heating RENAULT SCENIC 2000 J64 / 1.G Technical Note 3426A Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: SCENIC, Model: RENAULT SCENIC 2000 J64 / 1.GPages: 118, PDF Size: 1.5 MB

Page 2 of 118

Downloaded from www.Manualslib.com manuals search engine Contents

Page

07

10

11

12

VALUES AND SETTINGS

Capacities - Grades 07-1

Accessories belt tension 07-2

Checking the accessories belt tension 07-3

Tightening the cylinder head 07-5

Tyres and wheels 07-6

Brakes 07-7

Brake compensator 07-8

Underbody height 07-9

Front axle angle checking values 07-11

Rear axle angle checking values 07-13

ENGINE AND PERIPHERALS

Identification 10-1

Oil pressure 10-2

Engine and transmission assembly 10-3

Sump 10-8

TOP AND FRONT OF ENGINE

Timing belt 11-1

Cylinder head gasket 11-6

FUEL MIXTURE

Air inlet 12-1

TURBOCHARGING

Pressure regulating valve 12-2

Pressure adjustment 12-3

Turbocharger 12-4

Air-air exchanger 12-7

Manifolds 12-9

Priming catalytic converter 12-12Page

13

14

DIESEL EQUIPMENT

Technical specifications 13-1

Special features 13-3

Cleanliness 13-6

Location of components 13-9

Injection warning light 13-12

Immobiliser function 13-13

Injection programming/ air conditioning 13-14

Idle speed correction13-16

Pre-postheating control 13-17

Heater plugs 13-18

Thermoplunger 13-19

Low pressure pump (supercharging

pump)13-21

Fuel filter 13-22

High pressure pump 13-23

Injector gallery 13-27

Injectors 13-32

Checking diesel pressure and flow 13-37

Pressure sensor 13-38

Pressure regulator 13-39

Accelerator potentiometer 13-40

Centralised coolant temperature

management 13-41

Computer 13-42

ANTIPOLLUTION

Oil vapour rebreathing 14-1

Exhaust gas recirculation 14-2

Page 52 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Specifications

13

113

DIESEL EQUIPMENT

Specifications

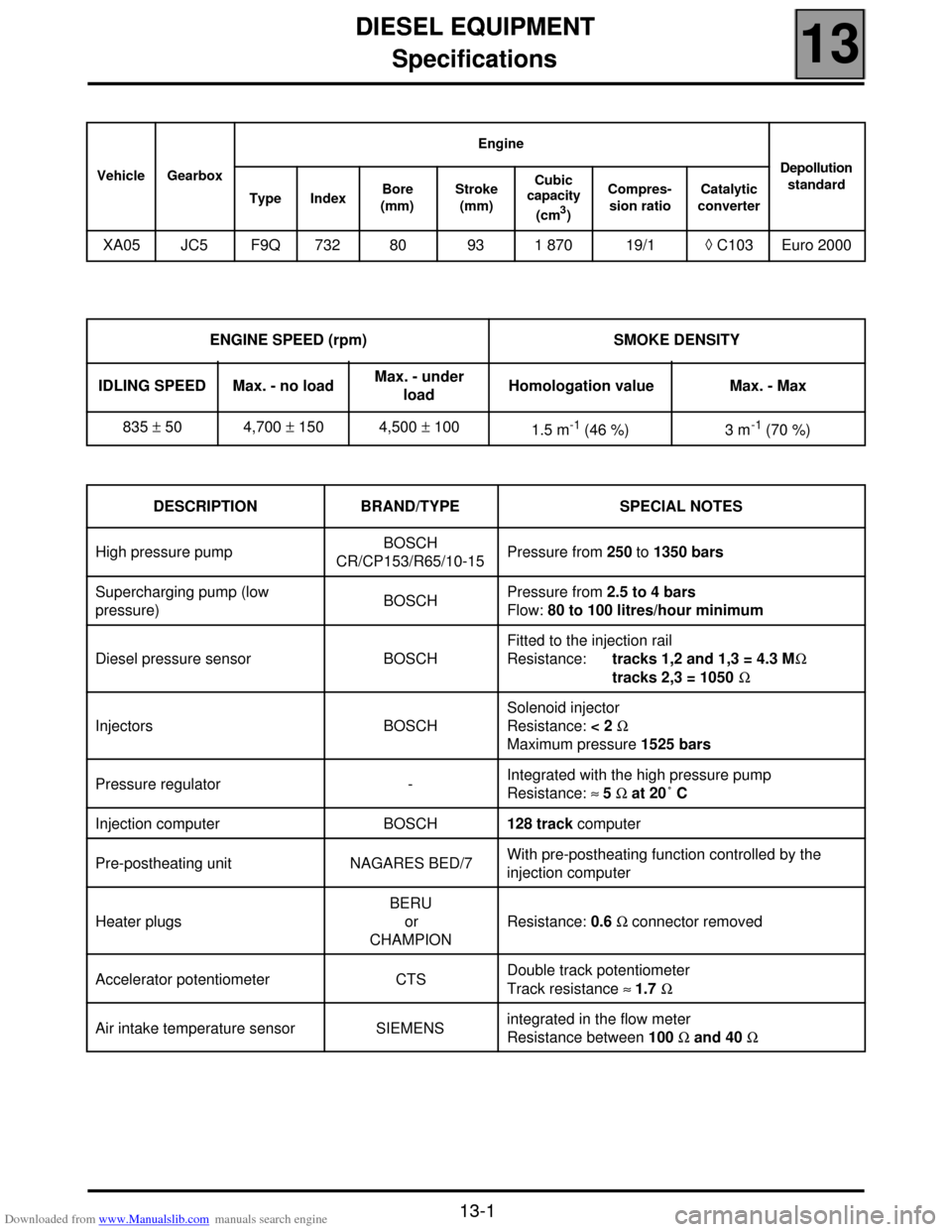

Vehicle GearboxEngine

Depollution

standard

Type IndexBore

(mm) Stroke

(mm) Cubic

capacity

(cm

3)Compres-

sion ratioCatalytic

converter

XA05 JC5 F9Q 732 80 93 1 870 19/1◊ C103 Euro 2000

ENGINE SPEED (rpm) SMOKE DENSITY

IDLING SPEED Max. - no loadMax. - under

loadHomologation value Max. - Max

835 ± 50 4,700 ± 150 4,500 ± 100

1.5 m

-1 (46 %) 3 m-1 (70 %)

DESCRIPTION BRAND/TYPE SPECIAL NOTES

High pressure pumpBOSCH

CR/CP153/R65/10-15Pressure from 250 to 1350 bars

Supercharging pump (low

pressure)BOSCHPressure from 2.5 to 4 bars

Flow: 80 to 100 litres/hour minimum

Diesel pressure sensor BOSCHFitted to the injection rail

Resistance: tracks 1,2 and 1,3 = 4.3 MΩ

tracks 2,3 = 1050 Ω

Injectors BOSCHSolenoid injector

Resistance: < 2 Ω

Maximum pressure 1525 bars

Pressure regulator - Integrated with the high pressure pump

Resistance: ≈ 5 Ω at 20˚ C

Injection computer BOSCH128 track computer

Pre-postheating unit NAGARES BED/7With pre-postheating function controlled by the

