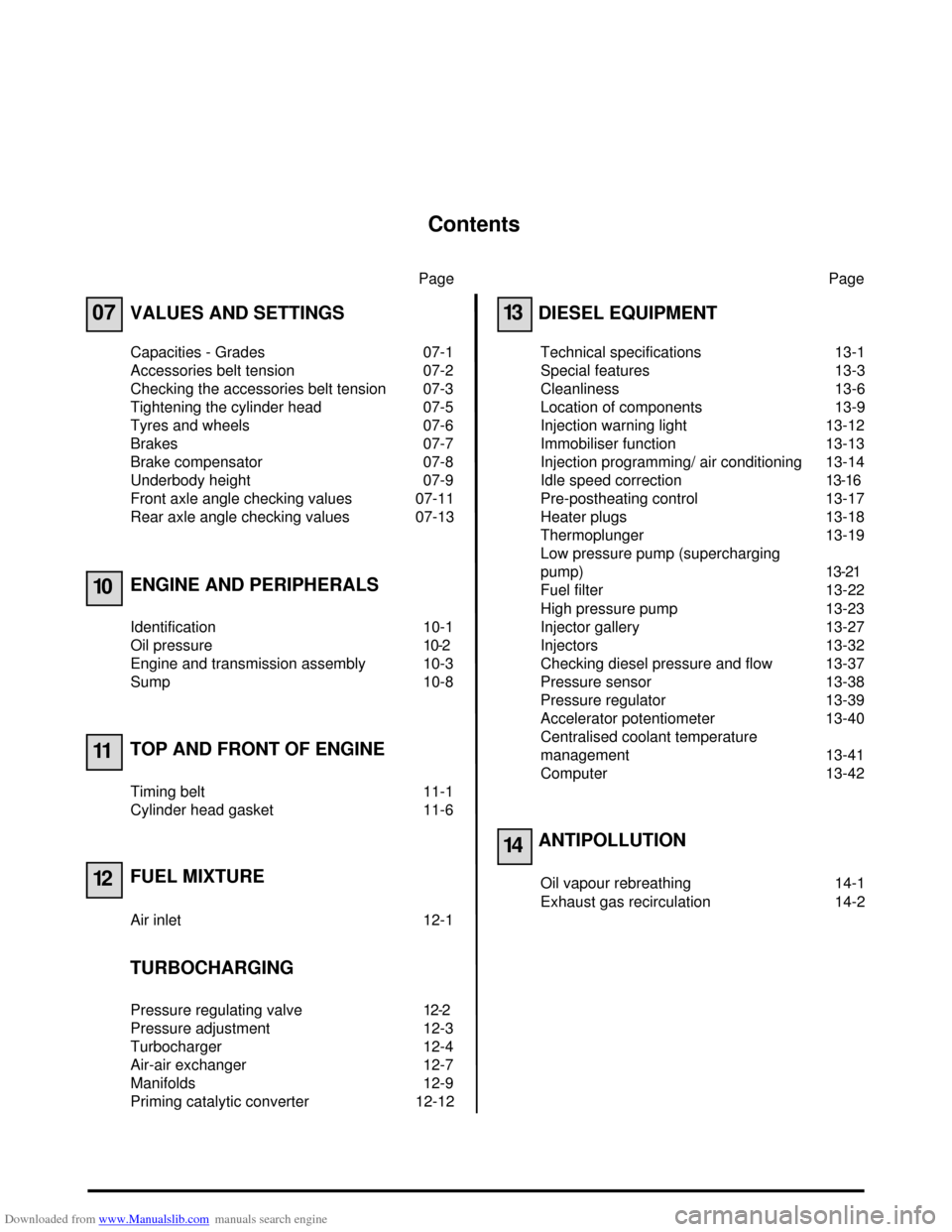

Downloaded from www.Manualslib.com manuals search engine Contents

Page

07

10

11

12

VALUES AND SETTINGS

Capacities - Grades 07-1

Accessories belt tension 07-2

Checking the accessories belt tension 07-3

Tightening the cylinder head 07-5

Tyres and wheels 07-6

Brakes 07-7

Brake compensator 07-8

Underbody height 07-9

Front axle angle checking values 07-11

Rear axle angle checking values 07-13

ENGINE AND PERIPHERALS

Identification 10-1

Oil pressure 10-2

Engine and transmission assembly 10-3

Sump 10-8

TOP AND FRONT OF ENGINE

Timing belt 11-1

Cylinder head gasket 11-6

FUEL MIXTURE

Air inlet 12-1

TURBOCHARGING

Pressure regulating valve 12-2

Pressure adjustment 12-3

Turbocharger 12-4

Air-air exchanger 12-7

Manifolds 12-9

Priming catalytic converter 12-12Page

13

14

DIESEL EQUIPMENT

Technical specifications 13-1

Special features 13-3

Cleanliness 13-6

Location of components 13-9

Injection warning light 13-12

Immobiliser function 13-13

Injection programming/ air conditioning 13-14

Idle speed correction13-16

