drain bolt RENAULT SCENIC 2000 J64 / 1.G Technical Note 3426A Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: SCENIC, Model: RENAULT SCENIC 2000 J64 / 1.GPages: 118, PDF Size: 1.5 MB

Page 20 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-4

Remove:

– the battery,

– the engine undertray.

Drain:

– the cooling circuit through the bottom hose of the

radiator,

– the gearbox and the engine (if necessary),

– the refrigerant circuit (if fitted) using filling equipment.

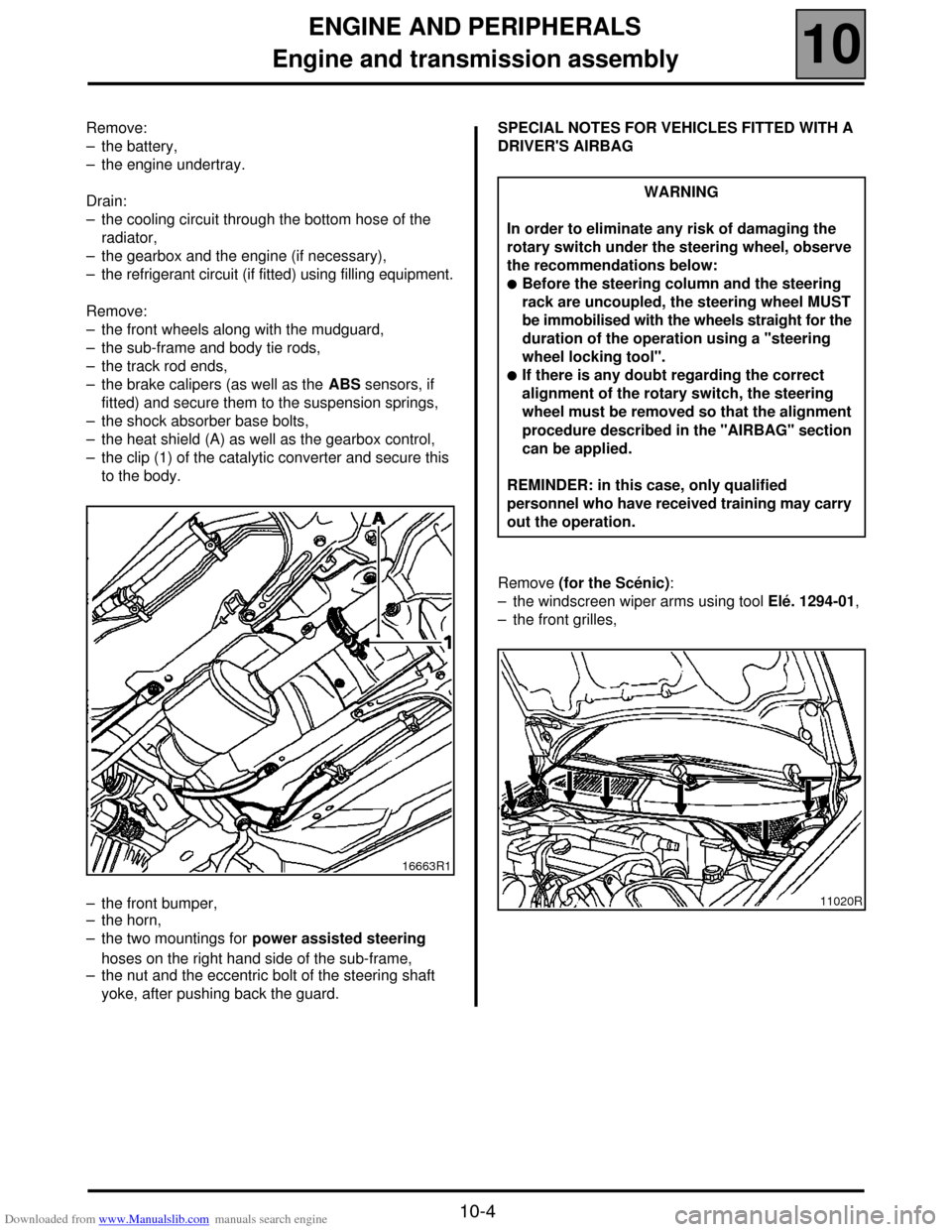

Remove:

– the front wheels along with the mudguard,

– the sub-frame and body tie rods,

– the track rod ends,

– the brake calipers (as well as the ABS sensors, if

fitted) and secure them to the suspension springs,

– the shock absorber base bolts,

– the heat shield (A) as well as the gearbox control,

– the clip (1) of the catalytic converter and secure this

to the body.

– the front bumper,

– the horn,

– the two mountings for power assisted steering

hoses on the right hand side of the sub-frame,

– the nut and the eccentric bolt of the steering shaft

yoke, after pushing back the guard.SPECIAL NOTES FOR VEHICLES FITTED WITH A

DRIVER'S AIRBAG

Remove (for the Scénic):

– the windscreen wiper arms using tool Elé. 1294-01,

– the front grilles,

16663R1

WARNING

In order to eliminate any risk of damaging the

rotary switch under the steering wheel, observe

the recommendations below:

!Before the steering column and the steering

rack are uncoupled, the steering wheel MUST

be immobilised with the wheels straight for the

duration of the operation using a "steering

wheel locking tool".