injection computer

Heater plugsBERU

or

CHAMPIONResistance: 0.6 Ω connector removed

Accelerator potentiometer CTSDouble track potentiometer

Track resistance ≈ 1.7 Ω

Air intake temperature sensor SIEMENSintegrated in the flow meter

Resistance between 100 Ω and 40 Ω

13-1

Page 60 of 118

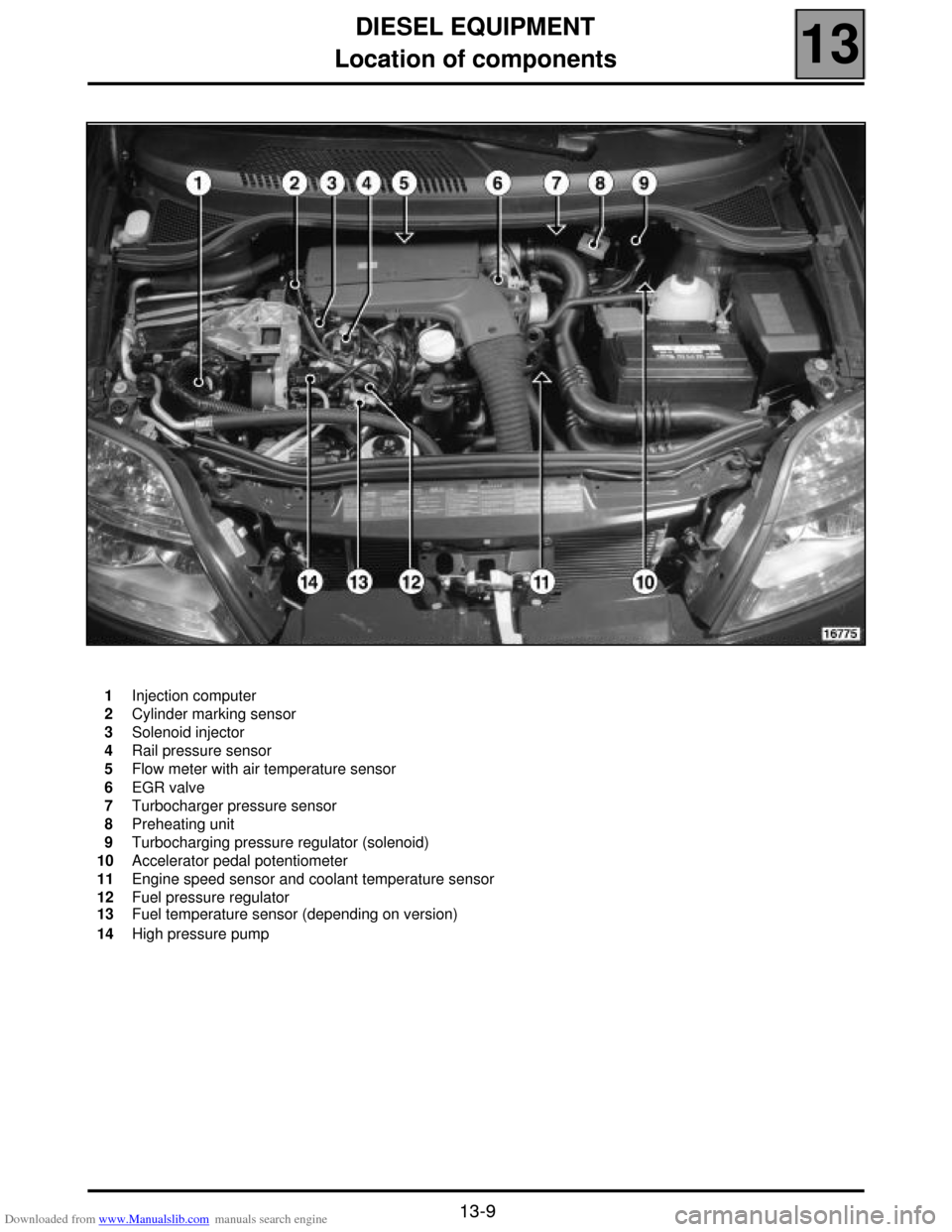

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Location of components

13

13-9

Location of components

1

2

3

4

5

6

7

8

9

10

11

12

13

14Injection computer

Cylinder marking sensor

Solenoid injector

Rail pressure sensor

Flow meter with air temperature sensor

EGR valve

Turbocharger pressure sensor

Preheating unit

Turbocharging pressure regulator (solenoid)