Pre-postheating control 13-17

Heater plugs 13-18

Thermoplunger 13-19

Low pressure pump (supercharging

pump)13-21

Fuel filter 13-22

High pressure pump 13-23

Injector gallery 13-27

Injectors 13-32

Checking diesel pressure and flow 13-37

Pressure sensor 13-38

Pressure regulator 13-39

Accelerator potentiometer 13-40

Centralised coolant temperature

management 13-41

Computer 13-42

ANTIPOLLUTION

Oil vapour rebreathing 14-1

Exhaust gas recirculation 14-2

Page 10 of 118

Downloaded from www.Manualslib.com manuals search engine VALUES AND SETTINGS

Brakes

07

07-7

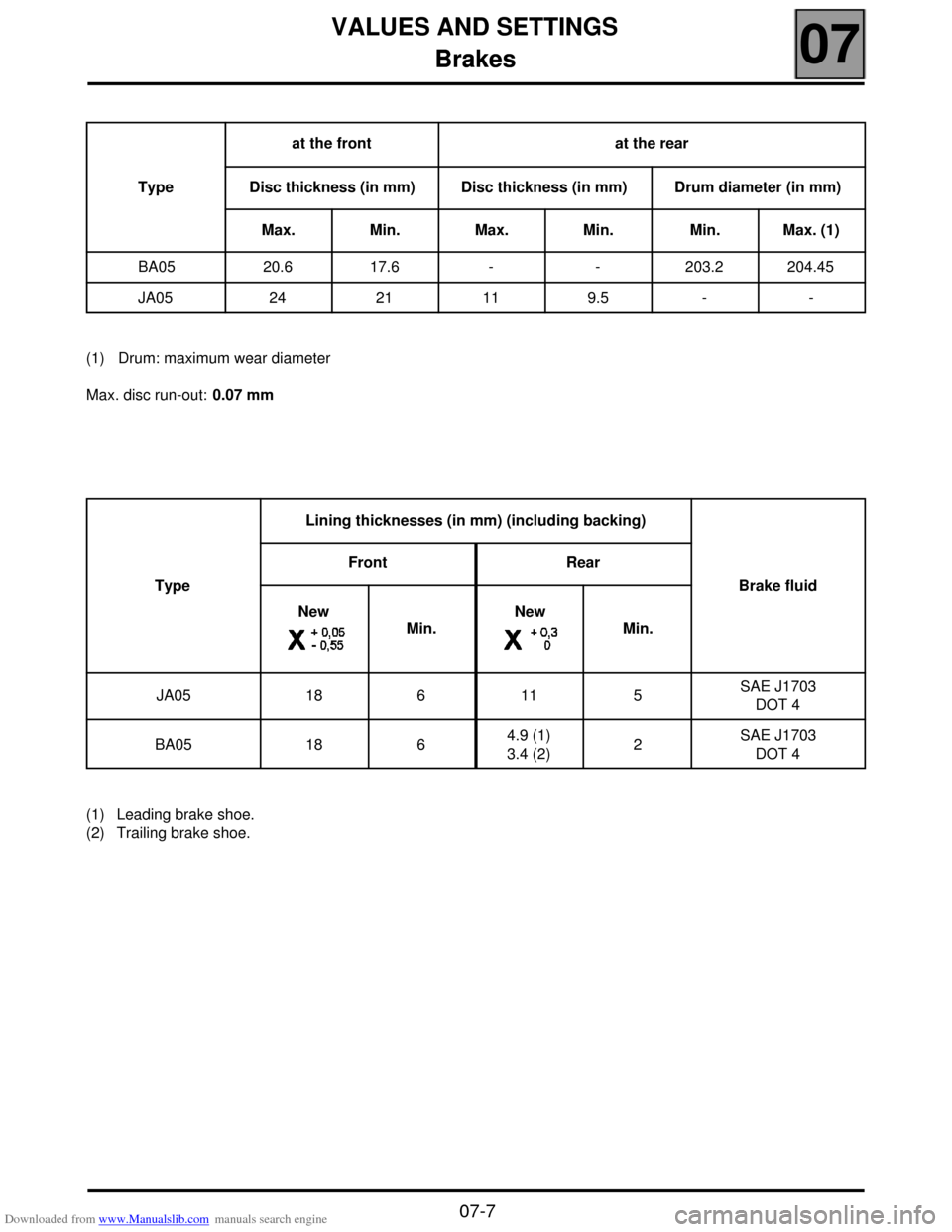

Brakes

(1) Drum: maximum wear diameter

Max. disc run-out: 0.07 mm

(1) Leading brake shoe.

(2) Trailing brake shoe.Typeat the front at the rear

Disc thickness (in mm) Disc thickness (in mm) Drum diameter (in mm)

Max. Min. Max. Min. Min. Max. (1)

BA05 20.6 17.6 - - 203.2 204.45

JA05 24 21 11 9.5 - -

TypeLining thicknesses (in mm) (including backing)

Brake fluid Front Rear

New

Min.New

Min.

JA05 18 6 11 5 SAE J1703

DOT 4

BA05 18 6 4.9 (1)