!If there is any doubt regarding the correct

alignment of the rotary switch, the steering

wheel must be removed so that the alignment

procedure described in the "AIRBAG" section

can be applied.

REMINDER: in this case, only qualified

personnel who have received training may carry

out the operation.

11020R

Page 24 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Sump

10

10-8

Sump

SPECIAL TOOLING REQUIRED

Mot. 1233-01 Threaded rods for lowering the

sub-frame

REMOVAL

Put the vehicle on a two post lift.

Disconnect the battery.

Remove the engine undertray.

Drain the engine.

Remove:

– the front wheels as well as the right hand mudguard

and the lower clip of the left hand mudguard,

– the nut and the eccentric bolt of the steering shaft

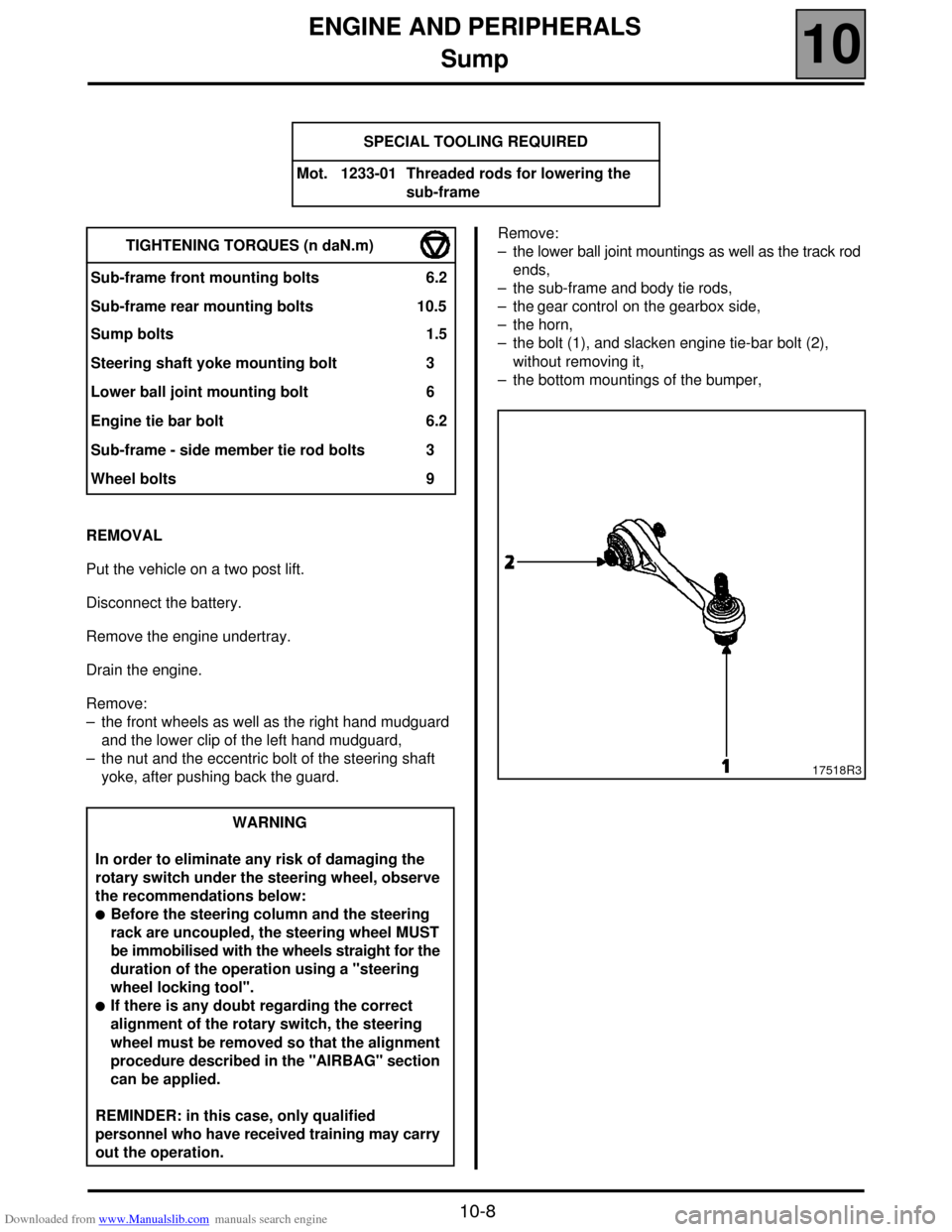

yoke, after pushing back the guard.Remove:

– the lower ball joint mountings as well as the track rod

ends,

– the sub-frame and body tie rods,

– the gear control on the gearbox side,

– the horn,

– the bolt (1), and slacken engine tie-bar bolt (2),

without removing it,

– the bottom mountings of the bumper, TIGHTENING TORQUES (n daN.m)

Sub-frame front mounting bolts 6.2

Sub-frame rear mounting bolts 10.5

Sump bolts 1.5

Steering shaft yoke mounting bolt 3

Lower ball joint mounting bolt 6

Engine tie bar bolt 6.2

Sub-frame - side member tie rod bolts 3

Wheel bolts 9

WARNING

In order to eliminate any risk of damaging the

rotary switch under the steering wheel, observe

the recommendations below:

!Before the steering column and the steering

rack are uncoupled, the steering wheel MUST

be immobilised with the wheels straight for the

duration of the operation using a "steering

wheel locking tool".