Accelerator pedal potentiometer

Engine speed sensor and coolant temperature sensor

Fuel pressure regulator

Fuel temperature sensor (depending on version)

High pressure pump

Page 62 of 118

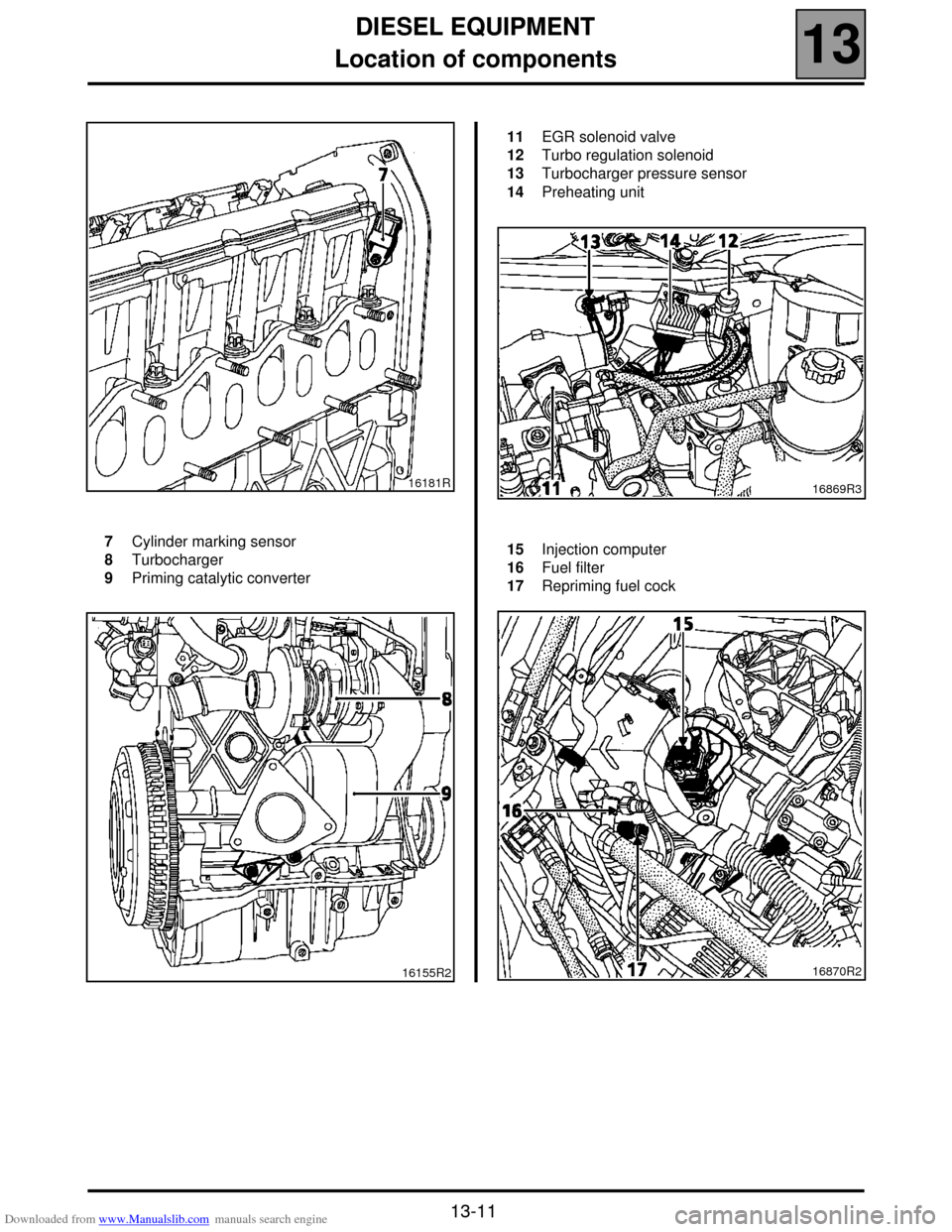

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Location of components

13

13-11

16181R

7

8

9Cylinder marking sensor

Turbocharger

Priming catalytic converter

16155R2

11

12

13

14EGR solenoid valve

Turbo regulation solenoid

Turbocharger pressure sensor

Preheating unit

16869R3

15

16

17Injection computer

Fuel filter

Repriming fuel cock

16870R2

Page 63 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Injection warning light