3.4 (2)2 SAE J1703

DOT 4

Page 11 of 118

Downloaded from www.Manualslib.com manuals search engine VALUES AND SETTINGS

Brake compensator

07

07-8

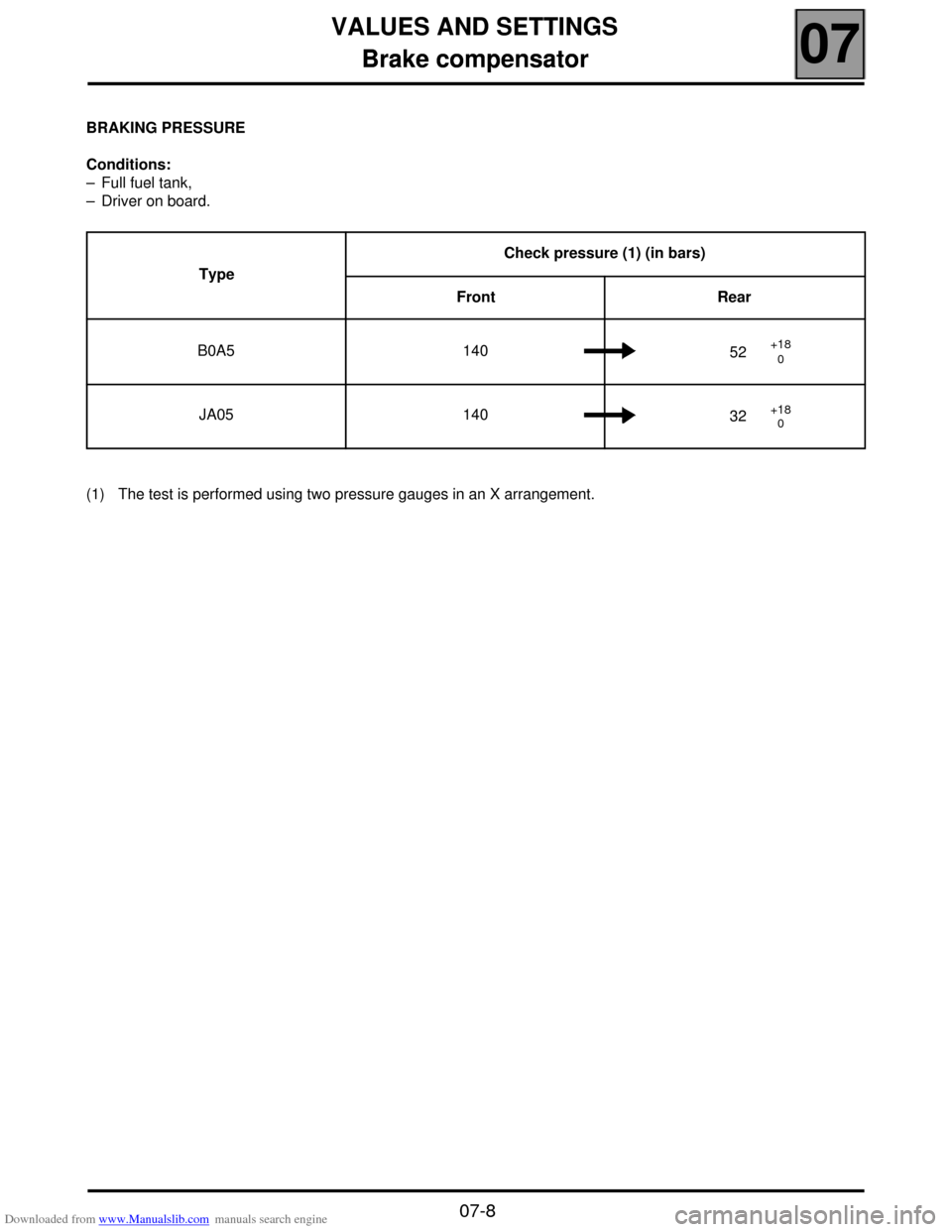

Brake compensator

BRAKING PRESSURE

Conditions:

– Full fuel tank,

– Driver on board.

(1) The test is performed using two pressure gauges in an X arrangement.TypeCheck pressure (1) (in bars)

Front Rear

B0A5 140

+18 52 0

JA05 140 +18 32 0

Page 12 of 118

Downloaded from www.Manualslib.com manuals search engine VALUES AND SETTINGS

Underbody height

07

07-9

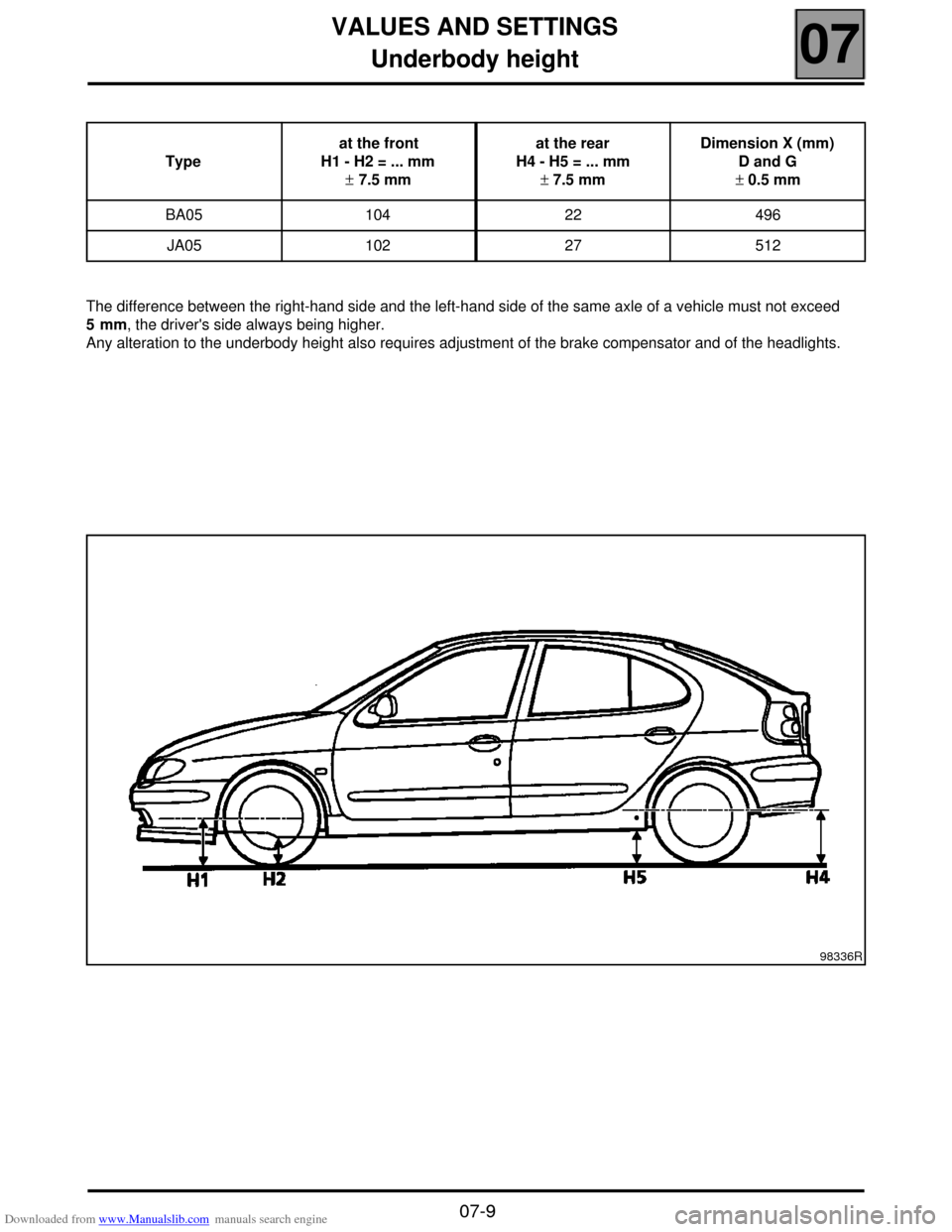

Underbody height

The difference between the right-hand side and the left-hand side of the same axle of a vehicle must not exceed

5 mm, the driver's side always being higher.