!If there is any doubt regarding the correct

alignment of the rotary switch, the steering

wheel must be removed so that the alignment

procedure described in the "AIRBAG" section

can be applied.

REMINDER: in this case, only qualified

personnel who have received training may carry

out the operation.

17518R3

Page 32 of 118

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Cylinder head gasket

11

11 - 6

Cylinder head gasket

SPECIAL TOOLING REQUIRED

Mot. 251 -01 Dial gauge support

Mot. 252 -01 Pressure plate to measure

piston protrusion

Mot. 1054 TDC setting pin

Mot. 1159 Tool for holding engine on

subframe

Mot. 1202 -01

Hose clip pliers

Mot. 1202-02

Mot. 1387 Tool for checking the automatic

tensioner centreline

Mot. 1448 Long nose pliers for hose clips

Mot. 1453 Engine support

Mot. 1505 Tool for measuring belt tension

Mot. 1453 Timing belt pretensioning

torque tool

ESSENTIAL SPECIAL TOOLING

Cylinder head testing equipment

14 torx socket

Angular tightening wrench

55 torx socket

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Remove the engine undertray.

Drain the cooling circuit through the lower radiator

hose.

Remove:

– the timing belt (see method described in section 11,

"Timing belt").

– the two PAS pipe mountings on the right hand sub-

frame. TIGHTENING TORQUES (in daN.m and/or ˚)

Tension roller nut 5

Crankshaft pulley bolt 2 + 115˚ ± 15˚

Suspended mounting cover bolt 6.2

Suspended mounting limiter bolt 6.2

Torque reaction arm 6.2

Wheel bolts 9

Page 107 of 118

Downloaded from www.Manualslib.com manuals search engine COOLING SYSTEM

Water pump

19

19-5

Water pump

REMOVAL

Put the vehicle on a two post lift.

Disconnect the battery.

Remove the engine undertray.

Drain the cooling circuit through the lower radiator

hose.

Unclip the diesel filter and remove it.

Remove:

– the front right wheel along with the mudguard,

– the style cover,

– the accessories belt (see Section 07 "Accessories

belt tension"),

– the coolant pump and power assisted steering pump

pulleys,

– the water pump.Cleaning

It is very important not to scratch the gasket faces.

Use the Décapjoint product to dissolve any part of the

gasket which remains attached.

Wear gloves whilst carrying out the following

operation.

– Apply the product to the parts to be cleaned; wait

about ten minutes, then remove it using a wooden

spatula.

Do not allow this agent to drip on to the paintwork.

REFITTING

Refit:

– the water pump (fitted with a new gasket), tightening

the bolts to a torque of 1.7 daN.m,

– the accessories belt and tension it (see section 07

"Accessories belt tension").

Fill and bleed the cooling circuit, (see section 19

"Filling and Bleeding"). SPECIAL TOOLING REQUIRED

Mot. 1202 -01

Hose clip pliers

Mot. 1202 -02

Mot. 1448 Long nose pliers for hose clips

TIGHTENING TORQUES (in daN.m)