13

13-12

Injection warning light

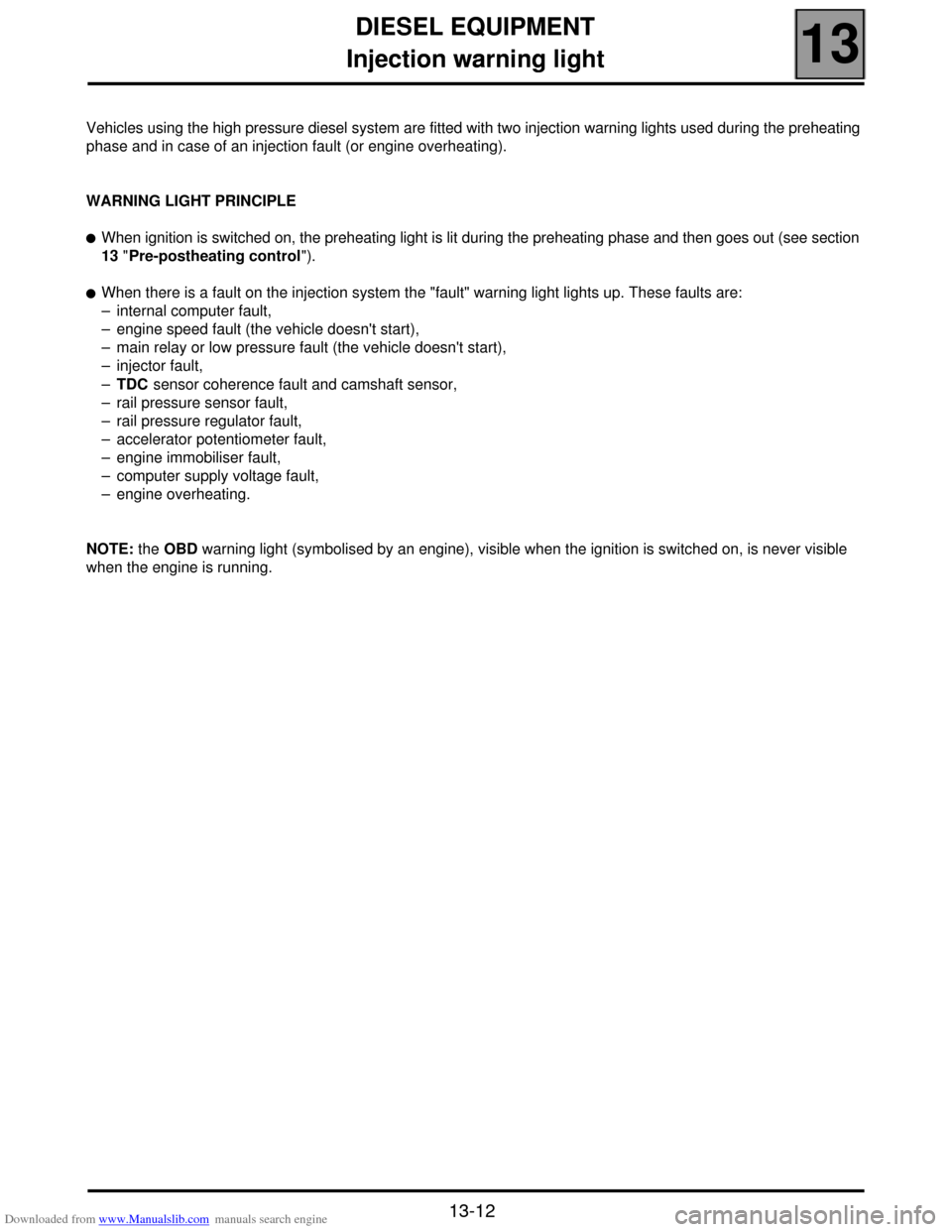

Vehicles using the high pressure diesel system are fitted with two injection warning lights used during the preheating

phase and in case of an injection fault (or engine overheating).

WARNING LIGHT PRINCIPLE

!When ignition is switched on, the preheating light is lit during the preheating phase and then goes out (see section

13 "Pre-postheating control").

!When there is a fault on the injection system the "fault" warning light lights up. These faults are:

– internal computer fault,

– engine speed fault (the vehicle doesn't start),

– main relay or low pressure fault (the vehicle doesn't start),

– injector fault,

–TDC sensor coherence fault and camshaft sensor,

– rail pressure sensor fault,

– rail pressure regulator fault,

– accelerator potentiometer fault,

– engine immobiliser fault,

– computer supply voltage fault,

– engine overheating.

NOTE: the OBD warning light (symbolised by an engine), visible when the ignition is switched on, is never visible

when the engine is running.