Any alteration to the underbody height also requires adjustment of the brake compensator and of the headlights.Typeat the front

H1 - H2 = ... mm

± 7.5 mmat the rear

H4 - H5 = ... mm

± 7.5 mmDimension X (mm)

D and G

± 0.5 mm

BA05 104 22 496

JA05 102 27 512

98336R

Page 19 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-3

Engine and transmission assembly

SPECIAL TOOLING REQUIRED

Mot. 1040-01 Dummy sub-frame for removing

and refitting engine and

transmission assembly

Mot. 1159 Tool for maintaining engine on

subframe

Mot. 1202-01

Hose clip pliers

Mot. 1202-02

Mot. 1233-01 Threaded rods for lowering the

sub-frame

Mot. 1294-01 Tool for removing windscreen

wiper arms

Mot. 1448 Long nose pliers for hose clips

Mot. 1453 Engine support tool

REMOVAL

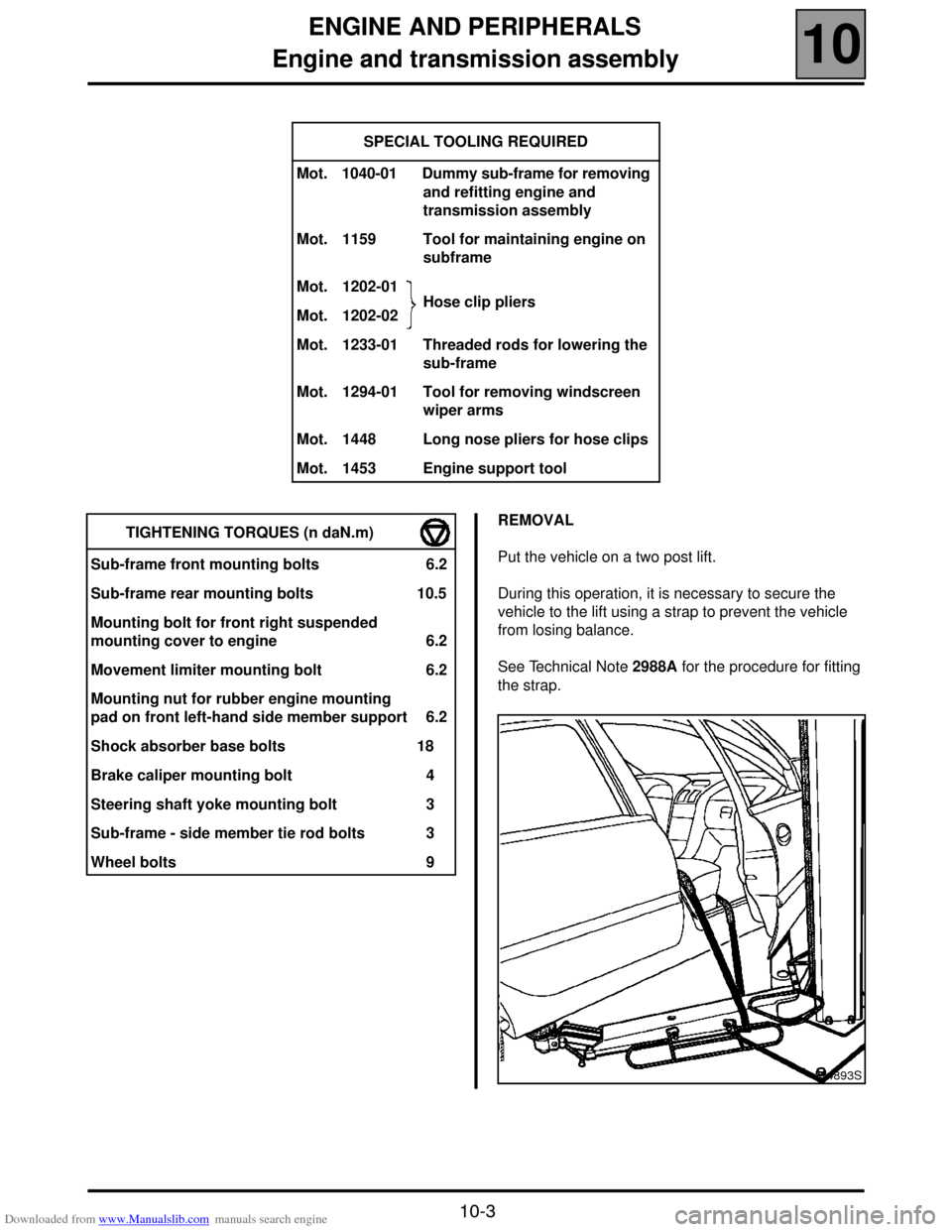

Put the vehicle on a two post lift.

During this operation, it is necessary to secure the

vehicle to the lift using a strap to prevent the vehicle

from losing balance.

See Technical Note 2988A for the procedure for fitting

the strap. TIGHTENING TORQUES (n daN.m)

Sub-frame front mounting bolts 6.2

Sub-frame rear mounting bolts 10.5

Mounting bolt for front right suspended

mounting cover to engine 6.2

Movement limiter mounting bolt 6.2

Mounting nut for rubber engine mounting

pad on front left-hand side member support 6.2

Shock absorber base bolts 18

Brake caliper mounting bolt 4

Steering shaft yoke mounting bolt 3

Sub-frame - side member tie rod bolts 3

Wheel bolts 9

14893S

Page 20 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-4

Remove:

– the battery,

– the engine undertray.