Water pump bolts 1.7

Page 113 of 118

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

Compressor

62

62-2

SCENIC Compressor

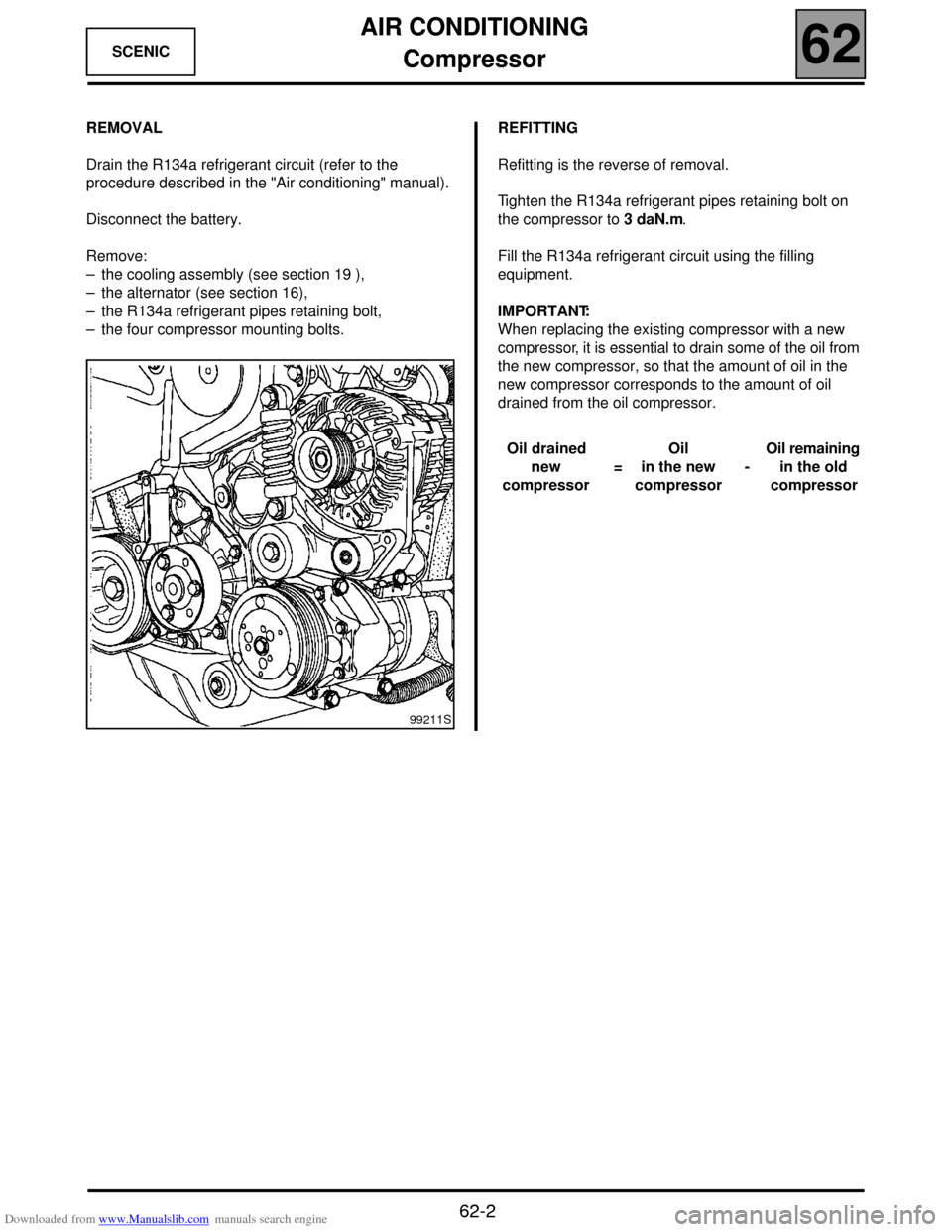

REMOVAL

Drain the R134a refrigerant circuit (refer to the

procedure described in the "Air conditioning" manual).

Disconnect the battery.

Remove:

– the cooling assembly (see section 19 ),

– the alternator (see section 16),

– the R134a refrigerant pipes retaining bolt,

– the four compressor mounting bolts.REFITTING

Refitting is the reverse of removal.

Tighten the R134a refrigerant pipes retaining bolt on

the compressor to 3 daN.m.

Fill the R134a refrigerant circuit using the filling

equipment.

IMPORTANT:

When replacing the existing compressor with a new

compressor, it is essential to drain some of the oil from

the new compressor, so that the amount of oil in the

new compressor corresponds to the amount of oil

drained from the oil compressor.