Page 68 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Pre-postheating control

13

13-17

Pre-postheating control

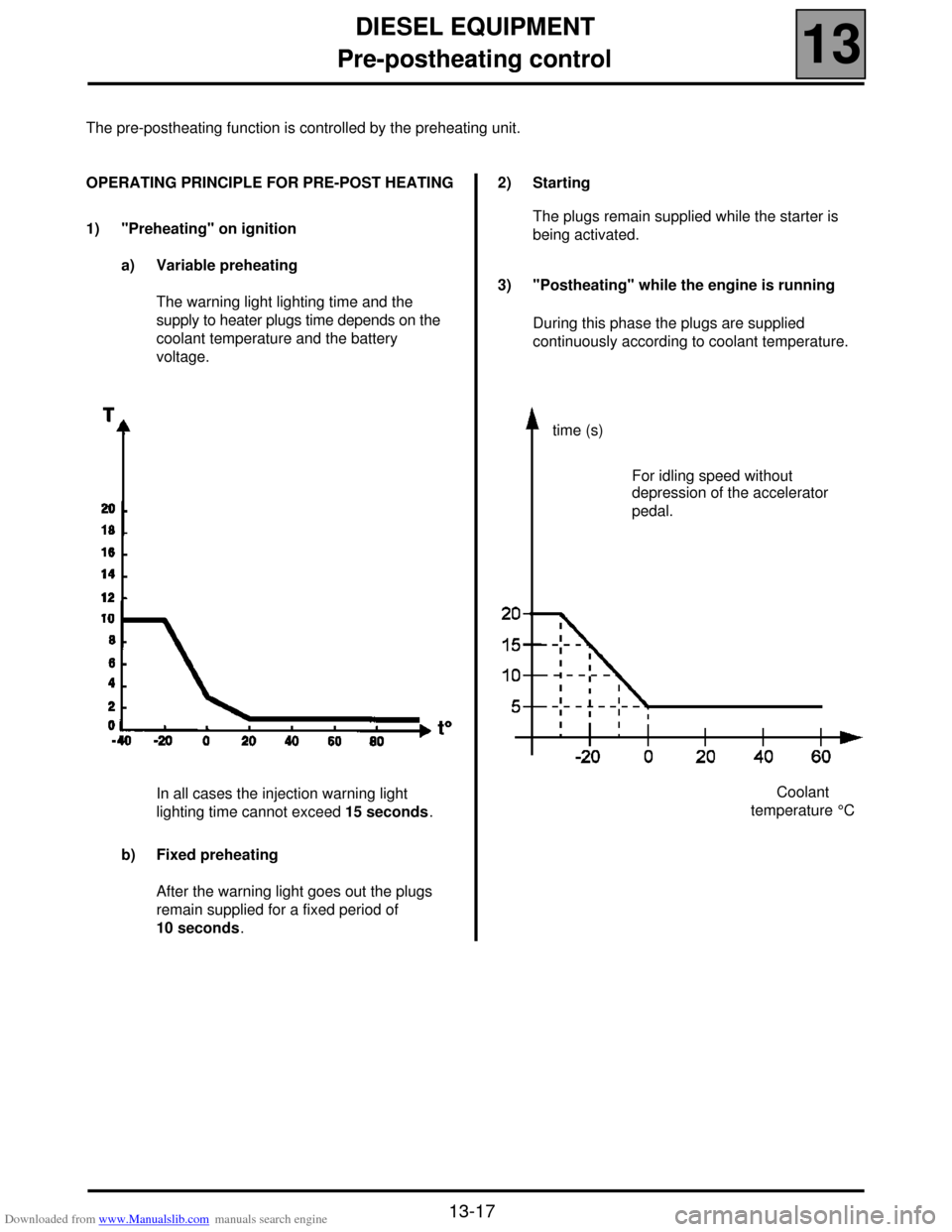

The pre-postheating function is controlled by the preheating unit.

OPERATING PRINCIPLE FOR PRE-POST HEATING

1) "Preheating" on ignition

a) Variable preheating

The warning light lighting time and the

supply to heater plugs time depends on the

coolant temperature and the battery

voltage.

In all cases the injection warning light

lighting time cannot exceed 15 seconds.

b) Fixed preheating

After the warning light goes out the plugs

remain supplied for a fixed period of

10 seconds.2) Starting

The plugs remain supplied while the starter is

being activated.

3) "Postheating" while the engine is running

During this phase the plugs are supplied

continuously according to coolant temperature.

time (s)

Coolant

temperature °C For idling speed without

depression of the accelerator

pedal.