Drain:

– the cooling circuit through the bottom hose of the

radiator,

– the gearbox and the engine (if necessary),

– the refrigerant circuit (if fitted) using filling equipment.

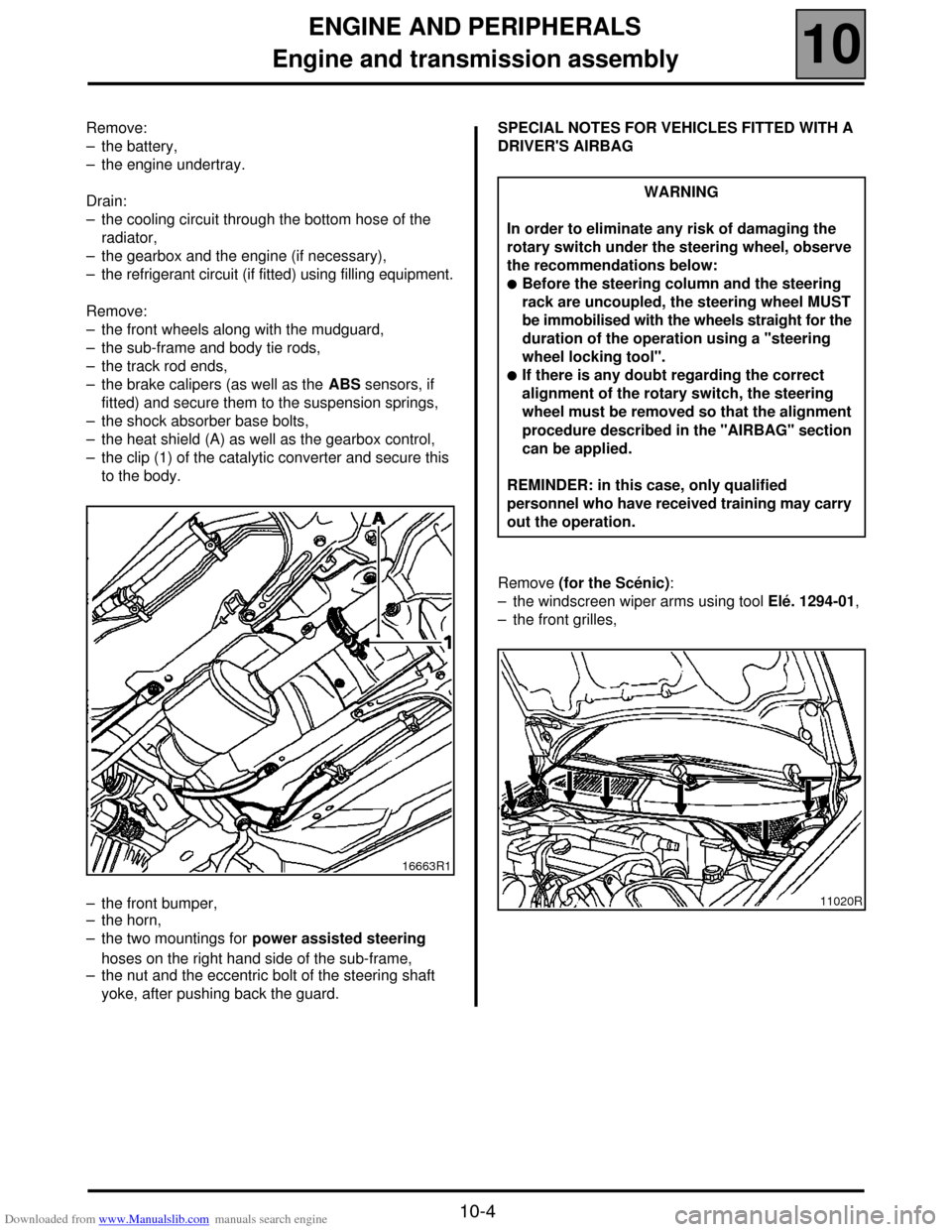

Remove:

– the front wheels along with the mudguard,

– the sub-frame and body tie rods,

– the track rod ends,

– the brake calipers (as well as the ABS sensors, if

fitted) and secure them to the suspension springs,

– the shock absorber base bolts,

– the heat shield (A) as well as the gearbox control,

– the clip (1) of the catalytic converter and secure this

to the body.

– the front bumper,

– the horn,

– the two mountings for power assisted steering

hoses on the right hand side of the sub-frame,

– the nut and the eccentric bolt of the steering shaft

yoke, after pushing back the guard.SPECIAL NOTES FOR VEHICLES FITTED WITH A

DRIVER'S AIRBAG

Remove (for the Scénic):

– the windscreen wiper arms using tool Elé. 1294-01,

– the front grilles,

16663R1

WARNING

In order to eliminate any risk of damaging the

rotary switch under the steering wheel, observe

the recommendations below:

!Before the steering column and the steering

rack are uncoupled, the steering wheel MUST

be immobilised with the wheels straight for the

duration of the operation using a "steering

wheel locking tool".

!If there is any doubt regarding the correct

alignment of the rotary switch, the steering

wheel must be removed so that the alignment

procedure described in the "AIRBAG" section

can be applied.

REMINDER: in this case, only qualified

personnel who have received training may carry

out the operation.