99211S

Oil drained

new

compressor=Oil

in the new

compressor-Oil remaining

in the old

compressor

Page 114 of 118

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

Dehydration canister

62

62-3

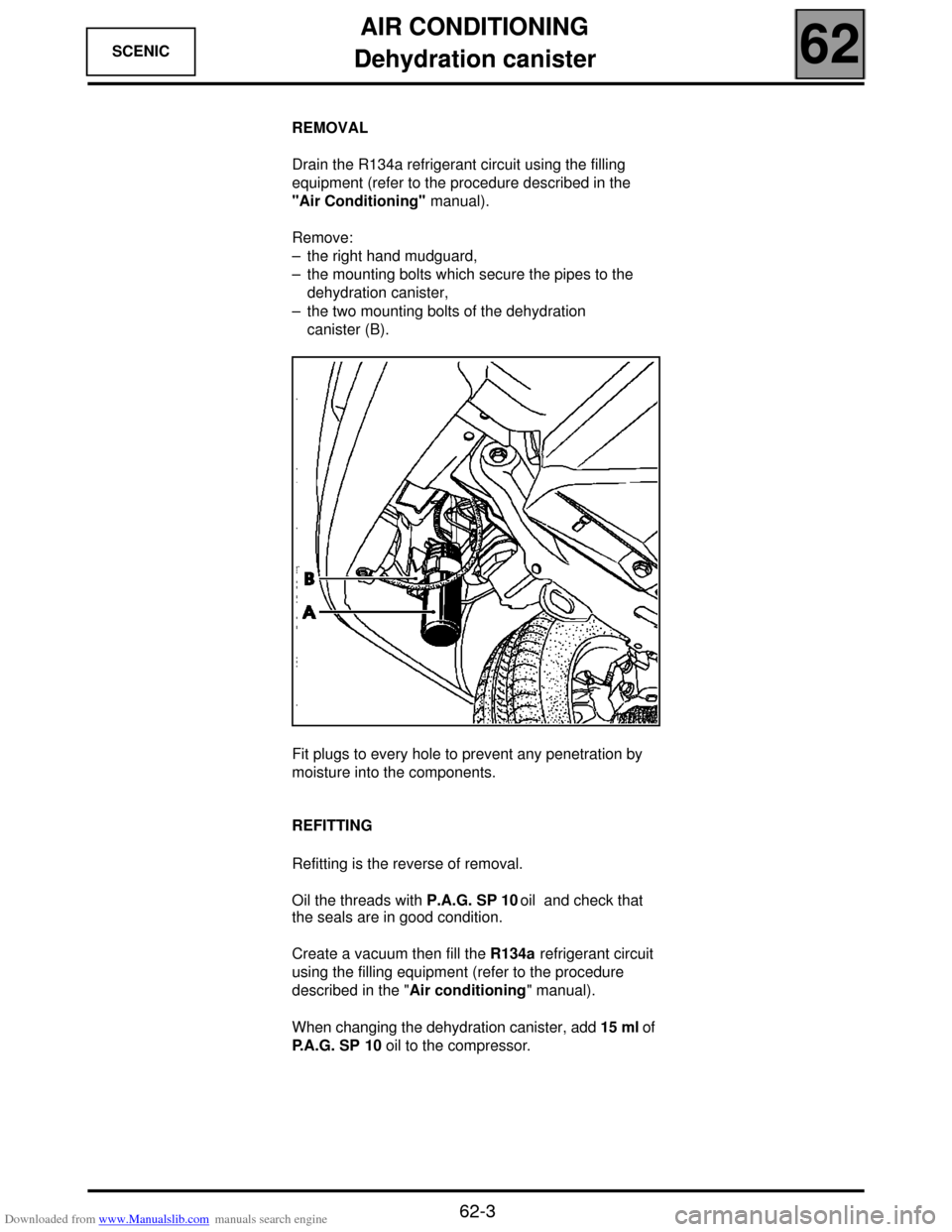

SCENIC Dehydration canister

REMOVAL

Drain the R134a refrigerant circuit using the filling

equipment (refer to the procedure described in the

"Air Conditioning" manual).

Remove:

– the right hand mudguard,

– the mounting bolts which secure the pipes to the

dehydration canister,

– the two mounting bolts of the dehydration

canister (B).

Fit plugs to every hole to prevent any penetration by

moisture into the components.

REFITTING

Refitting is the reverse of removal.

Oil the threads with P.A.G. SP 10 oil and check that

the seals are in good condition.

Create a vacuum then fill the R134a refrigerant circuit

using the filling equipment (refer to the procedure

described in the "Air conditioning" manual).

When changing the dehydration canister, add 15 ml of

P.A.G. SP 10 oil to the compressor.

16763R

Page 115 of 118

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

Condenser

62

62-4

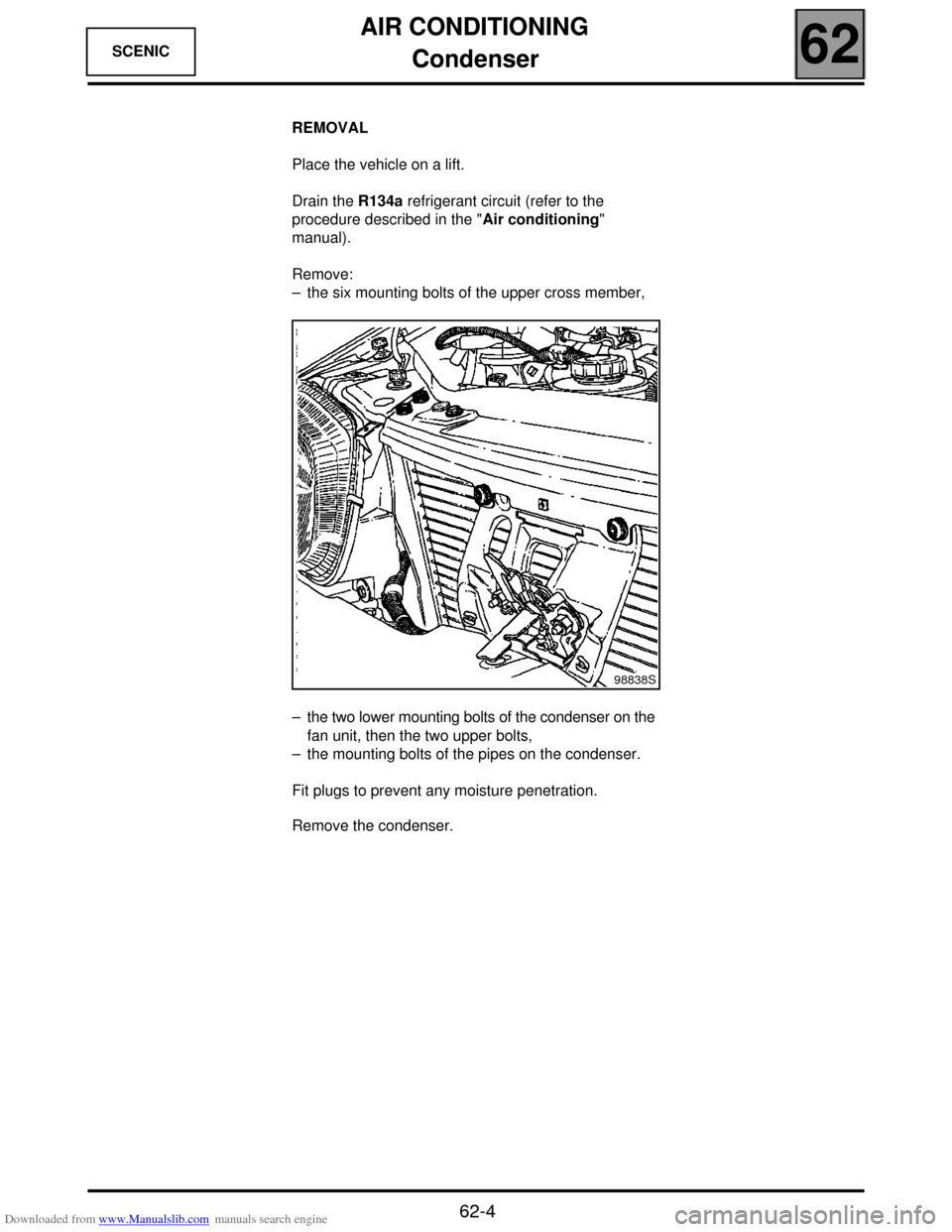

SCENIC Condenser

REMOVAL

Place the vehicle on a lift.