Page 70 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Thermal plunger

13

13-19

Thermal plunger

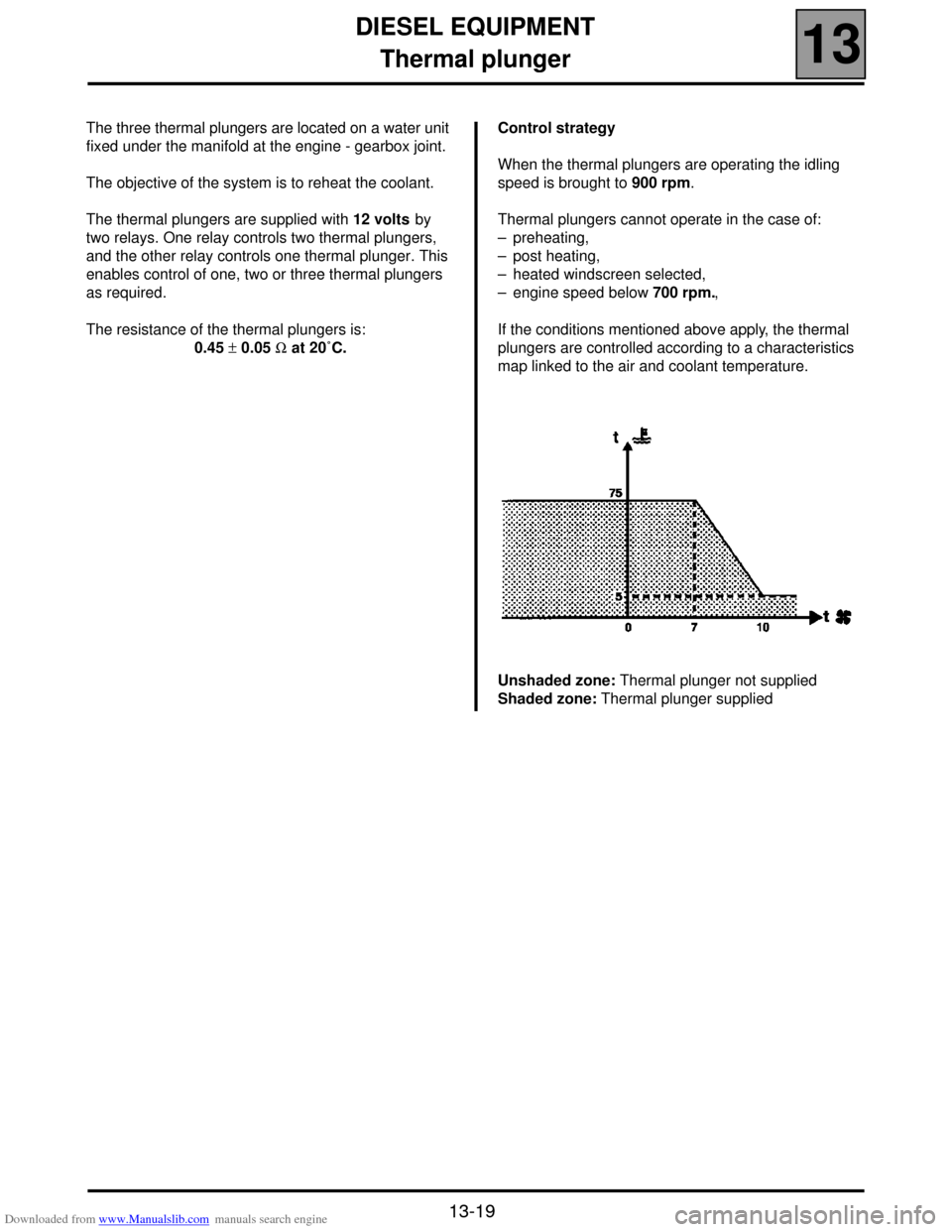

The three thermal plungers are located on a water unit

fixed under the manifold at the engine - gearbox joint.

The objective of the system is to reheat the coolant.

The thermal plungers are supplied with 12 volts by

two relays. One relay controls two thermal plungers,

and the other relay controls one thermal plunger. This

enables control of one, two or three thermal plungers

as required.

The resistance of the thermal plungers is:

0.45 ± 0.05 Ω at 20˚C. Control strategy

When the thermal plungers are operating the idling

speed is brought to 900 rpm.

Thermal plungers cannot operate in the case of:

– preheating,

– post heating,

– heated windscreen selected,

– engine speed below 700 rpm.,

If the conditions mentioned above apply, the thermal

plungers are controlled according to a characteristics

map linked to the air and coolant temperature.