11020R

Page 21 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-5

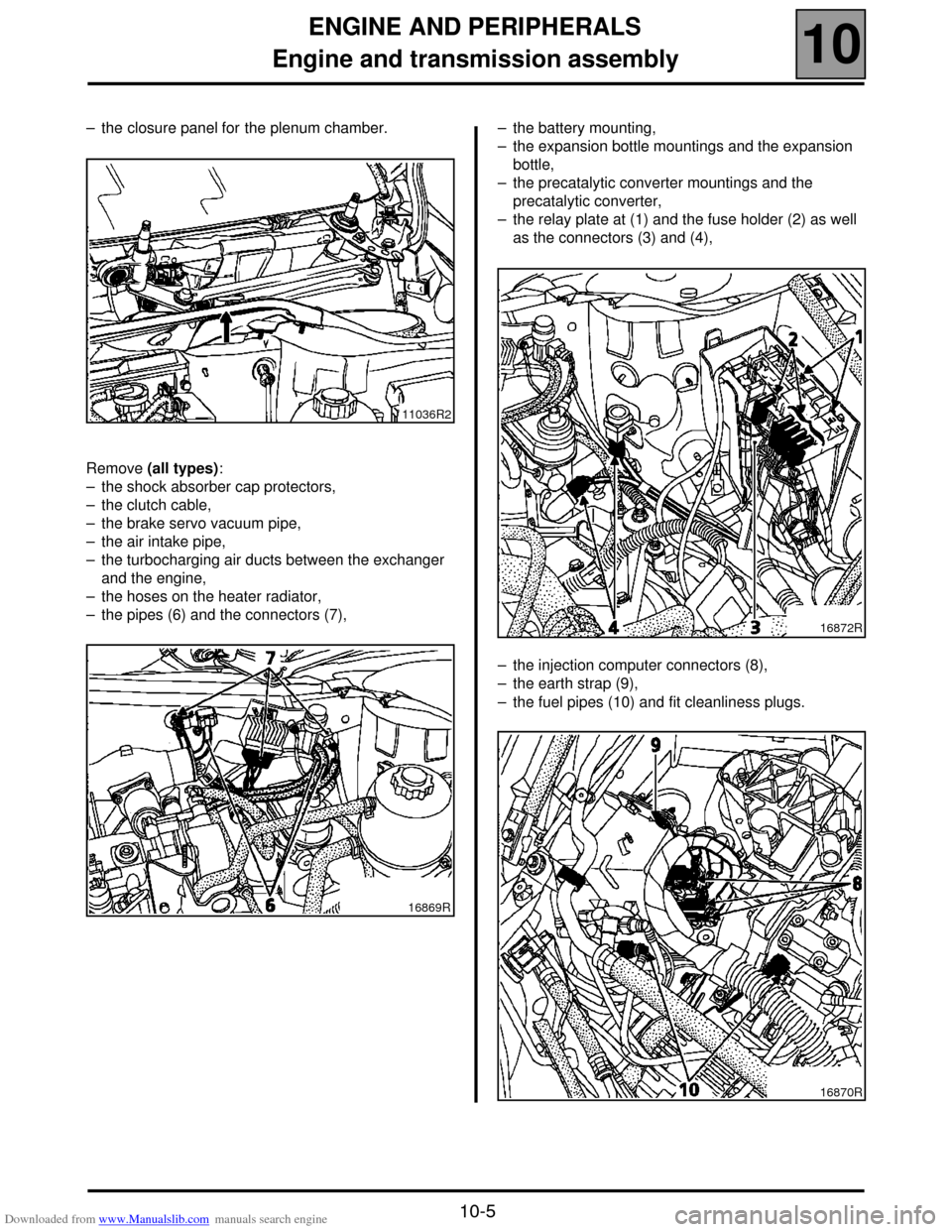

– the closure panel for the plenum chamber.

Remove (all types):

– the shock absorber cap protectors,

– the clutch cable,

– the brake servo vacuum pipe,

– the air intake pipe,

– the turbocharging air ducts between the exchanger

and the engine,

– the hoses on the heater radiator,

– the pipes (6) and the connectors (7),– the battery mounting,

– the expansion bottle mountings and the expansion

bottle,

– the precatalytic converter mountings and the

precatalytic converter,

– the relay plate at (1) and the fuse holder (2) as well

as the connectors (3) and (4),

– the injection computer connectors (8),

– the earth strap (9),

– the fuel pipes (10) and fit cleanliness plugs.