Drain the R134a refrigerant circuit (refer to the

procedure described in the "Air conditioning"

manual).

Remove:

– the six mounting bolts of the upper cross member,

– the two lower mounting bolts of the condenser on the

fan unit, then the two upper bolts,

– the mounting bolts of the pipes on the condenser.

Fit plugs to prevent any moisture penetration.

Remove the condenser.

98838S

Page 116 of 118

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

Pressure relief valve

62

62-5

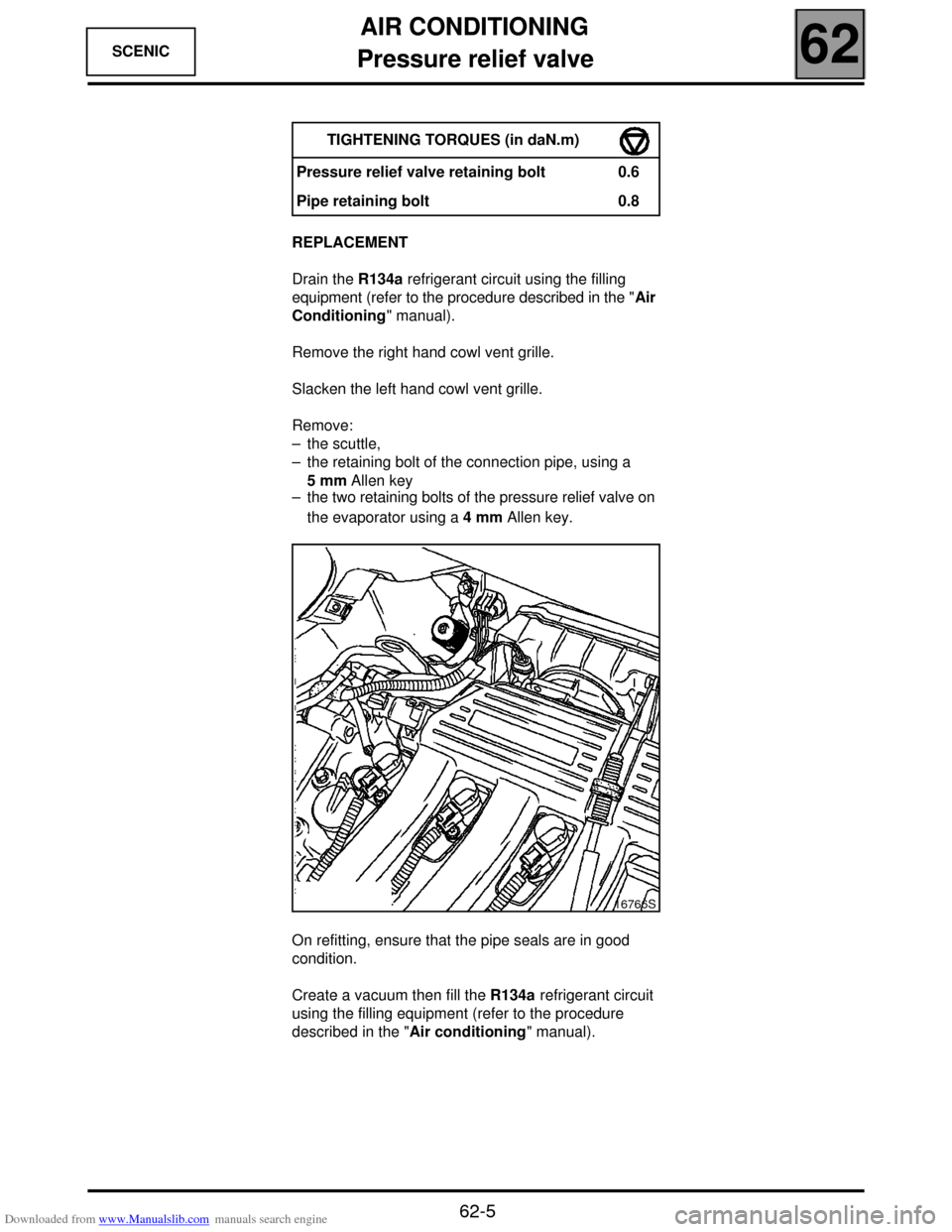

SCENIC Pressure relief valve

REPLACEMENT

Drain the R134a refrigerant circuit using the filling

equipment (refer to the procedure described in the "Air

Conditioning" manual).

Remove the right hand cowl vent grille.

Slacken the left hand cowl vent grille.

Remove:

– the scuttle,

– the retaining bolt of the connection pipe, using a

5 mm Allen key

– the two retaining bolts of the pressure relief valve on

the evaporator using a 4 mm Allen key.

On refitting, ensure that the pipe seals are in good

condition.

Create a vacuum then fill the R134a refrigerant circuit

using the filling equipment (refer to the procedure

described in the "Air conditioning" manual). TIGHTENING TORQUES (in daN.m)

Pressure relief valve retaining bolt 0.6

Pipe retaining bolt 0.8

16766S

Page 117 of 118

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

Connecting pipes

62

62-6

SCENIC Connecting pipes

Disconnect the battery.