Unshaded zone: Thermal plunger not supplied

Shaded zone: Thermal plunger supplied

Page 93 of 118

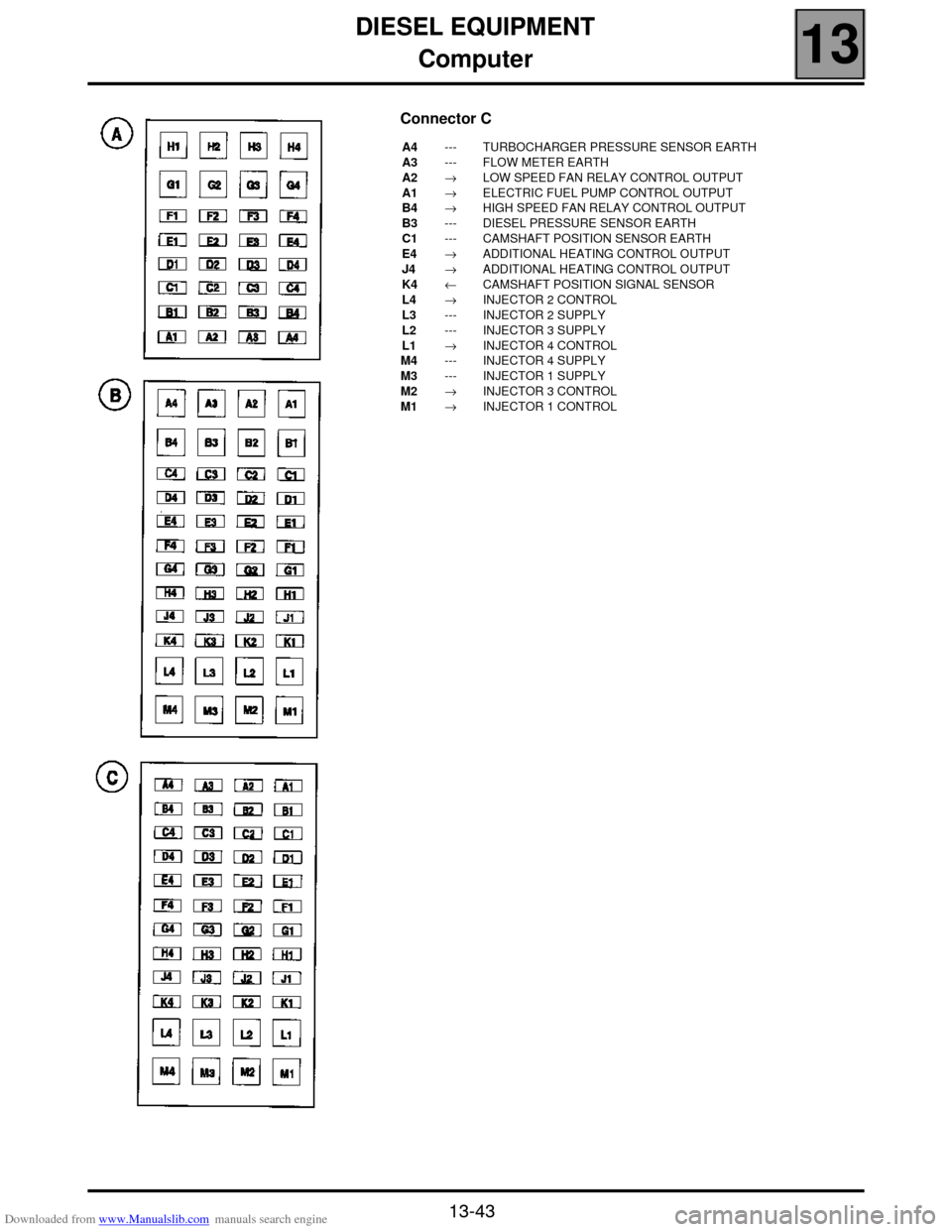

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Computer

13

13-42

Computer

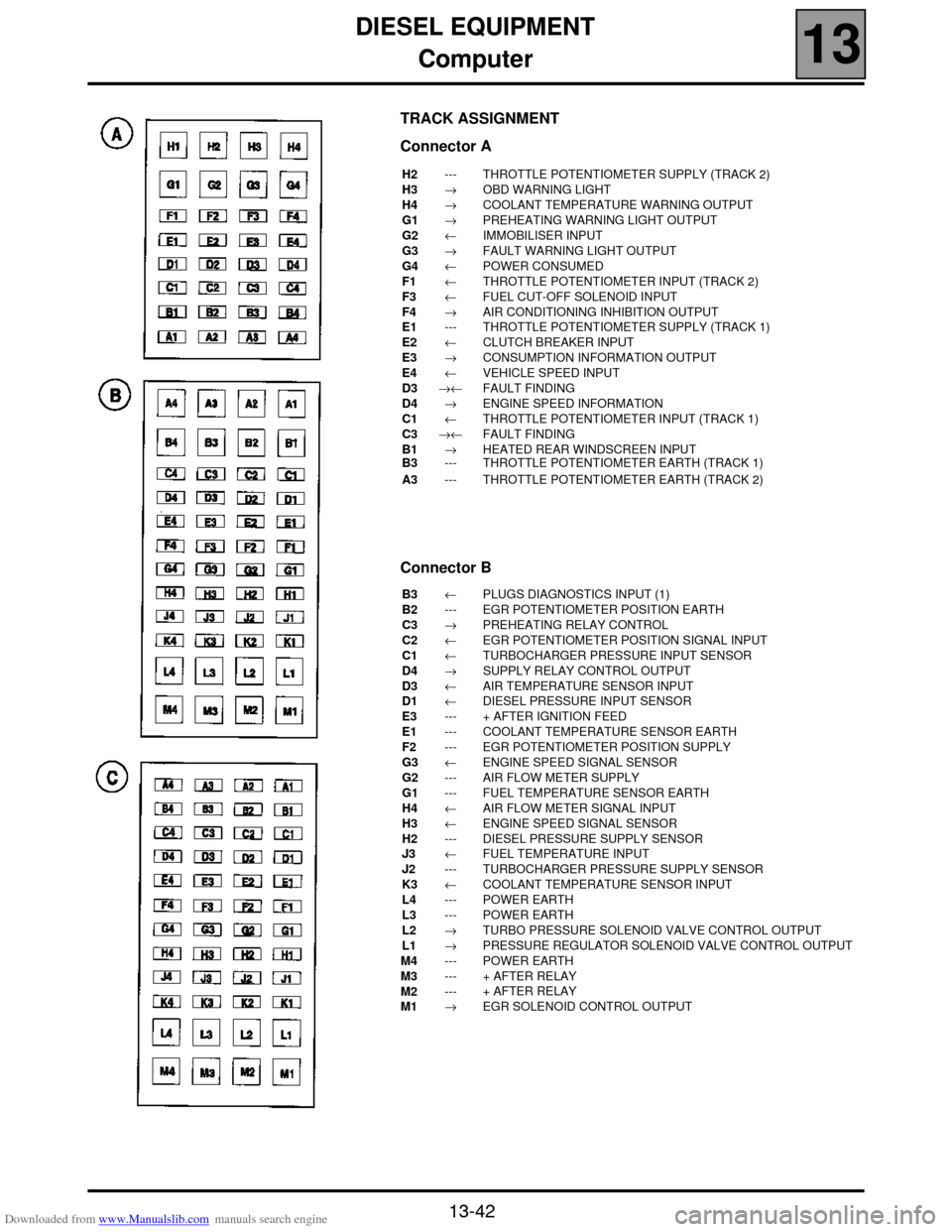

TRACK ASSIGNMENT

Connector A

H2

H3

H4

G1

G2

G3

G4

F1

F3

F4

E1

E2

E3

E4

D3

D4

C1

C3

B1

B3

A3---

→

→

→

←

→

←

←

←

→

---

←

→

←

→←

→

←

→←

→

---

---THROTTLE POTENTIOMETER SUPPLY (TRACK 2)

OBD WARNING LIGHT

COOLANT TEMPERATURE WARNING OUTPUT

PREHEATING WARNING LIGHT OUTPUT

IMMOBILISER INPUT

FAULT WARNING LIGHT OUTPUT

POWER CONSUMED

THROTTLE POTENTIOMETER INPUT (TRACK 2)

FUEL CUT-OFF SOLENOID INPUT

AIR CONDITIONING INHIBITION OUTPUT

THROTTLE POTENTIOMETER SUPPLY (TRACK 1)

CLUTCH BREAKER INPUT

CONSUMPTION INFORMATION OUTPUT

VEHICLE SPEED INPUT

FAULT FINDING

ENGINE SPEED INFORMATION

THROTTLE POTENTIOMETER INPUT (TRACK 1)

FAULT FINDING

HEATED REAR WINDSCREEN INPUT

THROTTLE POTENTIOMETER EARTH (TRACK 1)

THROTTLE POTENTIOMETER EARTH (TRACK 2)

Connector B

B3

B2

C3

C2

C1

D4

D3

D1

E3

E1

F2

G3

G2

G1

H4

H3

H2

J3

J2

K3

L4

L3

L2

L1

M4

M3

M2

M1←

---

→

←

←

→

←

←

---

---

---

←

---

---

←

←

---

←

---

←

---

---

→

→

---

---

---

→PLUGS DIAGNOSTICS INPUT (1)

EGR POTENTIOMETER POSITION EARTH

PREHEATING RELAY CONTROL