11036R2

16869R

16872R

16870R

Page 23 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-7

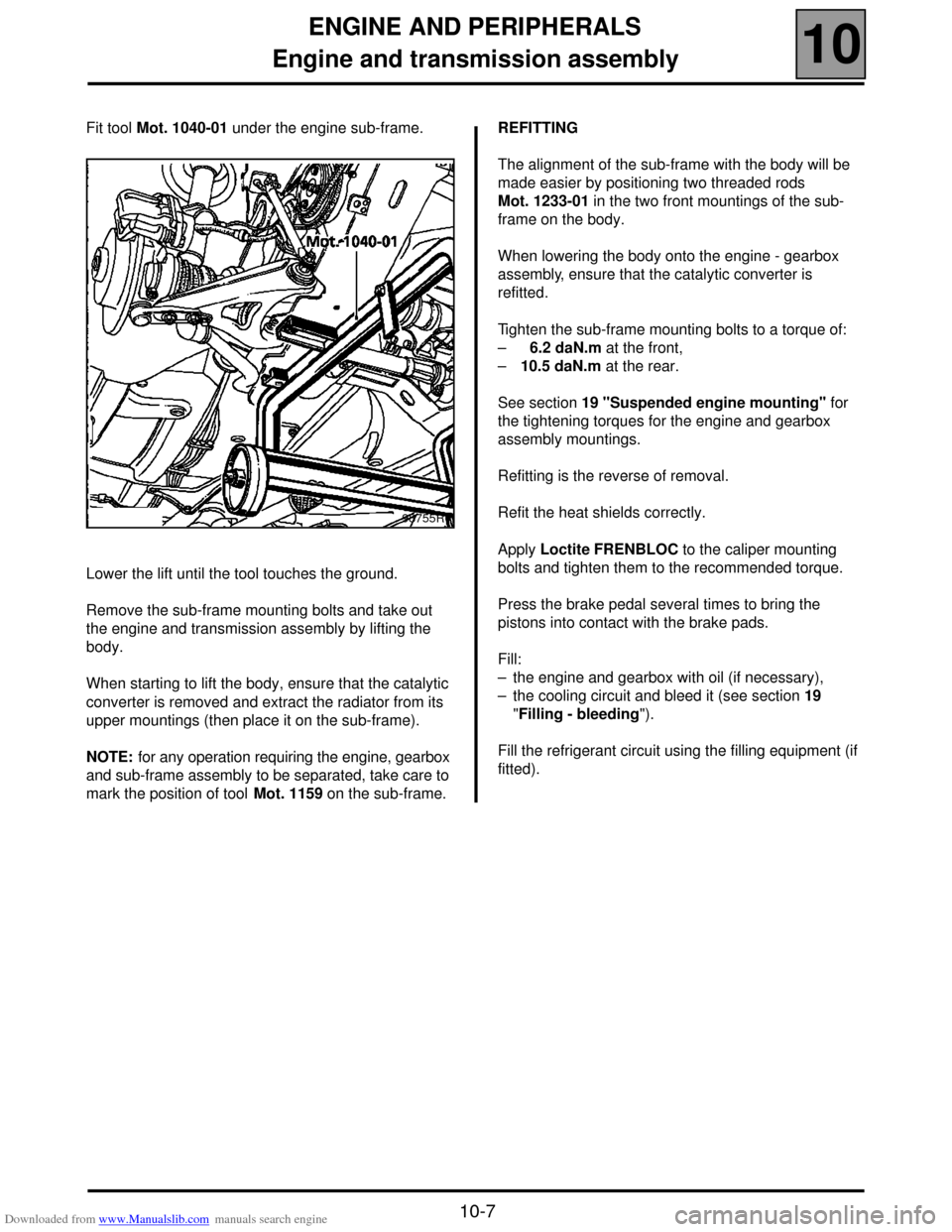

Fit tool Mot. 1040-01 under the engine sub-frame.

Lower the lift until the tool touches the ground.

Remove the sub-frame mounting bolts and take out

the engine and transmission assembly by lifting the

body.

When starting to lift the body, ensure that the catalytic

converter is removed and extract the radiator from its

upper mountings (then place it on the sub-frame).

NOTE: for any operation requiring the engine, gearbox

and sub-frame assembly to be separated, take care to

mark the position of tool Mot. 1159 on the sub-frame.REFITTING

The alignment of the sub-frame with the body will be

made easier by positioning two threaded rods

Mot. 1233-01 in the two front mountings of the sub-

frame on the body.

When lowering the body onto the engine - gearbox

assembly, ensure that the catalytic converter is

refitted.

Tighten the sub-frame mounting bolts to a torque of:

– 6.2 daN.m at the front,

–10.5 daN.m at the rear.

See section 19 "Suspended engine mounting" for

the tightening torques for the engine and gearbox

assembly mountings.

Refitting is the reverse of removal.

Refit the heat shields correctly.

Apply Loctite FRENBLOC to the caliper mounting

bolts and tighten them to the recommended torque.

Press the brake pedal several times to bring the

pistons into contact with the brake pads.

Fill:

– the engine and gearbox with oil (if necessary),

– the cooling circuit and bleed it (see section 19

"Filling - bleeding").

Fill the refrigerant circuit using the filling equipment (if

fitted).