Drain the R134a refrigerant circuit using the filling equipment (refer to the procedure described in the "Air

Conditioning" manual).

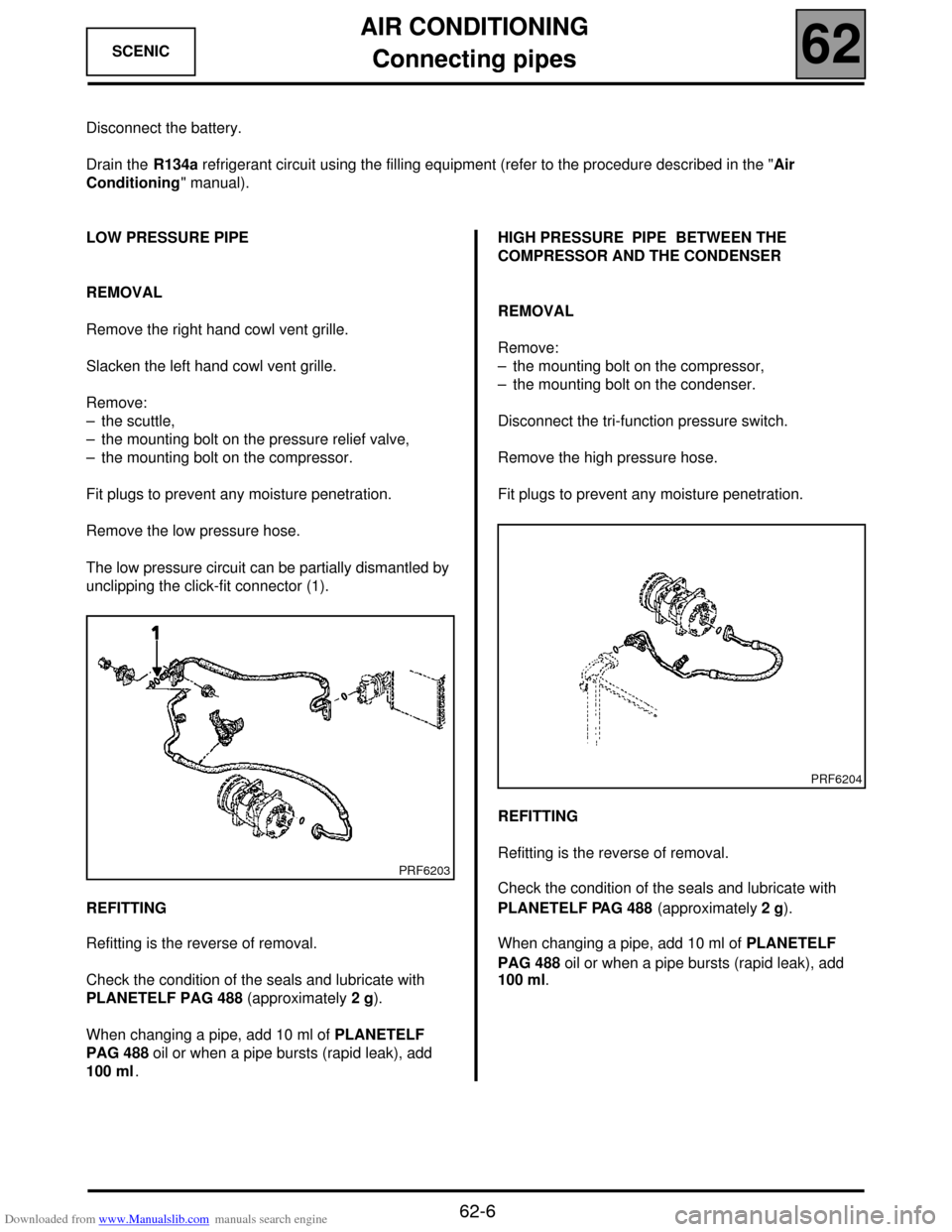

LOW PRESSURE PIPE

REMOVAL

Remove the right hand cowl vent grille.

Slacken the left hand cowl vent grille.

Remove:

– the scuttle,

– the mounting bolt on the pressure relief valve,

– the mounting bolt on the compressor.

Fit plugs to prevent any moisture penetration.

Remove the low pressure hose.

The low pressure circuit can be partially dismantled by

unclipping the click-fit connector (1).

REFITTING

Refitting is the reverse of removal.

Check the condition of the seals and lubricate with

PLANETELF PAG 488 (approximately 2 g).

When changing a pipe, add 10 ml of PLANETELF

PAG 488 oil or when a pipe bursts (rapid leak), add

100 ml.HIGH PRESSURE PIPE BETWEEN THE

COMPRESSOR AND THE CONDENSER

REMOVAL

Remove:

– the mounting bolt on the compressor,

– the mounting bolt on the condenser.

Disconnect the tri-function pressure switch.

Remove the high pressure hose.

Fit plugs to prevent any moisture penetration.

REFITTING

Refitting is the reverse of removal.

Check the condition of the seals and lubricate with

PLANETELF PAG 488 (approximately 2 g).

When changing a pipe, add 10 ml of PLANETELF

PAG 488 oil or when a pipe bursts (rapid leak), add

100 ml.