EGR POTENTIOMETER POSITION SIGNAL INPUT

TURBOCHARGER PRESSURE INPUT SENSOR

SUPPLY RELAY CONTROL OUTPUT

AIR TEMPERATURE SENSOR INPUT

DIESEL PRESSURE INPUT SENSOR

+ AFTER IGNITION FEED

COOLANT TEMPERATURE SENSOR EARTH

EGR POTENTIOMETER POSITION SUPPLY

ENGINE SPEED SIGNAL SENSOR

AIR FLOW METER SUPPLY

FUEL TEMPERATURE SENSOR EARTH

AIR FLOW METER SIGNAL INPUT

ENGINE SPEED SIGNAL SENSOR

DIESEL PRESSURE SUPPLY SENSOR

FUEL TEMPERATURE INPUT

TURBOCHARGER PRESSURE SUPPLY SENSOR

COOLANT TEMPERATURE SENSOR INPUT

POWER EARTH

POWER EARTH

TURBO PRESSURE SOLENOID VALVE CONTROL OUTPUT

PRESSURE REGULATOR SOLENOID VALVE CONTROL OUTPUT

POWER EARTH

+ AFTER RELAY

+ AFTER RELAY

EGR SOLENOID CONTROL OUTPUT

Page 94 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Computer

13

13-43

Connector C

A4

A3

A2

A1

B4

B3

C1

E4

J4

K4

L4

L3

L2

L1

M4

M3

M2

M1---

---

→

→

→

---

---

→

→

←

→

---

---

→

---

---

→

→TURBOCHARGER PRESSURE SENSOR EARTH

FLOW METER EARTH

LOW SPEED FAN RELAY CONTROL OUTPUT

ELECTRIC FUEL PUMP CONTROL OUTPUT

HIGH SPEED FAN RELAY CONTROL OUTPUT

DIESEL PRESSURE SENSOR EARTH

CAMSHAFT POSITION SENSOR EARTH

ADDITIONAL HEATING CONTROL OUTPUT

ADDITIONAL HEATING CONTROL OUTPUT

CAMSHAFT POSITION SIGNAL SENSOR

INJECTOR 2 CONTROL

INJECTOR 2 SUPPLY

INJECTOR 3 SUPPLY

INJECTOR 4 CONTROL

INJECTOR 4 SUPPLY

INJECTOR 1 SUPPLY

INJECTOR 3 CONTROL

INJECTOR 1 CONTROL