98755R1

Page 35 of 118

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Cylinder head gasket

11

11 - 9

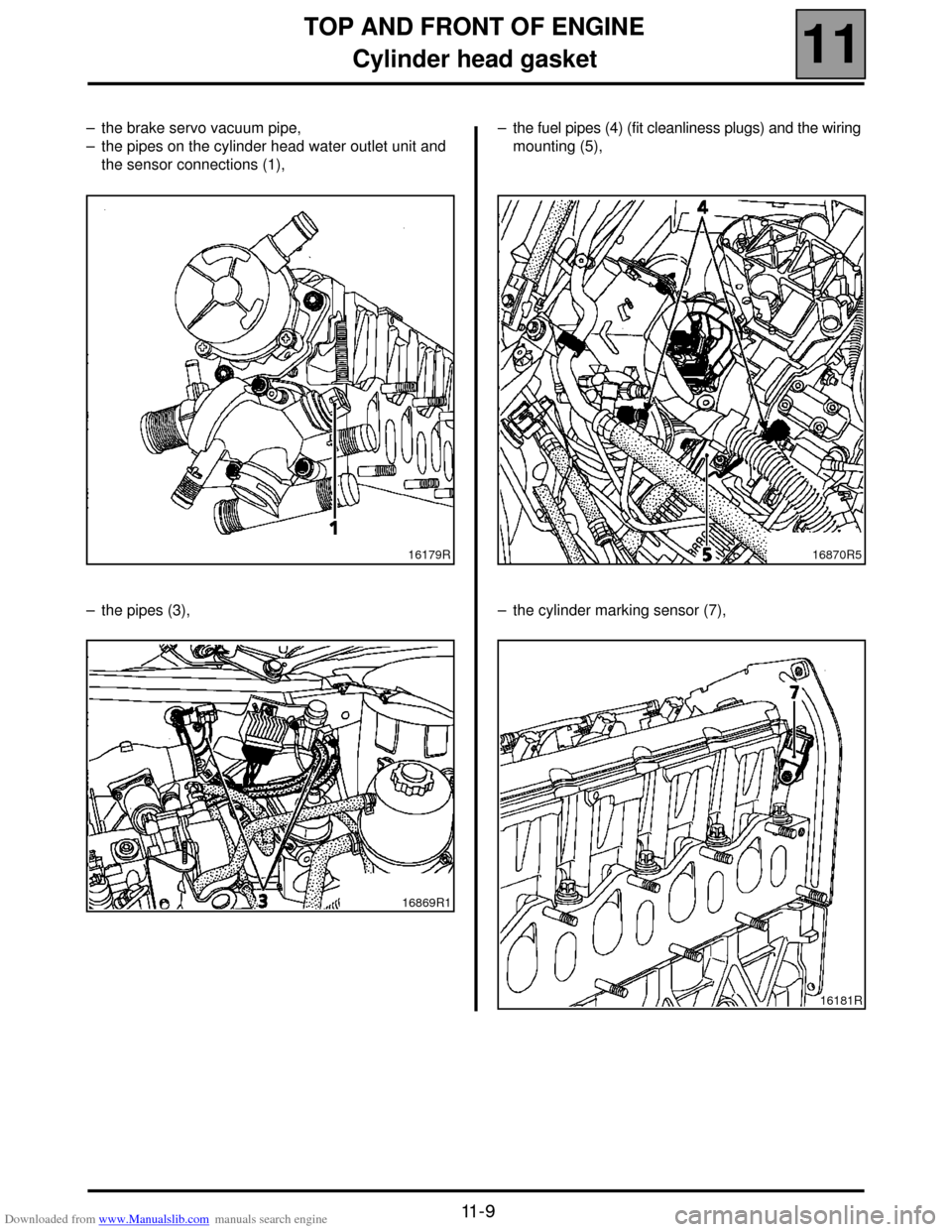

– the brake servo vacuum pipe,

– the pipes on the cylinder head water outlet unit and

the sensor connections (1),

– the pipes (3),– the fuel pipes (4) (fit cleanliness plugs) and the wiring

mounting (5),

– the cylinder marking sensor (7),

16179R

16869R116870R5

16181R

Page 67 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Idle speed correction

13

13-16

Idle speed correction

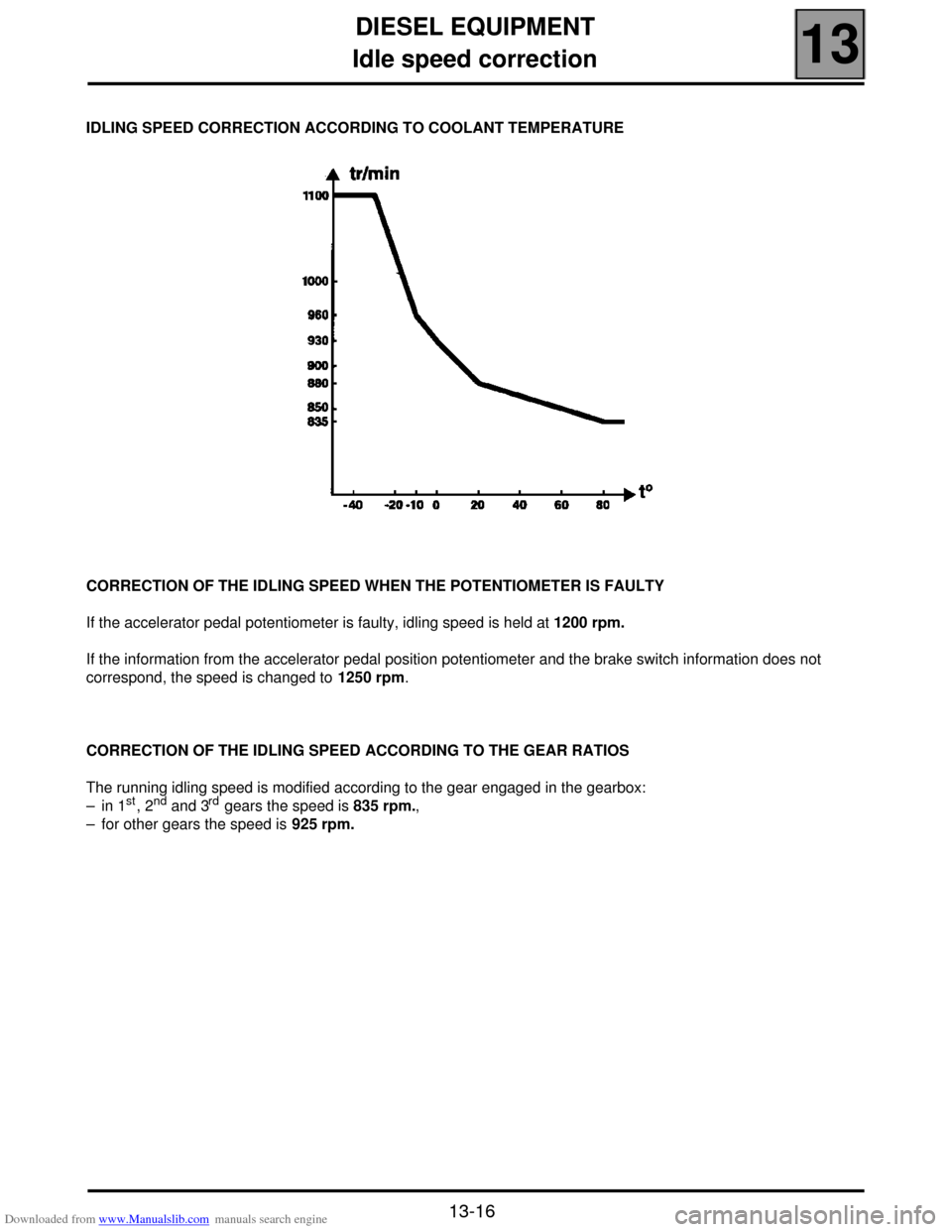

IDLING SPEED CORRECTION ACCORDING TO COOLANT TEMPERATURE

CORRECTION OF THE IDLING SPEED WHEN THE POTENTIOMETER IS FAULTY

If the accelerator pedal potentiometer is faulty, idling speed is held at 1200 rpm.

If the information from the accelerator pedal position potentiometer and the brake switch information does not

correspond, the speed is changed to 1250 rpm.

CORRECTION OF THE IDLING SPEED ACCORDING TO THE GEAR RATIOS

The running idling speed is modified according to the gear engaged in the gearbox:

– in 1

st, 2nd and 3rd gears the speed is 835 rpm.,

– for other gears the speed is 925 rpm.