PRF6203

PRF6204

Page 118 of 118

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

Connecting pipes

62

62-7

SCENIC

Disconnect the battery.

Drain the R134a refrigerant circuit using the filling equipment (refer to the procedure described in the "Air

Conditioning" manual).

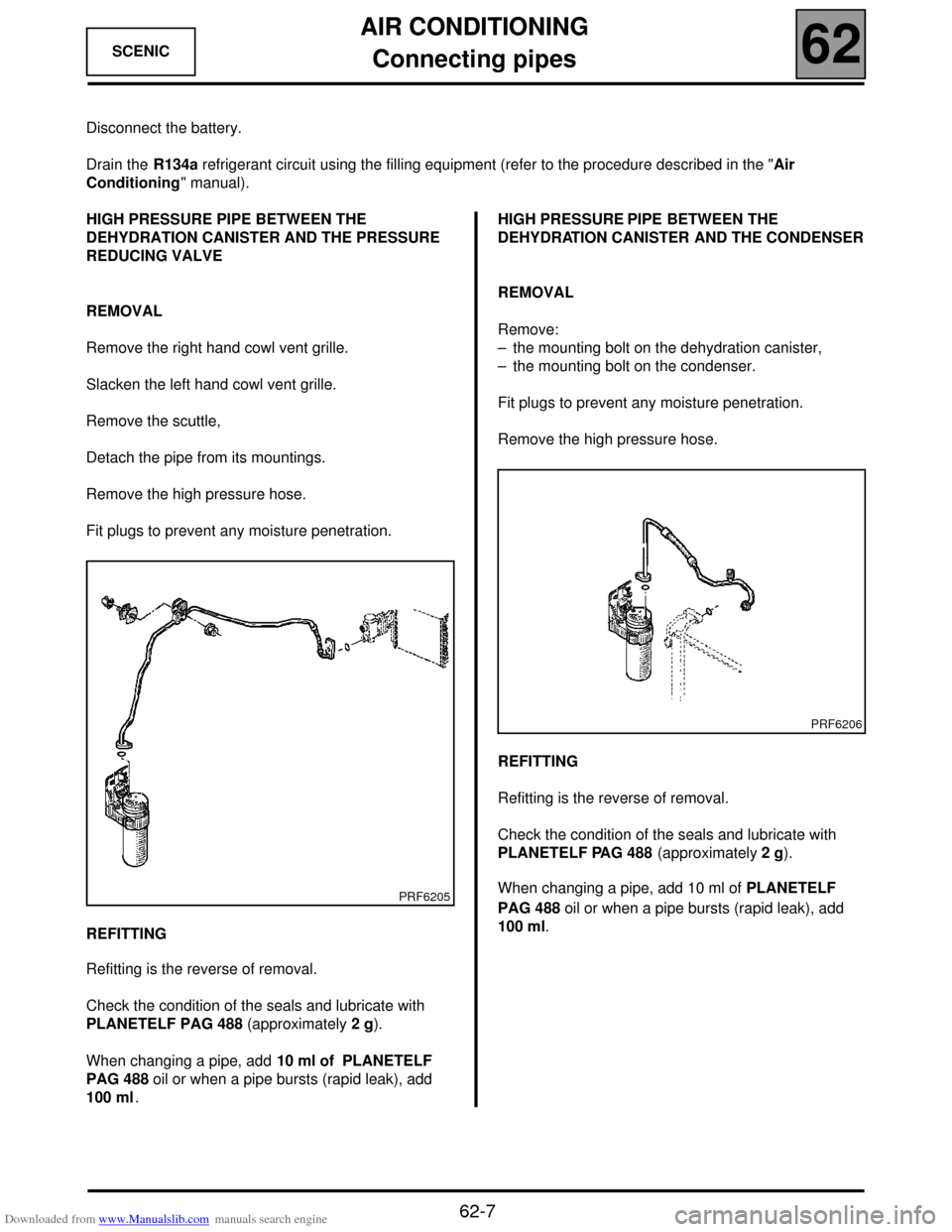

HIGH PRESSURE PIPE BETWEEN THE

DEHYDRATION CANISTER AND THE PRESSURE

REDUCING VALVE

REMOVAL

Remove the right hand cowl vent grille.

Slacken the left hand cowl vent grille.

Remove the scuttle,

Detach the pipe from its mountings.

Remove the high pressure hose.

Fit plugs to prevent any moisture penetration.

REFITTING

Refitting is the reverse of removal.

Check the condition of the seals and lubricate with

PLANETELF PAG 488 (approximately 2 g).

When changing a pipe, add 10 ml of PLANETELF

PAG 488 oil or when a pipe bursts (rapid leak), add

100 ml.HIGH PRESSURE PIPE BETWEEN THE

DEHYDRATION CANISTER AND THE CONDENSER

REMOVAL

Remove:

– the mounting bolt on the dehydration canister,

– the mounting bolt on the condenser.

Fit plugs to prevent any moisture penetration.

Remove the high pressure hose.

REFITTING

Refitting is the reverse of removal.

Check the condition of the seals and lubricate with

PLANETELF PAG 488 (approximately 2 g).

When changing a pipe, add 10 ml of PLANETELF

PAG 488 oil or when a pipe bursts (rapid leak), add

100 ml.

PRF6205

PRF6206